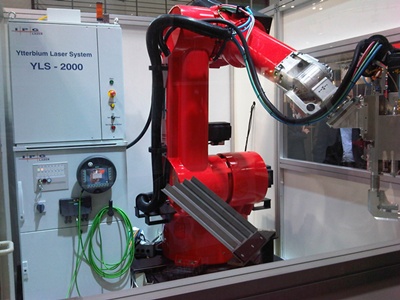

The global laser welding market is experiencing robust growth, driven by increasing demand for precision manufacturing across automotive, aerospace, medical devices, and electronics industries. According to Grand View Research, the global laser welding market size was valued at USD 4.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 8.7% from 2023 to 2030. This surge is fueled by advancements in high-power laser technologies, rising adoption of automation in production lines, and the growing need for energy-efficient and high-speed joining processes. As a key player in the space, ROFIN-Sinar—now part of Coherent Corp.—has set industry benchmarks in CO2 and solid-state laser systems, spurring competition and innovation among manufacturers worldwide. In response to evolving industrial demands, seven leading manufacturers have emerged as top suppliers of ROFIN-compatible and alternative high-performance laser welders, offering advanced solutions in beam delivery, process control, and system integration. This list highlights the most influential players shaping the future of industrial laser welding today.

Top 7 Rofin Laser Welder Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Technology

Website: luxinar.com

Key Highlights: Luxinar develops, manufactures and sells industrial laser sources. The company has been at the forefront of laser technology for over 25 years….

#2 Rofin Laser Welding

Website: lxshowlaser.com

Key Highlights: Rofin Laser Welding – Factory, Suppliers, Manufacturers from China … We have experienced manufacturing facilities with more than 100 employees. So we can ……

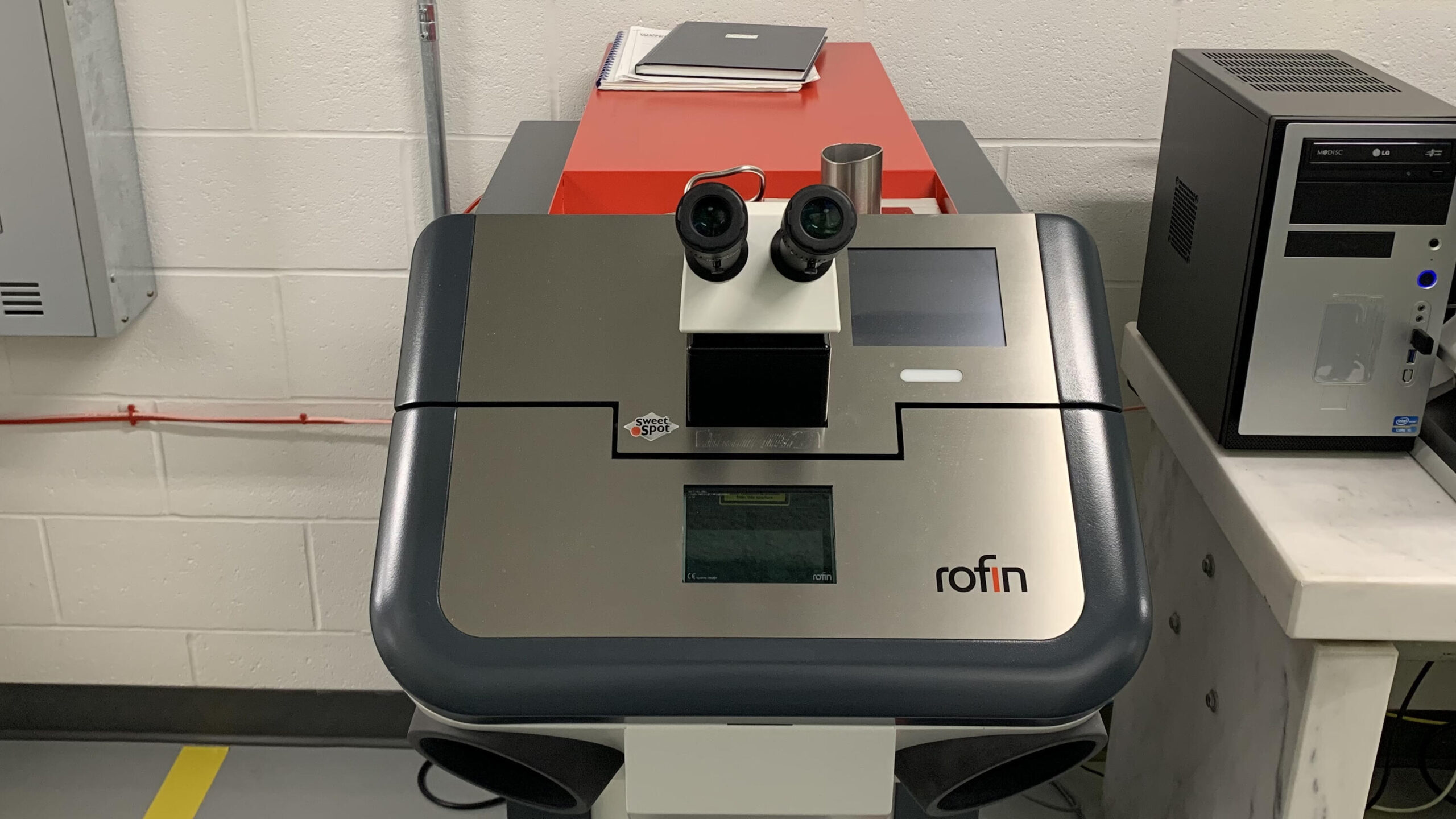

#3 Rofin Lasers

Website: stuller.com

Key Highlights: The Rofin laser is an easy to learn, easy to maintain machine, built by the world’s most experienced laser technology company….

#4 Laser Welding Machines

Website: coherent.com

Key Highlights: Get manual to fully automated laser welding machines that weld plastics and metals with speed and precision while improving throughput….

#5 Rofin 1000 Watt Laser

Website: atami.oregonstate.edu

Key Highlights: A high power, IR laser for cutting and wedling. A laser safe, purged cabinet contain and XYZ positioning system for a wide variety of cuts and welds….

#6 Desktop

Website: yubaohk.pro

Key Highlights: Our manual laser welding systems combine the excellent quality of laser welded joints with easy handling and fast operational readiness….

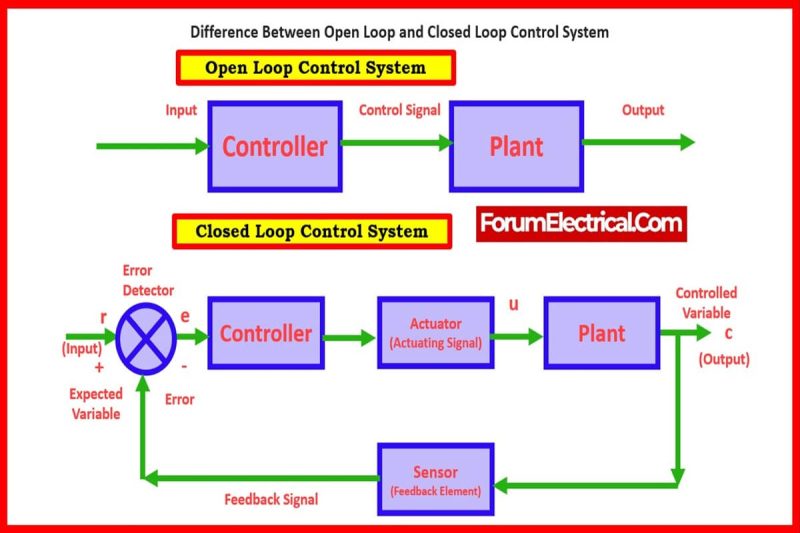

#7 Closed Loop Control of the Laser Welding Process …

Website: cordis.europa.eu

Key Highlights: Laser welding is a technique that is becoming more common. It is not only used in big factories, like in car manufacturing, but it can also be found in SME ……

Expert Sourcing Insights for Rofin Laser Welder

H2: Market Trends for Rofin Laser Welder in 2026

As we approach 2026, the market for industrial laser welding systems, including those produced by Rofin (a brand now fully integrated under Coherent Corp. following its acquisition), is being shaped by several transformative trends across manufacturing sectors. Rofin’s laser welders—renowned for precision, reliability, and versatility in applications ranging from automotive to medical device manufacturing—are positioned within a rapidly evolving technological and economic landscape.

1. Growth in Electric Vehicle (EV) Manufacturing Driving Demand

The global push toward electrification of transportation continues to accelerate, with major automotive OEMs expanding EV production capacity through 2026. Laser welding is a critical process in battery manufacturing (e.g., cell tab welding, busbar joining, and battery pack assembly), where Rofin’s fiber and disk laser systems offer high-speed, low-distortion joins. Demand for Rofin-enabled welding solutions is expected to rise significantly in Tier 1 battery and powertrain suppliers, particularly in North America, Europe, and China.

2. Increased Adoption of Automation and Industry 4.0 Integration

By 2026, manufacturers are increasingly integrating laser welding systems into fully automated production lines connected via IoT and AI-driven monitoring. Rofin laser systems—especially those co-developed or rebranded under Coherent—are being enhanced with smart diagnostics, predictive maintenance, and real-time process control. This shift supports higher throughput and quality compliance, particularly in high-mix, low-volume manufacturing environments such as medical devices and aerospace.

3. Advancements in Multi-Mode and Single-Mode Fiber Lasers

Technological improvements in laser sources are enhancing the capabilities of Rofin-originated systems. Newer multi-kilowatt single-mode fiber lasers (up to 6 kW) enable deeper penetration and narrower welds with minimal heat input—ideal for lightweight materials used in aerospace and EVs. These advancements allow Rofin-based solutions to compete more effectively with emerging Chinese laser brands while maintaining a premium positioning in precision markets.

4. Regional Shifts in Manufacturing and Supply Chain Localization

Geopolitical factors and supply chain resilience strategies are driving reshoring and nearshoring of manufacturing, especially in semiconductors, defense, and medical technology. In the U.S. and EU, incentives like the Inflation Reduction Act (IRA) and European Chips Act are fostering domestic production, increasing the need for advanced laser welding systems. Coherent, as the parent company, is leveraging Rofin’s established product lines to capture this localized demand with region-specific support and service networks.

5. Competitive Pressure and Market Consolidation

The industrial laser market remains highly competitive, with Chinese manufacturers such as Raycus and Max Photonics offering lower-cost alternatives. However, Rofin’s legacy of engineering excellence and integration with Coherent’s broader photonics ecosystem (including beam delivery, software, and application expertise) allows it to maintain a strong foothold in high-precision, mission-critical applications where reliability outweighs upfront cost.

6. Sustainability and Energy Efficiency Focus

Manufacturers are increasingly evaluating equipment based on energy efficiency and total cost of ownership. Rofin’s disk and fiber lasers, known for high wall-plug efficiency (up to 40% in newer models), align with corporate sustainability goals. By 2026, energy-efficient laser systems are becoming a differentiating factor in procurement decisions, especially in regulated industries.

Outlook for Rofin Laser Welders in 2026

While the Rofin brand is being gradually phased into the Coherent portfolio, the underlying technology remains influential. In 2026, systems derived from Rofin’s laser welding platforms are expected to play a key role in high-growth, high-precision markets. Their integration into automated, data-connected factories—combined with ongoing innovation in beam quality and process control—positions them as essential tools in next-generation manufacturing. Success will depend on Coherent’s ability to maintain Rofin’s reputation for quality while scaling support and digital capabilities globally.

Common Pitfalls When Sourcing a Rofin Laser Welder: Quality and Intellectual Property Risks

Sourcing a Rofin laser welder—especially used or third-party equipment—can present significant challenges related to quality assurance and intellectual property (IP) protection. Being aware of these pitfalls is crucial for ensuring a reliable, legal, and efficient acquisition.

Quality-Related Pitfalls

1. Counterfeit or Refurbished Units Sold as New

A major risk is purchasing a counterfeit, poorly refurbished, or misrepresented Rofin laser system. Unscrupulous sellers may present used, damaged, or knock-off units as genuine new equipment. These systems often lack proper calibration, fail prematurely, and may not meet safety standards, leading to costly downtime and repair expenses.

2. Lack of Genuine Spare Parts and Support

Rofin lasers require precise components for maintenance and repairs. Sourcing non-OEM (original equipment manufacturer) parts—whether from unauthorized vendors or gray-market suppliers—can compromise system performance, longevity, and warranty eligibility. Genuine parts ensure compatibility and reliability, whereas counterfeit or inferior parts may lead to system failure.

3. Inadequate Documentation and Service History

Used Rofin welders may come without complete service records, calibration certificates, or original manuals. This lack of documentation makes it difficult to assess the machine’s condition, verify maintenance history, or obtain technical support from authorized service providers. Poor maintenance history can hide underlying issues that surface after purchase.

4. Obsolete or Unsupported Models

Rofin (now part of TRUMPF) may discontinue support for older models, making spare parts and software updates unavailable. Purchasing an outdated system can lead to long-term operational risks, including reduced efficiency, inability to integrate with modern production systems, and lack of technical support.

Intellectual Property (IP) Risks

1. Unauthorized Use of Rofin/TRUMPF Trademarks and Technology

Some third-party vendors may illegally use the Rofin brand name, logos, or technical specifications to market non-genuine or reverse-engineered equipment. This not only misleads buyers but also exposes them to legal liability for using or distributing counterfeit machinery that infringes on TRUMPF’s intellectual property rights.

2. Software Licensing and Firmware Violations

Rofin laser systems often include proprietary control software and firmware protected by licensing agreements. Unauthorized duplication, modification, or transfer of this software—common in unverified resales—constitutes copyright infringement. Buyers may unknowingly acquire systems with pirated or tampered software, risking legal action and operational instability.

3. Risk of Reverse-Engineered or Clone Systems

Some suppliers offer “compatible” or “Rofin-style” laser welders that mimic genuine models but are built using reverse-engineered designs. These clones may violate patents and design rights held by TRUMPF. Purchasing such equipment can expose the buyer to IP infringement claims, especially in regulated industries or international markets.

4. Lack of Legal Recourse in Case of IP Disputes

If a sourced laser welder is found to violate IP laws, the original purchaser may face legal action, customs seizures (in cross-border transactions), or forced decommissioning of the equipment. Unlike purchases from authorized dealers, third-party or gray-market acquisitions often provide no legal protection or indemnification in such scenarios.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Purchase exclusively through authorized TRUMPF/Rofin distributors or certified resellers.

– Verify equipment authenticity using serial numbers and official documentation.

– Request complete service history, calibration records, and original software licenses.

– Consult legal counsel when acquiring used or international equipment to assess IP compliance.

– Avoid deals that seem too good to be true—significantly low prices may indicate counterfeit or illegal equipment.

By carefully vetting sources and prioritizing authenticity, buyers can mitigate both quality issues and intellectual property risks when sourcing Rofin laser welding systems.

Logistics & Compliance Guide for Rofin Laser Welder

This guide outlines the essential logistics and compliance considerations for the safe and legal transport, handling, installation, and operation of a Rofin Laser Welder. Adherence to these guidelines ensures personnel safety, regulatory compliance, and equipment integrity.

Shipping and Transportation

Ensure the Rofin Laser Welder is securely packed in its original manufacturer crate or a custom-built shipping container designed to withstand vibration and shock. Use certified freight carriers experienced in handling precision industrial equipment. Confirm that all external components (e.g., chiller units, control cabinets) are properly secured and labeled. Maintain a detailed packing list and bill of lading. For international shipments, verify compliance with export controls (e.g., EAR/ITAR, if applicable) and obtain necessary documentation such as a commercial invoice, packing list, and certificate of origin.

Import and Customs Compliance

Review destination country regulations regarding industrial laser systems. Verify if the Rofin Laser Welder requires import permits, pre-shipment inspections, or conformity assessments (e.g., CE, UKCA, or other regional certifications). Ensure Harmonized System (HS) code classification is accurate to determine applicable tariffs and duties. For shipments to the EU, confirm that the equipment meets CE marking requirements under the Machinery Directive (2006/42/EC) and the Laser Product Safety standard (IEC 60825-1). Retain all compliance documentation for customs clearance.

Site Preparation and Receiving

Prepare the installation site according to Rofin’s technical specifications, including floor loading capacity, power supply (voltage, phase, grounding), cooling requirements, and ventilation. Ensure adequate space for safe operation and maintenance access. Upon delivery, inspect the packaging for damage before accepting the shipment. Document any visible damage with photographs and notify the carrier and supplier immediately. Retain shipping materials until the equipment is fully inspected and commissioned.

Installation and Commissioning

Installation must be performed by qualified personnel following the manufacturer’s installation manual. Verify all electrical, pneumatic, and coolant connections comply with local codes and Rofin specifications. Conduct a safety interlock and emergency stop test during commissioning. Ensure the laser safety enclosure (if applicable) is fully operational and interlocked. A certified laser safety officer (LSO) should verify compliance with ANSI Z136.1 (or local equivalent) before operation begins.

Regulatory and Safety Compliance

The Rofin Laser Welder must comply with applicable laser safety standards, including but not limited to IEC 60825-1 and ANSI Z136.1. The system must be classified appropriately (typically Class 1 or Class 4 depending on configuration) and labeled with required warning signs. Implement engineering controls such as protective enclosures, interlocks, and beam shutters. Provide appropriate personal protective equipment (PPE), including laser safety eyewear with the correct optical density for the laser wavelength. Maintain a laser safety program, including training, standard operating procedures, and periodic audits.

Environmental and Waste Management

Dispose of consumables (e.g., lenses, nozzles) and coolant according to local environmental regulations. Used laser optics may contain hazardous coatings and should be handled as electronic or hazardous waste where required. Ensure coolant discharge (if any) complies with wastewater discharge standards. Maintain records of waste disposal for compliance audits.

Documentation and Recordkeeping

Retain all compliance-related documents, including the Declaration of Conformity, user manuals, safety certifications, installation records, maintenance logs, laser safety training records, and incident reports. These records are essential for regulatory inspections and insurance purposes.

Ongoing Compliance and Maintenance

Schedule regular preventive maintenance in accordance with Rofin’s recommended service intervals. Document all maintenance and repairs. Recertify laser safety systems annually or as required by local regulations. Update the laser safety program as equipment configurations or operational processes change.

Conclusion for Sourcing a Rofin Laser Welder

After a thorough evaluation of technical requirements, supplier reliability, cost considerations, and long-term operational needs, sourcing a Rofin laser welder presents a strategic and viable solution for achieving high-precision, reliable, and efficient welding capabilities. Rofin, as a well-established brand in the laser technology industry, offers advanced engineering, consistent performance, and strong technical support, making their laser welding systems suitable for demanding applications in industries such as automotive, aerospace, and medical device manufacturing.

While the initial investment in a Rofin laser welder may be higher compared to alternative options, the long-term benefits—such as reduced maintenance costs, high uptime, excellent beam quality, and energy efficiency—justify the procurement decision. Additionally, the availability of service agreements, spare parts, and expert training ensures continued operational excellence and minimal downtime.

In conclusion, sourcing a Rofin laser welder aligns with our goals of quality, productivity, and technological advancement. It is recommended to proceed with procurement, ensuring due diligence in finalizing configurations, warranties, and post-sales support to maximize return on investment and operational synergy.