The global RV insulation panels market is experiencing robust growth, driven by increasing recreational vehicle production and rising consumer demand for energy-efficient, lightweight, and thermally superior materials. According to Mordor Intelligence, the global recreational vehicle market was valued at USD 92.7 billion in 2023 and is projected to grow at a CAGR of over 5.8% through 2029, directly boosting demand for high-performance insulation solutions. As manufacturers prioritize thermal comfort, noise reduction, and fuel efficiency, advanced insulation panels made from polyurethane, polystyrene, and reflective foils have become critical components in modern RV construction. This growth trajectory, supported by innovations in material science and sustainable building practices, has intensified competition among insulation panel suppliers. In response, we’ve identified the top 10 RV insulation panels manufacturers shaping the industry through product innovation, scalability, and strong supply chain integration—companies positioned at the forefront of meeting evolving OEM and aftermarket demands.

Top 10 Rv Insulation Panels Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

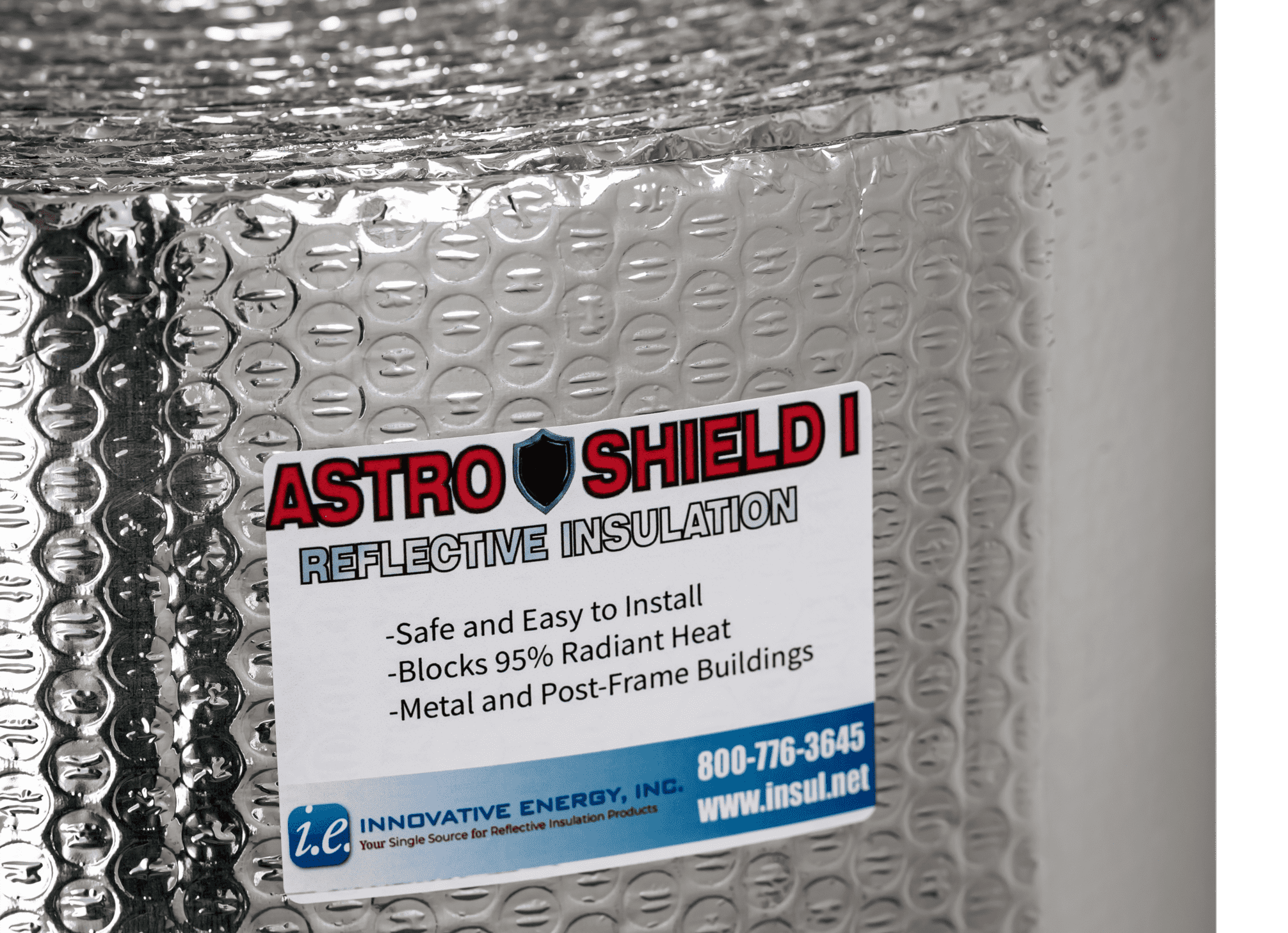

#1 AstroShield RV

Domain Est. 1997

Website: innovativeenergy.com

Key Highlights: AstroShield, an improved version of the product previously known as Astro Foil insulation, is an easy-to-install line of reflective insulation used for a ……

#2 R-TECH Insulation Panels

Domain Est. 1998

Website: insulfoam.com

Key Highlights: R-TECH Insulation Panels are environmentally friendly, achieve enhanced R–values and are typically less expensive than other comparable insulation ……

#3 Composite Panels to Meet All Your RV Needs

Domain Est. 2002

Website: coosacomposites.com

Key Highlights: Coosa’s composite panels are the bulwark of the strongest, most lightweight RVs. Our composite panel is made from high-density, closed-cell, polyurethane foam….

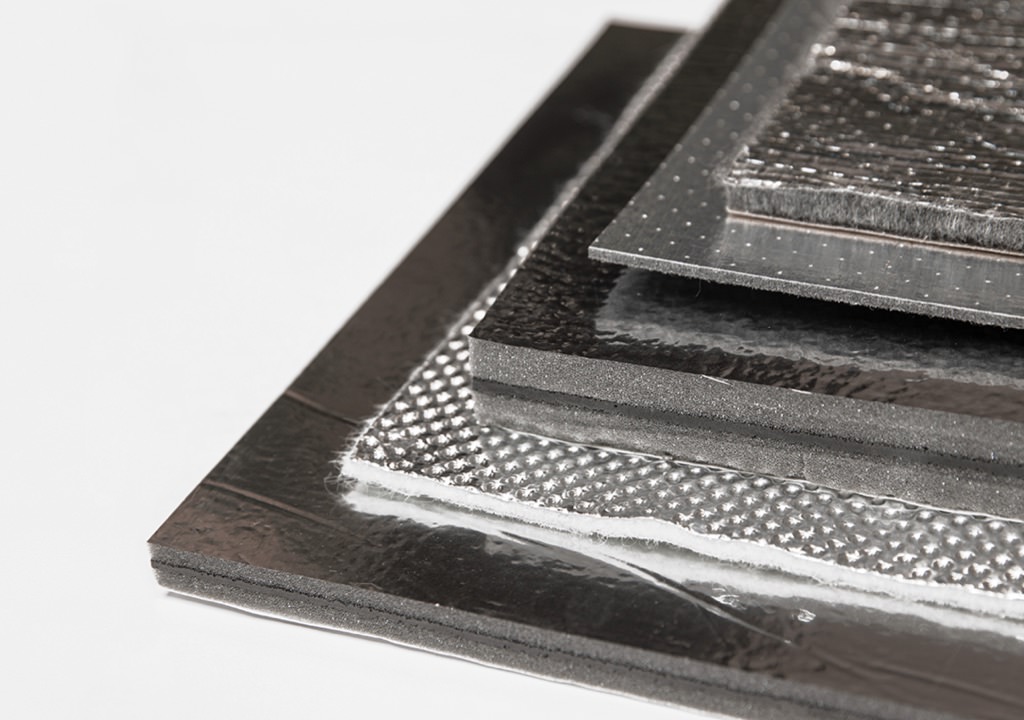

#4 RV Acoustic & Thermal

Domain Est. 2002

Website: genesisproductsinc.com

Key Highlights: Our new line of acoustic and thermal solutions brings next-level comfort to RV. From reducing rattle and noise in motorized units to controlling interior ……

#5 RV Insulation

Domain Est. 2005

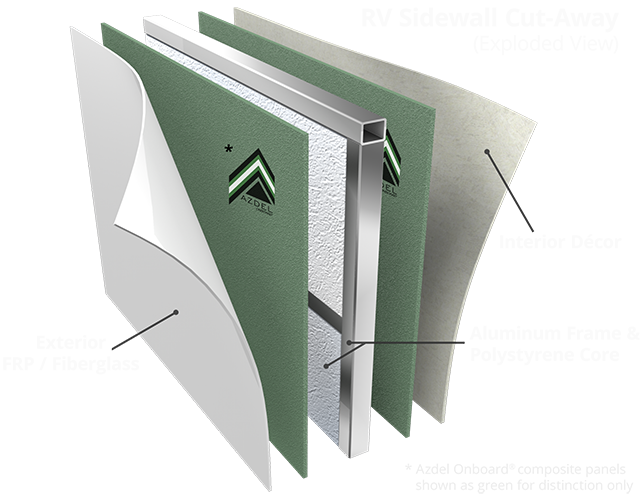

#6 Azdel Onboard

Domain Est. 2010 | Founded: 2006

Website: azdelonboard.com

Key Highlights: Azdel Onboard composite panels have been used in RV exterior and interior sidewall, ceilings, and more since 2006….

#7 Recreational Vehicles

Domain Est. 2014

Website: cptpanels.com

Key Highlights: Elevate your RV experience with CPT’s advanced composite panels, engineered for lightweight, robust, and enduring performance in the RV industry….

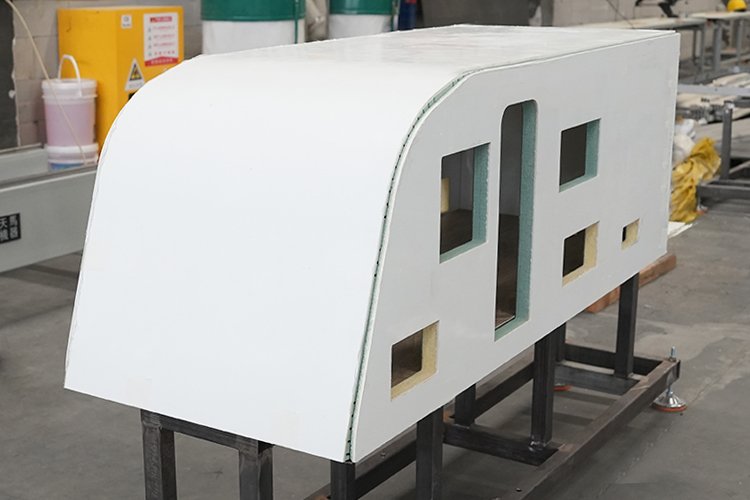

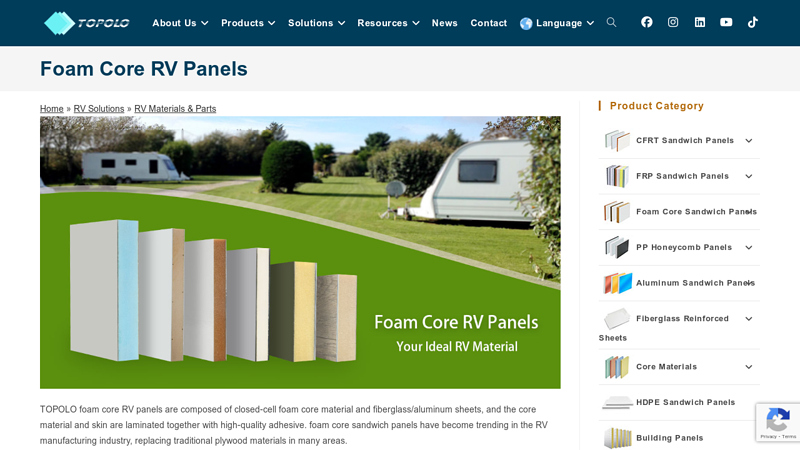

#8 Foam Core RV Panels

Domain Est. 2017

Website: topolocfrt.com

Key Highlights: TOPOLO foam core RV panels are composed of closed-cell foam core material and fiberglass/aluminum sheets, and the core material and skin are laminated together ……

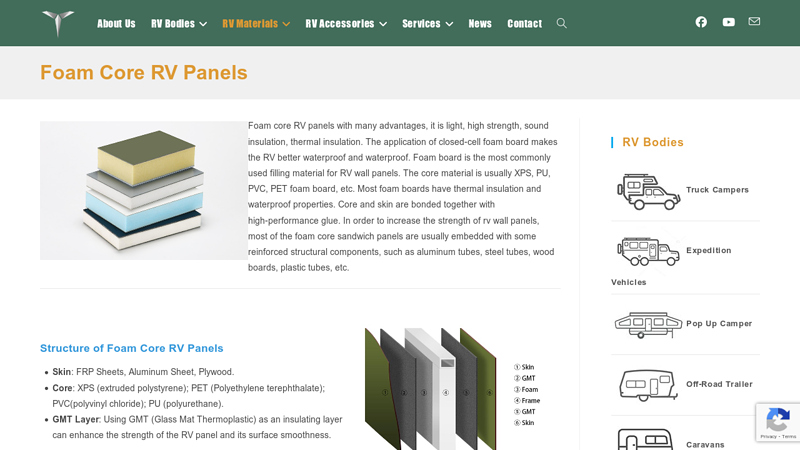

#9 Foam Core RV Panels Made in China

Domain Est. 2022

Website: topolo-rv.com

Key Highlights: Foam Core RV Panels With XPS/PET/PU/PVC Core Made in China. Custom Foam Composite Panels for Campers, Caravans, RVs, Teardrops, etc….

#10 Boreas Composite Panels

Domain Est. 2023

Website: boreascompositepanels.com

Key Highlights: Boreas Composite panels are what we use to build the toughest offroad camper, and we’re pleased to distribute these for DIY camper projects….

Expert Sourcing Insights for Rv Insulation Panels

H2: 2026 Market Trends for RV Insulation Panels

As the recreational vehicle (RV) industry evolves in response to consumer demands, technological advancements, and regulatory shifts, the market for RV insulation panels is poised for significant transformation by 2026. Several key trends are expected to shape the growth, innovation, and adoption of insulation solutions in the RV manufacturing and aftermarket sectors.

1. Rising Demand for Energy Efficiency and Comfort

With increasing consumer expectations for year-round usability and improved indoor comfort, RV manufacturers are prioritizing advanced insulation technologies. In 2026, high-performance insulation panels—including those made from polyiso, spray foam, vacuum insulated panels (VIPs), and aerogel composites—are anticipated to gain market share. These materials offer superior R-values per inch, helping maintain interior temperatures, reduce HVAC load, and enhance energy efficiency in off-grid and cold-weather travel.

2. Growth in Luxury and Full-Time RV Living

The shift toward full-time residency and luxury RV lifestyles is driving demand for premium insulation. Buyers are seeking residential-like comfort, leading to the integration of multi-layered and sound-dampening insulation systems. Insulation panels that also contribute to noise reduction and moisture control will be increasingly favored, particularly in high-end Class A and fifth-wheel models.

3. Sustainability and Eco-Friendly Materials

Environmental regulations and green consumerism are pushing manufacturers toward sustainable insulation solutions. By 2026, bio-based foams, recycled content panels, and low-global-warming-potential (GWP) blowing agents are expected to become standard in eco-conscious RV models. Certifications such as Greenguard and Cradle to Cradle will influence material selection, supporting a shift away from traditional petroleum-based foams.

4. Lightweight and Space-Optimized Designs

As RV manufacturers strive to improve fuel efficiency and maximize interior space, thin yet highly effective insulation panels will be in demand. Vacuum insulated panels (VIPs) and aerogel-enhanced composites offer exceptional thermal performance in minimal thickness, making them ideal for compact floorplans and weight-sensitive designs, especially in Class B and C motorhomes.

5. Integration with Smart Building Technologies

Insulation systems in 2026 may incorporate smart materials capable of adapting to temperature changes or integrating with energy management systems. While still emerging, phase-change materials (PCMs) embedded within insulation panels could help stabilize interior temperatures and reduce energy consumption, aligning with the broader trend of smart RVs.

6. Expansion of the Aftermarket and DIY Retrofitting

The growing popularity of RV ownership has spurred demand for aftermarket insulation upgrades. Consumers are seeking easy-to-install, high-R-value panels to improve thermal performance in older models. This trend supports a parallel market for modular, cut-to-fit insulation kits tailored for DIY installation.

7. Regional Market Variations

Cold-climate markets (e.g., Canada, northern U.S., and Scandinavia) will drive demand for high-performance insulation, while warmer regions may focus on radiant barrier panels and reflective insulation to combat heat gain. Manufacturers are likely to offer region-specific insulation packages by 2026.

Conclusion

By 2026, the RV insulation panel market will be shaped by a convergence of performance, sustainability, and consumer lifestyle trends. Innovation in material science, regulatory pressures, and evolving customer expectations will accelerate the adoption of advanced insulation solutions, positioning high-efficiency, lightweight, and eco-friendly panels as critical components in next-generation RV design.

Common Pitfalls When Sourcing RV Insulation Panels (Quality, IP)

Sourcing RV insulation panels requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these areas can lead to performance issues, legal risks, and reputational damage. Below are key pitfalls to avoid:

Poor Material Quality and Inconsistent Performance

Low-grade insulation materials often fail to provide adequate thermal resistance (R-value), leading to poor temperature regulation inside the RV. Buyers may encounter inconsistent thickness, delamination, or off-gassing of harmful chemicals. Always verify manufacturer specifications, request independent test reports (e.g., ASTM standards), and inspect samples before bulk ordering.

Misrepresentation of R-Value and Thermal Efficiency

Some suppliers exaggerate the R-value or thermal performance of their panels. This misleading information can result in suboptimal energy efficiency and increased heating/cooling costs. Ensure that R-values are third-party tested and applicable under real-world conditions, not just ideal lab settings.

Inadequate Moisture and Mold Resistance

RVs are exposed to fluctuating humidity and temperature, making moisture resistance critical. Panels lacking proper vapor barriers or mold inhibitors can degrade quickly, compromising structural integrity and indoor air quality. Confirm that insulation is treated for moisture resistance and complies with relevant building or RV safety codes.

Use of Non-Fire-Retardant or Unsafe Materials

Fire safety is paramount in confined spaces like RVs. Some imported or low-cost panels may not meet fire safety standards (e.g., NFPA 701 or FMVSS 302). Always require certification documentation proving compliance with fire safety regulations to avoid hazardous conditions and regulatory non-compliance.

Intellectual Property Infringement Risks

Sourcing from manufacturers who replicate patented panel designs, bonding techniques, or composite structures can expose buyers to IP litigation. This is especially common with innovative multi-layer or structural insulated panels (SIPs). Conduct due diligence on supplier IP rights, request proof of licensing where applicable, and avoid “knock-off” products mimicking well-known brands.

Lack of Traceability and Certification

Reputable insulation panels should come with full traceability, including material sourcing, production batch numbers, and compliance certifications. Suppliers who cannot provide this documentation may be cutting corners, increasing the risk of substandard or counterfeit products entering your supply chain.

Overlooking Environmental and Regulatory Compliance

Some insulation materials contain restricted substances (e.g., formaldehyde, CFCs) or fail to meet environmental regulations like RoHS or REACH. Ensure panels comply with regional environmental standards, especially if selling or operating in eco-sensitive markets.

Ignoring Long-Term Durability and Warranty Support

Cheap panels may degrade under vibration, UV exposure, or thermal cycling common in RV use. Evaluate warranty terms, expected lifespan, and the supplier’s track record for after-sales support. A lack of warranty or poor customer service can signal unreliable quality.

Avoiding these pitfalls requires thorough vetting of suppliers, requesting product samples and certifications, and involving technical experts in the selection process. Prioritizing quality and IP integrity ensures safer, more efficient RV builds and protects your business from legal and operational risks.

Logistics & Compliance Guide for RV Insulation Panels

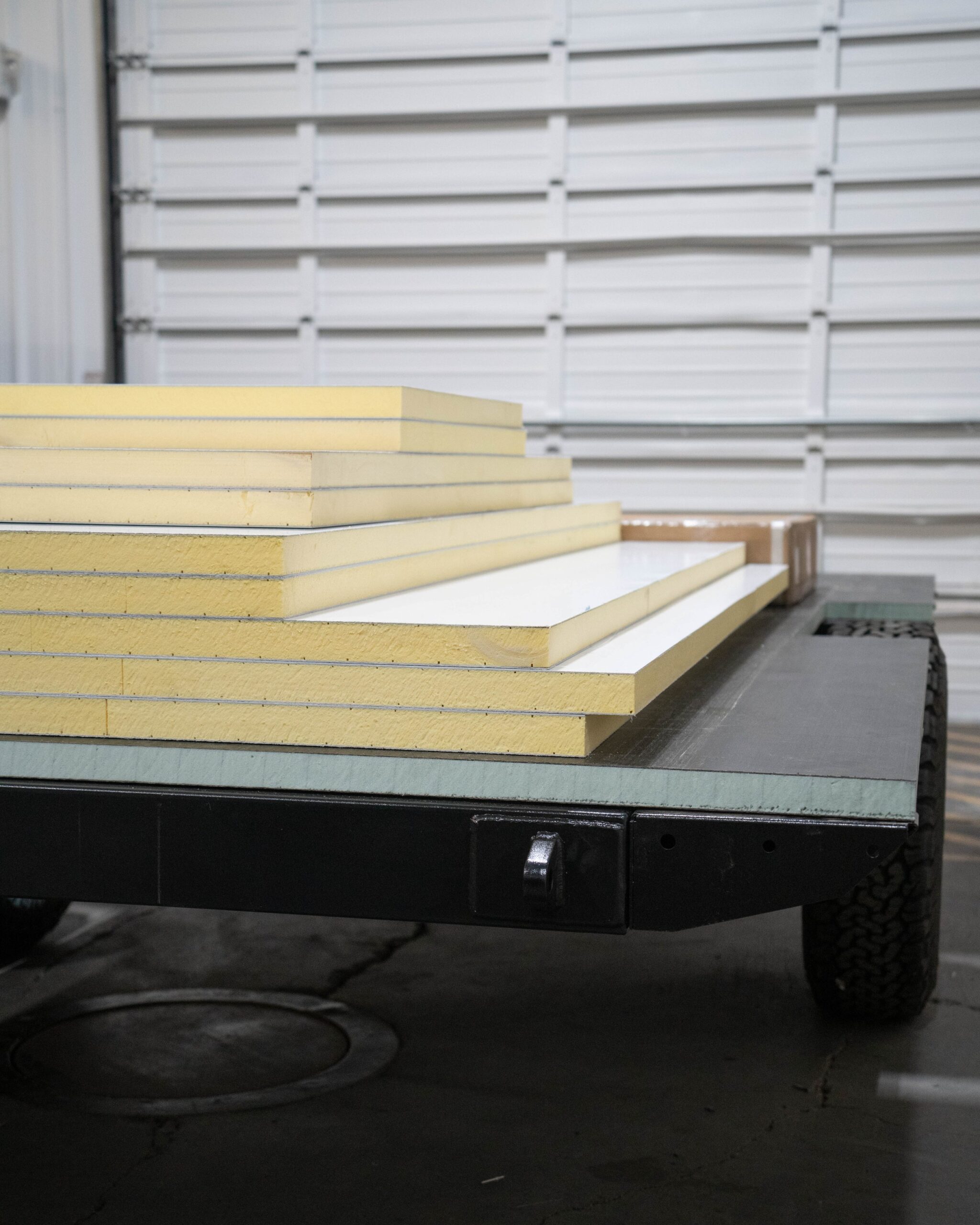

Product Overview and Specifications

RV insulation panels are specialized materials designed to improve thermal efficiency, reduce noise, and enhance overall comfort in recreational vehicles. Typically made from closed-cell foam, polyurethane, or reflective foil composites, these panels must meet specific performance, safety, and regulatory standards. Understanding their composition and intended use is essential for compliant logistics and distribution.

Regulatory Compliance Requirements

RV insulation panels must adhere to a range of national and international standards. In the United States, products should comply with Federal Motor Vehicle Safety Standards (FMVSS) 302 regarding flammability of interior materials. Additionally, insulation may need to meet ASTM E84 for surface burning characteristics. For shipments to the EU, compliance with the Construction Products Regulation (CPR) and CE marking may be required. Always verify region-specific fire, smoke, and toxicity (FST) regulations before distribution.

Packaging and Handling Procedures

To ensure product integrity during transit, RV insulation panels should be vacuum-sealed or wrapped in moisture-resistant plastic and secured on pallets with edge protectors. Panels must be stored and transported in dry, temperature-controlled environments to prevent warping or degradation. Label packages clearly with handling instructions such as “Fragile,” “Keep Dry,” and “This Side Up” to minimize damage risk.

Transportation and Shipping Guidelines

Use freight carriers experienced in handling lightweight, bulky materials. Insulation panels are often shipped via LTL (Less Than Truckload) or full truckload depending on volume. Ensure secure strapping and load stabilization to prevent shifting. For international shipments, provide accurate Harmonized System (HS) codes—typically 3921.12 or 6806.90 depending on material composition—and comply with import/export documentation, including commercial invoices and certificates of conformity.

Storage Conditions and Shelf Life

Store RV insulation panels indoors at temperatures between 50°F and 80°F (10°C to 27°C) and relative humidity below 60%. Avoid direct sunlight and contact with solvents or oils. When properly stored, most panels have a shelf life of 2–5 years. Rotate stock using a first-in, first-out (FIFO) system to prevent aging and maintain performance quality.

Environmental and Safety Compliance

Manufacturers and distributors must comply with environmental regulations such as EPA guidelines on volatile organic compounds (VOCs) and proper disposal of packaging materials. If panels contain HFCs or other regulated blowing agents, adherence to the Significant New Alternatives Policy (SNAP) is required. Provide Safety Data Sheets (SDS) for all insulation products, highlighting handling precautions and emergency measures.

Documentation and Traceability

Maintain comprehensive records including batch numbers, material test reports, compliance certifications, and shipping manifests. This traceability is critical for quality control and regulatory audits. For OEM customers, ensure documentation aligns with their supplier compliance programs and RV manufacturing standards.

Final Delivery and Installation Support

Coordinate with distributors or installers to confirm delivery accessibility and on-site storage options. Offer technical support documentation outlining proper installation methods, compatible adhesives, and sealing practices to maintain insulation performance and compliance post-installation.

Updates and Regulatory Monitoring

Stay informed about evolving regulations in the RV and building materials sectors. Subscribe to updates from agencies such as the National Fire Protection Association (NFPA), Department of Transportation (DOT), and European Committee for Standardization (CEN) to ensure ongoing compliance and avoid supply chain disruptions.

Conclusion on Sourcing RV Insulation Panels

Sourcing the right insulation panels for an RV is a critical step in enhancing comfort, energy efficiency, and overall performance in varying climates. After evaluating materials, thermal resistance (R-value), ease of installation, durability, and cost, it’s clear that the best choice depends on specific needs and usage patterns. Closed-cell foam, polyiso, and spray foam offer high R-values and moisture resistance, making them ideal for extreme temperatures and long-term use. Meanwhile, foil bubble wrap and fiberglass provide more budget-friendly options with easier DIY installation.

When sourcing, prioritize reputable suppliers that offer consistent product quality, detailed specifications, and customer support. Consider purchasing from RV specialty retailers or insulation manufacturers with proven track records in mobile applications. Additionally, factor in local climate conditions, desired interior space preservation, and installation expertise when making a decision.

Ultimately, investing in high-quality RV insulation panels not only improves thermal regulation and reduces reliance on heating and cooling systems but also contributes to a quieter, more comfortable living environment on the road. Careful sourcing ensures durability, safety, and long-term savings, making it a worthwhile endeavor for any RV owner.