The global laser cleaning market, a key enabler of precision rust removal, is experiencing robust growth driven by increasing demand for eco-friendly, non-abrasive surface treatment solutions. According to Grand View Research, the market was valued at USD 435.6 million in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 17.8% from 2023 to 2030. This surge is fueled by adoption across automotive, aerospace, and industrial maintenance sectors seeking sustainable alternatives to chemical and mechanical rust removal methods. As demand rises, a growing number of manufacturers are offering rust removal laser systems across diverse price points and performance tiers. Based on production scale, technology output, and market positioning, we analyze the top 9 manufacturers shaping today’s laser rust removal equipment landscape.

Top 9 Rust Removal Laser Price Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: Clean smarter with laser light. Fully cleaning rust of machine parts with the help of laser cleaning. WHY LASER CLEANING? Embrace the future of sustainable ……

#2 Laserax

Website: laserax.com

Key Highlights: Our laser cleaning solutions are used to remove a range of contaminants from metal surfaces such as rust, oxide, paint, and electrolyte. As contaminants are ……

#3 FOX P CL – laser for removing rust

Website: pulsar-laser.com

Key Highlights: The automatic safety warning light is supplied with PULSAR Laser cleaning machines according to current delivery conditions. 0 € Price without discount750 €….

#4 Argento Lux

Website: argentolux.com

Key Highlights: Laser cleaning removes paint, contaminants, rust, and residues with a high-energy laser beam which leaves the substrate untouched. Our Laser Ablation is the ……

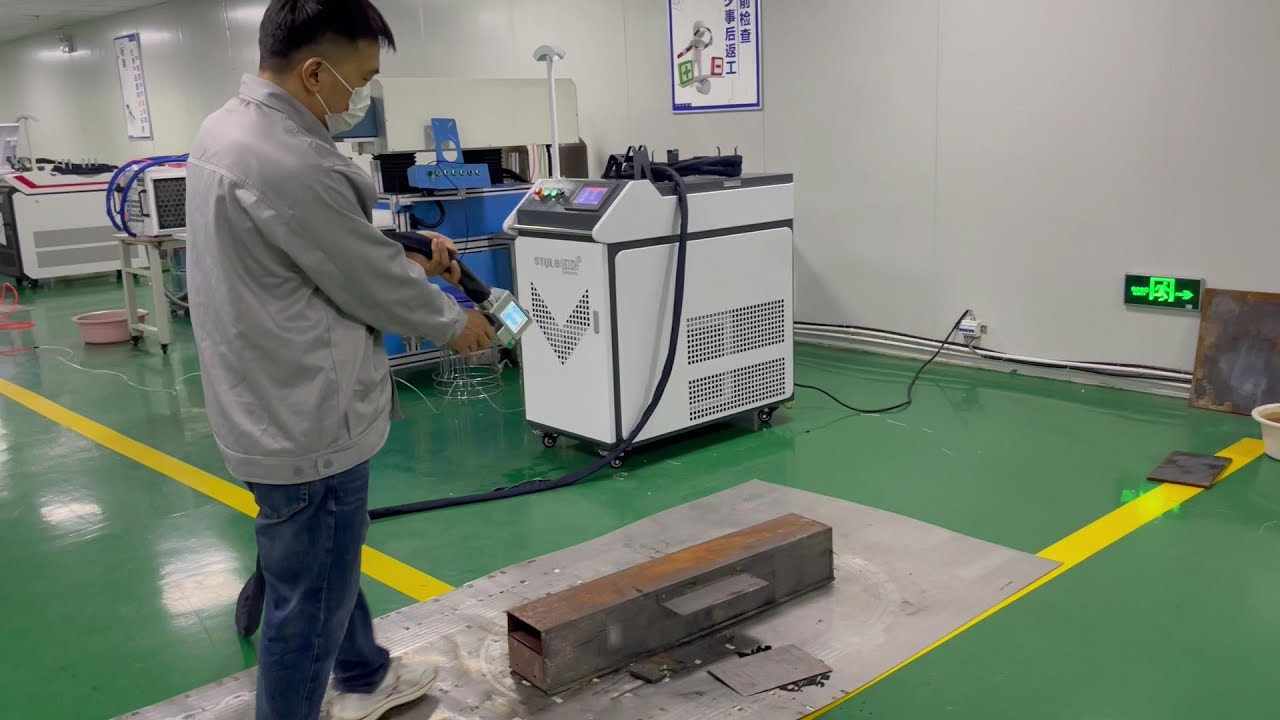

#5 Laser Cleaning Machine Manufacturer

Website: hantencnc.com

Key Highlights: We offer a wide range of laser cleaners, from 100W to 3000W. Our lineup includes handheld, backpack, and trolley-type products to meet diverse cleaning needs….

#6 500W 1000W Pulse Laser Cleaning Machine Laser Metal Rust Oil …

Website: sfxlaser.com

Key Highlights: In stock Free deliverySingle Mode Laser Cleaner(Gaussian Beam): Suitable for strong adhesion cleaning such as Heavy rust, Oxide Layer, Thick paint, Galvanized layer removal and ……

#7 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

#8 Nuwave Laser: Laser Cleaning Experts

Website: nuwavelaser.com

Key Highlights: Nuwave Laser uses high-powered lasers to remove contaminants from surfaces without chemicals. Call our laser cleaning experts today!…

#9 How Much does A Laser Rust Removal Machine Price

Website: dwcnclaser.com

Key Highlights: 1000w rust removal laser price $3800 – $3900 ; 1500w laser rust cleaner price $4610 – $4739 ; 2000w laser rust cleaner price $6583 – $6729….

Expert Sourcing Insights for Rust Removal Laser Price

2026 Market Trends for Rust Removal Laser Prices

As industries increasingly prioritize precision, efficiency, and eco-friendly solutions, laser-based rust removal technology is gaining traction across manufacturing, automotive, marine, and restoration sectors. Looking ahead to 2026, several interconnected market trends are expected to influence the pricing of rust removal lasers.

Technological Advancements Driving Cost Efficiency

By 2026, continued innovation in fiber laser technology—such as improved beam quality, higher pulse frequencies, and enhanced portability—is anticipated to boost performance while lowering production costs. Wider adoption of automation and AI-integrated control systems will increase initial equipment costs but improve long-term value through reduced labor and operational expenses. These advancements are likely to create a tiered pricing structure: lower-cost entry-level models for small businesses and premium systems for industrial applications.

Scaling Production and Market Competition

The growing number of manufacturers, particularly in Asia and Europe, is intensifying competition. As production scales and supply chains mature, economies of scale are expected to reduce unit costs. This increased competition will likely pressure prices downward, especially for mid-range systems. However, brands emphasizing reliability, service support, and advanced features may maintain premium pricing, creating a segmented market.

Rising Demand Across Key Industries

Industries such as shipbuilding, aerospace, and heritage restoration are increasingly adopting laser rust removal due to its non-abrasive, chemical-free benefits. This rising demand may initially support stable or slightly elevated prices, especially for high-power systems. However, as market penetration deepens and alternative solutions become more accessible, demand elasticity could push prices lower by 2026.

Regulatory and Environmental Influences

Stricter environmental regulations regarding chemical usage and waste disposal are encouraging a shift from traditional rust removal methods to lasers. Government incentives or industry certifications promoting green technologies could indirectly subsidize adoption, potentially moderating end-user prices through grants or tax benefits.

Conclusion

By 2026, rust removal laser prices are expected to experience moderate downward pressure due to technological improvements, manufacturing scale, and competition. However, differentiation in performance and application-specific features will sustain a range of price points. Overall, the market is moving toward greater affordability and accessibility, making laser rust removal a more viable option for a broader base of industrial and commercial users.

Common Pitfalls When Sourcing Rust Removal Laser Price (Quality, IP)

When sourcing a rust removal laser, especially with a focus on price, buyers often encounter several critical pitfalls related to quality and intellectual property (IP). Understanding these risks is essential to avoid costly mistakes and ensure long-term value.

Underestimating Quality Differences

One of the most common pitfalls is focusing solely on upfront price while overlooking significant variations in laser quality. Low-cost rust removal lasers may use inferior components such as lower-grade laser diodes, poor cooling systems, or substandard optics. These compromises lead to reduced efficiency, frequent maintenance, shorter lifespan, and inconsistent rust removal performance. Buyers may save initially but face higher total cost of ownership due to downtime and replacement costs.

Ignoring Intellectual Property (IP) Risks

Another major concern is sourcing from manufacturers who may not hold legitimate IP rights. Some low-cost suppliers offer systems that closely resemble patented technologies from established brands. Purchasing such equipment can expose buyers to legal liability, including infringement claims, import bans, or forced equipment seizure. Always verify that the supplier owns or legally licenses the technology, especially when pricing seems unusually competitive.

Lack of After-Sales Support and Warranty

Cheaper lasers often come from vendors with limited or no after-sales support. This includes missing technical assistance, unavailable spare parts, or voided warranties when issues arise. Without reliable support, even minor malfunctions can halt operations, impacting productivity and increasing long-term costs.

Inadequate Safety and Compliance Standards

Budget rust removal lasers may not meet international safety and regulatory standards (e.g., FDA, CE, IEC). Non-compliant systems pose serious safety risks to operators and may not be insurable. Additionally, using non-certified equipment can result in fines or operational shutdowns, especially in regulated industries.

Hidden Costs in Low-Price Quotations

Initial price quotes may exclude essential accessories, software updates, training, or installation services. These hidden costs can significantly increase the total expenditure. Always request a detailed breakdown of what is included in the quoted price.

Conclusion

While seeking an affordable rust removal laser, buyers must balance price with quality, IP legitimacy, and long-term operational reliability. Conducting thorough due diligence—such as checking certifications, verifying IP status, and assessing vendor reputation—can prevent costly setbacks and ensure a safe, effective, and legally compliant investment.

Logistics & Compliance Guide for Rust Removal Laser Pricing

When evaluating the cost and procurement of rust removal laser systems, it’s essential to consider both logistical and compliance factors that can significantly impact the final price and long-term operational efficiency. Understanding these elements ensures accurate budgeting, regulatory adherence, and smooth international trade operations.

Shipping and Delivery Costs

Transportation expenses are a critical component of the total landed cost of a rust removal laser. These systems are typically large, heavy, and sensitive to handling, requiring specialized packaging and freight services. Costs vary based on origin (domestic vs. international), shipping method (air, sea, or ground), and delivery speed. Air freight offers faster delivery but at a premium, while sea freight is more economical for overseas orders but takes longer. Include insurance and potential customs handling fees in your cost analysis.

Import Duties and Taxes

For cross-border purchases, import duties, value-added tax (VAT), or goods and services tax (GST) can substantially increase the final price. Duty rates depend on the country of import and the product’s Harmonized System (HS) code—typically classified under laser systems or industrial machinery. Research local tariff regulations and leverage free trade agreements where applicable to minimize tax liabilities. Accurate product classification ensures correct duty assessment and avoids customs delays.

Regulatory Compliance Requirements

Rust removal lasers must meet safety and technical standards in the destination market. Key compliance certifications include:

- CE Marking (EU): Required for laser products sold in Europe, indicating conformity with health, safety, and environmental protection standards.

- FDA/CDRH Registration (USA): The U.S. Food and Drug Administration regulates lasers under the Center for Devices and Radiological Health. Manufacturers must file product reports and comply with performance standards.

- Laser Safety Standards (IEC 60825): International standard for laser radiation safety, essential for user protection and regulatory approval.

- EMC & RoHS Compliance: Ensures electromagnetic compatibility and restriction of hazardous substances, particularly in the EU and other regulated markets.

Failure to meet these standards can result in shipment rejection, fines, or operational shutdowns.

Installation and Site Preparation

Proper site setup affects both logistics and total cost. Rust removal lasers often require stable power supplies, adequate ventilation, and designated safety zones. Some models may need compressed air, cooling systems, or integration with robotic arms. Factor in site assessment, installation labor, and necessary facility modifications when calculating the overall investment.

Training and Technical Support

Comprehensive training for operators and maintenance personnel is crucial for safe and efficient use. Include the cost of on-site or virtual training sessions, user manuals, and ongoing technical support. Suppliers offering extended warranties or service contracts may charge higher upfront prices but reduce long-term downtime and repair costs.

Environmental and Disposal Regulations

Laser rust removal is environmentally friendly compared to chemical or abrasive methods, but end-of-life disposal of the unit must comply with local e-waste laws. Ensure the supplier provides guidance on proper decommissioning and recycling, particularly for batteries, optics, and electronic components.

Warranty and Service Logistics

Review the warranty terms, including coverage duration, parts, and labor. International buyers should confirm whether service is available locally or requires shipping the unit back to the manufacturer. Extended service agreements may influence pricing but improve operational continuity.

By accounting for these logistical and compliance factors, businesses can make informed purchasing decisions and avoid unexpected costs related to rust removal laser systems.

In conclusion, sourcing a rust removal laser requires careful evaluation of several factors that influence price, including laser power, brand reputation, build quality, automation features, and after-sales support. While initial costs may appear high compared to traditional rust removal methods, the long-term benefits—such as reduced labor, minimized material damage, improved safety, and environmental sustainability—often justify the investment. Prices typically range from a few thousand to tens of thousands of dollars depending on specifications and intended applications. To secure the best value, it is essential to compare quotes from reputable suppliers, consider total cost of ownership, and assess the specific needs of your operation. Ultimately, investing in a high-quality rust removal laser can enhance efficiency, precision, and productivity in industrial maintenance and restoration processes.