The global wire fencing market is experiencing steady growth, driven by rising infrastructure development, urbanization, and increasing demand for perimeter security across residential, commercial, and agricultural sectors. According to Grand View Research, the global wire mesh market size was valued at USD 52.3 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. Similarly, Mordor Intelligence projects continued upward momentum in the fencing industry, citing increased investments in construction and smart security systems as key growth catalysts. With roll wire fencing—known for its durability, cost-efficiency, and ease of installation—being one of the most widely adopted solutions across agricultural and industrial applications, demand for high-quality manufacturers has surged. In this evolving landscape, identifying reliable and innovative roll wire fence producers is critical for contractors, distributors, and project planners seeking performance-driven solutions. Here, we spotlight the top 9 roll wire fence manufacturers shaping the industry through product quality, technological advancement, and global reach.

Top 9 Roll Wire Fence Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Master Halco

Domain Est. 1996

Website: masterhalco.com

Key Highlights: Master Halco is your leading manufacturer and wholesale distributor of fencing & decking products across the US and Canada….

#2 Rangemaster Fence

Domain Est. 2009

Website: rangemasterfence.com

Key Highlights: FENCE PRODUCTS. We supply performance-driven farm & ranch, and residential & commercial wire fence products for the agricultural and construction markets….

#3 Bekaert Fencing

Domain Est. 1993

Website: fencing.bekaert.com

Key Highlights: Since 1880, Bekaert Fencing has been the industry-leading fencing products. Delivering strong, corrosion resistant high tensile fences made in America….

#4 No Climb Horse Fence

Domain Est. 1996

Website: redbrand.com

Key Highlights: Red Brand has been making high quality wire fence since 1889. Our products are manufactured with the best materials available for long-lasting value and ……

#5 OK Brand

Domain Est. 2002

Website: okbrand.com

Key Highlights: OK Brand provides durable agricultural products, fencing solutions, and livestock panels for farms and ranches. Trusted for quality, strength, ……

#6 Fencing rolls: the largest product assortment

Domain Est. 2004

Website: betafence.com

Key Highlights: With our experience based on 135 years of manufacturing fencing wires, here we are offering a very large range of fencing rolls to protect your outside ……

#7 Pantanet Welded Wire Steel Fence Rolls

Domain Est. 2010

#8 Trident Fence

Domain Est. 2012

Website: tridentfence.com

Key Highlights: Trident Fence has been a leading wholesale fence supplier for effective wildlife control. Customers in the US and Canada will find quality fence supplies and ……

#9 Field & Agricultural Fencing

Domain Est. 2013

Website: redbrandstore.com

Key Highlights: 11–20 day delivery 30-day returnsRed Brand offers durable, reliable woven wire field fencing to keep your large livestock safe and secure….

Expert Sourcing Insights for Roll Wire Fence

2026 Market Trends for Roll Wire Fence: An In-Depth Analysis

Market Overview and Growth Projections

The global roll wire fence market is poised for steady expansion through 2026, driven by rising demand across residential, commercial, and agricultural sectors. According to industry forecasts, the market is expected to grow at a compound annual growth rate (CAGR) of approximately 4.8% from 2022 to 2026, reaching a projected value of USD 8.9 billion by the end of the period. This growth is underpinned by increasing urbanization, infrastructure development, and the need for cost-effective and durable perimeter security solutions.

Key regions contributing to this growth include North America, Europe, and Asia-Pacific, with China, India, and the United States leading in both production and consumption. Rapid industrialization and government investments in rural electrification and agricultural modernization in developing nations are further amplifying demand for roll wire fencing, particularly in farming and livestock management applications.

Material and Technological Advancements

A significant trend shaping the 2026 outlook is the shift toward high-tensile and galvanized steel wire, which offers superior strength, corrosion resistance, and longevity. Manufacturers are increasingly investing in advanced galvanization techniques—such as hot-dip galvanizing and zinc-aluminum alloy coatings—to enhance product durability, especially for outdoor and coastal environments.

Additionally, innovations in PVC-coated roll wire fences are gaining traction due to their aesthetic appeal and resistance to rust and weathering. These coated variants are becoming popular in residential and urban landscaping projects, where visual appeal is as important as security.

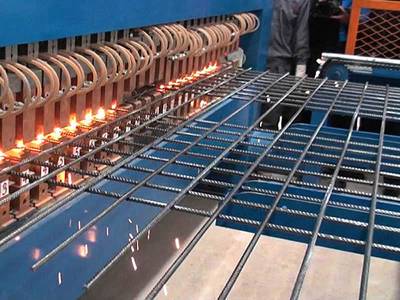

Automation in manufacturing processes is also improving production efficiency and consistency, enabling suppliers to meet the growing demand while maintaining tight quality control. Smart fencing integration, though still in early stages, may begin influencing niche segments by 2026, especially in high-security commercial zones.

Regional Market Dynamics

In North America, demand is driven by residential construction and the need to secure large properties and agricultural land. The U.S. Department of Agriculture (USDA) continues to promote the use of wire fencing for livestock containment, supporting market growth.

Europe is witnessing increased adoption of eco-friendly and recyclable fencing materials, aligning with EU sustainability goals. Countries like Germany and France are emphasizing long-life-cycle products, pushing manufacturers to improve recyclability and reduce carbon footprints.

In the Asia-Pacific region, rapid urbanization and government infrastructure projects—such as rural road development and smart village initiatives—are boosting demand. India’s “Pradhan Mantri Gram Sadak Yojana” and similar programs are creating new opportunities for roll wire fencing in perimeter protection for community assets and utilities.

Sustainability and Regulatory Influences

Environmental regulations are becoming a key factor in material selection and production methods. By 2026, stricter emissions standards and waste management requirements in key markets are expected to influence manufacturing practices. Companies are responding by adopting cleaner production technologies and sourcing raw materials from certified sustainable mills.

Moreover, green building certifications such as LEED and BREEAM are encouraging the use of recyclable and low-impact fencing solutions, further promoting galvanized and coated steel products with longer service lives.

Competitive Landscape and Strategic Outlook

The roll wire fence market remains fragmented, with a mix of large multinational producers and regional manufacturers. Leading players are focusing on strategic expansions, mergers, and product diversification to capture larger market shares. Customization—such as variable mesh sizes, heights, and coatings—has become a differentiating factor, allowing companies to serve specialized applications in agriculture, sports facilities, and industrial sites.

E-commerce platforms are also transforming distribution channels, enabling faster delivery and broader reach, especially in remote and rural areas.

Conclusion

By 2026, the roll wire fence market will be shaped by technological innovation, sustainability imperatives, and expanding infrastructure needs. With increasing emphasis on durability, cost-efficiency, and environmental responsibility, manufacturers who adapt to these trends are likely to gain a competitive edge. As global development continues, roll wire fencing will remain a cornerstone solution for security and boundary demarcation across diverse sectors.

Common Pitfalls When Sourcing Roll Wire Fence (Quality and Intellectual Property)

Sourcing roll wire fence—especially from international suppliers—can present several challenges related to both product quality and intellectual property (IP) risks. Being aware of these pitfalls helps ensure you receive durable, compliant products without exposing your business to legal or reputational damage.

Poor Material Quality and Durability

One of the most frequent issues is receiving roll wire fence made from substandard materials. Low-grade steel or inadequate galvanization can lead to premature rusting, reduced strength, and shorter lifespan. Suppliers may claim compliance with standards (like ASTM A641 or ISO 1461), but without proper third-party testing or on-site audits, these claims can be misleading. Always request material test reports (MTRs) and consider independent lab testing before large-scale procurement.

Inconsistent Mesh and Wire Gauge

Inconsistencies in mesh size, wire diameter (gauge), and tension can compromise the fence’s structural integrity and appearance. Some manufacturers cut costs by varying wire thickness or spacing, which may not be visible during initial inspection but affects performance over time. Verify specifications with precise tolerances in contracts and conduct random batch inspections during production.

Inadequate or Fake Certifications

Suppliers may present forged or outdated certifications to appear compliant with safety, environmental, or industry standards. This includes fake ISO, CE, or country-specific certifications. Always verify certifications through official databases or third-party inspectors and avoid suppliers who are reluctant to provide documentation.

Intellectual Property (IP) Infringement Risks

Sourcing from regions with weak IP enforcement can expose your business to legal risks. Some manufacturers may produce roll wire fence that copies patented designs, proprietary weaving patterns, or branded product features without authorization. If you import such products, you could face customs seizures, lawsuits, or damage to your brand reputation. Conduct due diligence on suppliers and require written assurances that products do not infringe on existing patents or trademarks.

Lack of Traceability and Supplier Transparency

Many suppliers, especially intermediaries or trading companies, lack visibility into their manufacturing processes. This opacity makes it difficult to trace raw material sources or verify production methods. Insist on direct factory engagement, site visits, or video audits to assess real production capabilities and quality control systems.

Hidden Costs from Re-Work or Rejection

Poor quality often leads to rejected shipments, delays, or the need for re-installation, significantly increasing total cost of ownership. Factor in potential rework, return logistics, and project downtime when evaluating supplier quotes. A lower initial price may not reflect the true cost if quality issues arise later.

Failure to Enforce Contractual Quality Clauses

Even with detailed specifications, weakly enforced contracts can lead to disputes. Ensure your purchase agreement includes clear quality benchmarks, inspection rights, penalties for non-compliance, and IP indemnification clauses to protect your business if issues arise post-delivery.

By proactively addressing these pitfalls—through rigorous vetting, contractual safeguards, and independent verification—you can source roll wire fence that meets both quality expectations and legal requirements.

Logistics & Compliance Guide for Roll Wire Fence

Roll wire fence, commonly used in agricultural, industrial, and security applications, requires careful attention to logistics and compliance throughout its supply chain. This guide outlines best practices and regulatory considerations for handling, transporting, storing, and installing roll wire fencing.

Product Handling and Packaging

Roll wire fences are typically shipped in tightly wound coils and must be properly packaged to prevent damage during transit. Standard packaging includes:

– Protective plastic wrapping or shrink wrap to prevent moisture exposure

– Steel or plastic banding to maintain coil integrity

– Wooden or metal skids for stability during handling

Handle rolls using forklifts or cranes equipped with appropriate lifting attachments. Avoid dragging or dropping rolls, which can deform the wire or compromise the roll structure.

Transportation Requirements

When transporting roll wire fence:

– Secure rolls on flatbed or enclosed trucks using straps or chains to prevent shifting

– Ensure loads are evenly distributed and within legal weight and dimension limits

– Comply with national and local road transport regulations (e.g., U.S. DOT, EU ADR)

– Protect rolls from environmental exposure, especially in coastal or humid regions

For international shipments, ensure compliance with:

– International Maritime Dangerous Goods (IMDG) Code (if applicable, though wire fencing is typically non-hazardous)

– Harmonized System (HS) codes for customs classification (e.g., HS 7314.31 or 7314.39 for steel wire fencing)

– Import/export documentation, including commercial invoices and packing lists

Storage Guidelines

Store roll wire fence in a dry, covered area to prevent rust and corrosion. If outdoor storage is necessary:

– Elevate rolls off the ground using pallets or racks

– Cover with waterproof tarps, ensuring air circulation to reduce condensation

– Avoid stacking excessive weight on lower rolls

Rotate stock using the First-In, First-Out (FIFO) method to minimize long-term exposure and potential quality degradation.

Regulatory and Safety Compliance

Ensure compliance with relevant safety and quality standards:

– ASTM Standards: Follow ASTM A392 (zinc-coated steel wire for fencing) and ASTM A90 (zinc coating mass testing)

– ISO Standards: Comply with ISO 1461 for hot-dip galvanizing quality (if applicable)

– OSHA Guidelines: Adhere to workplace safety standards during handling and installation (e.g., cut-resistant gloves, eye protection)

Workers should be trained in safe lifting techniques and the use of personal protective equipment (PPE) to prevent injuries from sharp wire edges.

Environmental and Disposal Considerations

- Galvanized wire fencing contains zinc coatings; disposal must comply with local environmental regulations

- Recycle scrap or damaged fencing through certified metal recyclers

- Avoid burning wire fencing, as this can release hazardous fumes

Import/Export Documentation

For cross-border shipments:

– Provide accurate product specifications (wire gauge, mesh size, coating type)

– Include mill test certificates or material certifications upon request

– Verify country-specific import requirements (e.g., CE marking in the EU, CCC in China)

Final Installation Compliance

Ensure installation meets:

– Local building codes and zoning regulations

– Security standards (e.g., for perimeter fencing in high-risk facilities)

– Wildlife protection guidelines (e.g., avoiding harmful designs in ecologically sensitive areas)

Following this logistics and compliance guide ensures the safe, efficient, and legal handling of roll wire fence from manufacturer to end use.

Conclusion for Sourcing Roll Wire Fence:

Sourcing roll wire fence requires a strategic approach that balances quality, cost, durability, and supplier reliability. After evaluating various suppliers, material options (such as galvanized steel, PVC-coated, or stainless steel), and fencing specifications (including mesh size, wire gauge, and roll length), it is evident that choosing the right product depends on the specific application—whether for agricultural, residential, commercial, or industrial use.

Establishing relationships with reputable manufacturers or distributors ensures consistent quality and timely delivery. Additionally, considering long-term factors like corrosion resistance, installation ease, and maintenance requirements contributes to cost-efficiency over time. By conducting thorough market research, obtaining competitive quotations, and prioritizing sustainability and compliance with industry standards, businesses can secure a reliable supply of roll wire fencing that meets both performance needs and budget constraints.

In summary, successful sourcing hinges on due diligence, clear specifications, and ongoing supplier evaluation to ensure optimal value and project success.