The global welding equipment market, including specialized processes like rustfri svejsning (stainless welding), is experiencing steady expansion driven by rising demand in construction, automotive, and heavy manufacturing sectors. According to Grand View Research, the global welding equipment market size was valued at USD 29.8 billion in 2023 and is projected to grow at a CAGR of 5.2% from 2024 to 2030. This growth is fueled by increasing infrastructure development, advancements in automation, and the need for high-integrity, corrosion-resistant welds—particularly in applications involving stainless steel and other non-ferrous materials. As industries prioritize durability and precision, manufacturers specializing in rustfri svejsning technologies are emerging as key players. Based on market presence, innovation, and technological capabilities, here are the top 9 rustfri svejsning manufacturers shaping the future of high-quality, corrosion-resistant welding solutions.

Top 9 Rustfri Svejsning Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

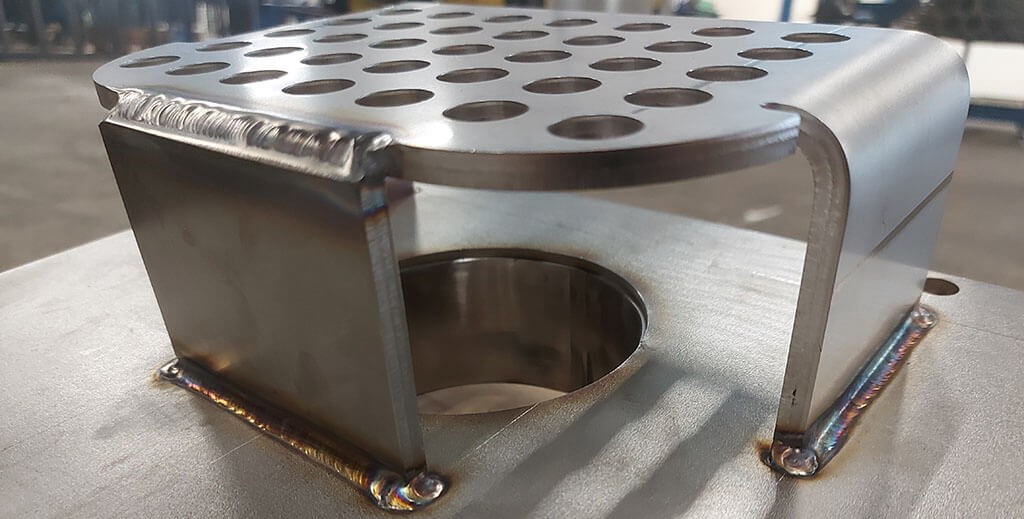

#1 Svejsning Rustfri Tanke

Website: magrinding.com

Key Highlights: Hos M&A Grinding ApS er vi specialister i svejsning af rustfri ståltanke, og vi leverer skræddersyede løsninger til kunder inden for industrier som mejeri, ……

#2 Rustfri svejsning

Website: dsm.dk

Key Highlights: Vores mål er at imødekomme dine unikke behov og standarder inden for rustfri svejsning. Vi tilbyder skræddersyede løsninger og rådgivning, der passer præcist ……

#3 Svejsning i Rustfrit Stål

Website: as-vst.dk

Key Highlights: AS-VST tilbyder højkvalitets svejsning i rustfrit stål og andre reparationsløsninger der lever op til dine industrielle krav. Læs mere her….

#4 Svejsning i rustfrit stål

Website: hosta.dk

Key Highlights: Inden for svejsning i rustfrit stål er der mulighed for både MIG/MAG-svejsning, TIG-svejsning, boltsvejsning og punktsvejsning. Du kan læse mere om de ……

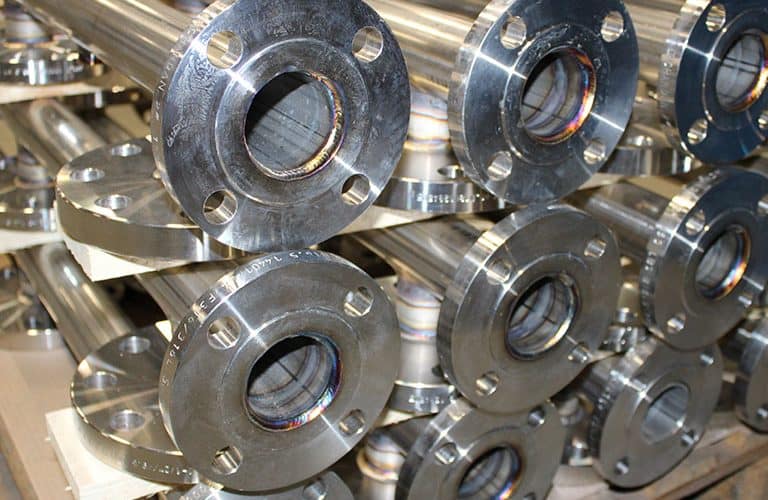

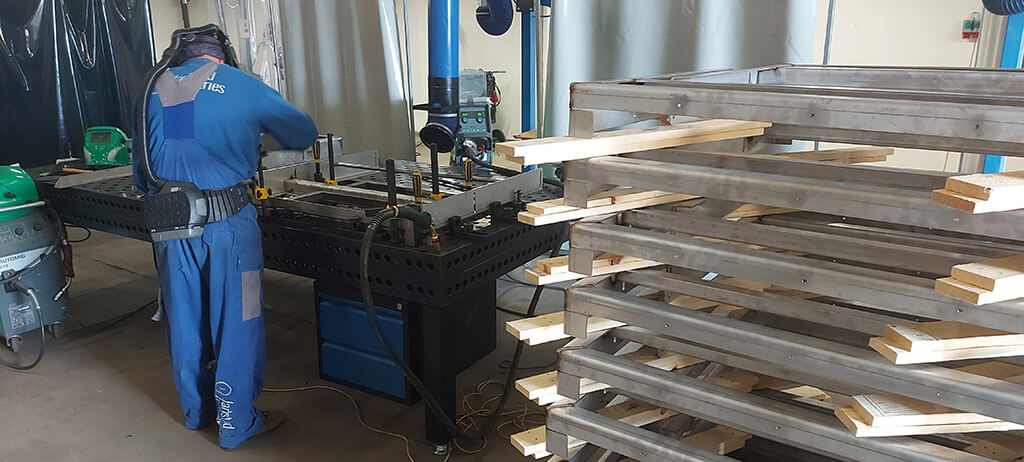

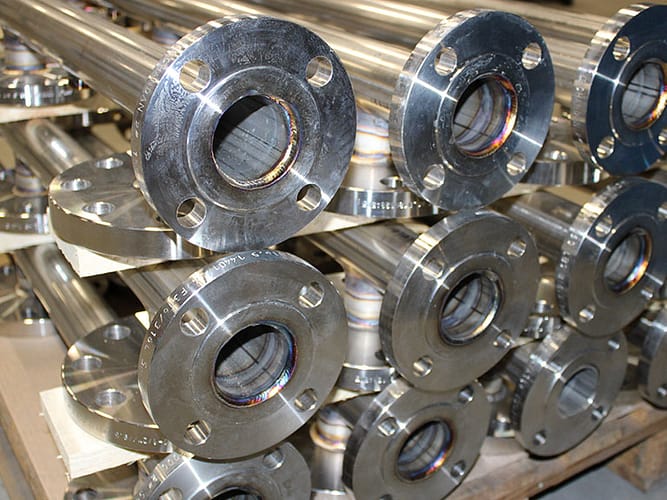

#5 Svejsning i stål, rustfrit stål og aluminium

Website: bsb-industry.dk

Key Highlights: Få svejsning i stål, rustfrit stål og aluminium, der lever op til branchens højeste krav. Kontakt os på 75 55 99 66 eller [email protected]….

#6 Svejsning i rustfast / rustfrit stål

Website: jarlstad-industries.dk

Key Highlights: Du skal være ekstra omhyggelig, når du arbejder med rustfast stål. Ved MIG-svejsning skal du også bruge en særlig bland-gas; 2% Co2 /98% Argon….

#7 Rustfri smede

Website: ceandersen.dk

Key Highlights: C.E. Andersen er rustfri smede og tilbyder skræddersyede løsninger i rustfrit stål, og vores produkter udføres kun af certificerede svejsere….

#8 Montage og sammenføjning

Website: energy-supply.dk

Key Highlights: Alle · Kompetencer · Underleverandør · Montage og sammenføjning · Svejsning · Tig svejsning · Rustfrit stål….

#9 Svejsning

Website: ralasteel.dk

Key Highlights: Hos RALA Stål tilbyder vi svejsning af alle typer emner uanset omfanget. Vi er DS/EN 1090 certificeret. Kontakt os i dag og hør nærmere….

Expert Sourcing Insights for Rustfri Svejsning

Market Trends for Rustfri Svejsning in 2026

By 2026, the market for rustfri svejsning (stainless steel welding) is expected to undergo significant transformation, driven by technological innovation, sustainability demands, and evolving industrial needs. Key trends shaping the sector include:

1. Increased Demand in Green Energy and Infrastructure

The global push toward renewable energy and sustainable infrastructure will boost demand for stainless steel welding. Projects such as hydrogen production facilities, offshore wind farms, and desalination plants rely heavily on corrosion-resistant materials, making rustfri svejsning essential. The construction and expansion of green hydrogen infrastructure in Europe and North America will particularly drive welding service demand due to the high purity and durability requirements.

2. Automation and Digitalization in Welding Processes

The integration of robotics, AI-driven monitoring systems, and digital twin technology will gain momentum. Automated orbital welding systems, especially for tube and pipe applications in pharmaceuticals and food processing, will become more prevalent, improving precision and reducing human error. Real-time weld quality monitoring using IoT sensors and predictive maintenance tools will enhance efficiency and reduce downtime in industrial settings.

3. Focus on Sustainability and Circular Economy

Environmental regulations will place greater emphasis on energy-efficient welding techniques and reduced emissions. The industry will see a shift toward low-carbon welding processes and the increased use of recycled stainless steel. Companies offering sustainable welding solutions—such as hybrid laser-arc welding or cold metal transfer (CMT)—will gain a competitive edge. Lifecycle assessments of welded components will become standard in procurement decisions.

4. Skilled Labor Shortages and Training Innovation

A persistent shortage of certified welders, particularly in Europe and North America, will accelerate investment in training through virtual reality (VR) simulators and augmented reality (AR) guidance systems. Modular and remote training platforms will expand access to skilled labor, while certification programs will increasingly emphasize digital competency alongside traditional welding skills.

5. Growth in High-Performance Alloys and Hybrid Materials

Demand for advanced stainless steels—such as super austenitic and duplex grades—will rise in aggressive environments like offshore oil & gas and chemical processing. This trend will require specialized welding procedures and filler materials, increasing the need for expert consultation and process validation. Hybrid joining techniques combining welding with adhesive bonding may also emerge in niche applications.

6. Regional Market Shifts

Emerging markets in Southeast Asia and the Middle East will expand their stainless steel fabrication capacity, creating new opportunities for rustfri svejsning service providers. Meanwhile, in mature markets like the EU and North America, retrofitting and maintenance of aging infrastructure will drive demand for high-integrity weld repairs and upgrades under stringent regulatory oversight.

In conclusion, the 2026 landscape for rustfri svejsning will be defined by technological sophistication, environmental responsibility, and a growing need for specialized expertise. Companies that adapt to automation, sustainability, and evolving material requirements will be best positioned for growth.

Common Pitfalls When Sourcing Rustfri Svejsning (Quality, IP)

Sourcing stainless steel welding services (Rustfri Svejsning) involves several potential pitfalls, especially concerning quality assurance and intellectual property (IP) protection. Being aware of these risks helps ensure a successful and secure procurement process.

Quality-Related Pitfalls

Lack of Certified Welders and Procedures

One of the most critical issues is engaging a supplier without certified welders (e.g., according to ISO 9606 or AWS D1.6) or approved welding procedures (WPS/PQR in accordance with ISO 15614). Without proper certification, weld integrity and long-term corrosion resistance cannot be guaranteed—especially crucial in stainless steel applications where passivation and microstructure matter.

Inadequate Material Traceability

Stainless steel components require full material traceability (e.g., through mill test certificates, EN 10204 3.1/3.2). Sourcing from vendors who cannot provide documented proof of material origin and grade risks using substandard or incorrect alloys, leading to premature failure.

Poor Surface Finish and Post-Weld Treatment

Improper cleaning, grinding, or lack of passivation after welding compromises the corrosion resistance of stainless steel. Aesthetic flaws and residual contaminants (like iron particles from carbon steel tools) can lead to rust spots—defeating the purpose of using “rustfri” materials.

Insufficient Quality Control and Documentation

Suppliers may skip mandatory non-destructive testing (NDT) such as dye penetrant (PT), radiographic (RT), or ultrasonic testing (UT), or fail to document inspections. Without proper QC reports and weld maps, verifying compliance with project specifications becomes impossible.

Intellectual Property (IP) Risks

Unprotected Design and Technical Data

Sharing detailed engineering drawings or proprietary designs with a welding subcontractor without a robust Non-Disclosure Agreement (NDA) or IP clause exposes sensitive information. This is especially risky when sourcing from third-party workshops without clear IP ownership terms.

Lack of Clear IP Ownership in Contracts

If the contract does not explicitly state that all work product, modifications, or tooling developed during the welding process remain the property of the client, the supplier may claim partial ownership or reuse designs for other customers.

Use of Subcontractors Without Oversight

Some suppliers outsource welding work to unvetted subcontractors. This not only introduces quality inconsistencies but also increases the risk of IP leakage across multiple parties who may not be bound by the same confidentiality agreements.

Digital File Exposure

Sharing CAD files or CNC welding programs electronically without encryption or usage controls can lead to unauthorized duplication or reverse engineering, particularly if the supplier operates in a jurisdiction with weak IP enforcement.

Mitigation Strategies

To avoid these pitfalls, always:

– Verify certifications (welders, processes, and company standards like ISO 3834).

– Require full material traceability and test reports.

– Define surface finish and post-weld treatment requirements clearly.

– Implement NDAs and contractual clauses securing IP ownership.

– Audit suppliers and monitor subcontracting practices.

– Limit access to sensitive digital files and use watermarked or restricted versions when necessary.

Proactively addressing these quality and IP concerns ensures reliable, compliant, and secure sourcing of Rustfri Svejsning services.

Logistics & Compliance Guide for Rustfri Svejsning

This guide outlines the essential logistics procedures and compliance requirements for Rustfri Svejsning to ensure efficient operations, regulatory adherence, and quality assurance across all stages of production and delivery.

Supply Chain Management

Establish reliable relationships with certified suppliers of stainless steel materials and welding consumables. All raw materials must meet applicable European standards (e.g., EN 10088 for stainless steel) and be accompanied by material test certificates (MTCs). Implement a vendor qualification system to audit and approve suppliers based on quality, delivery performance, and environmental compliance.

Inventory Control

Maintain real-time inventory tracking using digital systems to monitor stock levels of raw materials, work-in-progress, and finished goods. Conduct regular physical audits to ensure data accuracy. Store materials in a dry, organized environment to prevent corrosion and contamination, especially critical for stainless steel components.

Production & Quality Assurance

All welding operations must comply with ISO 3834 (quality requirements for fusion welding) and EN 15085 (if applicable for rail applications). Welders must be certified according to EN ISO 9606. Implement a documented quality control plan including visual inspections, non-destructive testing (e.g., dye penetrant testing), and final product verification. Maintain traceability through batch/lot numbering and welding logs.

Health, Safety & Environmental Compliance

Adhere to Danish and EU workplace safety regulations (e.g., Arbejdsmiljøloven and EU REACH/CLP). Ensure proper ventilation, use of personal protective equipment (PPE), and safe handling of hazardous substances such as grinding dust and cleaning agents. Conduct regular risk assessments and safety training. Manage waste according to environmental regulations, including proper disposal of metal swarf, oil, and packaging.

Transportation & Delivery

Use secure and weather-protected transport methods to prevent damage during transit. Provide proper packaging and labeling, including lifting points and handling instructions. Comply with road transport regulations (e.g., ADR if transporting hazardous materials). Offer delivery tracking and proof of delivery documentation for customer assurance.

Documentation & Traceability

Maintain comprehensive records for compliance audits, including material certifications, welding procedure specifications (WPS), inspection reports, and calibration logs. Ensure all documentation is stored securely and retained according to legal requirements (typically minimum 10 years for structural components).

Customer & Regulatory Compliance

Ensure all products meet customer specifications and applicable industry standards. Stay updated on changes in EU directives (e.g., Construction Products Regulation, Machinery Directive) that may affect product conformity. Issue EU Declarations of Conformity when required and affix CE marking where applicable.

By following this guide, Rustfri Svejsning ensures operational efficiency, legal compliance, and consistent delivery of high-quality stainless steel welding solutions.

Konklusion på sourcing af rustfri svejsning

Sourcing af rustfri svejsning kræver en omhyggelig vurdering af både tekniske krav, leverandørens kompetencer og økonomiske forhold. Gennem en struktureret sourcingproces er det afgørende at prioritere kvalitet og kompetence højt, idet rustfri svejsning stiller særlige krav til materialehåndtering, svejseteknik og efterbehandling for at sikre korrosionsbestandighed, styrke og estetik.

Ved evaluering af potentielle leverandører bør der lægges vægt på deres certificeringer (fx ISO 3834, EN 1090), erfaring med lignende projekter, kvalitetsstyringssystemer samt egnede produktionsfaciliteter. Desuden er det vigtigt at sikre gennemsigtighed i leveringstider, prisfastsættelse og serviceydelser, herunder eventuel eftersyns- og vedligeholdelsessupport.

En vellykket sourcingstrategi vil typisk kombinere en balance mellem lokal og international sourcing – lokal sourcing kan tilbyde hurtigere kommunikation og levering, mens international sourcing måske tilbyder omkostningsmæssige fordele, men med øget risiko for logistiske og kvalitetsmæssige udfordringer.

Konklusion: For at sikre bæredygtig kvalitet og pålidelighed i rustfri svejsning er det afgørende at vælge leverandører med dokumenteret ekspertise, stærkt kvalitetsfokus og god kommunikationskapacitet. En langsigtet samarbejdsstrategi med udvalgte leverandører bidrager til forbedret processtyring, færre fejl og samlet set bedre produktresultater – hvilket er afgørende indenfor krævende industriområder som f.eks. fødevare-, farmaceuting- og energisektoren.