The global automotive aftermarket continues to experience robust expansion, driven by increasing vehicle production, rising maintenance demand, and technological advancements in engine components. According to a 2023 report by Mordor Intelligence, the global automotive aftermarket valves market is projected to grow at a CAGR of over 4.8% from 2023 to 2028, fueled by heightened consumer focus on engine performance and efficiency. Rocker valve covers—critical components in protecting valvetrain systems from contaminants while maintaining proper oil circulation—are witnessing growing demand across OEM and replacement segments. As emissions regulations tighten and engine designs become more compact, manufacturers are prioritizing high-quality, durable rocker valve covers that support optimal engine performance. This increasing demand has elevated the prominence of leading global manufacturers who combine innovation, material integrity, and precision engineering. Based on market presence, product quality, and industry reputation, we’ve identified the top seven rocker valve cover manufacturers shaping the future of engine component performance.

Top 7 Rocker Valve Cover Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Jesel Valvetrain

Domain Est. 1997

Website: jesel.com

Key Highlights: The Great American Valvetrain Company. Jesel is a premium valvetrain parts manufacturer specializing in Rocker Arms, Roller Lifters, Belt Drives, ……

#2 Engine Valve Cover

Domain Est. 2013

Website: sdzcn.com

Key Highlights: Rating 4.4 (5) Our auto valve cover on engine can be made of plastic or aluminium alloy. Providing Alloy Rocker Cover, SDZ is Your Best Choice!…

#3 Briggs & Stratton OEM Rocker Covers

Domain Est. 2015

Website: briggsstrattonstore.com

Key Highlights: 3–5 day delivery 30-day returnsThese OEM rocker covers are designed to perfectly fit your engine, preventing oil leaks and ensuring optimal performance. Rocker Covers for ……

#4 Rocker Cover Gasket

Domain Est. 2016

Website: oilseal-tw.com

Key Highlights: Lian Yun rocker cover gasket is designed to help seal the joint between the rocker cover and the rest of the engine. The valve cover gasket also can keep in ……

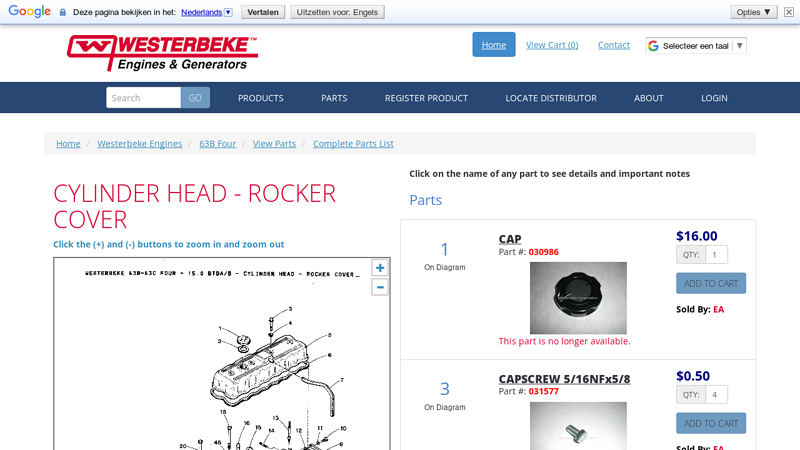

#5 CYLINDER HEAD

Domain Est. 1996

#6 Valve Covers – Rocker Box

Domain Est. 1999

Website: garimaglobal.com

Key Highlights: Rating 5.0 (5) Made of a variety of plastics or sheet metal, rocker covers are bolted on to the engine block to cover the rocker arm assembly and protect it from dirt….

#7 CFR Performance Compatible/Replacement Chevy GM LS …

Domain Est. 2002

Expert Sourcing Insights for Rocker Valve Cover

H2: Projected 2026 Market Trends for Rocker Valve Covers

The global market for rocker valve covers is anticipated to experience steady growth by 2026, driven by advancements in automotive engineering, rising demand for fuel-efficient vehicles, and the expansion of the aftermarket industry. Key trends shaping the rocker valve cover market include material innovation, integration with emission control systems, and regional shifts in manufacturing and consumption.

1. Material Innovation and Lightweighting

A dominant trend through 2026 will be the shift from traditional cast iron and steel to lightweight composite materials such as reinforced polymers and aluminum alloys. Automakers are increasingly adopting these materials to reduce engine weight and improve fuel economy, aligning with global emissions regulations. Rocker valve covers made from advanced thermoplastics offer durability, heat resistance, and noise reduction, making them favorable in both OEM and aftermarket segments.

2. Emission Standards and Engine Design Evolution

Stricter environmental regulations, particularly in North America, Europe, and China, are pushing engine manufacturers to optimize internal combustion engines (ICE). Rocker valve covers are being redesigned to integrate with positive crankcase ventilation (PCV) systems and oil mist separators, helping reduce hydrocarbon emissions. By 2026, demand is expected to rise for covers with built-in filtration and emission control features, especially in turbocharged and direct-injection engines.

3. Growth in the Automotive Aftermarket

The aftermarket segment is projected to account for a significant share of the rocker valve cover market by 2026. Aging vehicle fleets, increased vehicle longevity, and rising DIY maintenance trends are fueling demand for replacement parts. Online retail platforms and e-commerce expansion are making it easier for consumers to access high-quality aftermarket rocker valve covers, boosting market penetration.

4. Regional Market Dynamics

Asia-Pacific, led by China and India, is expected to be the fastest-growing region due to expanding automotive production and rising vehicle ownership. North America and Europe will maintain strong demand, supported by stringent emission norms and a mature aftermarket. Meanwhile, OEMs in emerging markets are increasingly localizing component production, creating opportunities for regional suppliers.

5. Impact of Electric Vehicles (EVs)

While the rise of electric vehicles may eventually reduce long-term demand for ICE components, the transition remains gradual. Through 2026, internal combustion and hybrid vehicles will continue to dominate global fleets, ensuring sustained demand for rocker valve covers. Moreover, hybrid engines still require traditional valve train components, preserving market relevance.

In conclusion, the rocker valve cover market in 2026 will be shaped by material advancements, regulatory pressures, and strong aftermarket demand. Manufacturers who innovate in design, sustainability, and integration will be best positioned to capture growth in this evolving landscape.

Common Pitfalls Sourcing Rocker Valve Covers (Quality, IP)

When sourcing rocker valve covers, overlooking critical quality and intellectual property (IP) considerations can lead to significant operational, legal, and financial risks. Below are common pitfalls to avoid:

Poor Material Quality and Durability

Sourcing low-grade materials such as substandard aluminum alloys or inferior plastic composites can result in premature cracking, warping, or oil leaks. These failures compromise engine performance and increase long-term maintenance costs. Always verify material specifications (e.g., ASTM standards) and request material test reports (MTRs) from suppliers.

Inadequate Sealing Performance

A common quality issue is improper gasket integration or flange surface finish, leading to oil seepage. Suppliers may cut corners on machining tolerances or use incompatible gasket materials. Ensure the valve cover meets OEM sealing specifications and conduct leak testing under simulated operating conditions.

Non-Compliance with IP Rights

Procuring rocker valve covers from unauthorized manufacturers or counterfeit sources risks infringing on patented designs or trademarked branding (e.g., OEM logos). This exposes your business to legal action, product seizures, and reputational damage. Always source from licensed suppliers and request proof of IP authorization or design rights.

Lack of OEM Certification or Testing Validation

Many aftermarket covers lack proper validation through OEM testing protocols (e.g., pressure cycling, thermal durability). Without certifications like ISO/TS 16949 or IATF 16949, you cannot guarantee reliability. Insist on test data and compliance documentation prior to bulk procurement.

Inconsistent Dimensional Accuracy

Poorly manufactured covers may have misaligned bolt holes or incorrect clearance for ignition components, causing fitment issues. Variability often stems from inconsistent tooling or lack of quality control. Require first-article inspections (FAI) and coordinate measuring machine (CMM) reports.

Hidden Costs from Short-Term Savings

Choosing the cheapest option often leads to higher total cost of ownership due to frequent replacements and engine downtime. Invest in higher-quality covers with proven reliability, even at a higher initial cost.

Avoiding these pitfalls requires due diligence in supplier qualification, rigorous quality audits, and strict adherence to IP compliance protocols.

Logistics & Compliance Guide for Rocker Valve Cover

This guide outlines the essential logistics and compliance considerations for the transportation, handling, and regulatory adherence related to Rocker Valve Covers—critical components in internal combustion engines used across automotive, industrial, and aftermarket sectors.

Product Classification & Documentation

Ensure accurate classification of the Rocker Valve Cover for international trade. Typically classified under HS Code 8409.91 (Parts suitable for use solely or principally with internal combustion piston engines). Confirm country-specific tariff classifications. Required documentation includes commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. Provide detailed product specifications, material composition (e.g., aluminum alloy, stamped steel), and intended use to avoid customs delays.

Packaging & Handling Requirements

Package Rocker Valve Covers to prevent damage during transit. Use corrugated cardboard boxes with internal dividers or foam inserts to avoid surface scratches or deformation. For bulk shipments, employ reusable containers or palletized loads secured with stretch wrap. Clearly label packages with part numbers, quantity, weight, and handling instructions (e.g., “Fragile,” “Do Not Stack”). Avoid exposure to moisture and extreme temperatures during storage and transport.

Transportation & Shipping Modes

Choose appropriate shipping mode based on volume, urgency, and destination. Air freight is ideal for urgent, low-volume orders; ocean freight is cost-effective for bulk shipments. Ensure compliance with carrier-specific regulations, including weight and dimension limits. For international shipments, confirm Incoterms® (e.g., FOB, EXW, DDP) to define responsibility for logistics and risk transfer. Utilize trackable shipping services for supply chain visibility.

Regulatory Compliance

Adhere to regional and international regulations. In the U.S., comply with EPA and DOT standards if shipped by motor carrier. For the EU, ensure conformity with REACH (registration, evaluation, authorization, and restriction of chemicals) and RoHS (restriction of hazardous substances) directives, particularly regarding coatings or plating materials. If exported from the U.S., follow EAR (Export Administration Regulations); licenses may be required for certain destinations or end-uses.

Import/Export Controls

Verify export licensing requirements based on destination country and end-user. Rocker Valve Covers are generally classified as EAR99, meaning they don’t require a license for most destinations unless destined for embargoed countries (e.g., Iran, North Korea) or military end-uses. Conduct end-user screening to comply with sanctions lists (e.g., OFAC, BIS). Maintain records of export transactions for a minimum of five years.

Environmental & Safety Considerations

Dispose of packaging materials according to local environmental regulations. If the valve cover contains residual oils or lubricants from testing, classify and transport as hazardous material under IATA/IMDG/ADR as applicable. Train warehouse and logistics personnel in proper handling and spill response. Implement waste reduction strategies such as recyclable packaging and returnable containers.

Quality Assurance & Traceability

Maintain traceability through batch/lot numbering and serialization where required. Ensure compliance with ISO 9001 or IATF 16949 quality management standards in manufacturing and distribution. Conduct regular audits of logistics partners to verify storage conditions and handling practices. Retain shipping records and inspection reports to support warranty claims or recalls.

Aftermarket & Reverse Logistics

Establish a returns process for defective or incorrect parts. Use return material authorization (RMA) systems to track and inspect returned valve covers. Refurbish or dispose of non-conforming units in compliance with environmental regulations. Optimize reverse logistics to reduce costs and improve customer satisfaction in aftermarket operations.

Conclusion for Sourcing Rocker Valve Cover:

After a thorough evaluation of suppliers, technical specifications, cost considerations, quality standards, and lead times, sourcing the rocker valve cover has been concluded with the selection of a reliable and capable vendor that meets all critical requirements. The chosen supplier demonstrates strong manufacturing capabilities, adherence to industry standards (such as ISO/TS certifications), and a proven track record in delivering durable, high-performance engine components.

Key factors supporting this conclusion include competitive pricing, consistent material and workmanship quality (e.g., aluminum alloy construction with proper surface finishing), compliance with OEM specifications, and responsive logistical support. Additionally, the supplier has shown flexibility in scaling production volumes and providing after-sales service, which enhances supply chain resilience.

In summary, the sourcing strategy for the rocker valve cover successfully balances cost-efficiency, quality assurance, and long-term supply continuity. Ongoing supplier performance monitoring and periodic quality audits are recommended to maintain standards and support continuous improvement.