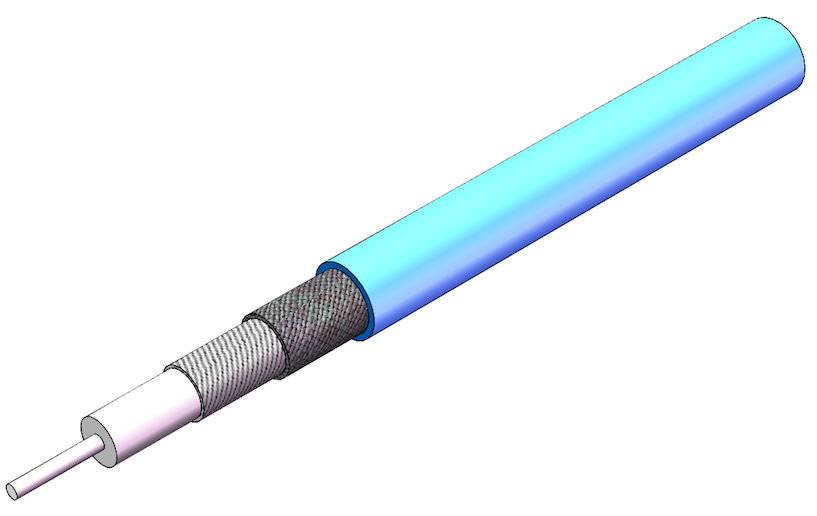

The global coaxial cable market is experiencing steady expansion, driven by rising demand for high-speed data transmission across telecommunications, aerospace, defense, and automotive sectors. According to Grand View Research, the global coaxial cable market size was valued at USD 10.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. The surge in infrastructure development, coupled with the increasing deployment of 5G networks and in-flight connectivity systems, has intensified the need for high-performance connectivity solutions — particularly right angle coaxial connectors, which offer space-saving benefits in compact electronic assemblies. As industries prioritize signal integrity and miniaturization, manufacturers specializing in right angle coax technologies are playing a pivotal role in enabling next-generation hardware performance. This growing demand landscape sets the stage for identifying the top 10 right angle coax manufacturers leading innovation, reliability, and scalability in the sector.

Top 10 Right Angle Coax Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 EZ Form Coaxial Cables & Connectors

Domain Est. 1996

Website: ezform.com

Key Highlights: EZ Form Cable, a Trexon Company, is an AS9100D certified manufacturer of Coaxial Cable, Coaxial Cable Assemblies, RF Connectors, and Coaxial Delay Lines….

#2 Amphenol RF

Domain Est. 2000

Website: amphenolrf.com

Key Highlights: Amphenol RF is the world’s largest manufacturer of coaxial connectors for use in radio frequency, microwave, and data transmission system applications….

#3 Connectors, Cables, Optics, RF, Silicon to Silicon Solutions

Domain Est. 1995

Website: samtec.com

Key Highlights: Flexible stacking board to board connectors in a variety of orientations such as low profile, elevated, right-angle and pass-through, with a choice of pitch ……

#4 Coaxial cable

Domain Est. 1996

Website: l-com.com

Key Highlights: 3-day delivery · 30-day returnsWe design, manufacture and assemble coaxial cable products. Whether it’s for entertainment systems, GPS, video security systems, telecom or WAN/LAN,…

#5 C Male Right Angle Connectors

Domain Est. 1997

Website: pasternack.com

Key Highlights: 2–3 day delivery 30-day returnsPasternack C male right angle connectors are manufactured with 50 Ohm impedance. These C male right angle designs are available in clamp/solder or cr…

#6 New Swept Radius RF Connector Design

Domain Est. 1997

Website: coaxicom.com

Key Highlights: Coaxicom’s innovative new swept right-angle connector designs incorporate the physical advantages of traditional designs (ie, low profile, compact size)….

#7 MegaPhase

Domain Est. 1998

Website: megaphase.com

Key Highlights: MegaPhase designs and manufactures coaxial cable assemblies and components through 110GHz, serving space, commercial telecom, and military markets, ……

#8 CELLFLEX Connectors & Accessories

Domain Est. 1999

Website: rfsworld.com

Key Highlights: At RFS we specialize in the design and manufacture of premium, future-ready cable solutions for customers across the globe….

#9 I

Domain Est. 2005

Website: i-pex.com

Key Highlights: I-PEX manufactures high-precision Micro-Coax, FPC, FFC, RF, and Board to Board commercial connector products….

#10 RF, Microwave, and mmWave Interconnects, Coax Cable …

Website: glenair.com

Key Highlights: Catalog: RF, Microwave, and mmWave Interconnects and Coax Cable Assemblies for Mission-Critical Aerospace Applications….

Expert Sourcing Insights for Right Angle Coax

H2: Market Trends for Right Angle Coax in 2026

As we approach 2026, the market for right angle coaxial (coax) connectors and cables is being reshaped by evolving demands in telecommunications, consumer electronics, aerospace, and defense industries. These components—valued for their space-saving design and high-frequency performance—are experiencing notable shifts driven by technological innovation, miniaturization, and the global rollout of next-generation networks.

1. Accelerated 5G and 6G Infrastructure Deployment

The continued global expansion of 5G networks and early-stage development of 6G testbeds are major growth drivers for right angle coax solutions. These connectors are essential in densely packed base stations, massive MIMO (Multiple Input Multiple Output) antenna arrays, and small cell installations where spatial constraints favor right angle designs. In 2026, demand will be particularly strong in urban and indoor deployment scenarios requiring high-density RF interconnects with minimal signal loss.

2. Miniaturization in Consumer and Mobile Devices

Smartphones, tablets, and wearable technology continue to shrink in size while increasing in RF complexity. Right angle coax cables enable efficient routing in tight internal layouts, especially for internal antennas, UWB (Ultra-Wideband), and mmWave modules. By 2026, leading OEMs are expected to adopt ultra-miniature right angle coax solutions (e.g., 0.81mm and 0.65mm pitch) to support advanced antenna-in-package (AiP) and display integration.

3. Growth in Automotive Radar and ADAS

Autonomous driving and advanced driver-assistance systems (ADAS) rely heavily on high-frequency radar (77–81 GHz), where right angle coax connectors provide reliable RF interconnects between sensors and ECUs. With increasing vehicle electrification and sensor fusion, the automotive sector is projected to be one of the fastest-growing markets for high-performance coax components. In 2026, automotive-grade right angle coax solutions with enhanced durability and temperature resistance will be in high demand.

4. Expansion in Aerospace and Defense Applications

Military and aerospace platforms—including drones, satellite communication (SATCOM) terminals, and electronic warfare (EW) systems—require compact, high-reliability RF interconnects. Right angle coax connectors are increasingly used in phased array radar systems and avionics due to their ability to reduce bend radius and save space. With global defense budgets rising, this sector will continue to fuel demand for ruggedized, high-frequency designs.

5. Advancements in Materials and Signal Integrity

To meet the performance requirements of high-speed data transmission (beyond 40 GHz), manufacturers are investing in low-loss dielectric materials, precision-machined contacts, and improved shielding. In 2026, right angle coax solutions with enhanced phase stability, reduced passive intermodulation (PIM), and superior impedance control will be critical, especially in mmWave and aerospace applications.

6. Regional Market Shifts

Asia-Pacific—led by China, Japan, and South Korea—remains the dominant manufacturing and consumption hub for right angle coax components, driven by electronics and telecom infrastructure investments. However, North America is seeing resurgence due to onshoring of semiconductor and defense manufacturing, boosting local demand for high-reliability interconnects.

7. Sustainability and Supply Chain Resilience

By 2026, there is growing emphasis on sustainable manufacturing, recyclable materials, and supply chain transparency. OEMs are favoring suppliers with robust ESG (Environmental, Social, and Governance) practices. Additionally, geopolitical factors are prompting diversification of supply chains, leading to increased regional sourcing and inventory buffering.

Conclusion

The 2026 market for right angle coax is characterized by strong growth across high-tech sectors, underpinned by the need for compact, high-performance RF connectivity. Innovation in materials, design, and application-specific solutions will define competitive advantage. Companies that align with 5G/6G, automotive electrification, and defense modernization trends while ensuring supply chain resilience will be best positioned to capitalize on emerging opportunities.

Common Pitfalls Sourcing Right Angle Coax (Quality, IP)

Sourcing right angle coaxial components—such as cables, connectors, or assemblies—requires careful consideration to ensure reliability, performance, and compliance, especially in high-frequency or rugged environments. Overlooking key aspects can lead to signal integrity issues, mechanical failures, or intellectual property (IP) risks. Below are common pitfalls to avoid:

Quality-Related Pitfalls

1. Compromised Signal Integrity Due to Poor Manufacturing

Low-cost suppliers may use substandard materials or imprecise manufacturing techniques, leading to impedance mismatches, increased insertion loss, or return loss. Right angle bends are particularly sensitive; poor forming can distort the coaxial geometry, degrading RF performance at higher frequencies.

2. Inconsistent Mechanical Durability

Right angle connectors are more prone to mechanical stress during mating and installation. Inferior plating, weak strain reliefs, or inadequate bonding can result in cracked solder joints, shield separation, or connector breakage—especially in high-vibration applications.

3. Lack of Environmental Sealing (IP Rating Misinterpretation)

Many right angle coax connectors claim IP (Ingress Protection) ratings, but not all meet the standard consistently. A common pitfall is assuming an IP67-rated connector maintains its rating after repeated mating cycles or under temperature extremes. Poor gasket design or inconsistent housing tolerances can compromise sealing over time.

4. Use of Non-Compliant or Counterfeit Materials

Some suppliers use unverified or counterfeit coaxial cable stock, which may not meet specifications for dielectric stability, shielding effectiveness, or fire resistance (e.g., failing UL or CPR standards). This can lead to intermittent failures or regulatory non-compliance.

Intellectual Property (IP) and Compliance Pitfalls

1. Infringement of Proprietary Connector Designs

Right angle versions of patented connectors (e.g., certain SMP, MCX, or custom OEM designs) may be reverse-engineered by third parties without proper licensing. Sourcing such clones risks IP litigation and may result in unreliable performance due to deviations from original specifications.

2. Lack of Traceability and Documentation

Reputable suppliers provide full traceability, RoHS/REACH compliance, and performance test data. Many low-cost sources offer minimal documentation, making it difficult to verify authenticity, support quality audits, or ensure regulatory compliance—especially critical in medical, aerospace, or defense applications.

3. No Access to Design Specifications or Support

When sourcing from obscure or unauthorized vendors, engineers may lack access to critical design files, mating specifications, or application support. This increases risk during integration and troubleshooting, particularly when signal integrity or mechanical fit is marginal.

Mitigation Strategies

- Source from Authorized Distributors or OEMs: Ensure components are genuine and supported.

- Demand Test Reports and Certifications: Request VSWR, insertion loss, and IP validation data.

- Verify IP Ratings with Real-World Testing: Don’t rely solely on datasheet claims; conduct lifecycle or environmental testing.

- Conduct Supplier Audits: Assess manufacturing quality systems (e.g., ISO 9001) and counterfeit prevention practices.

- Review Legal and Licensing Agreements: Confirm freedom to operate and avoid IP exposure.

Avoiding these pitfalls ensures long-term reliability, regulatory compliance, and protection against technical and legal risks when integrating right angle coax solutions.

Logistics & Compliance Guide for Right Angle Coax Cables

Overview

Right angle coaxial (coax) cables are widely used in telecommunications, broadcast, military, and networking applications where space constraints or cable routing challenges require compact, low-profile connections. Ensuring efficient logistics and regulatory compliance is essential for global supply chain operations, product safety, and market access.

Regulatory Compliance Requirements

International Standards

Right angle coax cables must comply with globally recognized standards, including:

– IEC 60227 / IEC 60245: For general requirements on insulated cables.

– RoHS (Restriction of Hazardous Substances) Directive 2011/65/EU: Restricts use of lead, mercury, cadmium, and other hazardous materials.

– REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Requires disclosure of Substances of Very High Concern (SVHC).

– CE Marking: Mandatory for products sold in the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

North American Regulations

- UL/ETL Listing (UL 44, UL 83, or UL 1581): Required for electrical safety in the U.S. and Canada.

- FCC Part 15: Governs electromagnetic interference (EMI) emissions for electronic devices using coaxial cables.

- NFPA 70 (National Electrical Code – NEC): Specifies safe installation practices, particularly for plenum and riser-rated cables.

Environmental and Material Compliance

- Conflict Minerals (Dodd-Frank Act Section 1502): Requires reporting on the use of tin, tantalum, tungsten, and gold (3TG) sourced from conflict-affected regions.

- Proposition 65 (California): Mandates warnings for products containing chemicals known to cause cancer or reproductive harm.

Packaging and Labeling

Required Markings

All right angle coax cables must be clearly labeled with:

– Manufacturer name or trademark

– Cable type and specifications (impedance, conductor size, shielding, frequency range)

– Voltage and temperature ratings

– Compliance markings (e.g., UL, CE, RoHS)

– Lot or batch number for traceability

Packaging Standards

- Use anti-static and moisture-resistant packaging to protect connectors and dielectric materials.

- Include compliance documentation (e.g., Declaration of Conformity, RoHS Certificate) with shipments.

- Label outer packaging with handling symbols (e.g., “Fragile,” “Do Not Bend,” “Keep Dry”).

Logistics and Transportation

Storage Conditions

- Store in a dry, temperature-controlled environment (typically 10°C to 30°C).

- Avoid prolonged exposure to UV light, extreme temperatures, or corrosive atmospheres.

- Store on reels or in coiled form to prevent kinking or connector damage.

Shipping Considerations

- Use rigid containers to protect right angle connectors from physical impact.

- Secure cables to prevent movement during transit.

- For international shipments, comply with:

- IMDG Code (maritime transport of dangerous goods – if applicable)

- IATA DGR (air transport regulations)

- ADR (road transport in Europe)

Import/Export Documentation

- Provide accurate Harmonized System (HS) codes (e.g., 8544.30 for insulated electric conductors).

- Submit commercial invoices, packing lists, and certificates of origin.

- Include compliance certificates (RoHS, REACH, UL) for customs clearance.

Quality Assurance and Traceability

Testing and Certification

- Perform routine electrical testing (impedance, VSWR, insertion loss, shielding effectiveness).

- Maintain certification from accredited third-party labs (e.g., TÜV, SGS, Intertek).

- Keep test records for minimum of 5 years for audit and traceability purposes.

Batch Traceability

- Assign unique batch/lot numbers to each production run.

- Maintain logs linking materials, production date, testing results, and shipment details.

- Support rapid recall procedures if non-conformities are identified.

Disposal and End-of-Life

WEEE Compliance (EU)

- Right angle coax cables fall under the Waste Electrical and Electronic Equipment (WEEE) directive.

- Provide take-back programs or partner with certified e-waste recyclers.

- Label products with the “crossed-out wheeled bin” symbol.

Recycling Guidance

- Recommend separation of copper conductors, dielectric materials, and shielding for recycling.

- Avoid incineration due to potential release of halogenated compounds (in PVC-jacketed cables).

Summary

Compliance and logistics for right angle coax cables involve adherence to technical standards, environmental regulations, and safe handling practices. Manufacturers and distributors must maintain rigorous documentation, ensure proper labeling, and follow international shipping protocols to support reliable and lawful product distribution.

Conclusion for Sourcing Right-Angle Coaxial Connectors

Sourcing the right-angle coaxial connectors requires a careful evaluation of technical specifications, application requirements, and supplier reliability. Right-angle coax connectors are essential in space-constrained or high-frequency applications where signal integrity, compact design, and ease of integration are critical. When selecting a supplier, key factors such as impedance compatibility (typically 50Ω or 75Ω), frequency range, connector type (e.g., SMA, BNC, N-Type), durability, and shielding performance must be prioritized.

It is recommended to source from reputable manufacturers or distributors with proven quality certifications (e.g., ISO, RoHS) and consistent performance in RF and microwave applications. Additionally, considering customization options, lead times, and total cost of ownership—not just unit price—will ensure long-term reliability and system efficiency.

In conclusion, a strategic sourcing approach that balances technical fit, quality assurance, and supply chain stability will lead to optimal performance and reliability of right-angle coaxial connectors in any RF or high-speed electronic system.