The global kitchen equipment market is undergoing robust expansion, driven by rising demand from commercial foodservice operations and innovations in energy-efficient appliances. According to Mordor Intelligence, the global commercial kitchen equipment market was valued at USD 86.5 billion in 2023 and is projected to grow at a CAGR of 5.8% through 2029. This growth is fueled by increasing urbanization, the proliferation of quick-service restaurants, and the need for high-performance, space-efficient cooking solutions. Within this competitive landscape, Salamander kitchen equipment—known for its targeted overhead grilling and broiling capabilities—has become a staple in professional kitchens, valued for precision finishing and versatility. As demand for high-efficiency catering appliances rises, manufacturers are investing in advanced materials, smart controls, and modular designs. Based on market presence, innovation, product range, and customer reviews, the following eight companies have emerged as leading Salamander kitchen equipment manufacturers shaping the industry’s future.

Top 8 Salamander Kitchen Equipment Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 1998

Website: imperialrange.com

Key Highlights: High-quality commercial and industrial cooking equipment manufacturer – Imperial Commercial Cooking Equipment. … Cheese Melters & Salamanders · Backguards ……

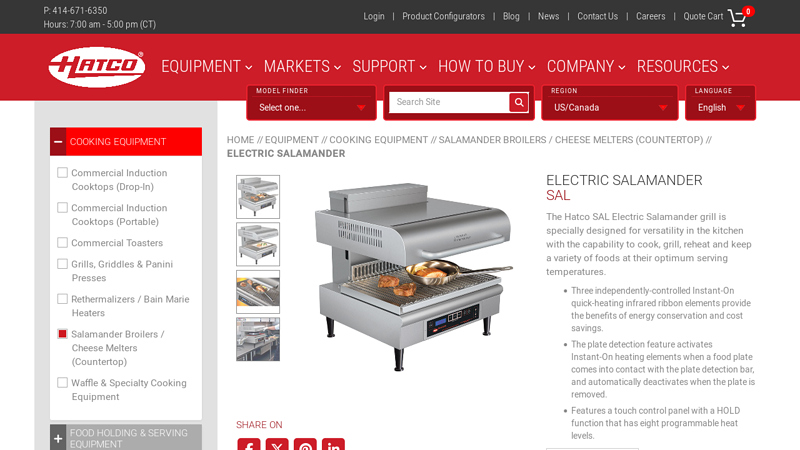

#2 SAL Salamander Grills

Domain Est. 1996

Website: hatcocorp.com

Key Highlights: The Hatco electric salamander grill is specially designed for versatility in the kitchen with the capability to cook, reheat and maintain warmth….

#3 Heat Up Your Kitchen With Salamanders

Domain Est. 1997

Website: fermag.com

Key Highlights: Salamanders are available in range-mounted, wall-mounted and countertop models. Range mounting works best when aligning a salamander with a ……

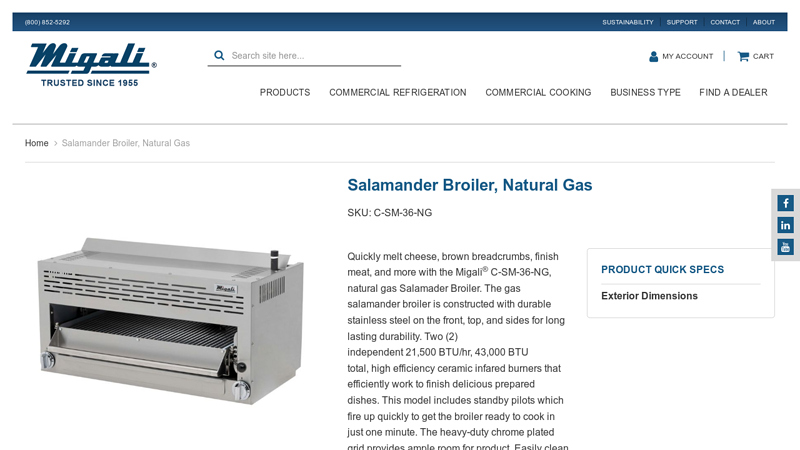

#4 Salamander Broiler, Natural Gas

Domain Est. 1999

Website: migali.com

Key Highlights: This model includes standby pilots which fire up quickly to get the broiler ready to cook in just one minute. The heavy-duty chrome plated grid provides ample ……

#5 Salamander Broilers – Commercial Finishing Broilers

Domain Est. 2001

#6 Salamander

Domain Est. 2004

Website: electroluxprofessional.com

Key Highlights: Electrolux Professional salamanders are fast to heat up and simple to use. Brown, gratin, cook, reheat and keep warm….

#7 Salamander Stoves

Domain Est. 2009

Website: salamanderstoves.com

Key Highlights: Compact, efficient and high quality. The Hobbit stove is a small cast iron multi-fuel stove designed for small spaces and magical places….

#8 Commercial Broilers

Domain Est. 2009

Website: vulcanequipment.com

Key Highlights: Upright Broiler. Warm, bake or broil large amounts of food in little time. Commonly used for steaks and other cuts of meat. · Salamander. Cook and broil foods at ……

Expert Sourcing Insights for Salamander Kitchen Equipment

2026 Market Trends for Salamander Kitchen Equipment

The salamander kitchen equipment market in 2026 is poised for transformation, driven by evolving culinary demands, technological innovation, and heightened operational efficiency requirements. As a critical tool for broiling, browning, melting, and finishing dishes, salamanders are adapting to meet the needs of modern commercial kitchens. Key trends shaping the market include:

1. Increased Demand for Energy Efficiency and Sustainability

In 2026, energy efficiency will be a top purchasing criterion. Operators are under pressure to reduce utility costs and meet environmental regulations. Salamander manufacturers are responding with high-efficiency infrared burners, improved insulation, and ENERGY STAR-compliant models. Gas-powered salamanders are seeing advancements in combustion efficiency, while electric models feature rapid heat-up times and precise temperature control to minimize energy waste. Sustainability will also influence material selection, with more brands using recyclable components and modular designs for easier repair and longer lifespans.

2. Integration of Smart Technology and IoT Connectivity

Smart kitchen appliances are becoming standard, and salamanders are no exception. By 2026, expect widespread adoption of IoT-enabled salamanders equipped with sensors for real-time temperature monitoring, usage tracking, and predictive maintenance alerts. These features integrate with kitchen management systems to optimize workflow, reduce downtime, and support data-driven decision-making. Touchscreen interfaces with programmable cooking profiles will allow chefs to replicate precise finishing techniques consistently across shifts.

3. Compact and Modular Designs for Space Optimization

As commercial kitchens—especially in urban areas and quick-service restaurants—face space constraints, demand for compact, stackable, and under-counter salamander units is rising. Manufacturers are prioritizing space-saving designs without sacrificing performance. Modular units that can be combined with other cooking equipment (e.g., combi ovens or ranges) offer flexibility for multi-functional kitchen layouts, appealing to cloud kitchens and small-format restaurants.

4. Growth in Specialty and Multi-Functional Models

Chefs are increasingly seeking versatility. In 2026, salamanders with dual-zone heating, adjustable broil heights, and combination functions (e.g., convection + broil) will gain traction. Specialty models tailored for specific cuisines—such as Japanese yakitori or Italian crème brûlée—will cater to niche markets. Additionally, portable and countertop salamanders will see growth in catering, food trucks, and pop-up kitchens due to their mobility and ease of use.

5. Emphasis on Hygiene and Easy Maintenance

Post-pandemic, cleanliness remains a priority. Salamanders with seamless surfaces, removable components, and antimicrobial coatings will be in demand. Designs that minimize grease buildup and simplify cleaning processes help kitchens comply with health regulations and reduce labor costs. Self-cleaning features, particularly in high-end models, will become more common.

6. Rising Adoption in Non-Traditional Foodservice Sectors

Beyond restaurants and hotels, salamanders are finding new applications in healthcare facilities, corporate cafeterias, and educational institutions. The need for high-quality, visually appealing meals in these settings drives investment in finishing equipment. Additionally, the growth of meal kit delivery services and ghost kitchens increases demand for efficient, consistent finishing tools like salamanders to enhance food presentation.

7. Regional Expansion and Customization

In emerging markets across Asia-Pacific, Latin America, and the Middle East, rising urbanization and dining-out culture are boosting demand for commercial kitchen equipment. Manufacturers are localizing designs—adjusting voltage, fuel types, and size—to meet regional needs. Customization options, such as branding or specialized controls, will allow businesses to tailor equipment to their operational workflows.

In conclusion, the 2026 salamander kitchen equipment market will be defined by innovation, efficiency, and adaptability. Brands that prioritize sustainability, smart functionality, and user-centric design will lead the industry, meeting the evolving needs of a dynamic foodservice landscape.

Common Pitfalls When Sourcing Salamander Kitchen Equipment (Quality and IP)

Sourcing salamander kitchen equipment—whether for commercial kitchens, food service operators, or equipment distributors—can be fraught with challenges, especially concerning product quality and intellectual property (IP) risks. Being aware of these pitfalls helps ensure reliable performance, compliance, and brand integrity.

Poor Build Quality and Material Shortcomings

One of the most prevalent issues is receiving salamanders constructed with substandard materials. Inferior stainless steel, thin gauge metal, or low-grade heating elements can lead to premature failure, inconsistent heat output, and safety hazards. Cheap models may warp under high temperatures, develop hot spots, or corrode quickly in high-moisture environments, compromising both performance and longevity.

Inaccurate Temperature Control and Calibration

Low-quality salamanders often suffer from poorly calibrated thermostats or inconsistent infrared burners, resulting in uneven cooking and under- or overcooked food. This not only affects food quality but can also pose health risks. Equipment lacking precise temperature control may fail health inspections or increase operational waste due to food spoilage.

Non-Compliance with Safety and Regulatory Standards

Many imported or unbranded salamander units do not meet regional safety certifications (e.g., NSF, CE, UL). Using non-compliant equipment can lead to failed inspections, insurance issues, or even liability in the event of fire or injury. Always verify that equipment complies with local electrical, gas, and food safety regulations before procurement.

Counterfeit or IP-Infringing Products

A significant IP risk arises when sourcing from manufacturers that copy patented designs or use trademarks without authorization. Some suppliers may offer “compatible” or “replica” versions of well-known salamander models, which infringe on intellectual property rights. Purchasing such equipment can expose businesses to legal action, shipment seizures, or reputational damage, especially if discovered during audits or customs inspections.

Lack of Technical Documentation and Support

Inferior suppliers often fail to provide adequate technical specifications, user manuals, or maintenance guides—critical for safe operation and troubleshooting. Additionally, poor after-sales support or nonexistent warranties can leave buyers stranded when repairs are needed, increasing downtime and operational costs.

Misrepresentation of Origin and Manufacturing Claims

Some suppliers falsely claim their equipment is made in countries known for high manufacturing standards (e.g., Italy, USA, Germany), when in reality, it’s produced in low-cost regions with lax quality oversight. This misrepresentation affects both performance expectations and warranty legitimacy, and may also breach procurement or branding requirements.

Inadequate Intellectual Property Due Diligence

Buyers who fail to verify the IP status of the equipment—such as design patents, utility models, or brand trademarks—risk importing or distributing infringing products. Conducting IP checks through patent databases or working with legal counsel can prevent costly disputes, especially in markets with strong IP enforcement.

Conclusion

To avoid these pitfalls, conduct thorough due diligence on suppliers, demand proof of compliance and IP legitimacy, and consider third-party inspections or certifications. Investing in quality and legally sound salamander equipment protects both operational efficiency and brand reputation in the long term.

Logistics & Compliance Guide for Salamander Kitchen Equipment

Overview

Salamander kitchen equipment, commonly used in commercial kitchens for broiling, browning, and finishing dishes, must be handled with care during logistics and in compliance with relevant regulations. This guide outlines best practices for the safe transportation, handling, and regulatory compliance of salamander units from manufacturing or distribution to end-user installation.

Packaging & Handling

Ensure salamander units are securely packaged in manufacturer-approved crates or protective wrapping to prevent damage during transit. Use corner protectors and foam padding to shield delicate control panels and heating elements. Always lift and move the equipment using appropriate material handling tools (e.g., pallet jacks, forklifts) and avoid tilting beyond manufacturer specifications to protect internal components.

Transportation Requirements

Transport salamanders on flatbed or enclosed trucks secured with straps or tie-downs to prevent shifting. Maintain a dry, temperature-controlled environment when possible, especially for units with electronic components. Avoid exposure to extreme temperatures, moisture, or corrosive substances during transit. Confirm that vehicle dimensions allow clearance for the equipment’s size and weight.

Regulatory Compliance

Comply with all local, national, and international regulations governing the shipment of commercial kitchen equipment. In the U.S., adhere to Department of Transportation (DOT) standards for freight classification and hazardous materials (if applicable). Ensure units meet National Sanitation Foundation (NSF) standards for food equipment and bear the appropriate certification marks (e.g., NSF/ANSI 4). Electrical models must comply with National Electrical Code (NEC) and carry UL or ETL certification.

Import & Export Considerations

For cross-border shipments, verify customs documentation, including commercial invoices, packing lists, and certificates of origin. Confirm adherence to destination country electrical standards (e.g., voltage, plug type) and safety certifications (e.g., CE in Europe, CCC in China). Include bilingual labeling when required and ensure all paperwork reflects accurate equipment classifications for tariff purposes.

Installation & Site Readiness

Prior to delivery, confirm site readiness: proper floor loading capacity, ventilation, gas/electric connections (as applicable), and clearance requirements per manufacturer guidelines. Coordinate with certified technicians for installation to ensure compliance with local building and fire codes. Provide end users with operation manuals, warranty information, and compliance certifications.

Maintenance & Compliance Records

Maintain detailed logistics records, including shipping manifests, inspection reports, and compliance documentation. Encourage end users to follow routine maintenance schedules to preserve safety certifications and equipment performance. Retain records for audit purposes and warranty claims.

Environmental & Safety Compliance

Dispose of packaging materials in accordance with local recycling and waste regulations. For end-of-life equipment, follow EPA and local guidelines for responsible disposal of electrical components and hazardous materials. Promote sustainability by offering take-back or recycling programs where available.

In conclusion, sourcing salamander kitchen equipment requires careful consideration of quality, durability, energy efficiency, and compliance with health and safety standards. Choosing the right supplier involves evaluating reputation, after-sales service, warranty options, and overall value for money. Whether for a commercial kitchen or high-volume culinary environment, investing in a reliable salamander grill enhances cooking efficiency, supports consistent results, and contributes to streamlined kitchen operations. By conducting thorough research and prioritizing long-term performance over initial cost, businesses can ensure a smart, sustainable procurement decision that meets both operational needs and budgetary constraints.