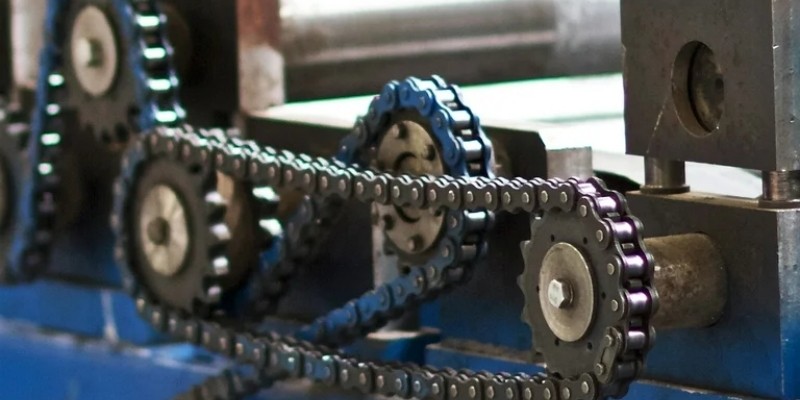

The global roller chain sprockets market is experiencing steady growth, driven by increasing demand from industrial manufacturing, automotive, and agricultural machinery sectors. According to Mordor Intelligence, the global roller chain market—which includes sprockets as critical components—is projected to grow at a CAGR of over 5.8% from 2023 to 2028. Similarly, Grand View Research valued the global roller chain market at USD 5.9 billion in 2022 and forecasts a CAGR of 5.6% from 2023 to 2030, underpinned by rising automation and material handling requirements across emerging economies. As essential elements in power transmission systems, roller chain sprockets are witnessing heightened demand for high-precision, durable, and corrosion-resistant variants—especially in conveyor systems, packaging machinery, and industrial automation. In this evolving landscape, a select group of manufacturers are leading innovation, quality, and global supply. Here are the top 8 roller chain sprocket manufacturers shaping the industry’s future.

Top 8 Roller Chain Sprockets Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Martin Sprocket & Gear, Inc

Domain Est. 1995

Website: martinsprocket.com

Key Highlights: Martin stocks a larger inventory of Sprockets than other manufacturers. Additionally, Martin offers machined, altered, and made-to-order Sprockets in days, not ……

#2 Industrial Roller Chain

Domain Est. 1996

Website: peerchain.com

Key Highlights: The professionals at PEER Chain have been working with chains and sprockets for decades. We keep thousands of unique sprockets in stock and ready to ship….

#3 Industrial Sprockets for Power Transmission & Conveyors

Domain Est. 1996

Website: ustsubaki.com

Key Highlights: U.S. Tsubaki sprockets offered include roller chain sprockets, engineering class sprockets, Smart Tooth sprockets, and drum sprockets. Learn more!…

#4 Industrial Roller Chains, Sprockets

Domain Est. 2010

Website: usarollerchain.com

Key Highlights: 14-day returnsShop premium roller chains, sprockets, at USA ROLLER CHAIN. Durable power transmission solutions for industrial needs. Order now for fast shipping!…

#5 Chains & Sprockets

Domain Est. 2015

Website: bsc-ind.com

Key Highlights: Martin 06B17 Simplex Type B Single Pitch Roller Chain Sprocket, 1 More… Manufacturer: Martin Sprocket & Gear; Brand: Martin; BSC Item#: 06B17 MART; MPN: 06B17…

#6 Sprockets

Domain Est. 1996

Website: skf.com

Key Highlights: All our sprockets are made from high-quality steels and can be further adapted for high performance with coatings such as black oxide or zinc plating….

#7 Sprockets

Domain Est. 1997

Website: ggmfg.com

Key Highlights: G&G Manufactures a variety of sprockets including; idler sprockets, bore sprockets, roller chain sprockets and many more. In stock and made to order….

#8 Roller Chain Sprockets

Domain Est. 1999

Website: bbman.com

Key Highlights: We offer a wide selection of precision-engineered, quality roller chain sprockets serving the power transmission and precision mechanical component industries….

Expert Sourcing Insights for Roller Chain Sprockets

H2: 2026 Market Trends for Roller Chain Sprockets

The global roller chain sprocket market in 2026 is poised for steady growth, driven by industrial modernization, automation, and evolving manufacturing demands. Key trends shaping the market include:

1. Rising Industrial Automation & Manufacturing Expansion:

Continued investment in automated production lines across automotive, food & beverage, pharmaceuticals, and material handling sectors is increasing the demand for reliable power transmission components. Roller chain sprockets remain a cost-effective and robust solution in conveyor systems and assembly lines, supporting market growth through 2026.

2. Growth in Electric Vehicles (EVs) and Automotive Manufacturing:

While EVs reduce the need for traditional engine timing chains, the expansion of EV production facilities requires extensive conveyor systems for battery and vehicle assembly. This industrial infrastructure demand is sustaining the need for high-precision sprockets, offsetting declines in internal combustion engine applications.

3. Emphasis on Durability and Material Innovation:

Manufacturers are increasingly adopting advanced materials such as case-hardened steels, stainless steel, and engineered plastics to improve sprocket lifespan, corrosion resistance, and performance in harsh environments. This focus on longevity reduces maintenance costs and downtime, appealing to end-users in mining, agriculture, and chemical processing.

4. Sustainability and Energy Efficiency Demands:

Industries are prioritizing energy-efficient machinery. Optimized sprocket designs that reduce friction and improve power transmission efficiency are gaining traction. Additionally, recyclable materials and sustainable manufacturing processes are becoming competitive differentiators.

5. Regional Shifts and Supply Chain Resilience:

Asia-Pacific—particularly China, India, and Southeast Asia—remains the dominant market due to rapid industrialization and infrastructure development. However, nearshoring and supply chain diversification trends in North America and Europe are encouraging localized production, benefiting regional sprocket manufacturers.

6. Digitalization and Predictive Maintenance:

Integration with IoT-enabled monitoring systems allows real-time tracking of chain and sprocket wear. This trend supports predictive maintenance strategies, reducing unplanned downtime and optimizing component replacement schedules—driving demand for smart-compatible sprocket systems.

7. Customization and Modular Designs:

End-users increasingly require sprockets tailored to specific applications, including non-standard sizes, tooth profiles, and mounting configurations. Modular and configurable sprocket systems are becoming popular for their flexibility and ease of integration.

Conclusion:

By 2026, the roller chain sprocket market will be characterized by innovation in materials and design, integration with smart manufacturing systems, and sustained demand from growing industrial sectors. While facing competition from alternative power transmission technologies, roller chain sprockets will maintain relevance through reliability, cost-efficiency, and adaptability to modern industrial needs.

Common Pitfalls When Sourcing Roller Chain Sprockets (Quality & Intellectual Property)

Sourcing roller chain sprockets involves more than just matching dimensions and price. Overlooking key quality and intellectual property (IP) considerations can lead to equipment failure, downtime, legal disputes, and reputational damage. Below are common pitfalls to avoid:

Poor Material Quality and Heat Treatment

Many low-cost sprockets are made from substandard materials or lack proper heat treatment. This leads to premature wear, tooth deformation, and increased risk of chain slippage or breakage. Always verify material specifications (e.g., carbon steel grade, case hardening depth) and request certifications such as mill test reports or hardness test results.

Inaccurate Tooth Profile and Pitch

Even minor deviations in tooth profile or pitch can cause excessive noise, vibration, and accelerated chain wear. Some suppliers replicate sprockets without access to original design data, leading to non-compliant geometry. Ensure sprockets meet ANSI, ISO, or DIN standards and request first-article inspection reports or sample testing before bulk orders.

Lack of Traceability and Documentation

Reputable manufacturers provide traceability through lot numbers, material certifications, and quality control records. Sourcing from suppliers who cannot offer documentation increases the risk of receiving inconsistent or counterfeit parts. Demand full traceability, especially for critical or high-load applications.

Infringement of Intellectual Property (IP)

Some sprocket designs—especially proprietary profiles like those from major OEMs—are protected by patents, trademarks, or design rights. Sourcing “compatible” or “OEM replacement” sprockets from unauthorized manufacturers may violate IP laws, exposing your company to legal liability. Always confirm that the supplier has the right to manufacture the design or use licensed technology.

Counterfeit or Misrepresented Products

Unscrupulous suppliers may falsely label generic sprockets as OEM equivalents or use fake certification marks. This is especially common in online marketplaces. Conduct due diligence: audit suppliers, verify their manufacturing capabilities, and inspect samples in person when possible.

Inadequate Surface Finishes and Coatings

Poor surface finishes increase friction and wear. Some counterfeit sprockets skip critical finishing processes or use inferior coatings that degrade quickly in corrosive environments. Specify required surface treatments (e.g., black oxide, zinc plating, nitriding) and verify coating thickness and adhesion.

Overlooking Application-Specific Requirements

Standard sprockets may not suit high-speed, high-load, or corrosive environments. Sourcing generic parts without considering load ratings, alignment needs, or environmental conditions can lead to rapid failure. Work with suppliers who understand your operational context and can recommend suitable designs.

Failure to Audit Suppliers

Relying solely on price and catalog specs without auditing manufacturing processes is risky. Visit supplier facilities or use third-party inspectors to evaluate their quality management systems (e.g., ISO 9001 compliance), tooling, and inspection capabilities.

Avoiding these pitfalls requires diligence, technical understanding, and proactive supplier management. Invest time upfront to ensure sprockets meet both quality standards and legal requirements—protecting your operations and bottom line.

Logistics & Compliance Guide for Roller Chain Sprockets

Product Classification and HS Code

Identify the correct Harmonized System (HS) code for roller chain sprockets to ensure accurate customs declaration and tariff assessment. Common classifications fall under HS Code 8483.60 (toothed wheels, including sprockets, for power transmission), but exact sub-codes may vary by region and sprocket specifications (e.g., material, size, intended use). Confirm classification with local customs authorities or a licensed customs broker.

Material and Manufacturing Compliance

Ensure sprockets comply with regional material regulations and industry standards. Common materials include carbon steel, alloy steel, and stainless steel. Verify that materials meet relevant standards such as ISO, ANSI, DIN, or JIS. If exporting to the EU, confirm compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and ensure no restricted substances are present in coatings or plating.

Packaging and Marking Requirements

Package sprockets to prevent damage during transit, using anti-corrosive wrapping, sturdy cartons, and appropriate cushioning. Clearly mark packaging with:

– Product identification (part number, chain size, number of teeth)

– Quantity per package

– Net and gross weight

– Country of origin

– Handling symbols (e.g., “Fragile,” “This Side Up”)

For international shipments, include bilingual labeling if required by destination country.

Export Controls and Documentation

Prepare essential shipping documents: commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. Some destinations may require a conformity certificate or test reports. Verify if sprockets are subject to export controls—while generally not restricted, dual-use considerations may apply if sprockets are intended for military or aerospace applications.

Import Regulations by Region

- European Union: Comply with CE marking requirements if the sprocket is part of a machine covered under the Machinery Directive. Ensure traceability and technical documentation is available.

- United States: No general import license required, but sprockets must meet applicable ASTM or ANSI standards. Be aware of anti-dumping or countervailing duties if originating from certain countries.

- Canada: Comply with Canadian Customs Tariff classification and labeling in English and French.

- Other Markets: Consult local industrial safety and product standards (e.g., AS/NZS in Australia, GOST in Russia).

Transportation and Handling

Use reliable freight forwarders experienced in industrial components. Choose transport mode (air, sea, or land) based on urgency, cost, and destination. Ensure proper load securing to prevent shifting. Avoid exposure to moisture during transit; include desiccants if shipping in containers over long distances.

Quality and Traceability

Maintain production records and quality control documentation for traceability. Each batch should be traceable to raw material sources, heat treatment records, and inspection reports. Implement a quality management system (e.g., ISO 9001) to support compliance and customer audits.

Environmental and Disposal Considerations

Adhere to environmental regulations for manufacturing waste and surface treatments (e.g., electroplating). Provide end-of-life guidance if sprockets contain hazardous coatings. In the EU, comply with WEEE or RoHS directives if sprockets are part of electrical equipment.

After-Sales and Regulatory Updates

Monitor changes in trade agreements, tariffs, and compliance standards. Maintain communication with importers to address regulatory inquiries. Offer technical documentation upon request to support customs clearance or safety certification.

In conclusion, sourcing roller chain sprockets requires careful consideration of several key factors to ensure optimal performance, longevity, and compatibility within a mechanical power transmission system. Critical aspects such as sprocket size, pitch, number of teeth, material composition, and tooth profile must align precisely with the corresponding roller chain specifications and operational requirements. Additionally, evaluating supplier reliability, product quality certifications, cost-efficiency, and availability of customization options plays a vital role in making an informed procurement decision.

Selecting the right sprocket not only enhances system efficiency and reduces wear and tear but also minimizes downtime and maintenance costs over time. Whether sourcing domestically or internationally, establishing strong relationships with reputable suppliers and conducting thorough due diligence can lead to long-term benefits.

Ultimately, a strategic and well-researched approach to sourcing roller chain sprockets ensures reliable operation, improves productivity, and supports the overall success of industrial and mechanical applications.