The global RJ45 connector market is experiencing robust expansion, driven by the escalating demand for high-speed data transmission in enterprise networks, data centers, and smart infrastructure. With the widespread adoption of Category 6A (Cat6A) cabling—capable of supporting 10 Gigabit Ethernet up to 100 meters—the need for high-performance RJ45 connectors has become critical. According to Grand View Research, the global Ethernet connector market size was valued at USD 6.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.7% from 2023 to 2030. This growth is fueled by rising investments in network infrastructure, increased deployment of Power over Ethernet (PoE) technologies, and the global push toward 5G and IoT ecosystems. As Cat6A cables become the standard for high-bandwidth applications, manufacturers of precision-engineered RJ45 connectors are playing a pivotal role in ensuring signal integrity, reduced crosstalk, and compliance with stringent performance standards. In this competitive landscape, nine manufacturers have emerged as leaders, offering innovative, reliable, and high-specification RJ45 connectors tailored for Cat6A cabling systems.

Top 9 Rj45 Connector For Cat6A Cable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 RJ45 Connector for CAT6A Cable, Qty 10

Domain Est. 1996

Website: winncom.com

Key Highlights: 30-day returnsRJ45 Connector for CAT6A Cable, Qty 10. Manufacturer PN #: N000082L174B. Pricing shown below may be subject to tariffs. List Price: $16.00. Your Price: Login….

#2 LAPP EPIC® DATA RJ45 Connectors

Domain Est. 2007

Website: lapptannehill.com

Key Highlights: 5-day deliveryLapp Tannehill offers various styles of RJ45 field wireable data connectors for industrial Ethernet applications from LAPP….

#3 Category 6 Plugs

Domain Est. 1994

Website: commscope.com

Key Highlights: CommScope offers a broad range of Cat 6 RJ45 modular plugs for your data and voice transmissions, providing excellent mechanical and signal ……

#4 Data connectors

Domain Est. 1996

Website: phoenixcontact.com

Key Highlights: Phoenix Contact offers a comprehensive portfolio of data connectors from RJ45 to USB, HDMI, and D-SUB, up to coaxial and FO connections, as well as for SPE….

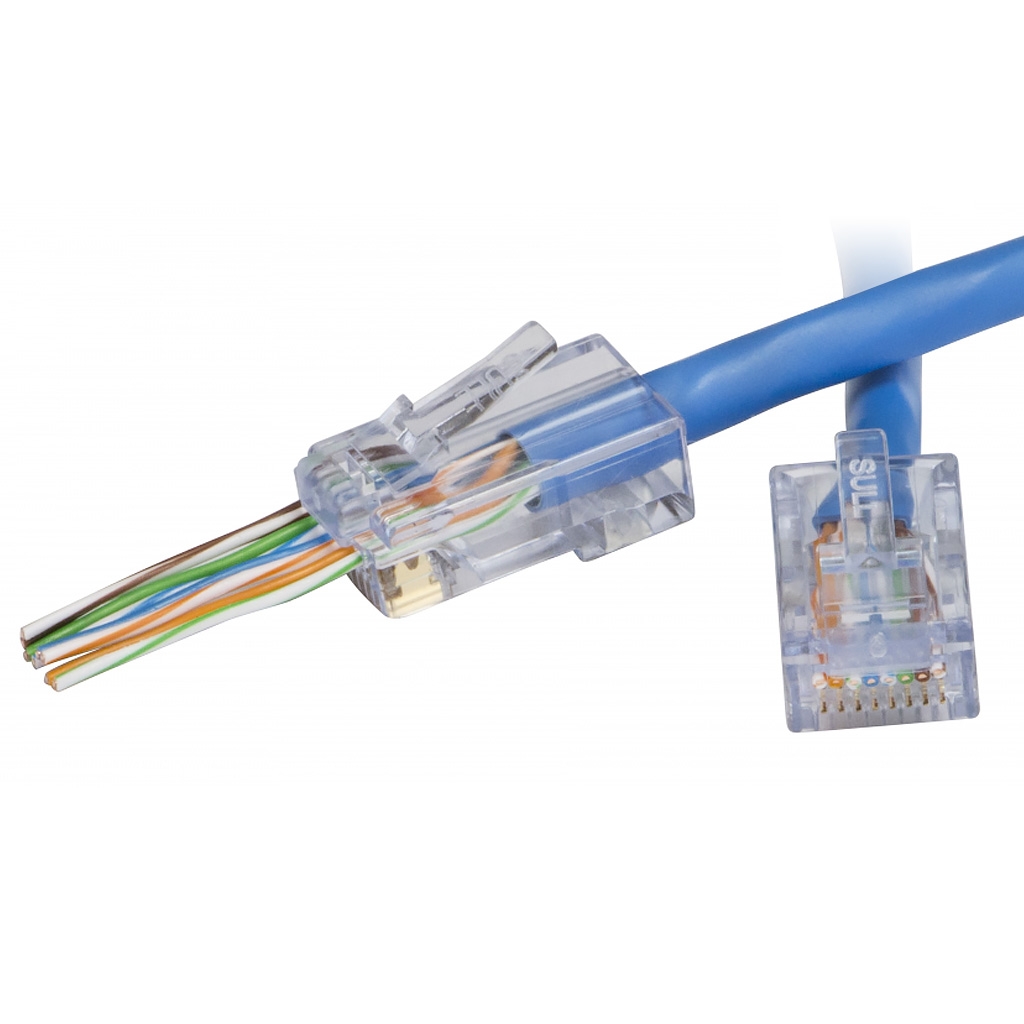

#5 EZ

Domain Est. 2001

Website: platinumtools.com

Key Highlights: The Original EZ-RJ45 CAT6 Connector simplifies twisted pair terminations by allowing the wires to be inserted through the connector and out the front….

#6 trueCABLE

Domain Est. 2004

Website: truecable.com

Key Highlights: Free delivery over $150Cat6/6A Pass Through RJ45 Connectors|Unshielded. Excellent quality Cat6 cable and RJ45 connectors that fit perfectly. Also used trueCable’s all in one ……

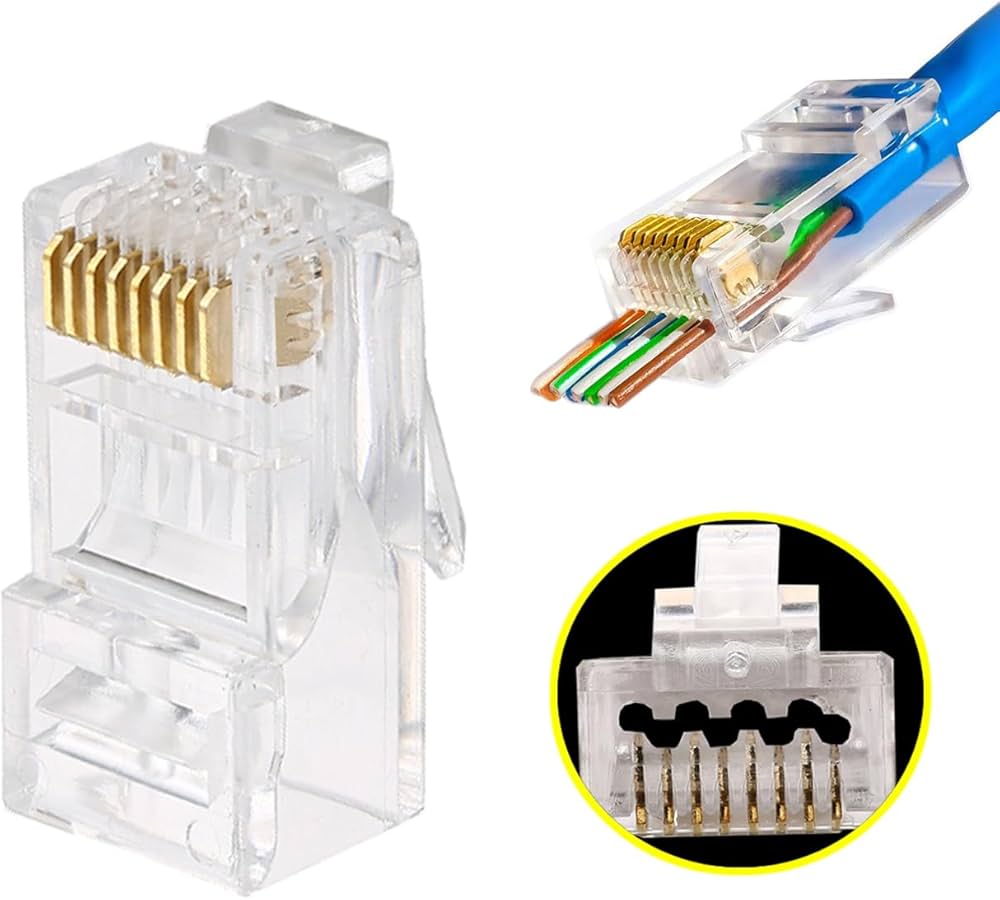

#7 CAT6A RJ45 Clear Connectors

Domain Est. 2010

Website: vericomsolutions.com

Key Highlights: These RJ45 unshielded connectors are composed of a polycarbonate material body, with gold plated contacts, and are suitable for use with Category 6A 22 – 26 AWG ……

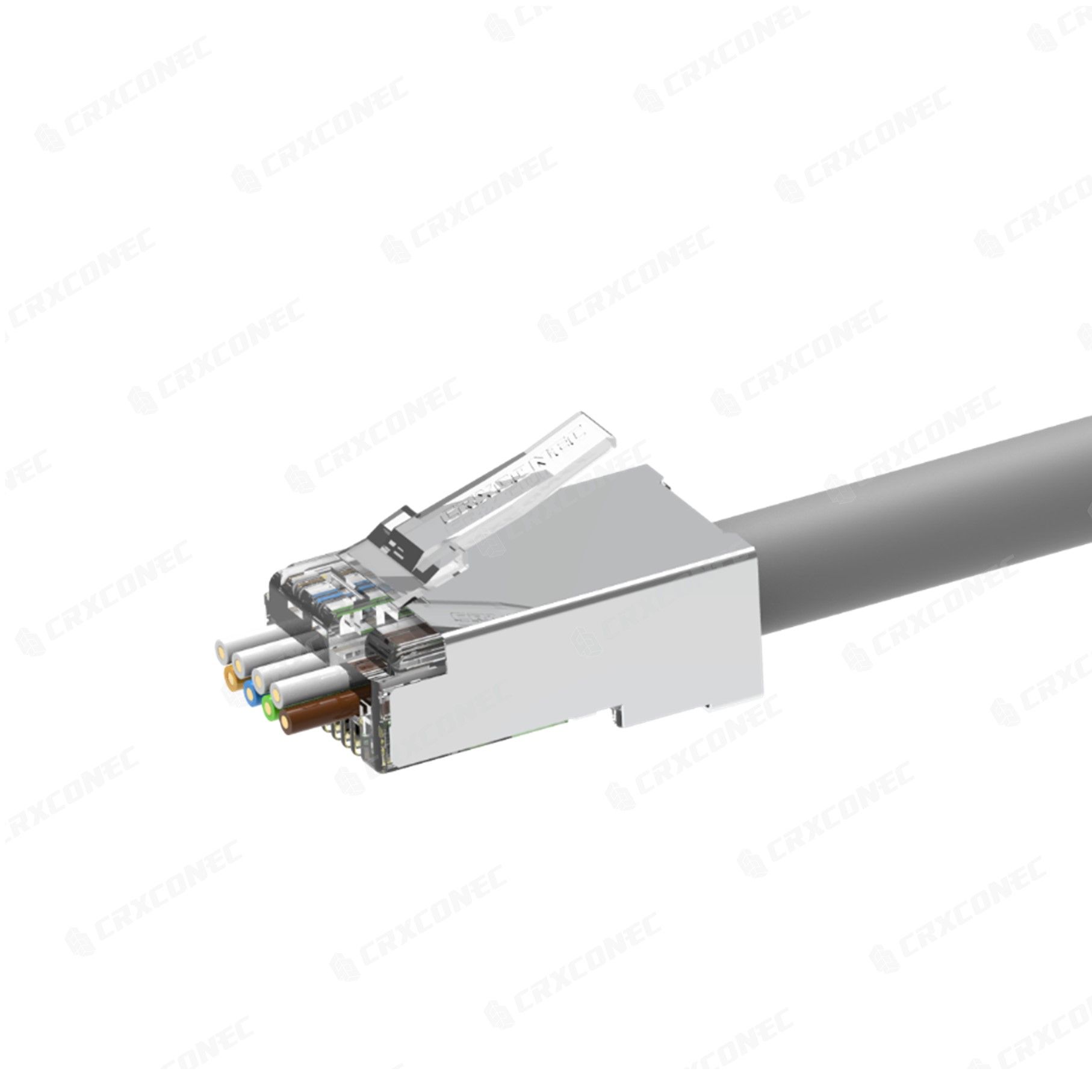

#8 CAT6a/6/5e Shielded Feed

Domain Est. 2012

#9 List of RJ45 Connectors Models & Products

Domain Est. 1992

Website: te.com

Key Highlights: Our RJ45 electronic components are available for six performance categories: Cat 3, Cat 4, Cat 5, Cat 5e, Cat 6, and Cat 6A. We offer options with LED status ……

Expert Sourcing Insights for Rj45 Connector For Cat6A Cable

2026 Market Trends for RJ45 Connectors for Cat6A Cables

As the global demand for high-speed data transmission continues to accelerate, the market for RJ45 connectors designed specifically for Cat6A cables is poised for significant evolution by 2026. These connectors, essential for supporting 10 Gigabit Ethernet over distances up to 100 meters, are experiencing shifts driven by technological innovation, infrastructure upgrades, and emerging applications. Below is an analysis of the key trends expected to shape this market in 2026.

Rising Demand from Enterprise and Data Center Upgrades

By 2026, enterprise networks and data centers will increasingly migrate from Cat6 to Cat6A infrastructure to support bandwidth-intensive applications such as cloud computing, virtualization, and high-performance computing. This transition is fueling demand for high-quality, shielded RJ45 connectors that maintain signal integrity at frequencies up to 500 MHz. The need for reduced crosstalk and improved shielding—especially in dense cable environments—is driving adoption of F/UTP (foiled unshielded twisted pair) and S/FTP (shielded/foiled twisted pair) compatible connectors. Manufacturers are responding with precision-molded connectors featuring tighter tolerances and enhanced grounding mechanisms.

Growth in Smart Buildings and IoT Integration

The proliferation of smart building technologies—including intelligent lighting, HVAC systems, security, and building automation—is pushing building owners toward future-proof cabling solutions. Cat6A, with its superior performance and backward compatibility, is becoming the standard for new commercial constructions and retrofits. RJ45 connectors designed for Cat6A are being optimized for reliability in PoE (Power over Ethernet) applications, supporting higher power levels (up to PoE++/802.3bt). This trend is leading to connectors with improved thermal management and materials resistant to heat buildup, especially in ceiling-mounted or enclosed environments.

Standardization and Performance Certification

By 2026, regulatory and industry standards such as ANSI/TIA-568.2-D and ISO/IEC 11801-1 will continue to influence connector design. There is an increasing emphasis on certified, performance-guaranteed RJ45 connectors to ensure compliance with Category 6A specifications. Market leaders are investing in third-party testing and certification programs, providing installers and enterprises with plug-and-play confidence. This trend supports the growth of modular, field-terminable connectors that maintain performance consistency without requiring specialized tools.

Innovation in Connector Design and Installation Efficiency

To meet the demands of faster deployment and lower labor costs, manufacturers are introducing tool-less or low-tool field-termination RJ45 connectors for Cat6A. These innovations reduce installation time and minimize human error, which is crucial in large-scale deployments. Additionally, angled and low-profile connector designs are gaining traction in high-density patch panels and tight spaces, improving airflow and cable management—especially in data centers.

Regional Market Expansion and Supply Chain Dynamics

While North America and Western Europe remain dominant markets due to early adoption of advanced network infrastructure, Asia-Pacific—particularly China, India, and Southeast Asia—is expected to witness the fastest growth by 2026. Urbanization, government-led digitalization initiatives, and expanding data center capacity are driving regional demand. However, supply chain resilience remains a concern, prompting manufacturers to localize production and diversify raw material sourcing, especially for copper and high-grade plastics.

Sustainability and Eco-Friendly Materials

Environmental regulations and corporate sustainability goals are influencing connector design. By 2026, there will be a growing preference for RJ45 connectors made from recyclable or bio-based plastics and lead-free manufacturing processes. Energy-efficient production and reduced packaging waste are becoming competitive differentiators, aligning with broader green IT and ESG (Environmental, Social, and Governance) initiatives.

In conclusion, the 2026 market for RJ45 connectors for Cat6A cables will be shaped by performance demands, installation efficiency, and sustainability. As digital transformation deepens across industries, these connectors will remain a critical enabler of reliable, high-speed connectivity—making innovation and quality paramount for market success.

Common Pitfalls When Sourcing RJ45 Connectors for Cat6A Cables (Quality and IP Considerations)

Sourcing RJ45 connectors for Cat6A cables requires careful attention to performance standards, material quality, and intellectual property (IP) compliance. Failure to address these factors can result in poor network performance, non-compliance with industry standards, and legal risks. Below are common pitfalls to avoid:

1. Compromising on Connector Quality

Using low-quality RJ45 connectors can severely degrade the performance of Cat6A cabling, which is designed to support 10 Gigabit Ethernet up to 100 meters with frequencies up to 500 MHz. Key quality-related pitfalls include:

– Poor Contact Plating: Connectors with insufficient gold plating (e.g., less than 1.27–2.54 µm) may suffer from oxidation and increased insertion loss.

– Inadequate Shielding: Cat6A requires robust shielding (e.g., screen-shielded or S/FTP cables) to reduce crosstalk and EMI. Non-compliant connectors may lack proper metal housing or grounding tabs, leading to signal integrity issues.

– Incorrect Dimensional Tolerances: Poorly manufactured connectors may not maintain proper wire pair separation, increasing alien crosstalk (AXT) and failing certification tests.

2. Ignoring Category Certification and Standards Compliance

Not all RJ45 connectors are Cat6A-rated. Using connectors labeled as “compatible” without formal certification (e.g., by UL, ETL, or TIA/EIA-568-C.2-10) can lead to:

– Failure in Field Testing: Installations may fail certification tests (e.g., Fluke DSX tests) due to marginal performance in NEXT, AXT, or return loss.

– Voided System Warranties: Many cable system warranties are voided if non-certified connectors are used.

3. Overlooking Intellectual Property (IP) and Counterfeit Risks

Many high-performance connector designs are protected by patents and trademarks. Pitfalls include:

– Using Counterfeit or Clone Products: Some suppliers offer RJ45 connectors that mimic reputable brands (e.g., Krone, Panduit, Siemon) but lack engineering validation. These clones often fail under real-world performance demands.

– Infringement Liability: Distributors or integrators using patented designs without licensing may face legal action, especially in regulated or enterprise environments.

– Lack of Traceability: Unbranded or generic connectors may not provide batch traceability, complicating compliance audits and warranty claims.

4. Mismatched Termination Method (IDC vs. Solder vs. Crimp)

Cat6A performance depends on precise termination. Using the wrong termination method or poorly designed insulation displacement contacts (IDC) can:

– Disturb pair geometry and increase crosstalk.

– Result in unreliable connections due to poor wire seating or cold joints.

Ensure connectors are designed specifically for Cat6A and match your termination tools and practices.

5. Neglecting Environmental and IP Ratings

In harsh environments (industrial, outdoor, or high-moisture areas), standard RJ45 connectors may fail. Common mistakes:

– Using Non-IP-Rated Connectors: For outdoor or washdown areas, connectors should have proper ingress protection (e.g., IP67 or IP68). Standard plastic connectors degrade quickly when exposed to dust or moisture.

– Inadequate Strain Relief: Poor strain relief leads to cable pull-out and broken connections, especially in high-vibration settings.

6. Focusing Only on Price

While cost is a factor, choosing the cheapest RJ45 connectors often leads to:

– Increased rework and labor costs due to failed tests.

– Higher long-term maintenance and network downtime.

– Compromised network reliability and scalability.

Conclusion

To avoid these pitfalls, always source Cat6A-rated RJ45 connectors from reputable manufacturers, verify third-party certifications, ensure IP compliance for the deployment environment, and confirm intellectual property legitimacy. Investing in quality connectors ensures long-term network performance, compliance, and reduced liability.

Logistics & Compliance Guide for RJ45 Connectors for Cat6A Cable

Overview

This guide provides essential logistics and compliance information for the procurement, handling, transportation, and regulatory adherence of RJ45 connectors designed specifically for Cat6A (Category 6 Augmented) Ethernet cables. These connectors are critical components in high-speed data networking infrastructure, supporting bandwidths up to 500 MHz and data rates of 10 Gbps over distances up to 100 meters.

Product Specifications

- Compatibility: Cat6A cables (23 AWG recommended)

- Shielding: Typically shielded (U/FTP or F/UTP systems); supports S/FTP or F/FTP configurations

- Performance Standard: Complies with ANSI/TIA-568-C.2 and ISO/IEC 11801 Class EA

- Contact Plating: Gold-plated contacts (typically 50 µin) for corrosion resistance and signal integrity

- Termination Type: Insulation Displacement Contact (IDC)

- Material: High-impact thermoplastic housing, brass contacts

- Operating Temperature: -10°C to +60°C

- RoHS Compliance: Yes (Restriction of Hazardous Substances Directive 2011/65/EU)

Regulatory Compliance

RoHS (EU)

RJ45 connectors for Cat6A must comply with the EU RoHS (Restriction of Hazardous Substances) Directive, restricting the use of lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB), and polybrominated diphenyl ethers (PBDE). Ensure supplier certification is provided.

REACH (EU)

Compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) is mandatory. Suppliers must confirm that substances of very high concern (SVHCs) are either absent or declared above threshold limits (0.1% by weight).

UL/ETL Listing

Connectors should be UL Listed or ETL Verified under relevant standards such as UL 444 (Communications Systems) and CSA C22.2 No. 232 (Canada). Look for markings indicating compliance on packaging and product.

FCC Part 15 (USA)

While passive components like connectors are generally exempt, ensure no active electronics are integrated. Maintaining EMI/RFI shielding integrity supports compliance with FCC Part 15 Class B for electromagnetic compatibility.

CE Marking

Required for products sold in the European Economic Area (EEA). CE marking indicates conformity with health, safety, and environmental protection standards, including RoHS and REACH.

Packaging and Labeling Requirements

- Inner Packaging: Anti-static bags or conductive trays to protect against electrostatic discharge (ESD)

- Outer Packaging: Sturdy cardboard boxes with cushioning; labeled with ESD-sensitive handling symbols

- Labeling:

- Product name and model number

- Manufacturer/supplier identification

- RoHS, REACH, and CE compliance symbols

- Quantity per pack

- Batch/lot number and manufacturing date

- Barcodes (GTIN/UPC) for inventory tracking

- Multilingual Labels: Required in EU markets (e.g., English, German, French)

Storage and Handling

- Environment: Store in a dry, climate-controlled area (15–25°C, 30–60% RH)

- ESD Protection: Handle using grounded wrist straps and ESD-safe work surfaces

- Shelf Life: Typically 24 months from manufacture; inspect for oxidation or damage if stored longer

- Stacking: Follow manufacturer stacking limits to avoid compression damage

Transportation and Shipping

- Mode: Air, sea, or ground transport acceptable with proper packaging

- ESD Protection: Maintain ESD-safe packaging throughout transit

- Temperature: Avoid exposure to extreme temperatures (>60°C or < -20°C)

- Documentation:

- Commercial invoice with HS Code: 8531.80.00 (Electrical apparatus for switchboards, etc.)

- Certificate of Conformity (CoC) for RoHS, REACH, and CE

- Packing list with item details and quantities

- Safety Data Sheet (SDS) if required by carrier or jurisdiction

Import/Export Considerations

- HS Code: 8531.80.00 (Harmonized System code for electrical connectors)

- Export Controls: Generally not subject to ITAR or EAR restrictions; verify with supplier

- Customs Declarations: Include accurate product description, value, origin (country of manufacture), and compliance certifications

- Duties and Taxes: Subject to local import duties and VAT/GST; rates vary by country (e.g., 0–5% in EU, varies in US)

Quality Assurance and Traceability

- Supplier Qualification: Use ISO 9001-certified manufacturers

- Incoming Inspection: Verify packaging, labeling, and sample performance (e.g., continuity, insertion loss)

- Traceability: Maintain batch/lot tracking for recalls or compliance audits

- Testing Standards: Reference TIA-568-C.2-1 for field testing procedures

Disposal and Environmental Responsibility

- End-of-Life: Treat as electronic waste (WEEE)

- Recycling: Follow local WEEE regulations; return to approved e-waste recyclers

- Hazardous Waste: Non-compliant or damaged units containing restricted substances must be disposed of per local environmental laws

Summary

Proper logistics and compliance management of RJ45 connectors for Cat6A cables ensures product performance, regulatory adherence, and supply chain reliability. Key priorities include ESD-safe handling, accurate documentation, and verification of RoHS, REACH, CE, and UL/ETL compliance. Partner with certified suppliers and maintain traceability throughout the product lifecycle.

Conclusion for Sourcing RJ45 Connectors for Cat6a Cables:

Sourcing the appropriate RJ45 connectors for Cat6a cables is critical to ensuring optimal performance, reliability, and compliance with industry standards. Cat6a cables support higher bandwidth (up to 500 MHz) and are designed for 10-Gigabit Ethernet over distances up to 100 meters, making it essential that the RJ45 connectors used are also rated for Cat6a performance.

Key considerations when sourcing include connector shielding (shielded vs. unshielded), compatibility with cable diameter and shielding type, termination method (solder, crimp, or insulation displacement), and adherence to ISO/IEC and TIA Category 6A standards. High-quality connectors with proper shielding (e.g., U/FTP or F/UTP compatible) help minimize crosstalk and electromagnetic interference, maintaining signal integrity.

It is recommended to source connectors from reputable manufacturers with proven performance and consistent quality control. While cost is a factor, selecting lower-cost, non-compliant connectors may lead to installation failures, network downtime, and compromised network speeds. Additionally, ease of termination and compatibility with commonly used tools should be considered to ensure efficient and error-free installations.

In conclusion, investing in certified, high-performance Cat6a-rated RJ45 connectors from trusted suppliers ensures long-term network reliability, future-proofs cabling infrastructure, and supports compliance with structured cabling standards. Proper sourcing ultimately leads to reduced maintenance costs and enhanced network performance.