The global automotive rubber bushing market is experiencing steady growth, driven by increasing vehicle production and the rising demand for enhanced ride comfort and noise, vibration, and harshness (NVH) reduction. According to a 2023 report by Mordor Intelligence, the market was valued at approximately USD 5.8 billion in 2022 and is projected to grow at a CAGR of over 4.5% through 2028. Similarly, Grand View Research reports that the broader automotive vibration control components market—which includes rubber bushings—is expected to expand at a CAGR of 5.2% from 2023 to 2030, fueled by advancements in suspension technology and the expanding automotive aftermarket. As manufacturers prioritize durability, performance, and sustainability, leading automakers are increasingly integrating high-performance rubber bushings into their vehicle platforms. The following list highlights the top 10 car manufacturers excelling in the design, integration, and innovation of rubber bushing systems, reflecting their commitment to ride quality, longevity, and engineering excellence.

Top 10 Rubber Bushing Car Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Custom Rubber Parts,Automotive Rubber Parts Manufacturer

Domain Est. 2009

Website: rubberandseal.com

Key Highlights: Explore high-quality custom molded rubber parts designed for automotive and industrial applications.Discover reliable solutions for your specific needs….

#2 GJBUSH

Domain Est. 2013

Website: gjbush.com

Key Highlights: GJBUSH is a leading Tier 1 OEM supplier of automotive-grade NVH & damping solutions. We engineer custom rubber bushings, mounts & bearings. Partner with us….

#3 SiberianBushing.com

Domain Est. 2013 | Founded: 2000

Website: siberianbushing.com

Key Highlights: Since 2000 “Siberian Bushing” was the first suspension parts manufacturer at the Siberia, who offered to car owners products with a quality equal to OEM parts….

#4 Leading Rubber Bushing Manufacturers

Domain Est. 2001

Website: extrudedrubber.net

Key Highlights: Connect with the top rubber bushing manufacturers and suppliers in the US who are able to create custom, durable bushings that are easy to order….

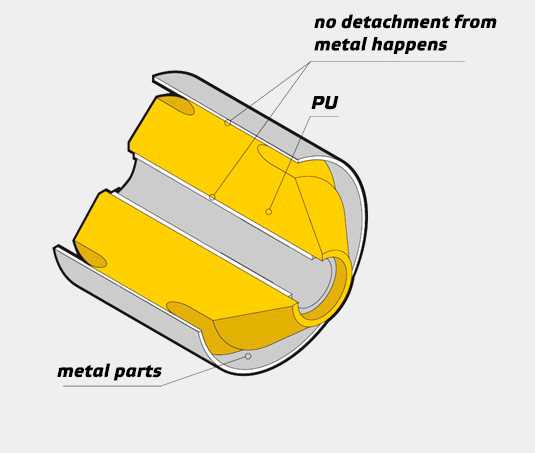

#5 car bushing manufacturer

Domain Est. 2022

Website: gdstauto.com

Key Highlights: As a car bushing manufacturer, GDST offers leaf spring bushings, control arm bushings, sway bar bushings, shock absorber bushings, etc….

#6 Rubber Bush Supplier

Website: gswautoparts.com

Key Highlights: Premium rubber bushings with excellent vibration control. Suitable for automotive chassis applications. OEM & custom orders available….

#7 Prothane

Domain Est. 1997

Website: prothane.com

Key Highlights: We offer an extensive line of professional urethane-based high-performance products for cars and trucks, all made in the USA!…

#8 Powerflex

Domain Est. 1997

Website: powerflex.co.uk

Key Highlights: Our bushes excel in your standard road car! Powerflex Suspension Bushes prolong tyre life, improve performance and increase the safety of your vehicle on the ……

#9 Polyurethane Suspension Parts

Domain Est. 2004

Website: energysuspensionparts.com

Key Highlights: Find Energy Suspension polyurethane bushings and other suspension parts by make and model or by size. FREE Lifetime Warranty upgrade….

#10 Energy Suspension

Domain Est. 2021

Website: teamenergysuspension.com

Key Highlights: Energy Suspension Car, Truck, SUV, Jeep and Classic bushings, tools and accessories. … Soft or worn-out O.E.M. rubber bushings and mounts will cause poor ……

Expert Sourcing Insights for Rubber Bushing Car

H2: 2026 Market Trends for Rubber Bushing in the Automotive Industry

The global market for rubber bushings in the automotive sector is poised for significant evolution by 2026, driven by technological advancements, shifting vehicle design philosophies, and increasing demand for enhanced ride comfort and noise, vibration, and harshness (NVH) reduction. As automakers focus on electrification, lightweighting, and improved performance, the role of rubber bushings—critical components in suspension, engine mounting, and chassis systems—is undergoing transformation.

One of the primary trends shaping the 2026 landscape is the rise of electric vehicles (EVs). With EVs producing less engine noise, NVH management has become even more critical to ensure passenger comfort. Rubber bushings are being redesigned with advanced elastomeric compounds and hybrid materials to better absorb high-frequency vibrations generated by electric drivetrains. This shift is pushing manufacturers to innovate beyond traditional natural rubber and synthetic rubber compounds, adopting polyurethane, silicone-based materials, and engineered thermoplastic elastomers (TPEs) for improved durability and performance.

Another key trend is the integration of smart and adaptive suspension systems. By 2026, an increasing number of premium and mid-tier vehicles are expected to feature active suspension technologies that rely on intelligent rubber bushings or bushings integrated with sensors. These “smart bushings” can adapt stiffness in real-time based on road conditions and driving dynamics, improving both handling and comfort. This trend is particularly evident in luxury and performance EVs from brands like Tesla, BMW, and Lucid.

Lightweighting remains a crucial objective across the automotive industry. Rubber bushings contribute to vehicle weight reduction not only through material optimization but also by enabling more efficient suspension designs. Manufacturers are focusing on developing compact, high-performance bushings that maintain structural integrity while reducing overall component mass—aligning with broader industry goals to improve energy efficiency and extend EV range.

Regionally, the Asia-Pacific market—led by China, Japan, and India—is expected to dominate rubber bushing demand in 2026 due to robust automotive production, growing EV adoption, and expanding aftermarket needs. Meanwhile, North America and Europe are witnessing strong growth driven by stringent noise regulations and the rapid rollout of EV models.

Additionally, sustainability is emerging as a pivotal factor. By 2026, leading suppliers are anticipated to increase the use of recycled rubber and bio-based elastomers to meet environmental standards and corporate ESG (Environmental, Social, and Governance) goals. This eco-conscious shift is influencing material research and supply chain strategies across the industry.

In conclusion, the 2026 rubber bushing market for automobiles will be defined by innovation in materials, integration with smart technologies, alignment with electrification trends, and a growing emphasis on sustainability. Suppliers who adapt to these evolving demands will be well-positioned to capture value in an increasingly competitive and dynamic landscape.

Common Pitfalls When Sourcing Rubber Bushing for Cars (Quality and Intellectual Property)

Sourcing rubber bushings for automotive applications involves navigating several critical challenges, particularly concerning quality consistency and intellectual property (IP) risks. Overlooking these pitfalls can lead to supply chain disruptions, product failures, and legal liabilities.

Poor Material Quality and Inconsistent Specifications

One of the most frequent issues in sourcing rubber bushings is receiving products made from substandard materials or with inconsistent physical properties. Suppliers may use inferior rubber compounds that degrade quickly under heat, oil, or stress, leading to premature failure. Additionally, variations in hardness (durometer), tensile strength, or compression set can compromise vehicle performance, ride comfort, and safety. Lack of adherence to OEM specifications or industry standards (e.g., ASTM, ISO) often results in bushings that do not meet durability requirements.

Inadequate Testing and Quality Control Processes

Many suppliers, especially low-cost manufacturers, lack rigorous in-house testing capabilities or fail to implement consistent quality control protocols. Without proper testing for dynamic performance, fatigue resistance, and environmental aging (e.g., ozone, UV, temperature cycling), defective bushings may pass initial inspections but fail in real-world conditions. The absence of documented quality assurance (QA) processes increases the risk of batch-to-batch variability and long-term reliability issues.

Non-Compliance with Automotive Industry Standards

Automotive rubber components must comply with stringent industry standards such as TS 16949 (now IATF 16949), REACH, and RoHS. Sourcing from suppliers without proper certifications can expose buyers to regulatory non-compliance, recalls, or rejection by OEMs. Additionally, failure to meet OEM-specific technical drawings and material specifications can result in costly redesigns or production delays.

Intellectual Property Infringement Risks

Sourcing rubber bushings from unauthorized or unverified suppliers increases the risk of IP violations. Many bushing designs—especially those engineered for specific vehicle models—are protected by patents or technical copyrights. Suppliers may replicate OEM designs without licensing, leading to legal exposure for the buyer if counterfeit or cloned parts are distributed. This is particularly common in regions with weak IP enforcement.

Lack of Traceability and Documentation

Reliable sourcing requires full traceability of materials and manufacturing processes. However, some suppliers provide incomplete or falsified documentation, such as material test reports (MTRs), certificates of compliance (CoC), or batch records. This lack of transparency makes it difficult to verify quality claims or investigate failures, and it can hinder compliance during audits or recalls.

Supply Chain and Tooling Ownership Issues

In some cases, suppliers retain ownership of the molds or tooling used to produce custom rubber bushings. This creates dependency and limits the buyer’s ability to switch suppliers or scale production. Additionally, unclear agreements on tooling rights can lead to disputes over IP and production control, especially if the supplier decides to produce identical parts for competitors.

Conclusion

To mitigate these pitfalls, buyers should conduct thorough supplier audits, require certifications, enforce strict quality agreements, and ensure IP rights are clearly defined in contracts. Partnering with reputable, certified manufacturers and investing in ongoing quality monitoring can significantly reduce risks associated with sourcing automotive rubber bushings.

Logistics & Compliance Guide for Rubber Bushing Car Components

Overview of Rubber Bushings in Automotive Applications

Rubber bushings are critical vibration-dampening components used in vehicle suspension, chassis, and drivetrain systems. Ensuring proper logistics handling and regulatory compliance is essential for maintaining product integrity, meeting safety standards, and avoiding supply chain disruptions.

Material & Environmental Compliance

Rubber bushings must comply with international environmental and chemical regulations. Key standards include:

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals. Ensure all raw materials (e.g., phthalates, heavy metals) are declared and restricted substances are below thresholds.

– RoHS (EU): Restriction of Hazardous Substances. Applies if bushings contain electronic or coated components.

– ELV (End-of-Life Vehicles Directive): Requires recyclability and reporting of hazardous materials in automotive parts.

– TSCA (USA): Toxic Substances Control Act. Confirm compliance for chemical substances used in rubber formulation.

Documentation such as Safety Data Sheets (SDS) and compliance certificates must accompany shipments.

Packaging & Handling Requirements

Proper packaging prevents deformation, contamination, and aging during transit:

– Use moisture-resistant, non-reactive packaging (e.g., sealed polyethylene bags inside corrugated cardboard).

– Avoid direct contact with metal surfaces or UV exposure to prevent degradation.

– Label packages with handling instructions: “Fragile,” “Keep Dry,” “Do Not Stack Excessively.”

– Implement FIFO (First In, First Out) inventory practices to minimize shelf-life issues.

Transportation & Storage Conditions

Rubber is sensitive to temperature and environmental factors:

– Store and transport within 10°C to 30°C (50°F to 86°F); avoid freezing or extreme heat.

– Keep away from ozone sources (e.g., electric motors, UV light) to prevent cracking.

– Limit exposure to solvents, oils, and direct sunlight.

– Use climate-controlled containers for long-haul or international shipping.

– Stack pallets no higher than recommended to prevent compression damage.

Import/Export Documentation & Tariff Classification

Ensure accurate customs documentation to avoid delays:

– HS Code: Typically classified under 8708.80 (Parts and accessories of motor vehicles, suspension components) or 4016.93 (Other articles of vulcanized rubber, of which over 50% by weight consists of rubber). Verify based on product design and use.

– Required documents: Commercial invoice, packing list, bill of lading/air waybill, certificate of origin, and compliance declarations (e.g., REACH, RoHS).

– Country-specific requirements: Check local automotive regulations (e.g., FMVSS in the U.S., ECE in Europe).

Quality & Traceability Standards

Maintain full traceability and quality assurance:

– Implement batch/lot tracking for raw materials and finished products.

– Comply with IATF 16949 (quality management for automotive production).

– Conduct periodic testing for compression set, hardness (Shore A), and durability per ISO 4664 or ASTM D2240.

– Retain records for audits and recalls.

End-of-Life & Recycling Considerations

Support circular economy principles:

– Design for disassembly where possible.

– Partner with certified recyclers for end-of-life rubber processing.

– Report recyclability data per ELV or local regulations.

Summary

Effective logistics and compliance for rubber bushings require attention to material regulations, environmental controls, proper documentation, and quality management. Proactive planning ensures on-time delivery, regulatory adherence, and long-term reliability in automotive applications.

In conclusion, sourcing rubber bushings for automotive applications requires careful consideration of factors such as material quality, compatibility with vehicle specifications, supplier reliability, and cost-effectiveness. High-quality rubber bushings play a crucial role in enhancing ride comfort, reducing noise and vibration, and ensuring optimal vehicle performance. By partnering with reputable suppliers, verifying industry standards (such as ISO or OEM compliance), and conducting thorough quality checks, automotive manufacturers or aftermarket service providers can ensure the durability and reliability of the components. Ultimately, a strategic and informed sourcing approach guarantees long-term value, improved vehicle safety, and customer satisfaction in the competitive automotive market.