The global robotic arm 3D printing market is experiencing robust expansion, driven by increasing demand for automation, precision, and production efficiency across industries such as automotive, aerospace, healthcare, and consumer goods. According to a report by Mordor Intelligence, the global 3D printing market was valued at USD 16.5 billion in 2022 and is projected to grow at a CAGR of over 21% from 2023 to 2028, with industrial automation fueling adoption of integrated robotic arm 3D printers. Similarly, Grand View Research highlights that the global collaborative robotics market—closely linked to robotic 3D printing systems—is expected to expand at a CAGR of 34.5% from 2023 to 2030, underpinned by rising investments in smart manufacturing and Industry 4.0 initiatives. As additive manufacturing shifts from prototyping to full-scale production, manufacturers are increasingly integrating robotic arms with 3D printing capabilities to enable scalable, multi-axis fabrication with enhanced flexibility. This convergence of robotics and additive manufacturing has given rise to a new generation of innovative players pioneering advanced solutions. Below, we highlight the top 9 robotic arm 3D printer manufacturers at the forefront of this technological evolution.

Top 9 Robotic Arm 3D Printer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 MX3D

Domain Est. 2002

Website: mx3d.com

Key Highlights: Industrial‑scale Metal 3D Printing with robotic WAAM (Wire Arc Additive Manufacturing), part of the DED (Directed Energy Deposition) family….

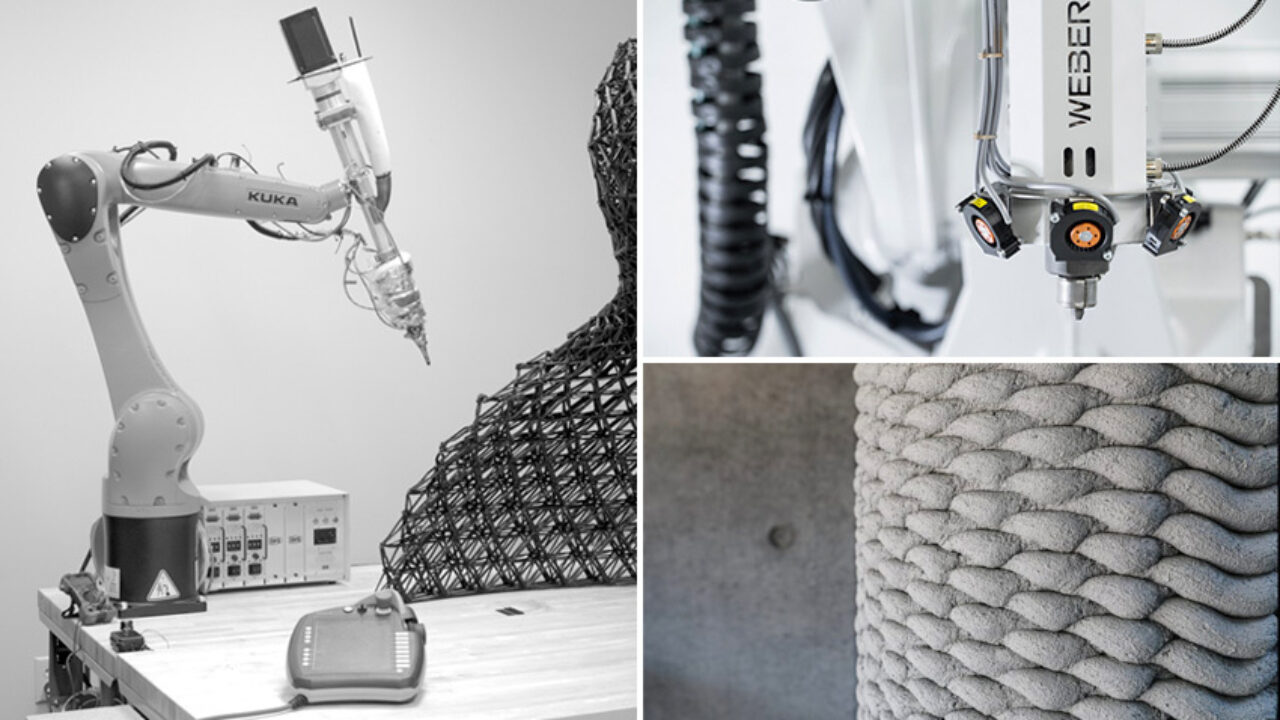

#2 Robotic arm 3D printing

Domain Est. 2017

Website: 3dwasp.com

Key Highlights: CEREBRO is a state-of-the-art system that allows robotic arms to be transformed into a 3D printer. Compliant to Industry 4.0 technology, it can collaborate ……

#3 Meltio Robot Cell

Domain Est. 2019

Website: meltio3d.com

Key Highlights: Allows the customer to receive a ready to use cell for robotic metal 3D printing. Tier-1 industrial hardware. Built with best-in-class robotic arms and laser- ……

#4 Advanced Manufacturing Solutions

Domain Est. 2019

Website: caracol-am.com

Key Highlights: Lead the future of manufacturing thanks to Caracol’s 3D printing technologies. Discover our solutions for industrial, Large Format Additive Manufacturing….

#5 ABB Robotics

Domain Est. 1990

Website: abb.com

Key Highlights: ABB Robotics leads in robotics and automation with integrated robots, AMRs, and software, helping industries boost resilience and efficiency….

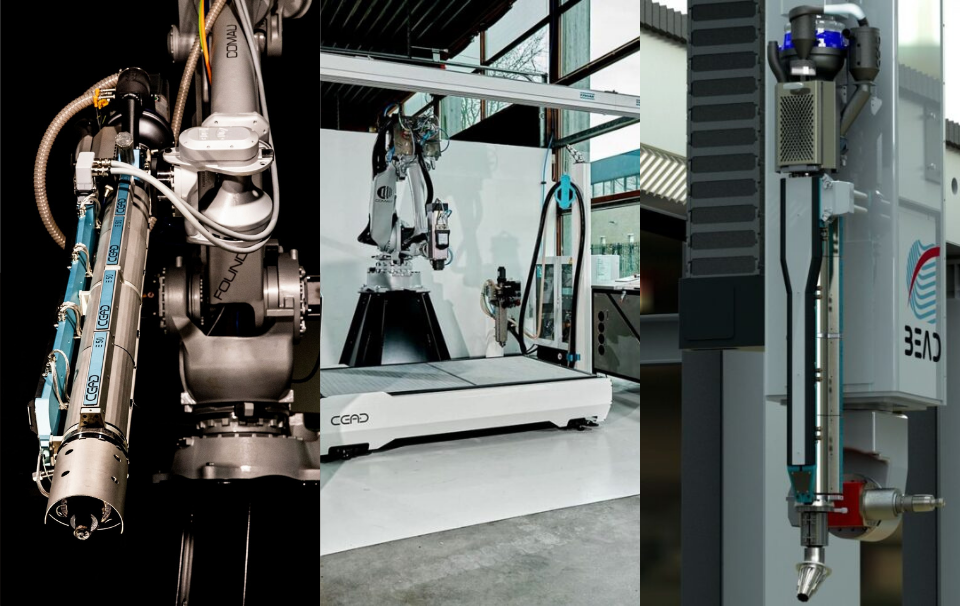

#6 CEAD B.V.

Domain Est. 2014

Website: ceadgroup.com

Key Highlights: CEAD develops and manufactures large format 3D printers. We help our customers with a successful implementation of large scale 3D printing….

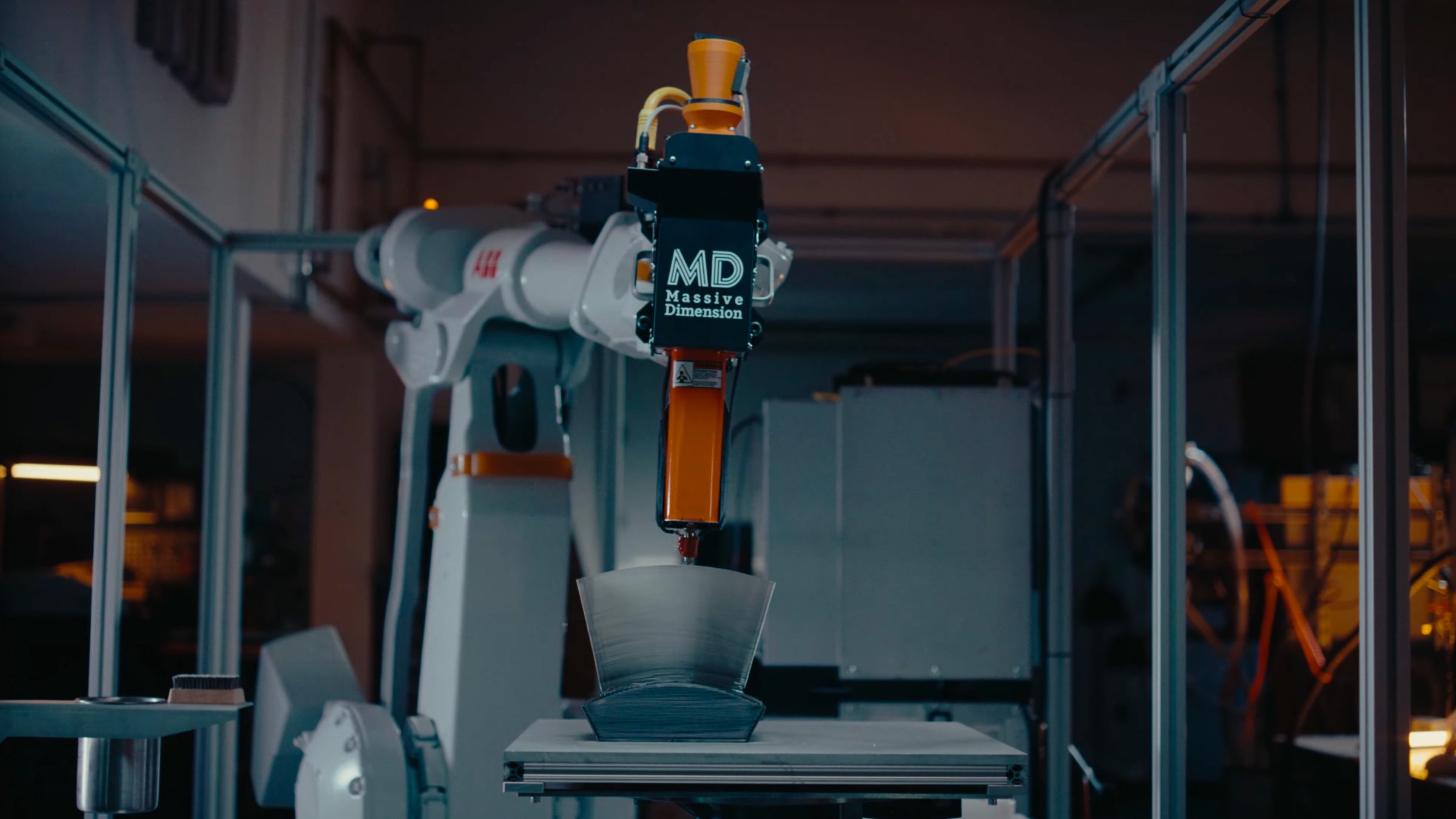

#7 Massive Dimension

Domain Est. 2015

Website: massivedimension.com

Key Highlights: We offer turn-key robotic 3D printing solutions using six-axis robotic arms, ideal for high-performance large format additive manufacturing. Our fully ……

#8 XtreeE, The large

Domain Est. 2015

Website: xtreee.com

Key Highlights: We design and manufacture large-scale, multi-material, 3D Printers for the construction industry. · Printheads · Robots · Software….

#9 Robotic Arm

Domain Est. 2020

Website: vertexdynamix.com

Key Highlights: The robotic arm, with its wide range of motion, opens up a whole new world of design freedom in 3D printing. The arm is able to print from virtually any angle….

Expert Sourcing Insights for Robotic Arm 3D Printer

H2: 2026 Market Trends for Robotic Arm 3D Printers

By 2026, the market for robotic arm 3D printers is poised for significant transformation, driven by technological convergence, expanding industrial applications, and evolving manufacturing demands. These hybrid systems, combining the dexterity of articulated robotic arms with the additive capabilities of 3D printing, are moving beyond niche prototyping into core production environments. Key trends shaping this landscape include:

1. Shift from Prototyping to End-Use Production:

Robotic arm 3D printers are increasingly moving beyond rapid prototyping into direct digital manufacturing. Advancements in print speed, material compatibility (including high-performance thermoplastics, composites, and even metals via Directed Energy Deposition), and process reliability enable consistent production of end-use parts. Industries like aerospace, automotive, and construction will adopt these systems for low-volume, high-complexity components where traditional methods are cost-prohibitive.

2. Integration of AI and Machine Learning:

By 2026, AI-driven process optimization will be standard. Machine learning algorithms will analyze real-time sensor data (thermal, vibration, vision) to dynamically adjust print parameters, predict and correct errors, and optimize toolpaths for material efficiency and structural integrity. This results in higher first-pass yield and reduced operator intervention, accelerating adoption in automated factories.

3. Expansion into Large-Scale and Construction Applications:

The inherent scalability of robotic arms makes them ideal for large-format additive manufacturing. Expect widespread deployment in construction (3D-printed walls, bridges, and entire building components) and industrial tooling (molds, jigs, fixtures). Collaborations between robotics firms and construction companies will drive innovation in printable concrete and composite materials tailored for robotic deposition.

4. Growth of Hybrid Manufacturing Systems:

Robotic arm 3D printers will increasingly integrate with subtractive (CNC milling), inspection (laser scanning), and finishing tools on a single platform. This “hybrid manufacturing” approach allows for near-net-shape printing followed by precision machining in one setup, reducing lead times and improving part accuracy—critical for aerospace and medical sectors.

5. Democratization via Open-Source and Modular Platforms:

While high-end industrial systems dominate, open-source initiatives and modular robotic platforms (e.g., based on UR, KUKA, or ABB arms) will lower entry barriers. This enables SMEs and research institutions to customize systems for specific applications, fostering innovation in sectors like customized prosthetics, art, and education.

6. Sustainability and Material Innovation:

Environmental concerns will drive demand for printers compatible with recycled and bio-based materials. Robotic arms, with their flexibility, can handle abrasive or viscous sustainable feedstocks (e.g., recycled polymers, mycelium composites) more effectively than Cartesian printers, positioning them as key enablers of circular economy models in manufacturing.

7. Regional Market Expansion:

Beyond North America and Western Europe, growth will accelerate in Asia-Pacific (especially China, Japan, and South Korea) and emerging markets, fueled by government smart manufacturing initiatives and investments in Industry 4.0 infrastructure. Localized production using robotic 3D printing will reduce supply chain dependencies.

In conclusion, by 2026, robotic arm 3D printers will evolve from experimental tools to essential components of agile, intelligent manufacturing ecosystems. Success will depend on seamless integration, material science advances, and the ability to deliver scalable, sustainable solutions across diverse industries.

Common Pitfalls When Sourcing a Robotic Arm 3D Printer: Quality and Intellectual Property Risks

Sourcing a robotic arm 3D printer—especially from emerging manufacturers or via open-source platforms—can offer innovation and cost advantages, but it also presents significant risks related to quality control and intellectual property (IP). Being aware of these pitfalls is critical to making informed procurement decisions.

Quality Control Challenges

One of the most prevalent issues when sourcing robotic arm 3D printers is inconsistent or inadequate quality control. Unlike standardized Cartesian 3D printers, robotic arm systems integrate complex kinematics, motion control, and extrusion systems, increasing the potential for performance variability.

- Inconsistent Build Accuracy: Robotic arms rely on precise calibration and repeatability. Poorly manufactured or assembled units may suffer from drift, vibration, or inaccuracies in print positioning due to substandard servos, gears, or control algorithms.

- Lack of Standardized Testing: Many suppliers, particularly smaller or startup manufacturers, do not conduct rigorous end-of-line testing or publish verifiable performance metrics (e.g., repeatability, positional accuracy, or thermal stability).

- Component Quality Variability: Use of low-grade bearings, motors, or 3D-printed structural parts can compromise long-term reliability and lead to frequent maintenance or failure.

- Software and Firmware Instability: The integration of robotic control software with slicing and path-planning tools is complex. Bugs, poor user interfaces, or lack of updates can severely impact usability and print success rates.

Without proper due diligence—such as requesting sample units, reviewing third-party validation, or conducting on-site audits—buyers risk acquiring systems that underperform or require extensive post-purchase troubleshooting.

Intellectual Property (IP) Risks

Sourcing robotic arm 3D printers, particularly from regions with lax IP enforcement or from open-source communities, exposes buyers to legal and reputational risks.

- Infringement of Patented Technologies: Some suppliers may incorporate patented motion control algorithms, kinematic designs, or extrusion mechanisms without proper licensing. Purchasing such systems could inadvertently involve your organization in IP disputes, especially if used commercially.

- Ambiguous Open-Source Licensing: While many robotic arm 3D printer designs are shared under open-source licenses (e.g., GPL, CERN OHL), these often come with obligations (e.g., derivative works must also be open-sourced). Misunderstanding license terms can lead to unintentional non-compliance and legal exposure.

- Counterfeit or Clone Systems: Some vendors sell modified versions of established designs under different branding. These clones may mimic high-end systems but lack proper engineering validation and could infringe on the original developer’s IP.

- Lack of IP Documentation: Suppliers may be unable or unwilling to provide documentation proving ownership or licensing of key technologies, making it difficult to assess legal risk before purchase.

To mitigate these risks, conduct IP due diligence—review design documentation, verify software licenses, and consider legal consultation—especially if the printer will be used in commercial production or integrated into proprietary systems.

Conclusion

Sourcing a robotic arm 3D printer requires careful evaluation beyond cost and specifications. Quality inconsistencies can undermine reliability and productivity, while unresolved IP issues may result in legal liabilities. Engaging with reputable suppliers, demanding transparency, and performing thorough technical and legal assessments are essential steps to avoid these common pitfalls.

Logistics & Compliance Guide for Robotic Arm 3D Printer

Product Classification and Regulatory Requirements

Robotic Arm 3D Printers are hybrid systems combining industrial robotics and additive manufacturing technology. As such, they fall under multiple regulatory domains depending on jurisdiction. In the European Union, these devices typically require CE marking under the Machinery Directive (2006/42/EC), the Electromagnetic Compatibility (EMC) Directive (2014/30/EU), and potentially the Radio Equipment Directive (RED) if wireless communication is included. In the United States, compliance with OSHA standards for machinery safety and FCC regulations for electronic emissions is mandatory. Manufacturers must conduct a thorough risk assessment and maintain a Technical File or Design Dossier to demonstrate conformity.

International Shipping and Export Controls

When shipping Robotic Arm 3D Printers internationally, classify the product under the correct Harmonized System (HS) code—typically 8479.89 for industrial robots or 8483.50 for 3D printing machines, depending on primary function. Exporters must verify if the product contains controlled components (e.g., high-precision motion controllers or dual-use technologies) that may require licenses under export control regimes such as the U.S. Export Administration Regulations (EAR) or the Wassenaar Arrangement. Accurate documentation—including commercial invoices, packing lists, and certificates of origin—is essential to avoid customs delays.

Safety and Operational Compliance

Robotic Arm 3D Printers must meet functional safety standards such as ISO 10218-1 (industrial robots) and ISO/ASTM 52913 (additive manufacturing systems). Emergency stop mechanisms, protective enclosures, and risk-reducing safeguarding (e.g., light curtains or safety interlocks) are required to meet machinery safety norms. Operators must be trained in both robotic safety and 3D printing processes, including handling of filament or powder materials, which may have specific storage and ventilation requirements under occupational health and safety regulations.

Environmental and Material Handling Regulations

The materials used in 3D printing—such as ABS, PLA, nylon, or metal powders—may be subject to environmental and hazardous material regulations. For example, metal powders may be classified as combustible dust under OSHA or ATEX directives in the EU, requiring explosion-proof equipment and ventilation systems. Waste material disposal must comply with local environmental laws, including proper segregation and documentation. Additionally, emissions from heated nozzles or laser sintering processes may require air filtration systems to meet indoor air quality standards.

Software and Cybersecurity Compliance

Embedded software controlling the robotic arm and print functions must comply with relevant cybersecurity and software safety standards, especially if connected to networks or cloud platforms. In sectors like aerospace or medical device manufacturing, adherence to standards such as IEC 62304 (medical software) or ISO/SAE 21434 (cybersecurity in automotive) may be applicable. Regular software updates and vulnerability assessments should be part of the compliance lifecycle to mitigate risks of unauthorized access or operational disruption.

Import Regulations and Duties

Importers must verify country-specific requirements, including conformity assessment procedures, labeling (e.g., CE, UKCA, or FCC marks), and language-specific user manuals. Some countries impose additional testing or certification through local authorities (e.g., INMETRO in Brazil, KC Mark in South Korea). Duty rates vary by HS code and trade agreements; leveraging preferential tariffs under agreements such as the USMCA or EU-South Korea FTA can reduce import costs. Engaging a licensed customs broker is recommended to ensure accurate tariff classification and duty payment.

End-of-Life and Recycling Obligations

Robotic Arm 3D Printers are subject to waste electrical and electronic equipment (WEEE) regulations in the EU and similar recycling laws in other regions. Producers must register with national WEEE authorities and provide take-back or recycling options for end-of-life equipment. Design for disassembly and use of recyclable materials can simplify compliance and support sustainability goals. Documentation on material composition (e.g., via an IPC-1752 declaration) may be required for corporate social responsibility reporting or customer sustainability audits.

Conclusion: Sourcing a Robotic Arm 3D Printer

Sourcing a robotic arm 3D printer represents a strategic step toward integrating advanced automation, flexibility, and efficiency in manufacturing, prototyping, or research applications. Unlike traditional Cartesian 3D printers, robotic arm-based systems offer a larger build envelope, multi-directional printing capabilities, and the potential for integration with other automated processes, making them ideal for complex, large-scale, or customized production needs.

When sourcing such a system, it is essential to evaluate key factors including payload capacity, precision, build volume, software compatibility, material support, and ease of integration with existing workflows. Additionally, considerations around technical support, scalability, and total cost of ownership—factoring in maintenance, training, and potential upgrades—are critical for long-term success.

While robotic arm 3D printers may come with a higher initial investment and steeper learning curve, their versatility and potential for innovation often justify the cost, particularly in industries such as aerospace, automotive, architecture, and custom manufacturing. Collaborating with reputable suppliers or manufacturers who offer robust documentation, training, and after-sales service can significantly enhance implementation success.

In conclusion, sourcing a robotic arm 3D printer is not just an equipment purchase but an investment in future-ready manufacturing technology. With careful evaluation and strategic planning, organizations can leverage these advanced systems to drive innovation, reduce production lead times, and gain a competitive edge in an increasingly automated industrial landscape.