The global laser safety eyewear market is experiencing steady growth, driven by increasing industrial automation, rising adoption of high-powered lasers in manufacturing, and stricter occupational safety regulations. According to Mordor Intelligence, the laser safety eyewear market was valued at USD 685.2 million in 2023 and is projected to reach USD 980.4 million by 2029, growing at a CAGR of 6.2% during the forecast period. This expansion reflects the escalating need for effective personal protective equipment (PPE) in industries such as precision machining, medical device manufacturing, and advanced materials processing, where laser applications are becoming more pervasive. As laser power levels and usage frequency rise, so does the risk of ocular exposure to hazardous wavelengths, making the selection of properly rated safety glasses critical. In response to these evolving demands, manufacturers and safety officers must prioritize eyewear that offers optical clarity, wavelength-specific protection, and long-term wearability. Based on performance metrics, compliance standards, and user feedback, here are the top 10 safety glasses tailored for professionals in the laser manufacturing sector.

Top 10 Safety Glasses For Laser Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 laserpair

Domain Est. 2013

Website: m.laserpair.com

Key Highlights: LASERPAIR Brand laser safety goggles focus on the middle and highend market, our products widely used in laser industrial, laser medical, laser military, ……

#2 Innovative Laser Safety

Domain Est. 2023

Website: innovativelasersafety.com

Key Highlights: A division of Innovative Optics, ILS is a world leader in laser safety products, specializing in Industrial, Research, Education, and Military….

#3 Laser Safety Glasses, Goggles & Eyewear

Domain Est. 1994

Website: newport.com

Key Highlights: Free delivery 30-day returnsWe offer high quality laser safety glasses and goggles from Honeywell and Laservision in a wide variety of different frame styles and optical ……

#4 laservision USA

Domain Est. 1997

Website: lasersafety.com

Key Highlights: laservision designs and manufactures a complete line of laser safety products including glasses, barriers, signs and windows….

#5 Wiley X Sunglasses and Safety Glasses

Domain Est. 2000

Website: wileyx.com

Key Highlights: Discover and shop high-end protective sunglasses, tactical goggles, apparel, and more available on the official Wiley X online store….

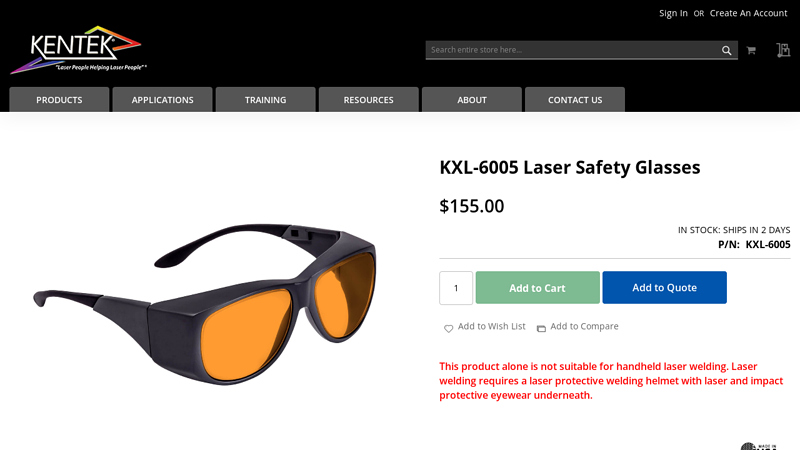

#6 KXL

Domain Est. 2000

Website: kenteklaserstore.com

Key Highlights: In stock Free deliveryKXL-6005 Laser Safety Glasses have light orange curved polymer lenses for wavelength-specific laser applications when Optical Density (OD) protection is ……

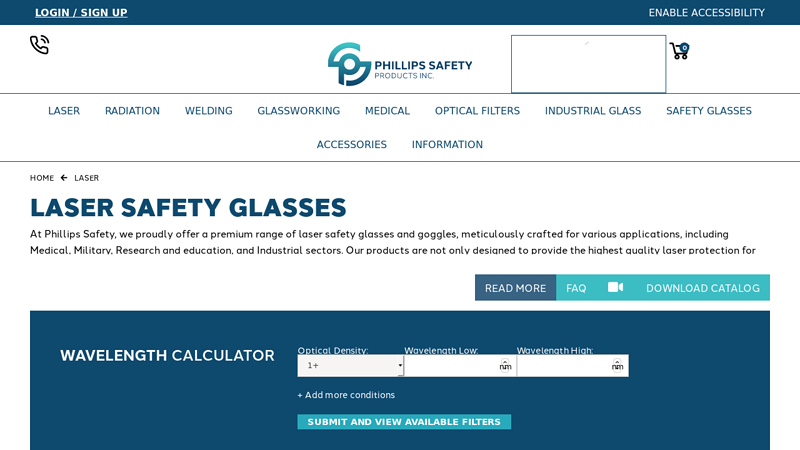

#7 Laser Safety Glasses & Goggles

Domain Est. 2001

Website: phillips-safety.com

Key Highlights: 7-day delivery 30-day returnsEach pair of Phillips Safety laser safety glasses meets the stringent ANSI Z136 Standard for Laser Safety, ensuring maximum protection against laser ex…

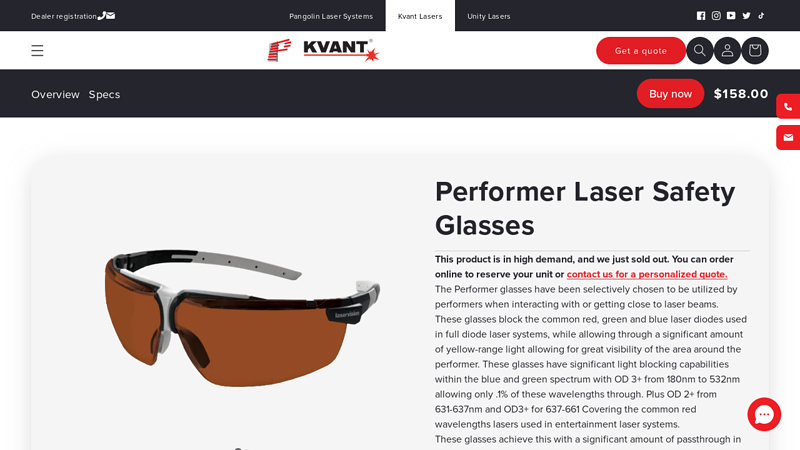

#8 Performer Laser Safety Glasses

Domain Est. 2015

Website: lasershowprojector.com

Key Highlights: These glasses block the common red, green and blue laser diodes used in full diode laser systems, while allowing through a significant amount of yellow-range ……

#9 Laser Protective Goggles

Domain Est. 2019

Website: us.store.bambulab.com

Key Highlights: In stock Free deliveryOverview. Laser Protective Goggles are highly effective in preventing accidental eye injuries caused by the laser of the H2D Laser and H2S Laser module….

#10 Laser Safety Glasses

Domain Est. 2023

Website: acmerlaser.com

Key Highlights: In stock Free deliveryLaser safety glasses are glasses specifically designed to protect your eyes from potentially harmful laser radiation. They are critical in environments ……

Expert Sourcing Insights for Safety Glasses For Laser

H2: 2026 Market Trends for Safety Glasses for Laser

The global market for laser safety glasses is poised for substantial growth by 2026, driven by increasing industrial automation, advancements in laser technologies, and stricter occupational safety regulations. As lasers become more prevalent across industries such as healthcare, manufacturing, telecommunications, and defense, the demand for high-performance protective eyewear is expected to rise significantly.

One of the key trends shaping the 2026 market is the growing adoption of laser-based technologies in medical applications, including dermatology, ophthalmology, and surgical procedures. This expansion necessitates specialized laser safety glasses that offer protection across specific wavelengths, particularly in clinics and hospitals where multiple laser systems operate simultaneously. As a result, manufacturers are focusing on producing multi-wavelength protective eyewear with enhanced optical clarity and comfort for prolonged use.

Another notable trend is the integration of smart materials and customizable features in laser safety glasses. By 2026, expect to see advancements in adaptive lens technology that can dynamically adjust optical density based on real-time laser exposure, improving both safety and usability. Additionally, ergonomic designs with lightweight frames, anti-fog coatings, and compatibility with prescription lenses are becoming standard, addressing user comfort and compliance.

Regulatory standards, such as ANSI Z136.1 in the U.S. and EN 207 in Europe, continue to play a crucial role in shaping product development. As enforcement of these standards becomes more rigorous, industries are investing in certified laser safety eyewear to meet compliance requirements and reduce liability risks. This is particularly evident in high-risk sectors like aerospace and defense, where high-powered lasers are used in testing and operations.

Moreover, the rise of compact and portable laser systems in research and education is expanding the market to include academic institutions and startups. These users demand cost-effective, reliable safety glasses that are easy to deploy and maintain.

In conclusion, by 2026, the laser safety glasses market will be characterized by innovation in materials and design, increased regulatory adherence, and broadening application scopes. Companies that prioritize technological differentiation, user-centric design, and global compliance will be well-positioned to lead in this evolving and safety-critical sector.

Common Pitfalls When Sourcing Safety Glasses for Laser Applications (Quality, IP)

Logistics & Compliance Guide for Safety Glasses for Laser

Overview and Importance

Safety glasses designed for laser protection are critical personal protective equipment (PPE) used in medical, industrial, research, and military environments. Due to their specialized function in shielding users from specific laser wavelengths and intensities, their logistics and compliance requirements are more stringent than standard safety eyewear. This guide outlines essential procedures for the safe and compliant handling, storage, distribution, and documentation of laser safety glasses throughout the supply chain.

Regulatory and Compliance Standards

Laser safety glasses must comply with international and regional safety standards to ensure user protection and legal distribution. Key regulatory frameworks include:

– ANSI Z136.1 (United States): The American National Standard for Safe Use of Lasers specifies requirements for laser protective eyewear, including optical density (OD), wavelength coverage, and labeling.

– IEC 60825-1 (International): International standard for laser product safety, covering classification and requirements for protective devices.

– EN 207 / EN 208 (Europe): European standards specifying performance requirements for filters and goggles used against laser radiation. CE marking is mandatory for sale within the EU.

– OSHA Regulations (USA): Mandate the use of appropriate PPE in workplaces with laser hazards under 29 CFR 1910.132.

– FDA/CDRH (USA): Regulates laser products and associated protective devices under 21 CFR Part 1040.10 and 1040.11.

Manufacturers and distributors must ensure that each product bears proper certification labels, includes traceable test reports, and comes with instructions for use compliant with local regulations.

Product Classification and Labeling Requirements

Each pair of laser safety glasses must be clearly labeled with:

– Laser protection wavelength range (e.g., 190–315 nm, 800–1100 nm)

– Optical Density (OD) at specified wavelengths

– Applicable standard(s) met (e.g., EN 207:2019, ANSI Z136.1-2022)

– Manufacturer name and model number

– Batch or serial number for traceability

– Expiration or inspection date (if applicable)

– Pictograms and warnings per ISO 7010

Proper labeling ensures users can verify suitability for specific laser systems and facilitates regulatory audits.

Packaging and Handling Procedures

To maintain optical integrity and compliance:

– Use protective packaging that prevents scratching, crushing, or exposure to contaminants.

– Include desiccants if lenses are sensitive to moisture.

– Pack with printed compliance documentation (Declaration of Conformity, test reports, user instructions).

– Avoid extreme temperatures during storage and transit; store between 10°C and 30°C.

– Use tamper-evident seals for sterile or calibrated models.

Handling should be done with clean gloves to prevent lens contamination. Returnable packaging may be used in controlled environments to reduce waste.

Supply Chain and Distribution Logistics

- Temperature Control: Maintain a stable environment; avoid exposure to UV light or high humidity during transport.

- Inventory Management: Utilize barcode/RFID systems to track models, compliance status, and expiration dates.

- Shipping Documentation: Include commercial invoices, packing lists, and certificates of compliance. For international shipments, provide bilingual labeling if required.

- Customs Compliance: Declare products under the correct HS Code (e.g., 9004.90 for other optical appliances). Provide proof of conformity to destination country standards.

- Cold Chain Avoidance: Unlike medical devices, laser glasses do not require refrigeration but must be protected from thermal shock.

Import and Export Regulations

- Verify that destination markets accept the certification standards applied (e.g., CE in EU, FDA in USA).

- Some countries require local testing or third-party verification (e.g., INMETRO in Brazil, KC in South Korea).

- Maintain records of compliance documentation for at least 10 years.

- Be aware of dual-use regulations if glasses are designed for high-power military-grade lasers (potential ITAR or EAR controls in the U.S.).

Quality Assurance and Traceability

Implement a quality management system (e.g., ISO 13485 or ISO 9001) to ensure consistent compliance. Each batch should undergo:

– Spectral transmission testing

– Optical density verification

– Durability and fit testing

– Documentation archiving with batch-specific reports

Full traceability from raw materials to end-user enables effective recalls and audits.

User Training and Documentation

Distribute with:

– Multilingual user instructions

– Laser compatibility chart

– Inspection and maintenance guidelines

– Replacement schedule based on use and damage

Employers must train personnel on proper selection, use, and inspection of laser safety glasses per OSHA and ANSI requirements.

Disposal and End-of-Life Management

- Do not dispose of as regular waste if materials are hazardous (e.g., leaded glass).

- Follow local e-waste or hazardous material disposal regulations.

- Consider manufacturer take-back programs for responsible recycling.

Proper disposal prevents environmental contamination and ensures compliance with WEEE or similar directives.

Summary and Best Practices

To ensure safe and compliant logistics for laser safety glasses:

1. Verify all products meet applicable regional and international standards.

2. Maintain detailed documentation and traceability throughout the supply chain.

3. Train staff and end users on compliance, handling, and proper use.

4. Audit suppliers and logistics partners regularly.

5. Stay updated on evolving laser safety regulations and technology standards.

Adhering to these guidelines protects users, ensures regulatory compliance, and supports operational continuity in laser-intensive environments.

Conclusion: Sourcing Safety Glasses for Laser Applications

In conclusion, sourcing appropriate safety glasses for laser environments is a critical step in ensuring the safety and well-being of personnel working with or near laser equipment. It is essential to select eyewear that is specifically designed for the laser’s wavelength(s), optical density (OD) requirements, and power levels to provide effective protection against both direct and reflected laser beams. Key considerations include compliance with recognized safety standards (such as ANSI Z87.1 or EN 207), proper fit and comfort for prolonged use, durability, and compatibility with other personal protective equipment.

Furthermore, engaging with reputable suppliers, verifying certification documentation, and staying updated on evolving laser safety regulations are crucial for making informed purchasing decisions. By prioritizing quality, precision, and user compliance, organizations can significantly reduce the risk of ocular injury and create a safer working environment in laser applications. Ultimately, investing in properly sourced laser safety glasses is not only a regulatory requirement but also a fundamental commitment to workplace safety.