The global ornamental fencing market, driven by rising demand for durable and aesthetically pleasing perimeter security solutions in residential, commercial, and industrial sectors, is experiencing steady growth. According to Grand View Research, the global fencing market was valued at USD 68.5 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A key segment within this market—wrought iron and forged steel fencing—continues to gain traction due to its longevity, architectural appeal, and high perceived value. With urbanization and infrastructure development accelerating worldwide, particularly across North America, Europe, and parts of Asia-Pacific, demand for high-quality wrought iron fence components—including posts, rails, spindles, and decorative finials—is on the rise. This growing demand has elevated the importance of reliable manufacturers capable of producing precision-engineered, corrosion-resistant parts at scale. Based on market presence, production capacity, innovation in design and materials, and global distribution reach, the following ten companies stand out as leading manufacturers of wrought iron fence parts today.

Top 10 Rod Iron Fence Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 2022

Website: davidiron.com

Key Highlights: David Iron Fence Manufacturer Inc. is a trusted manufacturer and distributor of wrought iron fences, gates, and railings across the United States. We combine ……

#2 Master Halco

Domain Est. 1996

Website: masterhalco.com

Key Highlights: Master Halco is your leading manufacturer and wholesale distributor of fencing & decking products across the US and Canada….

#3 Aluminum Fence

Domain Est. 1998

Website: ultrafence.com

Key Highlights: Our complete line of low-maintenance aluminum fencing products brings the traditional look of wrought-iron fence to Residential, Commercial and Industrial ……

#4 Wrought Iron Fence Parts

Domain Est. 1999

Website: industrialmetalsupply.com

Key Highlights: 30-day returnsDecorative wrought iron supplies are manufactured from premium materials and include ornamental handrails, spears, rails, twisted bar, balusters, and more….

#5 Orleans Ornamental Iron & Casting Distributors, Inc.

Domain Est. 2000 | Founded: 1974

Website: orleansornamental.com

Key Highlights: One stop supply house for all your ornamental iron needs. Serving america’s Fabricator, since 1974, quality castings, steel forgings & top of the line ……

#6 Iron World Fencing

Domain Est. 2005

Website: ironworldfencing.com

Key Highlights: The fastest-growing manufacturer and distributor of decorative and ornamental iron fencing, aluminum fencing, chain link, slide, and swing gates nationwide….

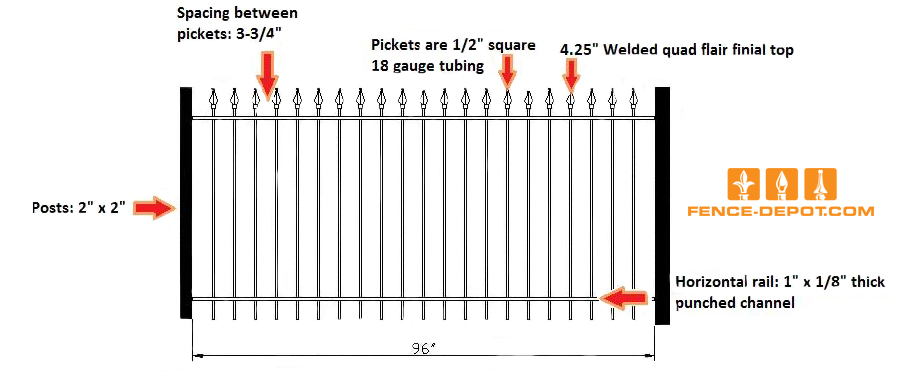

#7 Fence Depot

Domain Est. 2002

Website: fence-depot.com

Key Highlights: We sell aluminum fence, wrought iron fence, and more directly to homeowners and contractors who are looking for high quality fence, railing and gate products ……

#8 Iron Fence Shop

Domain Est. 2009

Website: ironfenceshop.com

Key Highlights: Premium wrought iron & aluminum metal fences. Over 60 years of combined industry experience. Free shipping over $5000 with 25-year warranty. Call now!…

#9 Steel & Wrought Iron Fence

Domain Est. 2012

Website: alekoproducts.com

Key Highlights: Free deliveryOur wrought iron style & steel fences are rust-proof and powder coated to prevent chips, peeling or cracks. Ship premium metal fencing directly to ……

#10 Ironrod Steel Co.

Domain Est. 2020

Expert Sourcing Insights for Rod Iron Fence Parts

H2: 2026 Market Trends for Wrought Iron Fence Parts

The market for wrought iron fence parts is poised for notable transformation by 2026, driven by evolving consumer preferences, technological advancements, and shifts in construction dynamics. As urbanization continues and homeowners increasingly prioritize security, aesthetics, and durability, wrought iron remains a preferred material despite competition from alternatives like aluminum and vinyl.

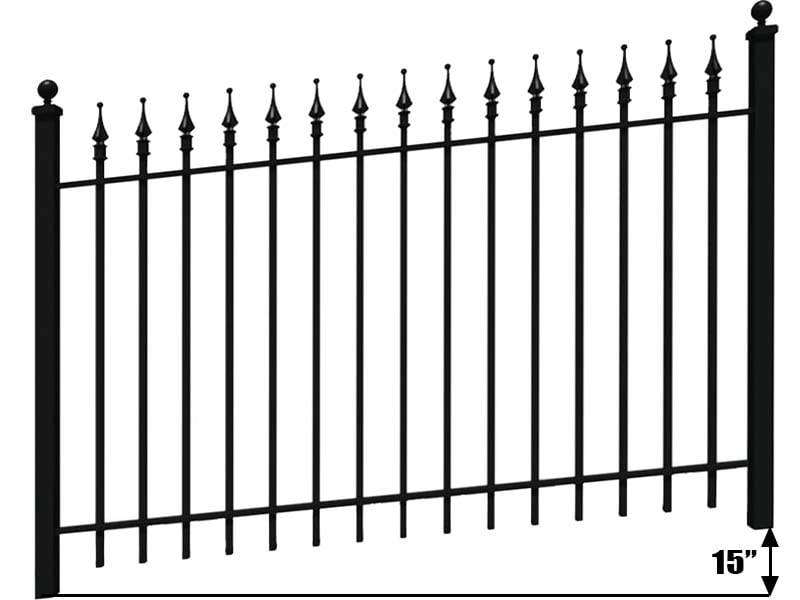

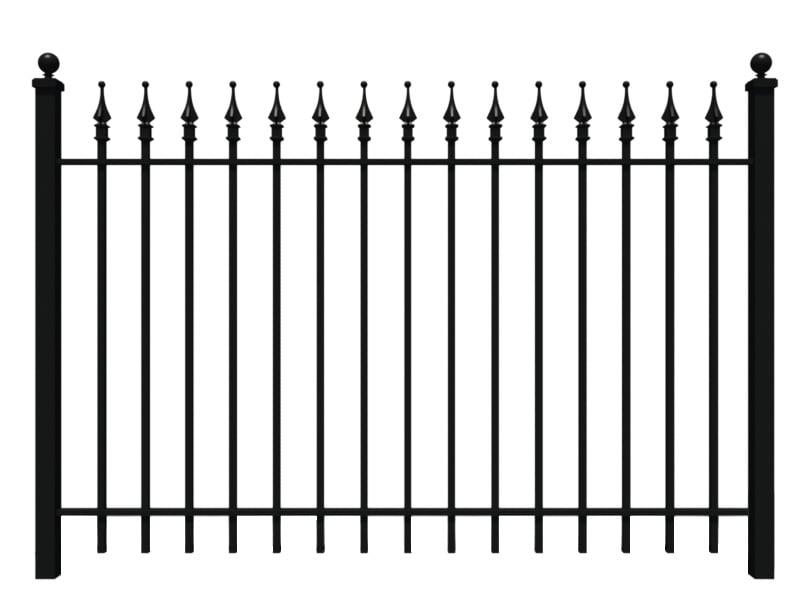

One key trend shaping the 2026 market is the growing demand for customizable and ornamental designs. Homeowners and commercial developers are seeking unique, artisanal touches in fencing systems, favoring wrought iron for its malleability and classic elegance. This has led to a rise in demand for modular wrought iron fence parts—such as pickets, finials, posts, and rails—that allow for easy assembly and design flexibility without sacrificing craftsmanship.

Another significant trend is the integration of smart security features. By 2026, many wrought iron fence systems are expected to incorporate smart technologies, such as embedded sensors, access control integration, and surveillance compatibility. Manufacturers are responding by designing fence parts that accommodate wiring and hardware for these technologies while maintaining the traditional visual appeal of wrought iron.

Sustainability and material innovation are also influencing the market. While wrought iron is inherently durable and recyclable, producers are investing in eco-friendly coatings and rust-resistant treatments to extend product lifespans and reduce environmental impact. Powder-coated finishes in a wide array of colors are becoming standard, offering both protection and design versatility.

Regionally, North America and Europe are expected to maintain strong demand due to residential renovation activity and heritage preservation projects. Meanwhile, emerging markets in Asia-Pacific and the Middle East are showing increasing interest in wrought iron for high-end residential and commercial developments.

Lastly, supply chain resilience and automation in manufacturing are expected to play a crucial role in 2026. With rising labor costs and material volatility, manufacturers are adopting robotic welding and precision cutting to produce consistent, high-quality fence components more efficiently.

In summary, the 2026 market for wrought iron fence parts will be characterized by a blend of tradition and innovation—where timeless design meets modern functionality, customization, and sustainability.

Common Pitfalls When Sourcing Ductile Iron Fence Parts (Quality, IP)

Sourcing ductile iron fence parts—such as posts, caps, bases, and connectors—requires careful attention to both material quality and intellectual property (IP) considerations. While ductile iron is valued for its strength and durability, several pitfalls can compromise project integrity, increase costs, or expose buyers to legal risks. Below are key challenges to watch for.

Inconsistent Material Quality

One of the most common issues when sourcing ductile iron components is variability in material quality. Inferior casting processes, substandard alloys, or poor heat treatment can lead to brittle, weak, or corroding parts. Buyers may receive components that fail under stress or degrade prematurely when exposed to weather.

- Low-Grade Alloys: Some suppliers may use recycled or off-spec iron that doesn’t meet ASTM A536 standards, the benchmark for ductile iron mechanical properties.

- Porosity and Inclusions: Poor casting techniques can introduce air pockets or slag inclusions, weakening structural integrity.

- Inadequate Coatings: Insufficient or improperly applied protective coatings (e.g., zinc galvanizing or powder coating) reduce corrosion resistance.

Lack of Quality Control and Certification

Many suppliers, especially overseas manufacturers, lack rigorous quality assurance programs. Without proper inspection protocols, non-conforming parts may be shipped.

- Missing Test Reports: Reputable suppliers provide material test reports (MTRs) and certification to confirm compliance with industry standards.

- No In-Process Inspections: Without documented inspections during production, defects may go undetected until installation.

Intellectual Property (IP) Infringement Risks

Architectural fence designs—especially ornamental or custom styles—often involve patented or copyrighted elements. Sourcing generic or replica parts can expose buyers and contractors to legal liability.

- Design Patent Violations: Using look-alike components that mimic patented designs (e.g., unique scrollwork or baluster patterns) may constitute infringement.

- Brand Imitation: Some suppliers produce knock-offs of well-known brands (e.g., reproductions of Estate Collection or other trademarked designs), risking trademark violations.

- Unauthorized Tooling: Molds or patterns may be copied without the original designer’s permission, leading to IP disputes.

Supply Chain and Traceability Issues

Without full traceability, it becomes difficult to verify material origin, production methods, or compliance with regulatory standards.

- Opaque Manufacturing Sources: Suppliers may subcontract to unvetted foundries with questionable practices.

- No Lot Traceability: If a defect emerges, the inability to trace components to a production batch complicates recalls or claims.

Mitigation Strategies

To avoid these pitfalls:

- Require Certification: Insist on ASTM A536 compliance and material test reports.

- Audit Suppliers: Conduct on-site or third-party audits of manufacturing facilities.

- Verify IP Status: Confirm that designs are either licensed, in the public domain, or original.

- Use Reputable Partners: Work with established suppliers known for quality and ethical sourcing.

- Include IP Clauses in Contracts: Ensure suppliers warrant that products do not infringe on third-party rights.

By addressing both quality and IP concerns proactively, buyers can ensure durable, compliant, and legally sound installations.

Logistics & Compliance Guide for Rod Iron Fence Parts

Product Classification and HS Codes

Rod iron fence parts are typically classified under the Harmonized System (HS) for international trade. The most common HS code is 7308.90, which covers “Framed prefabricated buildings and structural elements thereof, of iron or steel, n.e.s.” Specific components such as posts, rails, pickets, or brackets may fall under subcategories within Chapter 73 (Articles of Iron or Steel). Confirm the exact HS code with your customs broker or national tariff schedule to ensure accurate classification and duty assessment.

Packaging and Handling Requirements

Proper packaging is essential to prevent damage during transit. Rod iron fence parts should be:

– Bundled securely using rust-resistant strapping or shrink-wrapping.

– Protected with edge guards or corner protectors on sharp edges.

– Stored and transported in a dry environment to prevent oxidation.

– Labeled clearly with product description, part numbers, quantity, and handling instructions (e.g., “Do Not Stack,” “Fragile – Handle with Care”).

For international shipments, use pallets compliant with ISPM 15 standards if wood is involved.

Transportation and Freight Considerations

- Mode of Transport: Rod iron parts are commonly shipped via flatbed trucks domestically and containerized (20’ or 40’ dry containers) internationally. Oversized or long items may require specialized freight.

- Weight and Dimensions: Accurate measurement of weight and volume is critical for freight cost calculation and load planning.

- Load Securing: Use load bars, straps, and dunnage to prevent shifting during transit, especially for bulk shipments.

- Lead Times: Account for manufacturing, packaging, customs clearance, and transportation when planning delivery schedules.

Import/Export Documentation

Ensure all required documentation is complete and accurate:

– Commercial Invoice (with detailed description, value, and HS code)

– Packing List (itemized per package)

– Bill of Lading (for sea freight) or Air Waybill (for air freight)

– Certificate of Origin (may be required for preferential tariffs)

– Import/Export License (if applicable based on country regulations)

For U.S. imports, submit entry documentation to U.S. Customs and Border Protection (CBP), including the ISF (Importer Security Filing) 24 hours prior to vessel loading.

Regulatory Compliance

- Safety Standards: Rod iron fence parts must comply with local building codes and safety standards (e.g., ASTM standards in the U.S. for structural integrity and corrosion resistance).

- Environmental Regulations: Coated or galvanized parts may be subject to REACH (EU) or TSCA (U.S.) regulations regarding hazardous substances.

- Customs Duties and Taxes: Importers are responsible for payment of applicable duties, VAT, or GST based on the declared value and classification.

- Anti-Dumping Measures: Be aware of any anti-dumping or countervailing duties on steel products from certain countries.

Storage and Inventory Management

- Store in a dry, covered area to prevent rust and moisture damage.

- Elevate materials off the ground using pallets or racks.

- Implement a first-in, first-out (FIFO) inventory system to minimize aging and corrosion risks.

- Conduct regular inspections for signs of degradation, especially for galvanized or powder-coated finishes.

Returns and Reverse Logistics

Establish clear policies for damaged or incorrect shipments:

– Require photographic evidence and documentation within 48 hours of delivery.

– Use return material authorization (RMA) numbers to track and process returns.

– Coordinate carrier pickups or provide return shipping labels as needed.

Inspect returned items promptly and determine disposition (repair, replace, scrap).

Sustainability and Disposal

- Recycle scrap or damaged rod iron through certified metal recyclers.

- Follow local environmental guidelines for disposal of packaging materials (e.g., plastic wraps, wood pallets).

- Consider using recycled-content steel in manufacturing to meet sustainability goals.

Key Contacts and Resources

- Customs Broker: For classification and clearance support

- Freight Forwarder: For end-to-end logistics coordination

- Regulatory Agencies: U.S. CBP, EU Customs, local trade authorities

- Industry Standards: ASTM International, ISO, EN standards for metal products

Maintaining compliance and efficient logistics ensures timely delivery, cost control, and customer satisfaction for rod iron fence part operations.

In conclusion, sourcing wrought iron fence parts requires careful consideration of quality, durability, supplier reliability, and cost-effectiveness. By evaluating materials, verifying craftsmanship, and selecting reputable suppliers—whether local fabricators or established online vendors—buyers can ensure they obtain components that meet both aesthetic and structural requirements. Additionally, factoring in customization options, lead times, and long-term maintenance will contribute to a successful installation and lasting value. Ultimately, a well-informed sourcing strategy enhances the overall performance and appearance of the wrought iron fence, providing security, elegance, and longevity for years to come.