The global rust removal equipment market has experienced steady expansion, driven by increasing demand for surface preparation solutions in industrial maintenance, automotive restoration, and heavy machinery. According to a report by Mordor Intelligence, the global surface treatment market—encompassing rust removal technologies—was valued at USD 18.5 billion in 2023 and is projected to grow at a CAGR of 5.3% through 2029. This growth is fueled by rising infrastructure investments, stringent corrosion control regulations in industries like oil & gas, and the need for extended asset lifecycle management. As manufacturers adopt more efficient and eco-friendly rust removal methods such as abrasive blasting, laser cleaning, and electrochemical systems, the competitive landscape has evolved rapidly. Based on production scale, technological innovation, and global footprint, we’ve identified the top 9 rust removal machine manufacturers shaping the industry’s future.

Top 9 Rust Removal Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 FOX P CL – laser for removing rust

Website: pulsar-laser.com

Key Highlights: An innovative laser cleaner that revolutionizes the maintenance and restoration of large vehicles and industrial equipment….

#2 Industrial Laser Systems

Website: trilarindustrial.com

Key Highlights: Free delivery over $5,000Our continuous fiber laser technology delivers powerful solutions that eliminate rust, paint, oil, and contaminants without harsh chemicals or abrasive ……

#3 Industrial 1500W 2000W CW Laser Cleaning Machine Rusty Remove

Website: xinglaser.com

Key Highlights: XING Laser (6am Life LLC, DBA XING Laser) specializes in the development and manufacture of high-performance handheld laser cleaning and rust removal equipment….

#4 Laser Cleaning Machine

Website: sltl.com

Key Highlights: This futuristic laser cleaning solution can capably remove rust, oil, paint, grease, colour and other particles from the surface of the metals….

#5 Rust Removal with Laser Cleaning

Website: laserax.com

Key Highlights: Laser rust removal is a non-contact method that continuously removes rust while drastically lowering maintenance costs….

#6 Laser Rust Removal

Website: keyence.com

Key Highlights: The laser rust removal machine uses a focused laser beam with high peak power and short pulse to heat the external surface (the rust) to its evaporation point….

#7 Laser Cleaning Rust Removal

Website: nuwavelaser.com

Key Highlights: Our equipment uses pulsating lasers to blast away any contaminants from metal surfaces. This process is eco-friendly, as you won’t need any ……

#8 Laser Rust Removal

Website: powerlase-limited.com

Key Highlights: Achieve super fast rust removal rates with out lasers. Watch this super fast rust removal from carbon steel panel with the new ultra-lightweight Vulcan handheld ……

#9 ZAC Laser Machine

Founded: 2004

Website: zaclaser.com

Key Highlights: ZAC laser is the professional manufacture since 2004 which sell many laser machines such as laser rust removal-laser cleaning machine, laser engraver-laser ……

Expert Sourcing Insights for Rust Removal Machine

2026 Market Trends for Rust Removal Machines

The global market for rust removal machines is poised for significant transformation by 2026, driven by technological innovation, increasing industrial automation, and growing emphasis on equipment longevity and sustainability. As industries ranging from automotive and manufacturing to marine and infrastructure maintenance prioritize corrosion control, demand for efficient and eco-friendly rust removal solutions continues to rise. This analysis explores key trends shaping the rust removal machine market in 2026.

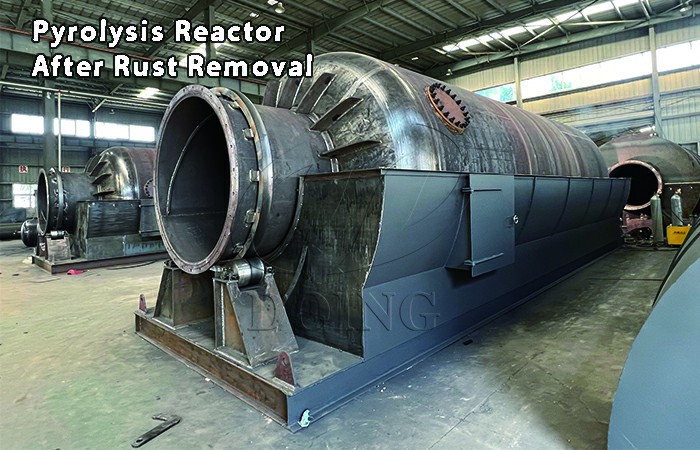

Rising Demand in Industrial Maintenance

Industries are increasingly investing in preventive maintenance to extend the life of metal assets, reduce downtime, and lower long-term operational costs. By 2026, sectors such as oil and gas, transportation, and heavy manufacturing are expected to lead adoption of advanced rust removal machines. The focus on operational efficiency and safety compliance is driving businesses to replace manual and chemical-based rust removal methods with mechanized systems.

Technological Advancements in Automation and Robotics

A major trend in 2026 is the integration of robotics and artificial intelligence (AI) into rust removal systems. Automated rust removal machines equipped with vision systems, machine learning algorithms, and robotic arms can detect rusted areas and optimize cleaning parameters in real time. These smart systems offer precision, consistency, and reduced labor costs—making them particularly valuable for large-scale industrial applications.

Growth of Eco-Friendly and Dry Rust Removal Methods

Environmental regulations are tightening worldwide, leading to a shift away from chemical stripping and abrasive blasting methods that generate hazardous waste. In response, manufacturers are developing dry, non-toxic rust removal technologies such as laser rust removal and electrolysis-based systems. Laser rust removal, in particular, is gaining traction due to its precision, minimal substrate damage, and zero waste production. By 2026, eco-conscious industries are expected to prefer these sustainable alternatives, boosting their market share.

Expansion in the Automotive and Aerospace Sectors

The automotive and aerospace industries are investing heavily in surface preparation technologies to ensure coating adhesion and structural integrity. With electric vehicle (EV) production on the rise, rust protection for underbody components and battery enclosures is becoming critical. In aerospace, stringent safety standards require high-precision rust and corrosion removal without damaging sensitive alloys. These sectors are expected to drive demand for portable, high-efficiency rust removal machines by 2026.

Regional Market Dynamics

Asia-Pacific is projected to be the fastest-growing region for rust removal machines by 2026, fueled by rapid industrialization, infrastructure development, and expansion of manufacturing hubs in countries like China, India, and Vietnam. North America and Europe will maintain strong demand due to aging infrastructure, strict environmental laws, and high adoption of automation technologies. Government initiatives for bridge and pipeline rehabilitation are further stimulating market growth in these regions.

Increasing Adoption of Portable and Handheld Devices

There is a growing preference for portable rust removal machines, especially in field maintenance and restoration projects. Handheld laser rust removers and compact electrochemical tools offer flexibility and ease of use, making them ideal for on-site applications. By 2026, advancements in battery technology and miniaturization are expected to enhance the performance and accessibility of these portable systems, broadening their appeal across small businesses and DIY markets.

Competitive Landscape and Innovation

The rust removal machine market in 2026 is becoming increasingly competitive, with both established industrial equipment manufacturers and new tech startups introducing innovative solutions. Key players are focusing on product differentiation through智能化 (smart features), energy efficiency, and user-friendly interfaces. Strategic partnerships, R&D investments, and expansion into emerging markets are common growth strategies.

Conclusion

By 2026, the rust removal machine market will be defined by technological sophistication, environmental sustainability, and industry-specific customization. Automation, green technologies, and regional industrial growth will be central to market expansion. Companies that invest in innovation and align with global sustainability goals are likely to lead the next wave of growth in this evolving sector.

Common Pitfalls When Sourcing a Rust Removal Machine (Quality and Intellectual Property)

Sourcing a rust removal machine—especially from international suppliers—can present significant challenges related to both product quality and intellectual property (IP) risks. Being aware of these pitfalls helps ensure a reliable, legally compliant, and cost-effective procurement process.

Poor Build Quality and Inconsistent Performance

One of the most frequent issues when sourcing rust removal machines is inconsistent or substandard build quality. Machines may use inferior materials, lack proper calibration, or fail to meet safety standards. This can result in frequent breakdowns, reduced efficiency, and higher maintenance costs. Buyers often discover these flaws only after deployment, leading to downtime and unexpected repair expenses.

Lack of Standardization and Certification

Many suppliers, particularly in emerging manufacturing regions, may not adhere to recognized international standards (e.g., CE, ISO, or UL). Without proper certification, the machine may not comply with local safety or environmental regulations, potentially leading to legal issues or workplace hazards. Always verify that the equipment meets relevant industry standards before purchase.

Inadequate After-Sales Support and Spare Parts Availability

Low-cost suppliers may offer attractive upfront pricing but fail to provide reliable technical support, training, or timely access to spare parts. This lack of after-sales service can severely impact operational continuity, especially if critical components fail and replacements take weeks to arrive.

Misrepresentation of Technical Specifications

Some vendors exaggerate machine capabilities—such as rust removal speed, compatibility with material types, or automation features. Buyers relying solely on sales brochures or unverified claims may end up with equipment that underperforms or doesn’t suit their application needs. Always request third-party test reports or conduct on-site demonstrations.

Intellectual Property Infringement Risks

Sourcing from manufacturers that copy or reverse-engineer patented designs exposes buyers to legal liability. If the rust removal machine incorporates protected technology—such as proprietary blasting nozzles, control systems, or software—you could face infringement claims, especially when used in regulated markets like the U.S. or EU.

Use of Counterfeit or Unlicensed Software

Some machines include control systems running unlicensed or pirated software. This not only violates copyright laws but can also introduce cybersecurity vulnerabilities and hinder system updates or integration with existing infrastructure.

Limited Warranty and Legal Recourse

Contracts with overseas suppliers may offer weak warranty terms or be governed by foreign laws that are difficult to enforce. In the event of defects or IP disputes, pursuing remedies can be costly and time-consuming, with little guarantee of resolution.

Recommendations to Mitigate Risks

- Conduct thorough due diligence on suppliers, including factory audits and reference checks.

- Require proof of certifications, IP ownership, and software licensing.

- Include clear quality assurance clauses and IP indemnification in contracts.

- Consider working with local distributors or agents who can provide support and legal accountability.

- Test samples rigorously before placing bulk orders.

By proactively addressing these quality and IP-related pitfalls, businesses can secure reliable rust removal solutions while minimizing legal and operational risks.

Logistics & Compliance Guide for Rust Removal Machine

Product Classification & Documentation

Ensure the rust removal machine is correctly classified under the appropriate HS (Harmonized System) code for customs purposes—typically within Chapter 84 (Nuclear reactors, boilers, machinery). Prepare essential shipping documentation, including commercial invoice, packing list, bill of lading, and certificate of origin. Include technical specifications (e.g., voltage, power rating, dimensions, weight) to support accurate classification and compliance assessment.

Import/Export Regulations

Verify compliance with export control regulations in the country of origin (e.g., U.S. EAR or EU Dual-Use Regulations) to confirm the machine does not require an export license. Check destination country import restrictions, especially if the equipment includes automated or high-voltage components. Some countries may require product registration or pre-shipment inspection.

Safety & Electromagnetic Compliance

Confirm the rust removal machine meets applicable safety standards such as IEC 60204-1 (safety of machinery) and local electrical codes (e.g., UL in the U.S., CE in the EU, CCC in China). Ensure electromagnetic compatibility (EMC) compliance per standards like IEC 61000 to prevent interference with other equipment. Provide necessary conformity markings and technical files.

Packaging & Shipping Requirements

Package the machine securely to prevent damage during transit, using palletization and protective materials. Clearly label packages with handling instructions (e.g., “Fragile,” “Do Not Invert”) and include product identification tags. Comply with international shipping standards such as ISTA for testing and IMDG/ADR regulations if transporting hazardous components (e.g., cleaning agents).

Environmental & Waste Compliance

Adhere to environmental regulations regarding the disposal of removed rust and waste byproducts. If the machine uses chemical or abrasive media, confirm compliance with REACH (EU), RoHS, or TSCA (U.S.) for restricted substances. Provide users with waste handling and disposal guidelines per local environmental laws.

Training & User Documentation

Supply comprehensive user manuals in the local language of the destination country, including operational instructions, safety warnings, and maintenance procedures. Offer training materials or on-site support where required to ensure safe and compliant operation, reducing liability and ensuring regulatory adherence.

After-Sales & Warranty Support

Establish a service and spare parts logistics network in the target market. Ensure warranty terms comply with local consumer protection laws (e.g., EU Consumer Rights Directive). Maintain records of shipped units for traceability and potential product recalls or compliance audits.

Conclusion for Sourcing a Rust Removal Machine:

After a thorough evaluation of available rust removal technologies, supplier capabilities, cost considerations, and production requirements, it is clear that investing in an appropriate rust removal machine will significantly enhance operational efficiency, product quality, and long-term cost savings. Both mechanical (such as shot blasting or sandblasting machines) and electrochemical (like electrolytic rust removers) options present viable solutions, each suited to specific applications, material types, and volume needs.

For high-volume industrial operations, automated shot blasting systems offer speed, consistency, and durability, making them ideal for heavy-duty components. Conversely, for smaller-scale or precision work, electrolytic or ultrasonic rust removal machines provide a non-destructive, environmentally friendly alternative with minimal material wear.

Key factors in the final sourcing decision should include machine reliability, ease of maintenance, safety compliance, energy efficiency, and supplier support. Additionally, assessing total cost of ownership—factoring in initial investment, operational costs, and lifespan—is crucial for long-term value.

Ultimately, selecting the right rust removal machine tailored to the specific operational context will not only improve surface preparation standards but also contribute to increased productivity, reduced labor costs, and enhanced product longevity. It is recommended to request demonstrations, review customer testimonials, and consult technical experts before finalizing procurement to ensure optimal performance and return on investment.