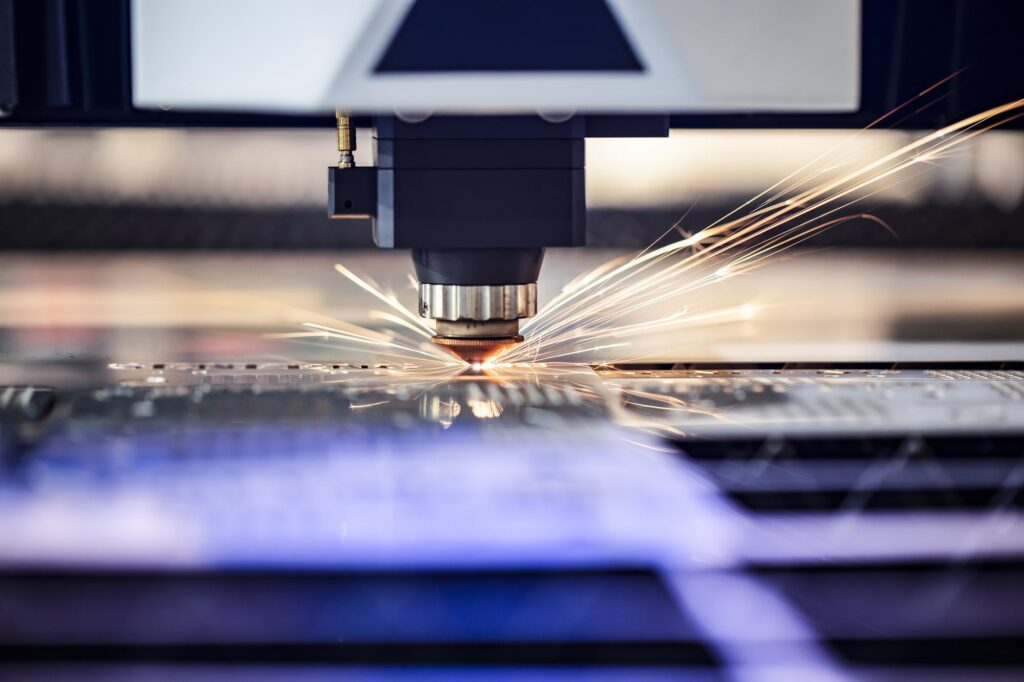

The global laser welding market is experiencing robust growth, driven by increasing demand for precision manufacturing across automotive, electronics, and medical device industries. According to Grand View Research, the global laser welding market size was valued at USD 1.8 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 7.3% from 2024 to 2030. This surge is fueled by the adoption of advanced manufacturing technologies, rising automation, and the need for high-speed, low-distortion joining processes. As industries prioritize efficiency and weld quality, laser welding—particularly high-precision saldatura laser systems—has become a critical enabler of innovation. In this competitive landscape, a select group of manufacturers are leading technological advancements, scaling production capabilities, and shaping the future of industrial joining solutions. Here, we present the top 10 saldatura laser manufacturers based on market presence, innovation, revenue performance, and application reach.

Top 10 Saldatura Laser Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

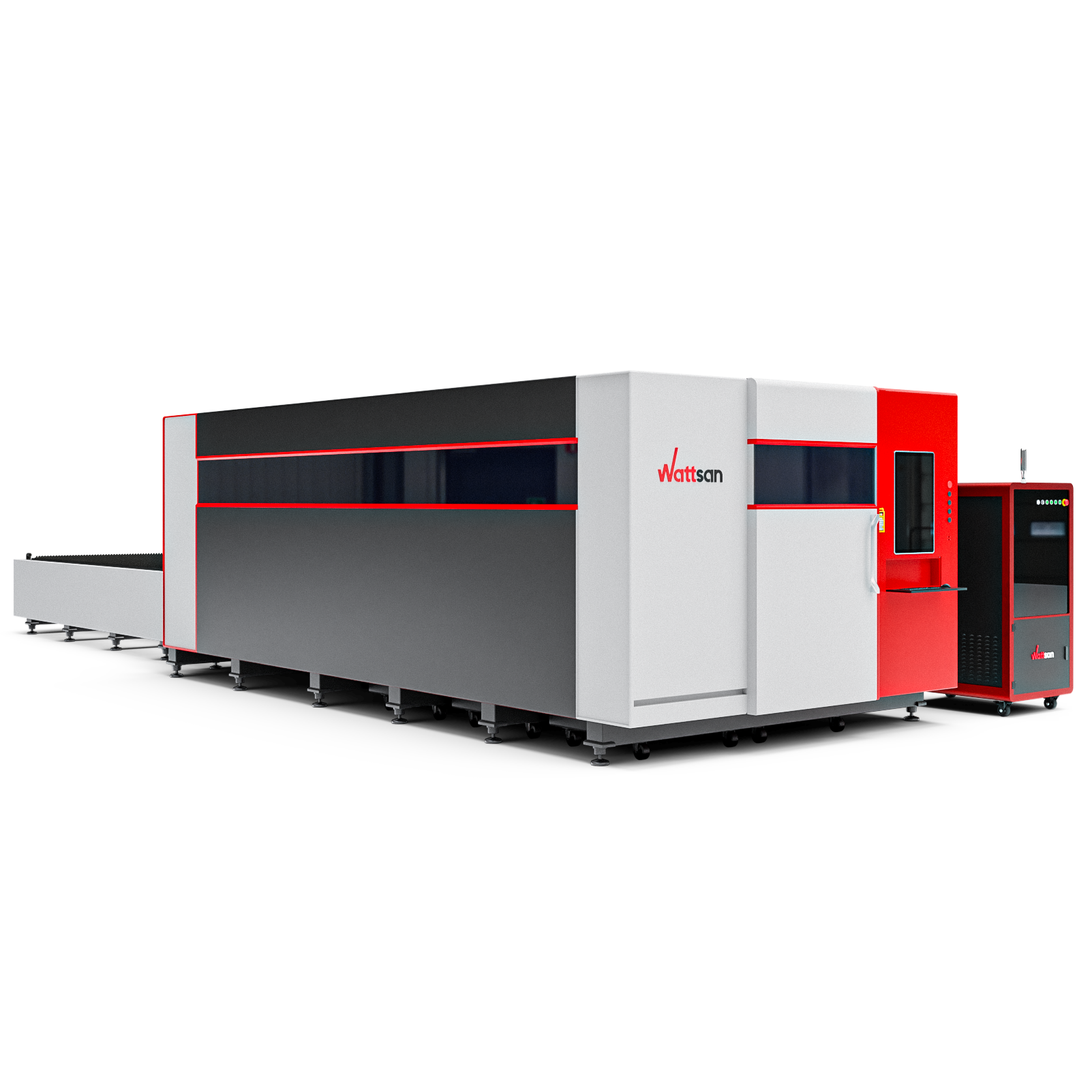

#2 Wattsan

Website: wattsan.com

Key Highlights: Wattsan is a manufacturer of laser and cnc milling machines of European quality at affordable prices with worldwide delivery….

#3 Saldatura laser

Website: siad.com

Key Highlights: Laser welding provides an efficient solution for large quantities of welding where high quality and speed are of paramount importance or simply for pieces ……

#4 Orotig: Macchinari laser

Website: orotig.com

Key Highlights: Siamo specializzati nell’ingegnerizzazione e nella produzione di macchinari per saldatura laser, marcatura laser, taglio laser e fusione e di metalli preziosi e ……

#5 Products

Website: tecnicasaldatura.it

Key Highlights: We offer high quality products by selecting the best suppliers and collaborating with leading companies in order to make the best quality Made in Italy….

#6 Laser machines for cutting, engraving, marking and …

Website: elettrolaser.com

Key Highlights: Laser machines for welding, engraving, marking, and cutting. Elettrolaser creates laser welding machines with engraving lasers that are among the best i……

#7 Machinery and laser systems

Website: sisma.com

Key Highlights: Machinery and laser systems – At SISMA S.p.A. we design and produce extremely high precision machinery and laser systems. Read more….

#8 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

#9 Arroweld

Website: arroweld.com

Key Highlights: Stai Cercando saldatura, utensilerie e strumenti di controllo? Bene, entra in Arroweld.com e vieni a scoprire tutti i nostri prodotti scelti per te!…

#10 Reci Laser

Website: reci-laser.com

Key Highlights: A series high-power single-mode continuous-wave fiber laser is developed and produced by Reci Laser. The average power exceeds 1000W….

Expert Sourcing Insights for Saldatura Laser

H2: Market Trends for Laser Welding (Saldatura Laser) in 2026

The global laser welding (saldatura laser) market is poised for significant transformation by 2026, driven by advancements in manufacturing technologies, rising demand for automation, and the adoption of high-precision joining methods across key industries. This analysis explores the major market trends shaping the laser welding landscape in 2026 under the H2 economic and industrial outlook.

1. Accelerated Adoption in Electric Vehicle (EV) Manufacturing

With the global push toward electrification of transportation, the automotive industry—particularly EV production—is becoming a primary driver of laser welding demand. By 2026, laser welding is expected to be integral in battery pack assembly, electric motor fabrication, and lightweight vehicle structures. The precision, speed, and minimal heat distortion offered by laser welding are critical for ensuring the safety and performance of EV components.

- Trend Impact: Increased investment in high-power fiber lasers for battery tab welding and body-in-white applications.

- Regional Focus: Europe and China leading in EV integration; North America catching up with policy incentives.

2. Growth in Industrial Automation and Smart Manufacturing

The proliferation of Industry 4.0 and smart factory initiatives is fueling demand for automated laser welding systems. By 2026, integration with robotics, IoT-enabled monitoring, and AI-based process optimization will become standard in laser welding setups.

- Trend Impact: Rise in demand for turnkey laser welding cells with real-time quality control.

- Technology Shift: Adoption of adaptive welding systems using sensors and machine learning to correct weld parameters dynamically.

3. Advancements in Laser Technology

Innovation in laser sources—especially fiber, disk, and blue diode lasers—is enhancing welding capabilities. By 2026, blue laser technology is expected to gain commercial traction for welding highly reflective materials like copper and aluminum, which are traditionally challenging for infrared lasers.

- Trend Impact: Expansion of laser welding applications in electronics and power electronics sectors.

- Efficiency Gains: Higher energy efficiency, lower operational costs, and reduced maintenance.

4. Expansion in Aerospace and Medical Device Manufacturing

High-integrity welding requirements in aerospace and medical industries continue to favor laser welding due to its precision and cleanliness. By 2026, stricter regulatory standards and demand for miniaturization will further boost adoption.

- Trend Impact: Growth in pulsed laser welding for delicate components and hermetic sealing.

- Material Focus: Increased use in titanium, nickel alloys, and specialized stainless steels.

5. Sustainability and Energy Efficiency Pressures

With growing emphasis on sustainable manufacturing, laser welding’s lower energy consumption and reduced material waste compared to traditional welding methods position it favorably. By 2026, environmental regulations and corporate ESG goals will incentivize manufacturers to shift toward laser-based solutions.

- Trend Impact: Incentives for retrofitting conventional welding lines with laser systems.

- Lifecycle Advantage: Longer equipment lifespan and recyclability of laser components.

6. Regional Market Dynamics and Supply Chain Localization

Geopolitical shifts and supply chain resilience concerns are prompting localized production, particularly in Europe and North America. By 2026, this will drive regional investments in domestic laser welding equipment manufacturing and R&D.

- Trend Impact: Growth of European laser OEMs leveraging H2 funding for clean tech and digitalization.

- Emerging Markets: India and Southeast Asia increasing adoption due to industrial modernization.

Conclusion

Under the H2 2026 outlook, the laser welding market is set for robust growth, with a CAGR estimated between 7% and 9% globally. Key drivers include electrification, digitalization, technological innovation, and sustainability. Companies investing in flexible, intelligent, and energy-efficient laser welding solutions will be best positioned to capitalize on emerging opportunities across automotive, industrial, medical, and high-tech sectors.

H2: Common Pitfalls When Sourcing Saldatura Laser – Quality and Intellectual Property Concerns

Sourcing laser welding (Saldatura Laser) systems, particularly from international suppliers, can present significant challenges related to both quality assurance and intellectual property (IP) protection. Understanding these pitfalls is essential for manufacturers and integrators aiming to maintain high standards and safeguard proprietary technology.

1. Inconsistent Quality Standards

One of the most prevalent issues when sourcing laser welding equipment is the variability in quality. Suppliers, particularly in regions with less stringent manufacturing oversight, may offer systems that claim high performance but fail to deliver consistent results. Key concerns include:

- Substandard laser sources or optical components that degrade quickly.

- Poor integration of motion systems and process controls, leading to unreliable weld quality.

- Lack of adherence to international standards (e.g., ISO, CE, or IEC), which can compromise safety and performance.

Without thorough due diligence—such as factory audits, sample testing, and certification verification—buyers risk acquiring systems that underperform or require costly maintenance.

2. Inadequate After-Sales Support and Documentation

Many suppliers, especially those outside established industrial markets, provide incomplete technical documentation or limited after-sales service. This can hinder system integration, troubleshooting, and operator training, ultimately affecting production uptime and weld repeatability.

3. Intellectual Property Risks

Sourcing laser welding technology also exposes companies to IP vulnerabilities:

- Reverse Engineering and Technology Copying: Some suppliers may use legitimate equipment purchases to reverse-engineer designs or replicate proprietary processes, especially in jurisdictions with weak IP enforcement.

- Unauthorized Use of Custom Configurations: If a buyer shares specific process parameters, automation layouts, or control software for customization, there is a risk these details could be used for other clients or sold to competitors.

- Lack of Legal Recourse: Enforcing IP rights across borders can be complex and costly. Contracts may lack clear clauses on data ownership, confidentiality, and usage rights, leaving buyers exposed.

4. Misrepresentation of Capabilities

Suppliers may overstate their system’s precision, speed, or compatibility with certain materials. This misrepresentation—intentional or not—can lead to production delays, rework, or safety issues if the equipment cannot meet operational demands.

Best Practices to Mitigate Risks

– Conduct on-site evaluations and request third-party quality certifications.

– Use robust contracts with explicit IP protection, non-disclosure agreements (NDAs), and clauses prohibiting reuse of custom designs.

– Partner with reputable suppliers who comply with international standards and offer comprehensive support.

In conclusion, while sourcing Saldatura Laser systems abroad can offer cost advantages, overlooking quality control and IP safeguards can lead to long-term operational and legal complications. A proactive, well-informed procurement strategy is crucial to mitigating these risks.

Logistics & Compliance Guide for Saldatura Laser

This guide outlines the essential logistics and compliance considerations for the handling, transportation, storage, and regulatory adherence related to Saldatura Laser (laser welding) equipment and operations.

Regulatory Compliance

Ensure all laser welding systems comply with applicable international, national, and local regulations. Key standards include:

– IEC 60825-1: Safety of laser products – Equipment classification and requirements.

– ANSI Z136.1: Safe Use of Lasers (U.S. standard).

– Machinery Directive 2006/42/EC (for EU markets): Requires CE marking and technical file documentation.

– OSHA Regulations (U.S.): Workplace safety standards for laser operations, including protective measures and hazard communication.

Maintain up-to-date certifications and conduct regular audits to confirm compliance.

Laser Safety Protocols

Implement comprehensive safety measures to protect personnel:

– Install interlocks, beam enclosures, and emergency stop mechanisms on all laser systems.

– Designate controlled access areas with appropriate warning signs (e.g., “Laser Radiation – Avoid Eye or Skin Exposure”).

– Provide certified laser safety eyewear matched to the laser’s wavelength and power output.

– Appoint a Laser Safety Officer (LSO) to oversee training, hazard assessments, and safety procedures.

Equipment Handling and Transportation

Handle laser welding systems with care during shipping and installation:

– Use original packaging or certified transport containers to protect sensitive optics and electronics.

– Secure equipment to prevent movement during transit; follow manufacturer guidelines for orientation and shock limits.

– Protect optical components from dust, moisture, and physical impact.

– Ensure all power and control cables are disconnected, coiled, and secured before transport.

Storage Conditions

Store laser welding equipment and components in a controlled environment:

– Maintain temperatures between 10°C and 40°C and relative humidity below 70% (non-condensing).

– Keep equipment in a clean, dry, dust-free area away from corrosive chemicals or vibrations.

– Cover exposed apertures and connectors to prevent contamination.

– Store spare optics in sealed containers with desiccant.

Import and Export Regulations

Adhere to international trade requirements when shipping laser equipment across borders:

– Confirm laser classification (e.g., Class 4) and check export control lists (e.g., EAR in the U.S., EU Dual-Use Regulation).

– Obtain necessary export licenses for high-power laser systems, especially to restricted destinations.

– Prepare accurate documentation: commercial invoice, packing list, certificate of origin, and technical specifications.

– Label shipments clearly with laser hazard warnings and compliance marks (e.g., CE, FDA).

Environmental and Disposal Compliance

Manage end-of-life equipment responsibly:

– Recycle or dispose of laser components (e.g., laser diodes, cooling fluids) in accordance with local environmental regulations (e.g., WEEE, RoHS in the EU).

– Handle and dispose of battery-powered units or coolant fluids as hazardous waste where applicable.

– Document disposal procedures to ensure traceability and regulatory compliance.

Training and Documentation

Maintain thorough records and provide ongoing training:

– Keep logs of equipment maintenance, safety inspections, and operator training.

– Provide multilingual user manuals and safety instructions.

– Train all operators and maintenance personnel on emergency procedures, safe operation, and compliance requirements.

Adhering to this guide ensures safe, legal, and efficient operations involving Saldatura Laser systems across the supply chain and operational lifecycle.

Conclusion for Sourcing Laser Welding (Saldatura Laser):

In conclusion, sourcing laser welding (saldatura laser) solutions requires a strategic approach that balances technological capability, cost-efficiency, and long-term reliability. As a high-precision and increasingly essential process in industries such as automotive, aerospace, medical devices, and advanced manufacturing, selecting the right laser welding technology—whether fiber, CO₂, or disk lasers—is critical to ensuring product quality and operational efficiency.

Key factors in successful sourcing include evaluating suppliers based on technical expertise, after-sales support, serviceability, and compliance with international standards. Additionally, considering total cost of ownership, including maintenance, training, and energy consumption, is vital for sustainable integration. Partnering with reputable manufacturers or integrators who offer customization, automation compatibility, and proven application experience can significantly enhance productivity and return on investment.

Ultimately, effective sourcing of laser welding systems not only improves manufacturing precision and speed but also supports innovation and competitiveness in an evolving industrial landscape. As laser technology continues to advance, staying informed and agile in procurement strategies will be essential for maintaining a cutting-edge production environment.