The global concrete molding products market is experiencing steady growth, driven by rising infrastructure development, urbanization, and demand for precast concrete solutions in residential and commercial construction. According to Grand View Research, the global precast concrete products market size was valued at USD 138.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is further supported by increased investments in sustainable building practices and efficient construction methodologies, where reusable molds—particularly round concrete molds—play a critical role in producing consistent, high-quality cylindrical structures such as columns, poles, and drainage systems. With the market expanding, a select group of manufacturers has emerged as leaders in innovation, durability, and product variety. Here, we present the top 10 round concrete mold manufacturers shaping the industry with data-backed performance, global reach, and technological advancement.

Top 10 Round Concrete Mold Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 AMICO

Domain Est. 2014

Website: amicoglobal.com

Key Highlights: Stay-form concrete forming system is the most cost-effective solution for forming bulkheads, tunnels, or any below-grade structure….

#2 Custom Round Concrete Molds

Domain Est. 2021

Website: siliconeconcretemolds.com

Key Highlights: Best custom round concrete shapes molds from Silicone Concrete Molds, your trusted manufacturer. Decorate your house with expertly crafted circle cement ……

#3 Precast Concrete Molds

Domain Est. 2021

Website: kfmoulding.com

Key Highlights: KF Moulding has been a trusted manufacturer and supplier of Precast Concrete Molds for over 30 years of experience, providing practical solutions to ……

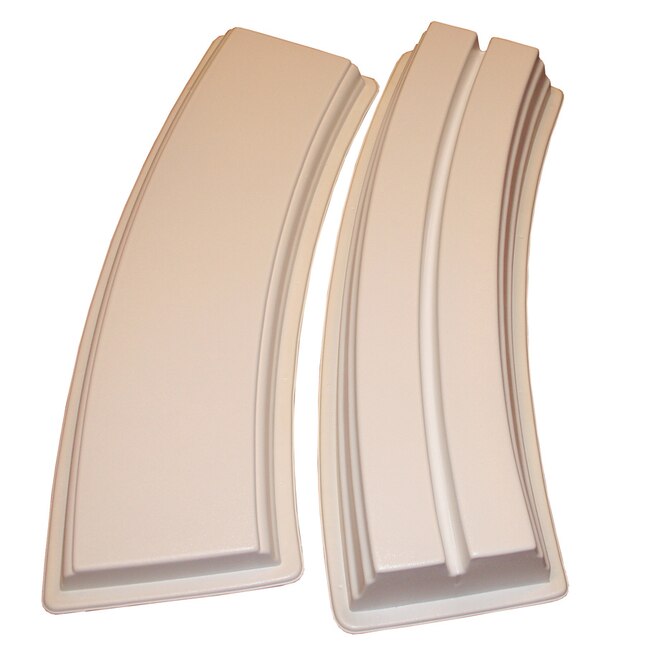

#4 Plastic Concrete Beam Mold, Interlocking

Domain Est. 1995

#5 Besser Company

Domain Est. 1996 | Founded: 1904

Website: besser.com

Key Highlights: Besser Company is a global leader in concrete production equipment, molds, and training. Serving the concrete industry with proven solutions since 1904….

#6 History Stones

Domain Est. 1998

Website: historystones.com

Key Highlights: Shop History Stones concrete molds to create your own balusters, columns, benches and more. High quality concrete molds for your home and garden….

#7 Norwalk Precast Molds

Domain Est. 2004

Website: norwalkprecastmolds.com

Key Highlights: Industry Leader in Precast Concrete Molds and Equipment. Septic Tanks · Burial Vaults · Highway Products….

#8 Custom Concrete Molds and Stamps

Domain Est. 2008

#9 Concrete Molds

Domain Est. 2017

Website: lcmolds.com

Key Highlights: Supply any kinds of concrete molds, looking for DIY paver molds, silicone molds for concrete, planter molds, animal statue molds or garden decor molds….

#10 Silicone Molds For Concrete

Domain Est. 2018

Website: deparhome.com

Key Highlights: Concrete Flower Pot Mold – M1B. 51.00 $ ; Silicone Mold for Concrete Planters- M1K. 32.00 $ ; Silicone Mold for Concrete Planters – M9B. 51.00 $ ; Silicone Mold ……

Expert Sourcing Insights for Round Concrete Mold

H2: 2026 Market Trends for Round Concrete Molds

The global market for round concrete molds is poised for significant transformation by 2026, driven by advancements in construction technologies, rising demand for sustainable infrastructure, and increased focus on architectural aesthetics. Key trends shaping the market include:

-

Growth in Infrastructure and Urban Development

Rapid urbanization, especially in emerging economies across Asia-Pacific, Latin America, and Africa, is fueling demand for durable and cost-effective construction materials. Round concrete molds are increasingly used in the development of utility poles, light posts, drainage systems, and decorative architectural elements. Governments investing in smart city projects and resilient infrastructure are accelerating adoption. -

Shift Toward Sustainable and Reusable Molds

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are pushing manufacturers and contractors to adopt reusable molds made from high-density polyethylene (HDPE), fiberglass, or recycled composites. By 2026, the market is expected to see a 15–20% increase in demand for eco-friendly, long-life molds that reduce waste and lifecycle costs. -

Technological Integration and Precision Manufacturing

The integration of digital design tools such as Building Information Modeling (BIM) and 3D printing is enabling more precise and customizable mold designs. CNC-machined and modular round molds are gaining traction, allowing for consistent quality and faster production cycles in precast concrete facilities. -

Rise in Demand for Aesthetic Concrete Elements

Architects and developers are increasingly using round concrete molds for decorative applications—such as columns, planters, fountains, and façade elements—driving demand for molds with textured finishes, embedded patterns, and custom diameters. This trend is particularly strong in high-end residential and commercial developments. -

Expansion of Pre-Cast Concrete Industry

The global pre-cast concrete market is projected to grow at a CAGR of over 6% through 2026, directly benefiting the round mold segment. Pre-casting offers faster construction timelines and improved quality control, making round molds essential for standardized components like manholes, pipes, and support columns. -

Regional Market Dynamics

- Asia-Pacific will remain the largest market due to ongoing megaprojects in India, China, and Southeast Asia.

- North America is expected to see steady growth, supported by infrastructure renewal programs and green building initiatives.

-

Europe will emphasize recyclable and low-carbon mold materials in alignment with EU sustainability directives.

-

Innovation in Mold Materials and Coatings

Manufacturers are investing in anti-stick coatings and enhanced release agents to improve demolding efficiency and surface finish. Silicone-based, flexible molds are gaining popularity for intricate round designs, offering high detail reproduction and ease of use.

In conclusion, the 2026 outlook for round concrete molds is optimistic, with innovation, sustainability, and urban development acting as primary growth drivers. Companies that prioritize adaptable designs, material efficiency, and environmental compliance will be best positioned to capture market share.

Common Pitfalls When Sourcing Round Concrete Molds (Quality and Intellectual Property)

Sourcing round concrete molds, especially for architectural or decorative applications, involves several potential pitfalls related to both quality assurance and intellectual property (IP) concerns. Being aware of these issues can help prevent costly mistakes, project delays, and legal complications.

Poor Material Quality and Durability

One of the most frequent issues is receiving molds made from substandard materials. Low-grade plastics, silicone, or fiberglass may degrade quickly after only a few casting cycles, leading to warped shapes, surface imperfections, or shortened lifespan. Always verify the material specifications and request samples or third-party test reports before bulk purchasing.

Inconsistent Dimensional Accuracy

Inferior molds often suffer from inconsistent wall thickness or imprecise diameters, resulting in non-uniform concrete products. This can be especially problematic in projects requiring tight tolerances or modular assembly. Ensure suppliers provide dimensional certifications and conduct incoming inspections.

Lack of UV and Temperature Resistance

Some molds degrade when exposed to sunlight or extreme temperatures, particularly if used in outdoor environments. Confirm that the mold material is rated for UV stability and thermal resistance to avoid premature cracking or deformation during curing.

Insufficient Surface Finish Quality

A mold’s surface finish directly impacts the appearance of the final concrete product. Poorly finished molds can lead to pitting, rough textures, or unwanted seams. Evaluate sample castings to assess surface replication quality before committing to a supplier.

Intellectual Property Infringement Risks

Many round concrete mold designs—especially those with unique textures, patterns, or structural features—are protected by design patents, copyrights, or trademarks. Sourcing molds from unauthorized manufacturers, particularly in regions with lax IP enforcement, can expose your project or company to legal liability. Always verify that the supplier has rights to produce the design or that the mold is in the public domain.

Counterfeit or Copycat Products

Some suppliers market imitation molds that closely resemble patented designs. These counterfeits may not only violate IP laws but also deliver inferior performance. Conduct due diligence on suppliers, request proof of design ownership or licensing, and consider working with reputable, established manufacturers.

Inadequate Documentation and Traceability

Lack of proper documentation—such as material data sheets, IP disclaimers, or compliance certificates—can create challenges in quality control and legal defense. Insist on full transparency from suppliers regarding both product specifications and design rights.

Overlooking Long-Term Support and Replacement

Some low-cost suppliers disappear after the initial sale, making it difficult to replace damaged molds or scale production. Choose partners with a proven track record, customer service, and long-term availability of spare parts or replacements.

By carefully evaluating both quality and intellectual property aspects during the sourcing process, buyers can avoid these common pitfalls and ensure reliable, legally compliant mold supply for their concrete casting needs.

Logistics & Compliance Guide for Round Concrete Mold

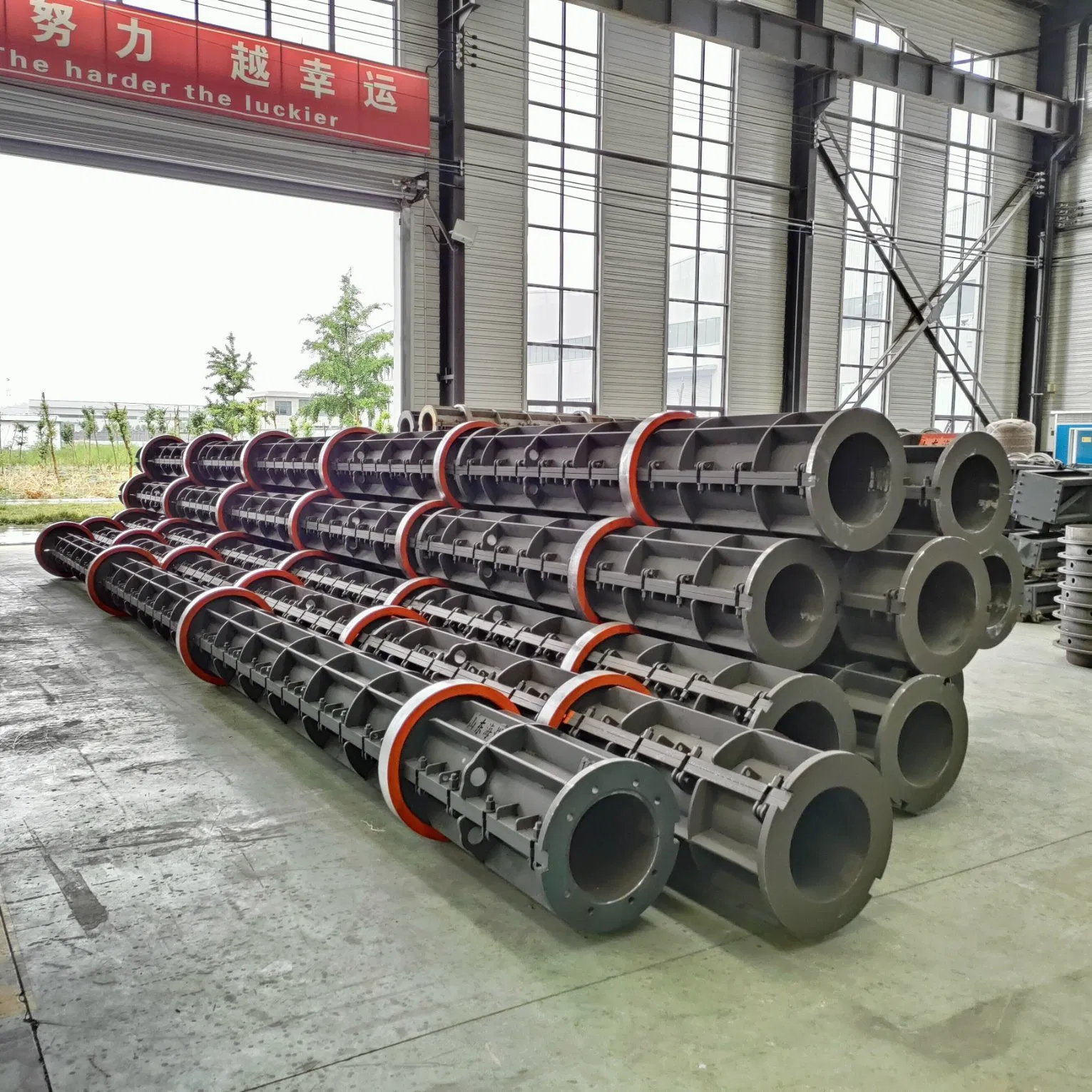

Product Overview

The Round Concrete Mold is a durable formwork solution designed for casting cylindrical concrete structures such as columns, piers, and footings. Constructed from high-strength steel or composite materials, it ensures dimensional accuracy, smooth surface finishes, and repeated reuse. This guide outlines logistics handling, transportation, storage, and regulatory compliance considerations.

Packaging & Handling

- Packaging: Molds are shipped in protective wooden crates or heavy-duty pallets with corner guards to prevent deformation. Individual components (clamps, bolts, sealing strips) are bagged and labeled.

- Handling Instructions: Use forklifts or overhead cranes with soft slings to avoid scratching. Never drag molds across surfaces. Ensure lifting points are engaged properly to prevent warping.

- Labeling: Each unit includes a barcode, model number, batch code, and handling symbols (e.g., “This Side Up,” “Do Not Stack”).

Transportation Requirements

- Domestic Shipments: Secure loads on flatbed or enclosed trailers using ratchet straps. Cover with weather-resistant tarps to protect against moisture and debris.

- International Shipments: Comply with ISPM 15 standards for wooden packaging. Provide export documentation including commercial invoice, packing list, and bill of lading.

- Weight & Dimensions: Confirm trailer compatibility—standard molds range from 50–200 kg (110–440 lbs) and 0.5–3 meters (1.6–10 ft) in height.

Storage Guidelines

- Environment: Store indoors in a dry, ventilated area. Avoid prolonged exposure to humidity, salt air, or extreme temperatures to prevent corrosion.

- Stacking: Limit vertical stacking to 3 units high with spacers to maintain shape. Place on level concrete or wooden flooring—never on soil or gravel.

- Maintenance: Clean with water and mild detergent after use. Apply a rust-inhibiting coating to metal surfaces before long-term storage.

Regulatory Compliance

- Material Safety: Molds contain no hazardous substances per REACH (EU) and RoHS directives. Documentation available upon request.

- Workplace Safety: Complies with OSHA 29 CFR 1926 (U.S.) and EU Machinery Directive 2006/42/EC for safe workplace use.

- Import/Export: Meets customs requirements in major markets (USA, EU, Canada, Australia). HTS code: 8479.89.9480 (Other machinery parts).

Quality Assurance & Documentation

- Certifications: ISO 9001 (Quality Management), ISO 14001 (Environmental Management).

- Inspection Records: Each batch undergoes dimensional tolerance checks and stress testing. Reports available digitally via QR code on packaging.

- Warranty: 2-year limited warranty against manufacturing defects.

Disposal & Sustainability

- End-of-Life: Recyclable steel components can be processed at certified metal recycling facilities.

- Environmental Policy: Aligns with circular economy principles—95% of mold materials are recoverable.

For specific compliance documents or logistics support, contact your regional distributor or visit [Company Support Portal].

In conclusion, sourcing a round concrete mold requires careful consideration of material quality, dimensions, durability, and intended application. Whether for decorative elements, architectural features, or functional concrete products, selecting the right mold ensures consistency, efficiency, and a professional finish. Evaluating suppliers based on reliability, cost-effectiveness, and customer reviews helps in making an informed decision. Ultimately, investing in high-quality round concrete molds contributes to long-term project success and product excellence.