The global roll tables market has experienced steady expansion, driven by rising demand across industries such as printing, material handling, and logistics. According to Grand View Research, the global material handling equipment market—of which roll tables are a key component—was valued at USD 190.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing automation in manufacturing, e-commerce expansion, and the need for efficient warehouse operations. Roll tables, essential for product transfer and conveyance, are witnessing advanced engineering focused on durability, load capacity, and modular integration. As industries adopt lean manufacturing and smart logistics solutions, the demand for high-performance roll tables continues to rise, positioning key manufacturers at the forefront of innovation and market share. This list highlights the top eight roll table manufacturers leading the industry through technological advancement, global reach, and strategic adaptation to evolving industrial needs.

Top 8 Roll Tables Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

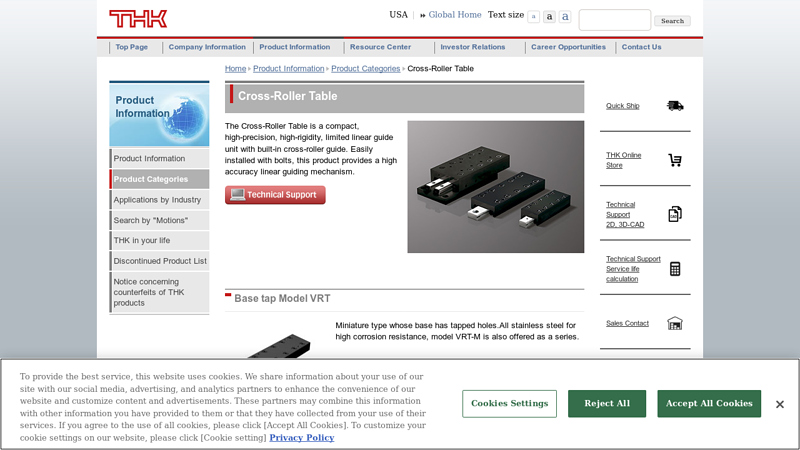

#1 Cross-Roller Table

Domain Est. 1995

Website: thk.com

Key Highlights: The Cross-Roller Table is a compact, high-precision, high-rigidity, limited linear guide unit with built-in cross-roller guide. Easily installed with bolts….

#2 Roll

Domain Est. 1995

#3 Fold

Domain Est. 1997

Website: biofit.com

Key Highlights: Popular and practical, this round Fold-N-Roll Series table is an ideal choice for classrooms, food courts, cafeterias, multipurpose areas and beyond….

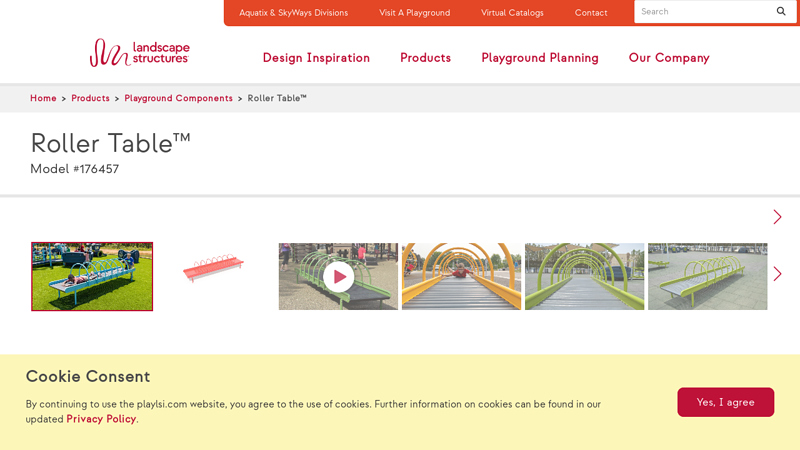

#4 Roller Table™

Domain Est. 1997

Website: playlsi.com

Key Highlights: The Roller Table™ is a freestanding playground component that helps kids develop “skin map” of tactile sensory receptors throughout the body….

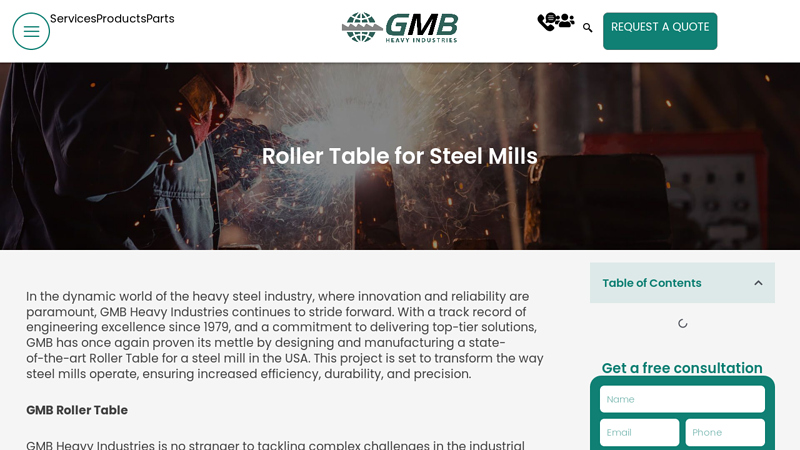

#5 Roller Table for Steel Mills

Domain Est. 1998

Website: gmbindustries.com

Key Highlights: Enhance your steel mill’s efficiency with GMB Heavy Industries’ custom-engineered roller tables, designed for seamless material handling and durability….

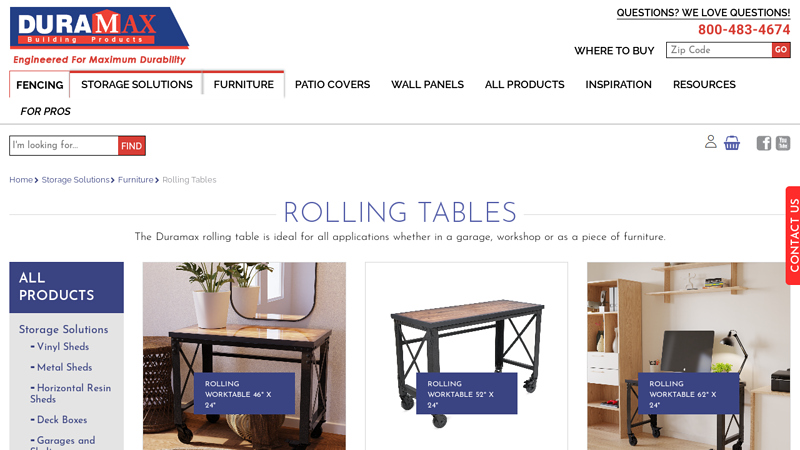

#6 Rolling Tables

Domain Est. 2003

Website: duramaxbp.com

Key Highlights: The Duramax 46 in. W x 24 in. D rolling worktable is ideal for all applications whether in a garage, workshop or as a piece of furniture….

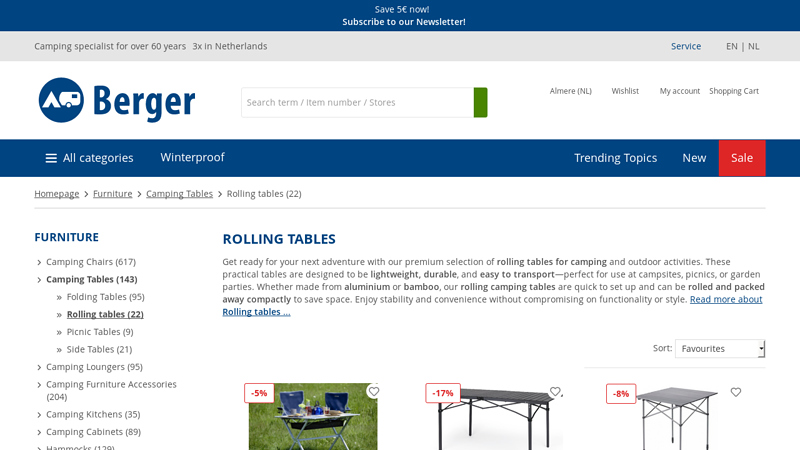

#7 Rolling tables

Domain Est. 2019

Website: berger-camping.com

Key Highlights: Rating 4.6 (625) · 30-day returnsLightweight Yet Stable: Rolling Tables with Aluminium Frame. Camping rollable tables feature a practical design with a rollable tabletop and a …

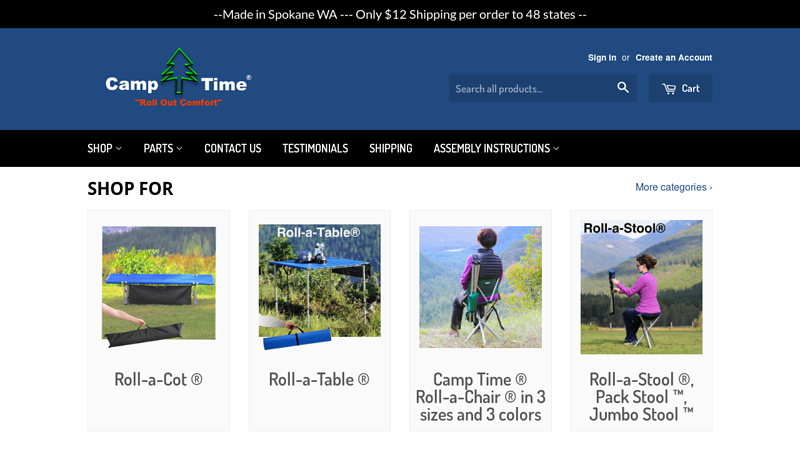

#8 Best camping tables, cots, stools

Domain Est. 2000

Website: camptime.com

Key Highlights: Explore CampTime® products for 10 sizes of Roll-a-Cot®, 5 sizes of Roll-a-Stool®, 2 sizes of Roll-a-Table® that will make your next outdoor adventure ……

Expert Sourcing Insights for Roll Tables

2026 Market Trends for Roll Tables

Roll tables, essential tools in rehabilitation, physical therapy, and home healthcare settings, are poised for significant evolution by 2026. Driven by demographic shifts, technological advancements, and changing care models, the market is expected to experience robust growth and innovation. Key trends shaping the landscape include:

Rising Demand from Aging Populations and Chronic Conditions

The global aging population is a primary driver for roll table adoption. As individuals over 65 face higher incidences of mobility issues, arthritis, and post-surgical recovery needs, demand for accessible and safe patient transfer and treatment solutions increases. Coupled with the rising prevalence of chronic conditions requiring ongoing physical therapy—such as back pain, musculoskeletal disorders, and neurological impairments—clinics and home care providers are investing in ergonomic roll tables to support both patient comfort and clinician efficiency.

Emphasis on Ergonomics and Clinician Safety

Preventing occupational injuries among healthcare workers remains a critical concern. By 2026, roll tables will increasingly feature advanced ergonomic designs, including adjustable height mechanisms (often electric), improved weight capacities, and enhanced stability. These features reduce physical strain on therapists during patient handling, aligning with workplace safety regulations and lowering employer liability and worker compensation costs.

Integration of Smart Technology and IoT

Smart roll tables equipped with sensors and Internet of Things (IoT) capabilities are emerging. By 2026, expect wider adoption of tables that monitor patient positioning, track treatment duration, and interface with electronic health records (EHRs). This data integration supports treatment personalization, improves documentation accuracy, and facilitates remote monitoring—particularly relevant in hybrid care models combining in-person and telehealth services.

Growth in Home and Mobile Therapy Services

The shift toward decentralized care and home-based rehabilitation is accelerating the demand for portable, lightweight, and easily adjustable roll tables. Compact folding designs and models tailored for mobile therapists allow practitioners to deliver high-quality care outside traditional clinics. This trend is supported by insurance reimbursements expanding for home-based services and patient preferences for convenience and comfort.

Sustainability and Eco-Conscious Manufacturing

Environmental responsibility is becoming a competitive differentiator. By 2026, leading manufacturers are expected to adopt sustainable materials (e.g., recyclable metals, eco-friendly upholstery), reduce packaging waste, and implement energy-efficient production processes. Healthcare providers, particularly in Europe and North America, are prioritizing vendors with strong environmental, social, and governance (ESG) credentials.

Regional Market Expansion and Customization

While North America and Western Europe remain dominant markets, growth in Asia-Pacific and Latin America is accelerating due to improving healthcare infrastructure and rising disposable incomes. Manufacturers are responding with region-specific designs—adjusting for average patient height, local regulatory standards, and climate-resilient materials—to capture emerging opportunities.

In conclusion, the 2026 roll table market will be defined by intelligent, ergonomic, and adaptable solutions that meet the dual demands of patient-centered care and clinician well-being. Innovation will focus on connectivity, portability, and sustainability, positioning roll tables as integral components of modern, efficient rehabilitation ecosystems.

Common Pitfalls Sourcing Roll Tables (Quality, IP)

Sourcing roll tables—whether for manufacturing, printing, or industrial processing—can present several challenges, particularly concerning quality consistency and intellectual property (IP) risks. Being aware of these pitfalls helps organizations make informed procurement decisions and avoid costly complications.

Poor Material and Construction Quality

A frequent issue when sourcing roll tables, especially from low-cost suppliers, is substandard materials and inconsistent craftsmanship. Inferior steel, inadequate welding, or imprecise machining can lead to misalignment, vibration, and premature wear. These flaws compromise product quality and increase downtime and maintenance costs. Buyers must verify material certifications, conduct factory audits, and request performance testing data to ensure durability and precision.

Inconsistent Tolerances and Precision

Roll tables require exact alignment and tight dimensional tolerances to function effectively in high-speed or precision applications. Sourcing from vendors without robust quality control processes often results in variations between units or batches. This inconsistency can disrupt production lines, especially when replacing or adding tables to existing systems. Always specify tolerance requirements clearly in contracts and validate them through third-party inspection.

Lack of Traceability and Compliance Documentation

Many suppliers, particularly in less-regulated markets, fail to provide essential documentation such as material test reports (MTRs), ISO certifications, or compliance with safety standards (e.g., CE, OSHA). Without traceability, organizations face risks related to regulatory non-compliance, liability, and difficulty in troubleshooting failures. Insist on full documentation and audit supplier quality management systems before placing orders.

Intellectual Property Infringement Risks

When sourcing roll tables—especially custom or high-tech designs—there’s a risk that the supplier may be using patented mechanisms, proprietary engineering, or copied designs without authorization. Purchasing such equipment can expose the buyer to IP litigation, especially in markets with strong IP protections. Conduct due diligence on the supplier’s design origins and include IP indemnification clauses in procurement contracts.

Inadequate Protection of Custom Designs

If you provide custom specifications or proprietary designs to a supplier, there’s a risk they may reuse or resell that design to competitors. Without a strong non-disclosure agreement (NDA) and clear ownership terms in the contract, your innovation could be compromised. Always secure IP rights in writing and limit design disclosure to what is strictly necessary.

Hidden Costs from Poor After-Sales Support

Low initial pricing can be misleading if the supplier lacks technical support, spare parts availability, or service networks. Downtime due to unavailability of replacement rollers or lack of troubleshooting assistance can far exceed the original purchase price. Evaluate the supplier’s service capabilities and spare parts logistics before finalizing the deal.

By addressing these quality and IP-related pitfalls proactively, businesses can ensure reliable performance, protect their innovations, and maintain long-term operational efficiency when sourcing roll tables.

Logistics & Compliance Guide for Roll Tables

Roll tables are essential equipment in various industries, including manufacturing, warehousing, and material handling. Proper logistics planning and compliance adherence are critical to ensure safe transportation, installation, and operation. This guide outlines best practices for handling, shipping, regulatory compliance, and operational safety.

Transportation and Handling

Proper handling during transportation prevents damage and ensures safety. Roll tables are often heavy and bulky, requiring specialized equipment and trained personnel.

- Use forklifts or pallet jacks with adequate load capacity when moving roll tables.

- Secure roll tables on flatbed trailers or shipping containers using straps or chains to prevent shifting.

- Protect rollers and frame components with padding or protective covers during transit.

- Follow manufacturer guidelines for lifting points and orientation during transport.

Packaging and Storage

Appropriate packaging and storage minimize risks of corrosion, deformation, or component loss.

- Store roll tables in dry, indoor environments to prevent rust and degradation.

- Keep rollers covered or wrapped if stored long-term to avoid dust and debris accumulation.

- Stack only if approved by the manufacturer, and use protective layers between units.

- Label packages clearly with handling instructions (e.g., “This Side Up,” “Fragile Components”).

Regulatory Compliance

Roll tables must comply with regional and industry-specific regulations to ensure workplace safety and legal operation.

- Ensure adherence to OSHA (Occupational Safety and Health Administration) standards in the U.S., particularly 29 CFR 1910 for general industry.

- Comply with CE marking requirements in the EU, including Machinery Directive 2006/42/EC for safe design and construction.

- Follow ANSI/RIA R15.06 standards if integrating roll tables into automated or robotic systems.

- Verify electrical components (e.g., powered roller drives) meet NEC (National Electrical Code) or IEC standards as applicable.

Installation and Site Preparation

Proper installation ensures optimal performance and reduces long-term maintenance issues.

- Confirm floor load capacity can support the roll table and maximum load.

- Ensure alignment with adjacent conveyors or workstations to prevent material jams.

- Anchor the roll table securely if required, especially in high-vibration environments.

- Verify power supply specifications match motorized roller requirements (voltage, phase, frequency).

Safety and Operational Compliance

Operators and maintenance personnel must follow safety protocols to prevent accidents.

- Install guarding or safety covers where pinch points or rotating components are exposed.

- Post clear warning signs near moving parts (e.g., “Danger: Rotating Rollers”).

- Implement lockout/tagout (LOTO) procedures during maintenance in accordance with OSHA 1910.147.

- Provide operator training on safe use, emergency stops, and hazard recognition.

Documentation and Certification

Maintain comprehensive records to demonstrate compliance and support audits.

- Keep copies of product manuals, compliance certificates (CE, UL, etc.), and inspection reports.

- Retain records of periodic maintenance, repairs, and safety checks.

- Ensure material certifications (e.g., steel grade, fire resistance) are available upon request.

- Update as-built drawings if modifications are made to the roll table or system.

By following this logistics and compliance guide, organizations can ensure the safe, efficient, and lawful deployment of roll tables in their operations. Regular review of applicable standards and manufacturer recommendations is advised to maintain ongoing compliance.

Conclusion for Sourcing Roll Tables

In conclusion, sourcing roll tables are valuable tools in procurement and supply chain management, enabling organizations to evaluate, compare, and select suppliers effectively based on predefined criteria such as cost, quality, delivery performance, capacity, and compliance. By systematically ranking potential suppliers, businesses can make data-driven decisions that align with strategic objectives, mitigate risks, and promote long-term supplier relationships. The use of sourcing roll tables enhances transparency, supports competitive bidding, and ensures consistency across sourcing events. When implemented alongside robust supplier evaluation processes, roll tables contribute to improved operational efficiency, cost savings, and supply chain resilience. Ultimately, mastering the application of sourcing roll tables is essential for organizations aiming to optimize their procurement strategies in dynamic market environments.