The global small engine components market, which includes carburetor replacements for power tools like Ryobi’s lineup, is experiencing steady expansion driven by rising demand in landscaping, agriculture, and residential applications. According to Grand View Research, the global outdoor power equipment market was valued at USD 33.6 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. This sustained growth underscores the increasing need for reliable replacement parts, particularly for widely used platforms such as the Ryobi 18002300 carburetor. As consumers prioritize equipment longevity and cost-effective maintenance, third-party manufacturers have stepped in to meet demand with compatible, high-performance alternatives. Based on product availability, customer reviews, and OEM-equivalent quality metrics, the following three manufacturers have emerged as top suppliers of Ryobi 18002300 carburetor replacements.

Top 3 Ryobi 18002300 Carburetor Replacement Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ryobi Chainsaw RYI2300BTA

Domain Est. 2004

Website: ereplacementparts.com

Key Highlights: 1–2 day delivery · 365-day returnsA complete guide to your RYI2300BTA Ryobi Chainsaw at eReplacementParts. We have model diagrams, OEM parts, symptom–based repair help, instructio…

#2 Ryobi

Domain Est. 2010

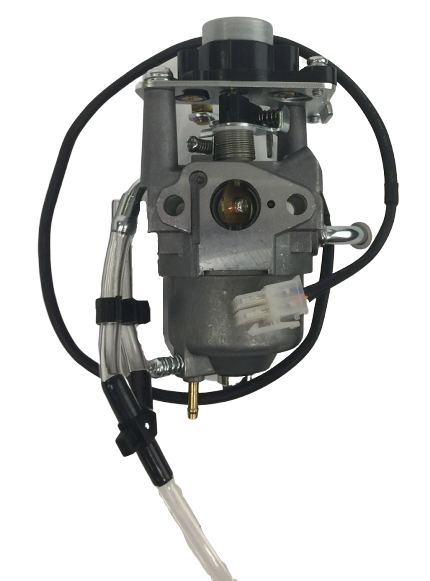

#3 Ryobi Inverter Carburetor Assembly Replacement For Ryobi …

Domain Est. 2022

Website: virtualnorse.com

Key Highlights: Carburetor Assembly Replacement For Ryobi RYi2300BTA 1800/2300 Watt Inverter Generator · Internet # 1250675 · Model # 3685752 · Store SKU # 16778238114 · Customers ……

Expert Sourcing Insights for Ryobi 18002300 Carburetor Replacement

H2: 2026 Market Trends for Ryobi 18002300 Carburetor Replacement

The market for the Ryobi 18002300 carburetor replacement is expected to experience notable shifts by 2026, driven by evolving consumer behavior, technological advancements, and broader industry trends in outdoor power equipment (OPE). As Ryobi continues to maintain a strong presence in the home and DIY landscaping tools market, demand for replacement parts such as the 18002300 carburetor will be influenced by several key factors.

-

Growing Demand for Aftermarket Parts

By 2026, the aftermarket for small engine components is projected to expand due to the increasing lifespan of outdoor power tools. Consumers are opting to repair rather than replace aging Ryobi equipment—especially two-stroke engines used in string trimmers, leaf blowers, and hedge trimmers—driving consistent demand for carburetor replacements like the 18002300 model. This trend is further amplified by cost-conscious users seeking affordable maintenance solutions. -

Shift Toward Electrification and Its Impact

While Ryobi is aggressively expanding its cordless 18V ONE+ system, a large installed base of older gas-powered tools will remain in use through 2026. This creates a transitional period where demand for carburetor replacements remains stable. However, long-term demand may plateau post-2026 as gas-powered tools are gradually phased out in favor of battery-operated alternatives, especially in residential markets. -

Increased Availability of Compatible and Universal Replacements

The market will see a rise in third-party and universal carburetor replacements compatible with the Ryobi 18002300. These alternatives, often priced lower than OEM parts, will appeal to budget-focused consumers and repair shops. As a result, Ryobi and authorized distributors may need to emphasize authenticity, reliability, and warranty support to maintain market share. -

E-Commerce Dominance in Parts Distribution

By 2026, online platforms such as Amazon, eBay, and specialized OPE parts retailers will dominate the distribution of carburetor replacements. Enhanced search algorithms, customer reviews, and fast shipping will make it easier for users to source the 18002300 or compatible models. This trend favors suppliers with strong digital presence and accurate product listings. -

Focus on Sustainability and Repairability

Regulatory pressures and consumer advocacy for sustainable practices are encouraging repairability of tools. Initiatives like the “Right to Repair” movement may influence OEMs, including Ryobi, to maintain spare parts availability. This supports continued access to the 18002300 carburetor, at least through the mid-2020s. -

Geographic Demand Variation

Demand for the Ryobi 18002300 carburetor will remain strongest in rural and suburban areas of North America, where gas-powered tools are still prevalent. In contrast, urban markets with stricter emissions regulations may see faster adoption of electric tools, reducing long-term replacement needs.

In summary, the 2026 market for the Ryobi 18002300 carburetor replacement will be characterized by steady but gradually declining demand, sustained by the existing fleet of gas-powered tools and consumer preference for cost-effective repairs. While electrification poses a long-term challenge, the transitional phase ensures relevance for this part through the mid-decade, especially in the aftermarket and e-commerce channels.

Common Pitfalls When Sourcing the Ryobi 18002300 Carburetor Replacement

When replacing the Ryobi 18002300 carburetor, buyers often encounter several challenges related to product quality and intellectual property (IP) concerns. Being aware of these pitfalls can help ensure a reliable and cost-effective repair.

1. Poor-Quality Aftermarket Carburetors

One of the most common issues is purchasing low-quality aftermarket replacements. Many third-party carburetors labeled as compatible with the Ryobi 18002300 are manufactured using inferior materials and lack precise tolerances. These substandard units often lead to:

– Inconsistent engine performance

– Difficulty starting

– Fuel leaks

– Short lifespan requiring frequent replacements

Always verify reviews, brand reputation, and material specifications before buying.

2. Misrepresentation of Compatibility

Some sellers inaccurately list carburetors as compatible with the Ryobi 18002300 when they are designed for different models. This mismatch can result in:

– Incorrect fuel mixture

– Poor engine idle

– Installation difficulties

Double-check OEM part numbers and consult your equipment’s manual to confirm compatibility.

3. Counterfeit or Unbranded Products

The market is flooded with counterfeit or unbranded carburetors that mimic genuine parts. These often lack proper quality control and may infringe on intellectual property rights. Signs of counterfeit products include:

– Unusually low prices

– Vague product descriptions

– Missing branding or inconsistent packaging

Purchasing from authorized dealers or reputable suppliers helps avoid such risks.

4. Intellectual Property (IP) Violations

Many generic carburetor manufacturers replicate the design of the original Ryobi 18002300 without licensing, potentially violating design patents or trademarks. While these parts may function, supporting IP infringement can:

– Undermine innovation

– Lead to legal or warranty complications

– Result in inconsistent part availability

Opting for OEM (original equipment manufacturer) parts or licensed replicas supports compliance and ensures part authenticity.

5. Lack of Warranty or Support

Cheap or unauthorized replacements often come without warranties or customer support. If the carburetor fails shortly after installation, you may be left with no recourse. Always choose suppliers that offer:

– Clear return policies

– Technical support

– Product guarantees

This ensures long-term reliability and peace of mind.

By being vigilant about quality, compatibility, and IP integrity, you can avoid the most common pitfalls when sourcing a replacement for the Ryobi 18002300 carburetor.

H2: Logistics & Compliance Guide for Ryobi 18002300 Carburetor Replacement

This guide outlines the logistics and regulatory compliance considerations when replacing the Ryobi 18002300 carburetor in outdoor power equipment (e.g., string trimmers, chainsaws, leaf blowers). Proper handling ensures safety, environmental protection, and adherence to regulations.

H2: Logistics Considerations

1. Part Sourcing & Inventory Management

– Correct Part Identification: Confirm the Ryobi 18002300 carburetor is compatible with the specific engine model. Cross-reference using the engine serial number and original equipment manufacturer (OEM) specifications.

– Supplier Reliability: Source carburetors from authorized distributors or reputable suppliers to ensure authenticity and quality. Avoid counterfeit parts.

– Inventory Tracking: Maintain a log of carburetor stock, including batch numbers and receipt dates, for traceability and warranty claims.

2. Transportation & Handling

– Packaging: Store and transport carburetors in original packaging or sealed anti-static bags to prevent contamination, damage, or loss of small components.

– Environmental Conditions: Store in a dry, temperature-controlled environment (10–30°C / 50–86°F) to avoid fuel degradation, diaphragm warping, or corrosion.

– Hazardous Materials: Empty old carburetors of residual fuel before handling or shipping. Residual fuel may be classified as flammable liquid under transport regulations (e.g., DOT 49 CFR in the U.S.).

3. Installation Workflow

– Tools & Equipment: Use calibrated tools (e.g., screwdrivers, wrenches) and follow OEM service procedures. Include torque specifications to avoid over-tightening.

– Calibration & Tuning: After installation, perform idle and high-speed adjustments per manufacturer guidelines using a tachometer. Improper tuning affects emissions and performance.

– Waste Management: Collect used carburetors, gaskets, and filters for proper disposal or recycling.

H2: Compliance Requirements

1. Environmental Regulations

– EPA Emission Standards (U.S.): Replacement carburetors must meet current EPA Phase 3 or Tier 3 emission standards for small off-road engines (SORGE). The Ryobi 18002300 must be a certified replacement part compliant with 40 CFR Part 1054.

– CARB Compliance (California): Verify the carburetor is California Air Resources Board (CARB)-certified, especially if servicing equipment in California. Look for a CARB Executive Order (EO) number.

– Fuel System Integrity: Ensure all fuel lines, seals, and connections are replaced as needed to prevent evaporative emissions. Use only EPA-compliant materials (e.g., low-permeation fuel lines).

2. Worker & Consumer Safety

– PPE Requirements: Technicians must wear safety glasses, gloves, and work in well-ventilated areas when handling fuel or disassembling carburetors.

– Chemical Handling: Follow OSHA Hazard Communication Standard (29 CFR 1910.1200) for handling fuel, carburetor cleaners, and solvents. Use material safety data sheets (MSDS/SDS).

– Product Liability: Use only OEM or EPA/CARB-certified replacement parts. Non-compliant parts may void warranties and expose service providers to liability.

3. Waste Disposal & Recycling

– Spent Carburetors: Classified as hazardous waste if contaminated with fuel or oil. Dispose through licensed hazardous waste handlers in compliance with RCRA (Resource Conservation and Recovery Act).

– Used Oil & Filters: Collect used engine oil and filters separately; recycle through authorized facilities per local and federal regulations.

– Plastic & Metal Components: Recycle non-hazardous plastic housings and metal parts through municipal or industrial recycling programs.

4. Documentation & Recordkeeping

– Maintain service records including:

– Date of replacement

– Serial number of old and new carburetor

– Technician name and certification

– EPA/CARB compliance confirmation

– Retain records for a minimum of 5 years for audit and warranty purposes.

H2: Best Practices Summary

- Always use EPA- and CARB-compliant replacement parts.

- Follow OEM installation and tuning procedures precisely.

- Train technicians on environmental and safety regulations.

- Partner with certified waste disposal providers.

- Audit compliance annually to ensure ongoing adherence.

By following this guide, service centers and end-users can ensure safe, legal, and environmentally responsible carburetor replacements.

In conclusion, sourcing a replacement carburetor for the Ryobi 18002300 model requires careful attention to compatibility and authenticity. After researching various options, original equipment manufacturer (OEM) parts from authorized Ryobi dealers or reputable suppliers offer the most reliable performance and fit, ensuring the longevity and efficiency of the equipment. While aftermarket alternatives may be more affordable, they can vary in quality and may lead to operational issues if not properly matched. Online marketplaces such as Amazon, eBay, and specialized outdoor power equipment retailers provide convenient access, but buyers should verify part numbers (such as 308101001 or 308101002, commonly associated with this model) and read customer reviews before purchasing. Additionally, consulting the user manual or contacting Ryobi customer support can help confirm the correct part. Ultimately, investing in a high-quality, compatible carburetor—preferably OEM—ensures optimal engine performance and reduces the likelihood of future maintenance issues.