The global road construction equipment market is experiencing robust growth, driven by increasing infrastructure development and government investments in transportation networks. According to Mordor Intelligence, the road construction equipment market was valued at USD 35.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. Similarly, Grand View Research reports that the broader construction machinery market—encompassing key segments like paving equipment—is expected to expand at a CAGR of 5.8% through 2030, fueled by urbanization and large-scale road rehabilitation projects across emerging and developed economies alike. Within this landscape, road pavement machines have become critical assets, ensuring efficiency, precision, and durability in highway and urban road construction. As demand surges, a select group of manufacturers are leading innovation, offering advanced asphalt pavers, slipform pavers, and intelligent compaction technologies. Here are the top 10 road pavement machine manufacturers shaping the future of infrastructure development.

Top 10 Road Pavement Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Gencor Industries Inc.

Domain Est. 1997

Website: gencor.com

Key Highlights: Gencor is the leading construction industry equipment manufacturer of asphalt plants, soil remediation plants, combustion systems and heat transfer systems….

#2 CRAFCO

Domain Est. 1996

Website: crafco.com

Key Highlights: Crafco is the world’s leading manufacturer in quantity and diversity of packaged pavement preservation products for asphalt and concrete….

#3 Sealcoat Manufacturers

Domain Est. 1998

Website: sealmaster.net

Key Highlights: SealMaster is one of the world’s largest manufacturers of pavement sealer and sealcoat with over 100 pavement sealer manufacturing plants and distribution ……

#4

Domain Est. 2000

Website: wirtgen-group.com

Key Highlights: The Global Leader in Road Construction Technology. A complete range of machines and plants, perfected for North America. From mining and milling to paving, ……

#5 National Asphalt Pavement Association (NAPA)

Domain Est. 2007

Website: asphaltpavement.org

Key Highlights: NAPA is the only trade association that exclusively represents the interests of the asphalt producer/contractor on the national level….

#6 Asphalt Paving Machines: Screeds & Asphalt Pavers

Domain Est. 1993

Website: cat.com

Key Highlights: 2-day deliveryCaterpillar offers a broad range of asphalt paving machines from wheel and track asphalt pavers to tamper bar and vibratory screeds….

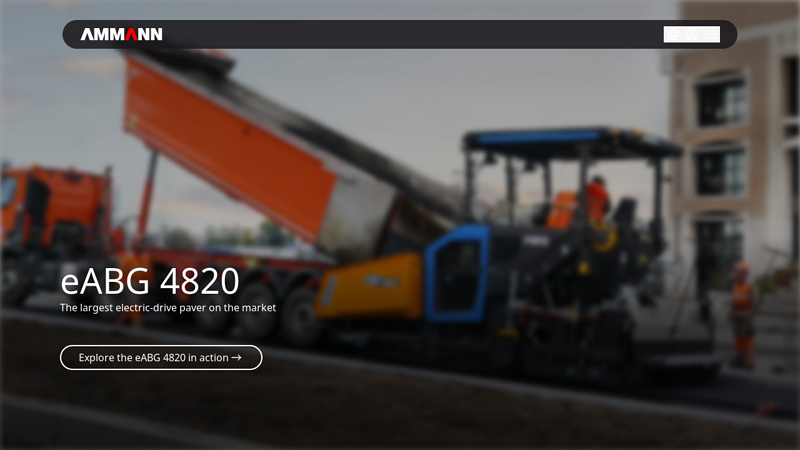

#7 Ammann ABG Asphalt Pavers

Domain Est. 1996

Website: ammann.com

Key Highlights: With a complete range of asphalt pavers Ammann ABG offers the right machine for all needs when it comes to asphalt paving….

#8 GOMACO Corporation

Domain Est. 1997

Website: gomaco.com

Key Highlights: GOMACO Corporation manufactures curb and gutter machines, concrete slipform pavers, placer/spreaders, trimmer/placers, cylinder finishers, canal machinery and ……

#9 LeeBoy

Domain Est. 1998

Website: leeboy.com

Key Highlights: Made in the USA, our ISO-certified manufacturing is evidence of our dedication to quality and our commitment to provide the absolute best equipment solutions….

#10 Equipment

Domain Est. 2006

Website: weilerproducts.com

Key Highlights: Based in Knoxville, Iowa, Weiler designs, engineers and manufactures equipment for the paving market….

Expert Sourcing Insights for Road Pavement Machine

H2: Market Trends in Road Pavement Machines for 2026

The global road pavement machine market is poised for significant transformation by 2026, driven by infrastructural expansion, technological innovation, environmental regulations, and increasing urbanization. As governments and private sectors invest heavily in transportation infrastructure, the demand for advanced, efficient, and sustainable road construction solutions continues to rise. Below is an analysis of key market trends shaping the road pavement machine industry in 2026.

1. Increased Adoption of Smart and Automated Paving Technologies

By 2026, automation and digitalization are expected to be central to road paving operations. Manufacturers are integrating GPS guidance systems, telematics, and machine control technologies into asphalt pavers and other pavement equipment. These advancements enable precision paving, reduce material waste, and enhance operational efficiency. Autonomous and semi-autonomous paving machines are gaining traction, particularly in developed economies, where labor shortages and the need for consistent quality drive automation.

2. Emphasis on Sustainability and Eco-Friendly Equipment

Environmental regulations are pushing the industry toward greener solutions. In 2026, there is a growing shift toward low-emission and electric-powered pavement machines. Manufacturers are investing in hybrid and electric asphalt pavers to comply with emission standards such as Euro V and upcoming Euro VI norms. Additionally, the use of warm-mix asphalt (WMA) technologies, which require lower production temperatures and reduce energy consumption, is increasing—spurring demand for compatible paving equipment.

3. Infrastructure Development in Emerging Economies

Asia-Pacific, Latin America, and Africa are witnessing massive investments in road infrastructure, fueled by urbanization and economic growth. Countries like India, Indonesia, Brazil, and Nigeria are launching large-scale highway and rural road projects, significantly boosting demand for road pavement machines. Government initiatives such as India’s Bharatmala Pariyojana and China’s Belt and Road Initiative are key growth drivers in the region.

4. Growth in Private-Public Partnerships (PPPs) and Infrastructure Funding

Increased collaboration between governments and private investors is accelerating infrastructure projects worldwide. These PPP models provide the capital needed for long-term road development, directly influencing the procurement of modern paving machinery. In North America and Europe, infrastructure stimulus packages are revitalizing aging road networks, further supporting market growth.

5. Technological Integration with IoT and Data Analytics

By 2026, Internet of Things (IoT) integration in pavement machines allows real-time monitoring of machine health, performance, and location. Predictive maintenance, enabled by data analytics, reduces downtime and extends equipment lifespan. Fleet management systems are becoming standard, helping contractors optimize utilization and reduce operational costs.

6. Rising Demand for Multi-Functional and Modular Machines

Contractors are increasingly seeking versatile pavement machines that can adapt to various job site conditions and paving requirements. Modular designs that allow quick configuration for different widths, materials, and terrains are gaining favor. This flexibility improves efficiency and reduces the need for multiple specialized machines.

7. Supply Chain Optimization and Local Manufacturing

Global disruptions have prompted manufacturers to localize production and diversify supply chains. By 2026, key players are establishing regional manufacturing hubs to reduce lead times and logistics costs, especially in high-growth markets. This trend also supports faster service and parts availability, improving customer satisfaction.

Conclusion

The road pavement machine market in 2026 is characterized by technological sophistication, sustainability, and global infrastructure growth. Companies that innovate in automation, reduce environmental impact, and cater to emerging market demands are likely to gain a competitive edge. As digital integration and smart construction practices become the norm, the industry is set to enter a new era of efficiency and scalability.

Common Pitfalls When Sourcing Road Pavement Machines: Quality and Intellectual Property (IP) Concerns

Sourcing road pavement machines—such as asphalt pavers, slipform pavers, and material transfer vehicles—requires careful due diligence to avoid significant risks related to machine quality and intellectual property (IP) infringement. Overlooking these factors can lead to costly downtime, legal disputes, and reputational damage. Below are key pitfalls to watch for in both quality and IP domains.

Quality-Related Pitfalls

1. Inadequate Verification of Manufacturing Standards

Many suppliers, especially from emerging markets, may claim compliance with international standards like ISO or CE but fail to consistently adhere to them. Buyers often assume certifications equate to reliable quality, but without third-party audits or site visits, these claims can be misleading.

2. Use of Substandard Components

To reduce costs, some manufacturers substitute critical components—such as hydraulic systems, engines, or electronic controls—with lower-grade alternatives. These parts may fail prematurely under heavy-duty paving conditions, leading to unplanned maintenance and reduced machine lifespan.

3. Lack of Real-World Performance Data

Suppliers may provide theoretical performance metrics without verifiable field data. Machines that perform well in controlled environments may not withstand the rigors of actual road construction, resulting in reliability issues on job sites.

4. Insufficient After-Sales Support and Spare Parts Availability

Even high-quality machines become liabilities if spare parts are unavailable or technical support is slow. Sourcing from manufacturers without a robust service network—especially in remote regions—can lead to extended downtime and increased operational costs.

5. Inconsistent Build Quality Across Production Batches

Some manufacturers experience variability between production runs due to poor quality control processes. A buyer may receive a well-built machine in one order and a flawed unit in the next, undermining predictability and trust.

Intellectual Property (IP) Risks

1. Counterfeit or Copycat Machines

A major concern when sourcing from certain regions is the prevalence of machines that closely mimic patented designs from leading brands (e.g., Volvo, Caterpillar, Wirtgen). These knockoffs may infringe on design patents, utility models, or trademarks, exposing buyers to legal liability.

2. Unauthorized Use of Proprietary Technology

Some suppliers integrate patented technologies—such as intelligent compaction systems, automatic grade control, or material distribution mechanisms—without proper licensing. Purchasing such machines can inadvertently involve the buyer in IP infringement claims.

3. Lack of IP Documentation and Warranties

Reputable suppliers provide clear IP indemnification clauses in contracts, protecting buyers from third-party claims. Many low-cost suppliers omit these warranties or cannot prove the originality of their designs, leaving buyers vulnerable.

4. Grey Market and Rebranded Equipment

Some sellers rebrand used or refurbished machines as new, or source equipment through unauthorized channels. These machines may have compromised software, outdated firmware, or tampered serial numbers, raising both IP and safety concerns.

5. Software and Firmware IP Violations

Modern pavement machines rely on proprietary software for operation and diagnostics. Unauthorized duplication or reverse-engineering of control software not only violates copyright laws but can also lead to instability, security vulnerabilities, and lack of updates.

Mitigation Strategies

- Conduct factory audits and request third-party quality certifications.

- Verify component sources and request documentation for critical parts.

- Demand references and conduct site visits to observe machines in operation.

- Include IP warranty clauses in procurement contracts.

- Work with legal counsel to assess IP risks, especially when sourcing from high-risk jurisdictions.

- Partner with authorized distributors or OEMs to ensure authenticity and support.

By proactively addressing both quality and IP concerns, buyers can minimize risks and ensure reliable, legally sound investments in road paving equipment.

Logistics & Compliance Guide for Road Pavement Machine

Overview

This guide provides essential information for the safe, efficient, and compliant transportation, handling, and operation of road pavement machines. It covers logistics planning, regulatory compliance, documentation, and best practices to ensure project success and adherence to international and local standards.

Equipment Classification & Specifications

Road pavement machines include pavers, milling machines, screeds, and auxiliary equipment used in asphalt and concrete paving operations. Key specifications affecting logistics include:

– Dimensions (length, width, height)

– Weight (operational and transport)

– Power requirements (diesel, electric)

– Road classification (on-highway vs. off-road transport)

Ensure accurate machine data is available from the manufacturer for proper transport planning.

Transport Regulations and Permits

Transporting heavy road paving equipment typically requires special permits due to oversized or overweight loads. Key considerations:

– National and Local Regulations: Comply with Department of Transportation (DOT) or equivalent authority rules (e.g., FMCSA in the U.S., DVSA in the UK).

– Oversize/Overweight Permits: Required when exceeding legal dimensions or weight limits. Apply in advance with route details, equipment specs, and travel dates.

– Escort Vehicles: Often mandatory for wide or long loads; check regional requirements.

– Route Planning: Avoid low bridges, weak roads, and restricted zones. Use GPS tools designed for heavy hauls.

Loading, Securing, and Transport

Proper loading and securing are critical for safety and compliance:

– Trailer Selection: Use lowboy trailers, extendable deck trailers, or RORO (roll-on/roll-off) as appropriate.

– Loading Procedures: Engage certified operators; use ramps with proper incline and traction.

– Securing Equipment: Follow the International Safe Container Loading (CTU) Code and national standards. Use rated chains, binders, and dunnage to prevent shifting. Minimum of four tie-down points typically required.

– Weight Distribution: Ensure even axle loading to comply with bridge formula laws.

Customs and International Shipping

For cross-border or international transport:

– Export/Import Documentation: Prepare commercial invoice, packing list, bill of lading, and certificate of origin.

– HS Code Classification: Typically under HS 8479.89 (Machines for working stone, ceramics, or concrete). Confirm with local customs.

– Duties and Taxes: Research import tariffs, VAT, or temporary import relief (e.g., ATA Carnet for temporary equipment entry).

– Sanitary and Phytosanitary (SPS) Checks: Clean equipment to avoid soil or organic matter that could trigger agricultural inspections.

Environmental and Safety Compliance

Adhere to environmental and safety standards during transport and operation:

– Emissions Standards: Ensure machine meets local emission regulations (e.g., EPA Tier 4, EU Stage V).

– Noise Regulations: Comply with site-specific or municipal noise limits during operation.

– Spill Prevention: Equip machines with secondary containment for fuel and hydraulic fluids.

– Operator Certification: Operators must hold valid licenses or certifications per OSHA (U.S.) or equivalent bodies.

Documentation and Record Keeping

Maintain accurate records to support compliance and traceability:

– Equipment registration and title

– Transport permits and route approvals

– Maintenance logs and inspection reports

– Operator training certificates

– Customs documentation (for international moves)

Risk Management and Insurance

Protect against liability and loss:

– Transport Insurance: Covers damage during transit (include all-risk coverage).

– Liability Insurance: Essential for public road use and worksite operations.

– Contingency Planning: Prepare for delays due to weather, permit issues, or mechanical failure.

Best Practices

- Conduct pre-transport inspections of machine and trailer.

- Communicate with local authorities before entering urban or restricted zones.

- Use GPS tracking for real-time shipment monitoring.

- Train personnel on emergency procedures and spill response.

Conclusion

Successful logistics and compliance for road pavement machines require meticulous planning, adherence to regulations, and proper documentation. By following this guide, stakeholders can ensure safe transport, avoid delays, and maintain legal compliance across jurisdictions.

Conclusion for Sourcing a Road Pavement Machine

Sourcing a road pavement machine is a critical decision that significantly impacts the efficiency, quality, and cost-effectiveness of road construction and maintenance projects. After evaluating key factors such as machine type (e.g., paver, roller, milling machine), capacity, brand reputation, technical specifications, after-sales support, and total cost of ownership, it is essential to select a machine that aligns with both current project requirements and future operational needs.

Prioritizing reliable suppliers or manufacturers with proven track records ensures access to durable, high-performance equipment and comprehensive service networks. Whether opting for new or used machinery, thorough due diligence, site visits, and operator training should be integral parts of the procurement process. Additionally, considering sustainability and fuel efficiency can contribute to long-term savings and environmental compliance.

In conclusion, a well-informed sourcing strategy—balancing performance, reliability, cost, and support—will maximize return on investment and enhance project delivery, ultimately supporting the development of durable, high-quality road infrastructure.