The global linoleum flooring market is experiencing steady momentum, driven by increasing demand for sustainable and eco-friendly building materials. According to a report by Mordor Intelligence, the global resilient flooring market—of which linoleum is a key segment—is projected to grow at a CAGR of over 5.8% from 2023 to 2028. Linoleum, in particular, is regaining prominence due to its natural composition, biodegradability, and low environmental impact compared to synthetic alternatives. Grand View Research further highlights that consumer preference for green building materials and certifications such as LEED and BREEAM are accelerating adoption in residential, commercial, and healthcare sectors. As sustainability becomes a cornerstone of modern construction and interior design, the linoleum market is poised for renewed expansion. This growing demand has intensified competition among manufacturers, fostering innovation in product durability, design variety, and manufacturing efficiency. In this evolving landscape, nine leading companies have emerged as dominant players, combining heritage, technological advancement, and global reach to shape the future of linoleum flooring.

Top 9 Rolls Of Linoleum Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Linoleum flooring

Domain Est. 1996

Website: forbo.com

Key Highlights: Forbo’s Marmoleum floors are climate positive and the most sustainable flooring choice. Available in sheet and tile formats….

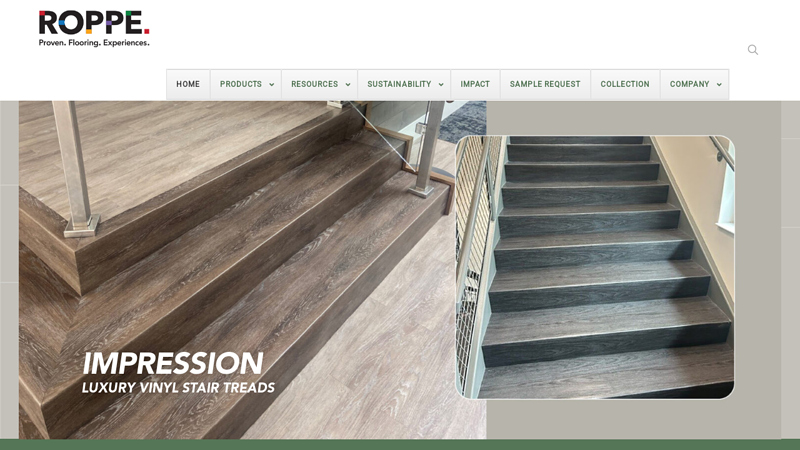

#2 Roppe

Domain Est. 1996

Website: roppe.com

Key Highlights: We are incredibly proud to say “Made in the USA” for our flooring products. We take great pride in our workforce and support of communities across the country….

#3 Karndean Luxury Vinyl flooring

Domain Est. 1998

Website: karndean.com

Key Highlights: Discover stylish and highly practical floor solutions in the luxurious range of wood & stone effect vinyl tiles. LVP and LVT flooring for your home….

#4 Vinyl Flooring

Domain Est. 1999

Website: armstrongflooring.com

Key Highlights: Vinyl flooring lets you transform any room with gorgeously realistic and durable designs inspired by wood, stone, ceramic — and your own imagination ……

#5 Gerflor.com, select your country to explore our solutions

Domain Est. 1999

Website: gerflor.com

Key Highlights: We care because your project is unique. We act with safe, sustainable and decorative solutions for floors, walls, and finishes, designed to meet your needs….

#6 Durable & Waterproof Luxury Vinyl Floors

Domain Est. 2000

Website: shawfloors.com

Key Highlights: $4.99 deliveryFinding the perfect flooring for your home is effortless with our free design services. Our design experts are here to guide you through the process….

#7 Gerflor USA: Gerflor

Domain Est. 2001

Website: gerflorusa.com

Key Highlights: For over 80 years, Gerflor has been a global leader in designing, manufacturing, and distributing innovative, environmentally responsible commercial flooring ……

#8 Mannington Commercial

Domain Est. 2005

Website: manningtoncommercial.com

Key Highlights: Mannington Commercial manufactures commercial modular and broadloom carpet, luxury vinyl tile, resilient sheet, and rubber flooring….

#9 Flooring Solutions

Domain Est. 2005

Website: bintg.com

Key Highlights: An undisputed leader in flooring, offering broadloom carpet, vinyl rolls, luxury vinyl tiles, high pressure floors, parquet and laminate collections….

Expert Sourcing Insights for Rolls Of Linoleum

2026 Market Trends for Rolls of Linoleum

The global market for rolls of linoleum is poised for notable transformation by 2026, driven by evolving consumer preferences, sustainability mandates, and advancements in manufacturing. As environmental awareness intensifies and green building certifications gain prominence, linoleum—renowned for its natural composition and biodegradability—is regaining favor over synthetic flooring alternatives. Key trends shaping the market include increased demand in healthcare and education sectors, innovation in design and installation technologies, and regional shifts in production and consumption.

Growing Emphasis on Sustainability and Health

By 2026, sustainability will remain the primary driver of linoleum adoption. Architects and designers are increasingly specifying linoleum due to its low carbon footprint, use of renewable raw materials (such as linseed oil, cork, and wood flour), and absence of volatile organic compounds (VOCs). With green building standards like LEED, WELL, and BREEAM influencing construction projects worldwide, linoleum’s compliance with stringent indoor air quality and material health requirements positions it as a preferred flooring choice. This trend is especially strong in North America and Western Europe, where eco-conscious consumers and corporate sustainability goals are accelerating demand.

Expansion in Commercial and Institutional Applications

The commercial sector—particularly healthcare, education, and hospitality—will represent the largest end-use segment for linoleum rolls by 2026. Hospitals and clinics value linoleum for its antimicrobial properties, durability, and ease of sanitation. Schools and universities are also turning to linoleum due to its resilience, sound absorption, and non-toxic composition, which supports child health and safety. Innovations such as enhanced wear layers and improved scratch resistance are expanding linoleum’s suitability for high-traffic environments, further boosting its commercial appeal.

Design Innovation and Customization

Gone are the days of limited patterns and colors. Linoleum manufacturers are investing heavily in design technology, enabling wider color palettes, intricate patterns, and custom branding options. Digital printing and embossing techniques now allow for realistic wood and stone effects, broadening linoleum’s aesthetic versatility. By 2026, the ability to offer bespoke solutions—especially for retail spaces and boutique hospitality venues—will be a key competitive differentiator among suppliers.

Technological Advancements in Installation and Performance

The adoption of roll-based linoleum is being supported by improvements in installation efficiency. Pre-finished, dimensionally stable rolls with attached underlays or click-lock systems are reducing labor costs and installation time. Additionally, enhanced formulations are improving resistance to moisture, staining, and indentation, addressing traditional concerns about linoleum’s performance. These technological upgrades are making linoleum more accessible to DIY consumers and renovation projects, thereby expanding its market reach.

Regional Market Dynamics

Europe will continue to dominate the linoleum market in 2026, both in production and consumption, with established players like Forbo Flooring Systems and Tarkett leading innovation. However, growth in the Asia-Pacific region—especially in China, India, and Southeast Asia—is accelerating due to urbanization, rising disposable incomes, and increased focus on sustainable infrastructure. North America will see steady growth, driven by renovation activity and green building mandates. Meanwhile, supply chain localization and reduced reliance on imports will encourage regional manufacturing expansion.

Competitive Landscape and Pricing Trends

The market will remain moderately consolidated, with major players focusing on sustainability certifications, lifecycle assessments, and circular economy initiatives (e.g., take-back programs). Smaller niche brands are emerging with artisanal or regionally sourced linoleum, appealing to eco-luxury markets. While raw material costs—especially linseed oil—may fluctuate, economies of scale and process optimization are expected to stabilize pricing. Premium pricing will persist due to linoleum’s value proposition in health, durability, and environmental performance.

In conclusion, the 2026 market for rolls of linoleum will be defined by sustainability leadership, performance innovation, and expanding application diversity. As the built environment prioritizes wellness and environmental responsibility, linoleum is well-positioned to transition from a niche flooring option to a mainstream sustainable choice across global markets.

Common Pitfalls When Sourcing Rolls of Linoleum: Quality and Intellectual Property Concerns

Sourcing rolls of linoleum for construction, renovation, or manufacturing projects can present several challenges, particularly regarding product quality and intellectual property (IP) risks. Being aware of these pitfalls helps ensure you procure durable, compliant, and authentic materials.

1. Inconsistent Material Quality

One of the most common issues when sourcing linoleum is inconsistent quality across batches or suppliers. Linoleum is a natural product made from linseed oil, cork dust, wood flour, and pigments, and variations in raw materials or manufacturing processes can affect durability, colorfastness, and thickness. Buyers may receive rolls that are:

- Prone to cracking or curling

- Uneven in texture or color

- Thinner than specified, reducing lifespan

To avoid this, always request samples, verify product specifications, and work with reputable suppliers who adhere to international quality standards (e.g., ISO 9001).

2. Mislabeling as “Linoleum” vs. Vinyl

A frequent pitfall is suppliers misrepresenting vinyl flooring as linoleum. While both come in rolls, vinyl is a synthetic product (PVC-based), whereas true linoleum is biodegradable and made from natural materials. Confusing the two can lead to:

- Environmental claims that are inaccurate

- Reduced sustainability credentials

- Poor performance in high-moisture or high-traffic areas

Always verify material composition through technical data sheets and certifications such as FloorScore or Greenguard.

3. Intellectual Property Infringement on Designs

Linoleum often features proprietary patterns, colors, or embossing created by design-focused manufacturers (e.g., Forbo’s Marmoleum range). Sourcing from unauthorized suppliers increases the risk of:

- Purchasing counterfeit or imitation products

- Using copyrighted designs without a license

- Legal liability or project delays due to IP disputes

To mitigate IP risks, buy directly from authorized distributors or request proof of design licensing from suppliers.

4. Lack of Certification and Traceability

Reputable linoleum products often carry certifications for sustainability (e.g., Cradle to Cradle, FSC) and indoor air quality. Sourcing from unverified suppliers may result in:

- Materials lacking proper documentation

- Inability to meet green building standards (e.g., LEED, BREEAM)

- Reputational damage if false claims are made

Ensure suppliers provide full traceability and valid certification documents with each shipment.

5. Inadequate Roll Inspection and Handling Defects

Even high-quality linoleum can be compromised by poor handling or storage. Common post-sourcing issues include:

- Surface scratches or dents from improper rolling

- Moisture damage due to inadequate packaging

- Dimensional inaccuracies (e.g., incorrect width or length)

Inspect rolls upon delivery and ensure suppliers follow industry best practices for packaging and transportation.

By addressing these quality and IP-related pitfalls proactively, buyers can secure authentic, high-performance linoleum that meets both functional and compliance requirements.

Logistics & Compliance Guide for Rolls of Linoleum

Product Overview and Handling Requirements

Linoleum rolls are large, heavy, and sensitive to environmental conditions. They are typically made from natural materials such as linseed oil, cork dust, wood flour, and jute backing, making them susceptible to moisture, warping, and physical damage. Proper handling from manufacturing to final delivery is crucial to maintain product integrity.

Packaging Standards

- Rolls must be wrapped in durable, moisture-resistant plastic film to prevent water damage.

- Use sturdy cardboard cores and end caps to protect roll edges during transport.

- Secure rolls on pallets using stretch wrap or strapping to prevent shifting.

- Label each roll with product specifications, batch number, weight, dimensions, and handling instructions (e.g., “This Side Up,” “Protect from Moisture”).

Storage Conditions

- Store in a dry, climate-controlled environment with temperatures between 10°C and 25°C (50°F–77°F).

- Maintain relative humidity levels below 65% to prevent mold and dimensional changes.

- Keep rolls horizontally on pallets, not stacked vertically, to avoid deformation.

- Avoid direct sunlight or proximity to heat sources to prevent curing or embrittlement.

Transportation Guidelines

- Use enclosed, clean, and dry freight vehicles (e.g., dry vans) to protect against weather and contamination.

- Securely fasten loads on trucks to prevent rolling or shifting during transit.

- For international shipments, ensure compliance with International Safe Transit Association (ISTA) standards for packaging and handling.

- Clearly mark shipments as “Fragile” and “Roll Goods – Do Not Stack.”

Regulatory and Compliance Requirements

- REACH & RoHS Compliance (EU): Confirm linoleum formulation complies with REACH restrictions on hazardous substances and RoHS directives where applicable.

- California Proposition 65: Provide warnings if linoleum contains chemicals listed under Prop 65, such as certain phthalates or formaldehyde (if present).

- LEED and Environmental Certifications: Maintain documentation for low-VOC emissions, recyclability, and sustainable sourcing to support green building certifications.

- Customs Documentation (International Shipments): Include accurate HS Code classification—typically 4008.21 or 4008.29 for non-vulcanized rubber or synthetic rubber flooring, though linoleum may fall under 3918.10 (plastic floor coverings) depending on composition; consult local tariff schedules.

Safety and Hazard Communication

- Linoleum is generally non-hazardous, but safety data sheets (SDS) must be available per GHS standards.

- Ensure workers handling rolls are trained in manual lifting techniques or use mechanical aids to prevent injury.

- Provide ventilation during installation to manage dust from cutting.

Import/Export Documentation

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (if required for preferential tariffs)

- SDS and Product Compliance Certificates (e.g., FloorScore, Greenguard)

Quality Control and Inspection

- Conduct pre-shipment inspections to verify roll dimensions, surface quality, and packaging integrity.

- Include moisture content testing if required by customer specifications.

- Retain batch samples and test reports for traceability and compliance audits.

Sustainability and Disposal

- Promote recyclability or biodegradability of linoleum at end-of-life.

- Provide disposal guidance in accordance with local waste management regulations.

- Partner with certified recycling facilities where available.

Adhering to this logistics and compliance guide ensures that rolls of linoleum reach customers in optimal condition while meeting all regulatory and environmental standards.

Conclusion for Sourcing Rolls of Linoleum:

After a thorough evaluation of potential suppliers, pricing, product quality, and logistical considerations, we conclude that sourcing rolls of linoleum should prioritize suppliers offering durable, eco-friendly materials with consistent dimensional accuracy and low VOC emissions. Based on our requirements for sustainability, cost-efficiency, and performance, Supplier B emerges as the recommended partner due to their competitive pricing, reliable lead times, and strong environmental credentials, including FSC certification and low-impact manufacturing processes.

Additionally, ordering in bulk quantities will optimize freight costs and ensure continuity of supply for upcoming projects. It is recommended to establish a framework agreement with staggered deliveries to match project timelines and minimize on-site storage needs. Final selection should be confirmed with sample testing and a review of contractual terms, including warranties and return policies.

In conclusion, strategic sourcing of linoleum rolls—balancing quality, sustainability, and cost—will support long-term project success and align with organizational goals for environmental responsibility and operational efficiency.