The global market for advanced surface treatment technologies, including laser-based rust and paint removal systems, is experiencing robust growth driven by increasing demand for eco-friendly, precision-based solutions in industries such as automotive, aerospace, and marine. According to Mordor Intelligence, the industrial laser systems market was valued at USD 14.67 billion in 2023 and is projected to grow at a CAGR of over 6.8% from 2024 to 2029. A significant contributor to this expansion is the rising adoption of laser ablation technology for non-abrasive cleaning applications, which eliminates hazardous chemicals and reduces secondary waste. As regulatory pressures mount and sustainability becomes a key operational priority, manufacturers are shifting toward high-precision, low-impact methods—positioning laser-based rust and paint removal as a critical innovation. This shift has spurred the emergence of specialized players focused on industrial laser cleaning systems, leading to a competitive landscape of technologically advanced manufacturers. The following list highlights the top 10 companies at the forefront of developing and commercializing laser solutions for rust and paint removal, combining performance, reliability, and cutting-edge engineering.

Top 10 Rust And Paint Removing Laser Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 FOX P CL – laser for removing rust

Website: pulsar-laser.com

Key Highlights: An innovative laser cleaner that revolutionizes the maintenance and restoration of large vehicles and industrial equipment….

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: LPC-100 Laserpack is a laser cleaning backpack. P-laser teambuilding. QF-2000 Laser removes almost any other kind of contamination, including grease, rust….

#3 Laserax

Website: laserax.com

Key Highlights: Our laser cleaning solutions are used to remove a range of contaminants from metal surfaces such as rust, oxide, paint, and electrolyte. As contaminants are ……

#4 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: IPG | cleanLASER has been developing and producing high-precision laser systems for cleaning and industrial surface treatment for more than 20 years….

#5 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, ……

#6 Argento Lux

Website: argentolux.com

Key Highlights: Laser cleaning removes paint, contaminants, rust, and residues with a high-energy laser beam which leaves the substrate untouched. Our Laser Ablation is the ……

#7 Industrial 1500W 2000W CW Laser Cleaning Machine Rusty Remove

Website: xinglaser.com

Key Highlights: XING Laser (6am Life LLC, DBA XING Laser) specializes in the development and manufacture of high-performance handheld laser cleaning and rust removal equipment….

#8 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

#9 Laser Cleaning

Website: ipgphotonics.com

Key Highlights: Laser cleaning is used across a variety of industries to remove unwanted surface materials like coatings, paints, rust, oil, and for surface preparation for ……

#10 Nuwave Laser: Laser Cleaning Experts

Website: nuwavelaser.com

Key Highlights: Nuwave Laser uses high-powered lasers to remove contaminants from surfaces without chemicals. Call our laser cleaning experts today!…

Expert Sourcing Insights for Rust And Paint Removing Laser

2026 Market Trends for Rust and Paint Removing Lasers

The market for rust and paint removing lasers is poised for significant transformation by 2026, driven by technological advancements, environmental regulations, and growing industrial demand for precision and efficiency. Key trends shaping the landscape include:

H2: Increased Adoption Across Automotive and Aerospace Sectors

By 2026, the automotive and aerospace industries are expected to become primary adopters of laser-based rust and paint removal systems. Manufacturers are increasingly prioritizing non-abrasive, substrate-safe methods to maintain structural integrity during maintenance and restoration. In aerospace, laser cleaning ensures precise removal without damaging sensitive composite materials or aluminum alloys. Similarly, automotive OEMs and aftermarket service providers are integrating laser systems into production lines and repair shops to improve surface preparation for repainting and reduce waste.

H2: Advancements in Portable and Handheld Laser Systems

A major trend through 2026 is the rapid development and commercialization of portable and handheld laser units. These innovations make laser cleaning accessible for on-site applications in shipbuilding, bridge maintenance, and heritage restoration. Enhanced ergonomics, improved battery life, and integrated safety features are expected to drive adoption among field technicians. The shift toward mobility will lower the entry barrier for small- and medium-sized enterprises (SMEs), expanding the market beyond large industrial players.

H2: Stricter Environmental Regulations Fueling Demand

Growing global emphasis on sustainability and environmental protection will accelerate the shift from chemical- and abrasive-based cleaning methods to laser alternatives. By 2026, regulations in regions like the EU and North America are expected to further restrict the use of toxic paint strippers and sandblasting due to hazardous waste and airborne particulates. Laser cleaning, which produces minimal waste and no secondary pollutants, aligns with ESG (Environmental, Social, and Governance) goals, making it a preferred solution for eco-conscious industries.

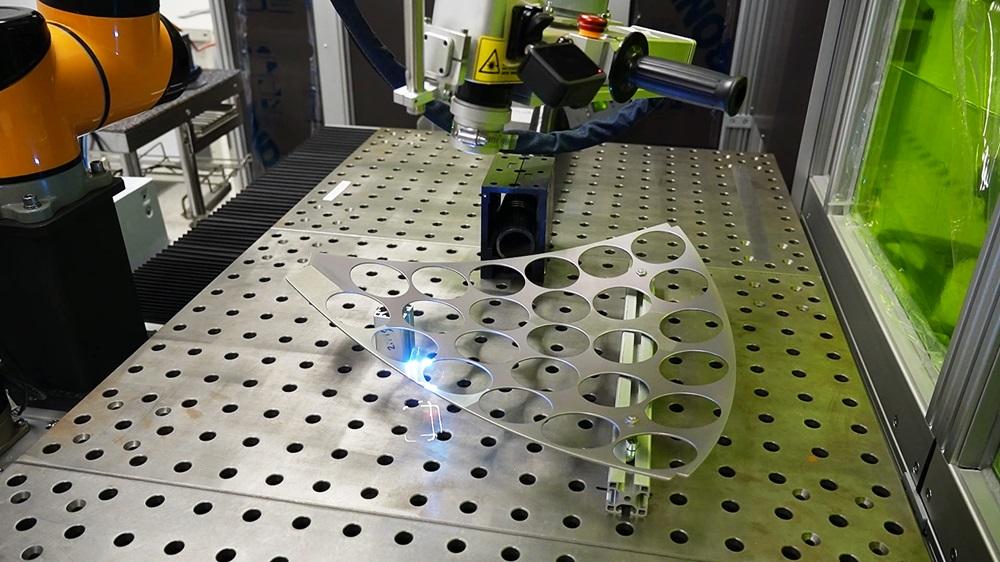

H2: Integration with Automation and Robotics

The convergence of laser cleaning technology with robotics and AI-driven automation will be a defining trend in 2026. Automated robotic arms equipped with laser cleaning heads are being deployed in high-volume manufacturing environments for consistent, repeatable surface preparation. Machine vision systems allow real-time monitoring and adaptive control, optimizing removal efficiency and minimizing human intervention. This integration not only boosts productivity but also enhances worker safety by reducing exposure to harmful processes.

H2: Cost Reduction and Improved ROI Driving Market Penetration

Although initial investment remains higher than traditional methods, the total cost of ownership for laser systems is expected to decline by 2026 due to falling component prices, increased competition, and longer operational lifespans. As reliability improves and maintenance requirements decrease, return on investment (ROI) timelines are shortening. This economic shift is prompting more businesses to transition from conventional cleaning methods, particularly in high-value applications where precision and quality are paramount.

In summary, the 2026 market for rust and paint removing lasers will be characterized by broader industrial adoption, technological portability, environmental compliance, automation integration, and improved cost efficiency—positioning laser cleaning as a mainstream solution in industrial surface treatment.

Common Pitfalls When Sourcing Rust and Paint Removing Lasers (Quality and IP)

Sourcing laser systems for rust and paint removal presents unique challenges, particularly concerning quality assurance and intellectual property (IP) protection. Falling into common traps can lead to subpar performance, legal risks, and financial losses.

Poor Build Quality and Component Selection

Many low-cost laser systems, especially from less reputable suppliers, use inferior components such as underpowered or unstable laser sources, inadequate cooling systems, or fragile optical assemblies. These shortcomings result in inconsistent cleaning performance, frequent breakdowns, and shortened equipment lifespan. Buyers may also encounter misrepresented specifications—such as exaggerated wattage or duty cycles—leading to mismatched expectations and operational inefficiencies.

Lack of Safety and Compliance Certifications

A critical quality pitfall is the absence of international safety certifications like CE, FDA, or IEC 60825. Without these, the laser may not meet essential safety standards for eye and skin protection, beam containment, or electrical safety. Using non-compliant equipment increases liability risks and may violate workplace safety regulations, potentially leading to accidents or regulatory fines.

Inadequate Cooling and Duty Cycle Misrepresentation

High-power lasers generate significant heat, and reliable thermal management is essential. Some suppliers use passive or undersized cooling systems that cannot sustain prolonged operation, causing thermal throttling or system shutdowns. Misleading duty cycle claims (e.g., advertising 100% duty cycle without real-world validation) can disrupt production planning and reduce overall productivity.

Weak or Non-Existent Intellectual Property Protection

When sourcing from manufacturers—especially in regions with less stringent IP enforcement—there’s a risk of inadvertently acquiring systems that infringe on patented technologies. This exposes the buyer to legal challenges from original equipment manufacturers (OEMs). Additionally, reverse-engineered or cloned systems may lack innovation and reliability, offering poor long-term value.

Insufficient Technical Support and Documentation

Low-quality suppliers often provide minimal technical documentation, training, or after-sales support. This makes installation, maintenance, and troubleshooting difficult. Without access to firmware updates, spare parts, or responsive customer service, downtime increases, affecting operational continuity.

Hidden Costs from Poor Integration and Scalability

Some lasers are not designed with integration in mind—lacking standard communication protocols (e.g., Ethernet/IP, Modbus) or mechanical interfaces. This complicates automation and integration into existing production lines. Systems that cannot scale with evolving needs may require costly replacements or upgrades sooner than expected.

Risk of Counterfeit or Refurbished Components

In the quest for lower prices, buyers may receive lasers assembled with counterfeit or recycled parts. These components often fail prematurely and do not perform to specification. Without proper quality control and traceability, verifying authenticity becomes difficult, undermining system reliability.

Conclusion

To mitigate these pitfalls, conduct thorough due diligence: verify supplier credentials, demand third-party test reports, inspect physical units if possible, and ensure all IP rights are clearly documented and legally transferable. Prioritizing quality and IP integrity during sourcing safeguards both operational performance and legal compliance.

Logistics & Compliance Guide for Rust and Paint Removing Laser Systems

Product Classification and Regulatory Overview

Rust and Paint Removing Laser systems are industrial-grade equipment that use high-powered lasers to ablate coatings, rust, and contaminants from metal surfaces. Due to their power and operational hazards, these systems are subject to national and international regulations covering safety, emissions, transportation, and environmental compliance.

Hazard Classification and Safety Standards

These laser systems typically fall under Class 4 laser products, the highest risk category according to the International Electrotechnical Commission (IEC) 60825-1 standard. Class 4 lasers can cause skin burns, eye injuries, and pose fire hazards. Compliance with IEC 60825-1 and the U.S. FDA/CDRH 21 CFR Part 1040.10 is mandatory for sale and operation in most jurisdictions. Equipment must include safety interlocks, emergency stop mechanisms, and proper labeling.

Import and Export Controls

Due to their high power and potential dual-use applications, laser systems may be subject to export control regulations such as the U.S. Export Administration Regulations (EAR) under the Commerce Control List (CCL), particularly ECCN 6A003.b.4. Exporters must verify licensing requirements based on destination country, end-user, and end-use. Similar controls exist under the EU Dual-Use Regulation (EU) 2021/821.

Transportation and Shipping Requirements

When shipping Rust and Paint Removing Lasers:

– Power units and lasers must be securely packed to prevent damage.

– Batteries (if applicable) must comply with IATA Dangerous Goods Regulations (DGR) for air transport or IMDG Code for sea freight.

– Laser systems should be shipped with all safety covers engaged and power disconnected.

– Shipping documentation must include technical specifications, laser class, and compliance statements.

Customs Documentation and Duties

Accurate Harmonized System (HS) codes are essential for customs clearance. A common classification is 8543.70 for electrical apparatus for physical treatment using laser radiation. Import duties and taxes vary by country—consult local customs authorities. Certificates of Conformity (e.g., CE, UKCA, FCC) may be required to prove compliance with regional safety and electromagnetic compatibility (EMC) standards.

On-Site Installation and Operational Compliance

Upon delivery, ensure:

– Installation by qualified personnel in accordance with manufacturer guidelines.

– Use in controlled environments with appropriate laser safety barriers and signage.

– Operators are trained and equipped with certified laser safety goggles (OD-rated for the specific wavelength).

– Compliance with OSHA (U.S.), HSE (UK), or local occupational safety regulations.

Environmental and Waste Management Considerations

Laser ablation produces particulate matter, including metal oxides and vaporized coating residues. Systems must be used with high-efficiency particulate air (HEPA) filtration or fume extraction units. Collected waste may be classified as hazardous depending on substrate materials and local environmental laws (e.g., EPA regulations in the U.S.). Proper disposal through licensed waste handlers is required.

Maintenance, Servicing, and Documentation

Maintain detailed logs of:

– Regular safety inspections and laser alignment checks.

– Calibration records and service history.

– Training records for operators and safety officers.

Retention of technical files and Declaration of Conformity supports ongoing compliance during audits.

Recalls and Incident Reporting

In the event of malfunctions or safety incidents, follow national reporting protocols. In the U.S., manufacturers must report under FDA MedWatch for laser-related injuries. EU operators follow RAPEX procedures for non-compliant products. Proactive monitoring and reporting demonstrate regulatory diligence.

Summary and Best Practices

To ensure smooth logistics and compliance:

– Verify regulatory requirements in both origin and destination countries.

– Partner with certified freight forwarders experienced in high-tech industrial equipment.

– Maintain up-to-date compliance documentation and labeling.

– Train staff in laser safety and emergency procedures.

Adhering to this guide minimizes delays, avoids penalties, and ensures safe, legal operation of Rust and Paint Removing Laser systems worldwide.

Conclusion:

The sourcing of a laser system for rust and paint removal presents a forward-thinking, efficient, and environmentally sustainable solution for surface preparation. Compared to traditional methods such as sandblasting, chemical stripping, or mechanical grinding, laser ablation offers superior precision, minimal substrate damage, reduced waste, and lower long-term operational costs. As industries increasingly prioritize clean, efficient, and eco-friendly technologies, investing in laser rust and paint removal systems aligns with both economic and environmental goals.

While the initial capital investment may be higher than conventional tools, the long-term benefits—including reduced labor time, elimination of consumables, compliance with environmental regulations, and improved worker safety—justify the cost. Additionally, advancements in fiber laser technology have made these systems more compact, user-friendly, and accessible for a wide range of industrial applications, from automotive restoration to aerospace and marine maintenance.

In conclusion, sourcing a laser-based rust and paint removal system represents a strategic move toward modernizing surface treatment processes. It enhances productivity, ensures consistent quality, and supports sustainability initiatives, positioning businesses at the forefront of industrial innovation. Careful supplier evaluation, consideration of power requirements, and workforce training will be key to maximizing return on investment and achieving optimal performance.