The global electrical conduit market is experiencing steady expansion, driven by rising infrastructure development, increasing demand for energy-efficient building systems, and stringent safety regulations across industrial and commercial construction sectors. According to Grand View Research, the global electrical conduit market size was valued at USD 9.2 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is further fueled by urbanization, modernization of aging electrical infrastructure, and the proliferation of smart buildings—trends that are amplifying the need for high-quality conduit solutions that ensure electrical safety, durability, and compliance. As demand rises, a select group of manufacturers have emerged as industry leaders, combining innovation, scalability, and reliability to dominate regional and global supply chains. Here’s a look at the top 8 RGS (rigid galvanized steel) electrical conduit manufacturers shaping the market today.

Top 8 Rgs Electrical Conduit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 RGS and PVC coated RGS electrical conduit

Domain Est. 2007

Website: modinest.com

Key Highlights: RGS and PVC coated RGS electrical conduits complete range available with high quality and excellent price offer at Modern Industrial Company….

#2 Electrical RSC RGS GRC RMC Conduit Elbow

Domain Est. 2017

Website: chinagipipe.com

Key Highlights: We’re known as one of the leading Rigid Electrical Conduit manufacturers and suppliers in China. Welcome to wholesale the quality electrical rsc rgs grc rmc ……

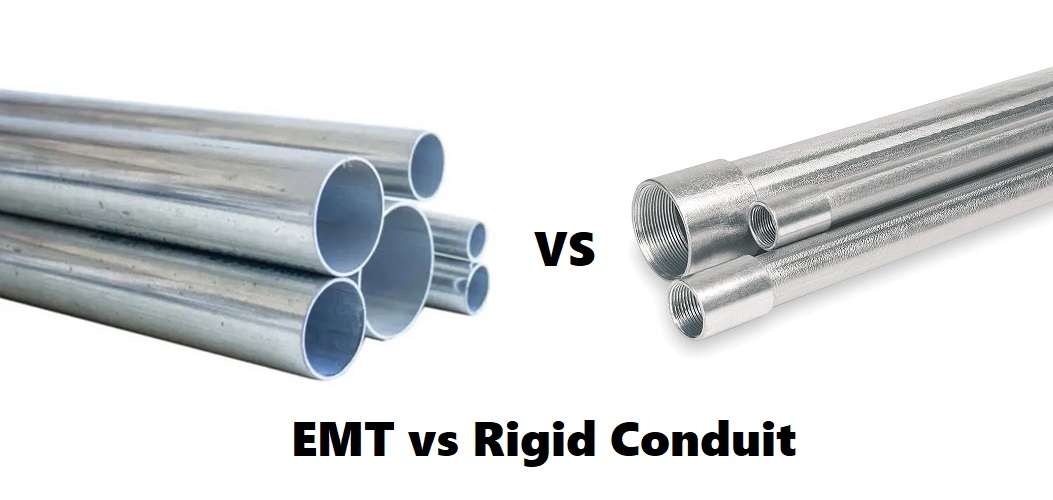

#3 EMT Conduit Vs. Rigid Conduit

Domain Est. 2020

Website: ctube-gr.com

Key Highlights: 2.1 What Is EMT Conduit? EMT (Electrical Metallic Tubing) is a thin-wall metal conduit commonly used in commercial and light industrial wiring….

#4 rgs electrical rigid conduit pipe

Domain Est. 2022

Website: gi-pipes.com

Key Highlights: Good quality rgs electrical rigid conduit pipe from rgs electrical rigid conduit pipe manufacturers, We sell rgs electrical rigid conduit pipe online from China ……

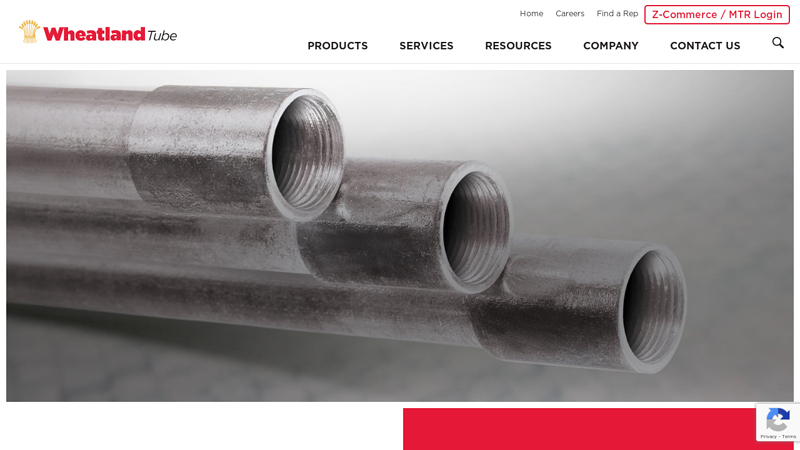

#5 Steel Rigid Metal Conduit (RMC)

Domain Est. 1995

Website: wheatland.com

Key Highlights: Wheatland’s steel rigid metal conduit (RMC) is made and melted in America and hot-dipped galvanized for use in tough environments….

#6 rgs electrical conduit: Durable, UL

Domain Est. 1997

Website: accio.com

Key Highlights: Rating 5.0 (50) · Free 14-day returnsNov 14, 2025 · Looking for reliable rgs electrical conduit? Discover UL-certified, hot-dip galvanized steel conduits with heavy wall thickn…

#7 World Electric Supply

Domain Est. 1999

Website: worldelectricsupply.com

Key Highlights: FEATURED CATEGORIES · Metal Clad & Armored Cables · Circuit Breakers · Copper Building Wires & Cables · Electrical Fittings · PVC Conduit · Receptacles ……

#8 Allied Tube & Conduit

Domain Est. 2010

Website: atkore.com

Key Highlights: We are a manufacturing leader of steel, PVC, and aluminum conduit as well as mechanical, safety, and traffic solutions….

Expert Sourcing Insights for Rgs Electrical Conduit

H2: 2026 Market Trends for RGS Electrical Conduit

Based on current industry trajectories, technological advancements, and macroeconomic factors, the market for RGS (Rigid Galvanized Steel) electrical conduit in 2026 is expected to experience steady demand driven by foundational construction needs, but also face significant competitive and environmental pressures. Here’s a breakdown of key trends:

1. Steady Demand in Core Sectors, But Growth Moderated by Alternatives:

RGS conduit will maintain a strong foothold in traditional applications where its durability, fire resistance, and mechanical protection are paramount. Key growth areas include:

* Commercial & Industrial Construction: Ongoing development of offices, warehouses, data centers, and manufacturing facilities will require robust, code-compliant wiring protection, benefiting RGS.

* Infrastructure & Renewables: Government infrastructure spending (e.g., grid upgrades, public buildings) and the expansion of solar farms and EV charging stations (requiring durable conduit for outdoor and grounding applications) will provide consistent demand.

* Retrofit & Renovation: Existing building upgrades often necessitate RGS for compliance and safety, ensuring a baseline market.

However, this demand growth will be moderated by the increasing adoption of lighter, easier-to-install alternatives like EMT (Electrical Metallic Tubing) and non-metallic conduits (PVC, HDPE, FMC) in residential and some commercial applications, particularly where cost and installation speed are critical.

2. Intensifying Competition from Lightweight & Non-Metallic Conduits:

The most significant competitive pressure will come from:

* EMT (Thin-Wall Conduit): Its lower material cost, lighter weight, and faster installation (no threading) make it highly attractive for cost-sensitive projects where extreme mechanical protection isn’t required. Its market share is likely to grow at RGS’s expense in standard applications.

* PVC & HDPE Conduits: These dominate underground, wet locations, and corrosive environments due to superior corrosion resistance and lower installation costs. Their use in direct-burial applications and telecom will continue to expand.

* FMC & LFMC: Used for short connections to moving equipment, offering flexibility RGS cannot match.

RGS will need to emphasize its unique value proposition (superior crush resistance, fire rating, EMI shielding, grounding capability, longevity) to justify its higher cost and labor requirements.

3. Rising Focus on Sustainability & Material Efficiency:

Sustainability will become a more prominent factor:

* Recyclability: RGS is 100% recyclable, a significant advantage over non-metallics ending up in landfills. This will be a key marketing point, especially with green building certifications (LEED, BREEAM).

* Embodied Carbon: While steel production is carbon-intensive, the longevity and recyclability of RGS can offset this over its lifecycle. Manufacturers may face pressure to demonstrate lower-carbon steel sourcing and production methods.

* Material Optimization: Designers and contractors will seek solutions minimizing material use. This could favor EMT or optimized conduit routing, challenging RGS’s bulk.

4. Supply Chain Resilience & Cost Volatility:

Steel Prices: RGS costs remain highly sensitive to global steel prices, scrap metal markets, and energy costs. Geopolitical instability and trade policies could cause significant price fluctuations, impacting project budgets.

* Logistics & Sourcing:* Continued focus on supply chain resilience may lead to regional sourcing preferences, benefiting manufacturers with local/nearshore production capabilities. Disruptions remain a risk.

5. Technological & Installation Efficiency Pressures:

Prefabrication & BIM: The rise of off-site prefabrication and Building Information Modeling (BIM) favors conduits that integrate easily into modular systems and digital workflows. RGS’s rigidity can be both an advantage (precision) and disadvantage (less flexibility in complex layouts) compared to more flexible options.

* Labor Costs & Skill Shortages: High labor costs and skilled trades shortages amplify the advantage of faster-installation conduits like EMT or pre-threaded/prefab RGS solutions. Manufacturers offering value-added services (pre-threading, bending, labeling) or easier installation systems* will gain market share.

Conclusion for RGS in 2026:

RGS electrical conduit will remain a vital and reliable solution, particularly in demanding commercial, industrial, infrastructure, and safety-critical applications where its inherent strength and fire performance are non-negotiable. However, its market will be constrained by the superior cost-effectiveness and ease of installation of EMT and the dominance of non-metallics in corrosive/underground environments. Success for RGS manufacturers and distributors in 2026 will depend on:

* Emphasizing Core Strengths: Relentlessly marketing durability, fire safety, grounding, and longevity.

* Innovation: Offering value-added services (prefab, pre-threading) and potentially exploring lighter-weight galvanized options or improved installation tools.

* Sustainability Story: Leveraging recyclability and long lifespan as key environmental benefits.

* Supply Chain Management: Mitigating steel cost volatility and ensuring reliable delivery.

* Targeted Strategy: Focusing efforts on sectors where RGS’s advantages are most valued and difficult to replace.

Common Pitfalls Sourcing RGS Electrical Conduit (Quality, IP)

Sourcing RGS (Rolled Galvanized Steel) electrical conduit requires careful attention to ensure long-term performance and safety. Overlooking key factors can lead to compromised quality, inadequate ingress protection (IP), and project delays. Below are common pitfalls to avoid:

Inadequate Material Thickness and Structural Integrity

One frequent issue is procuring conduit with insufficient wall thickness. Substandard RGS conduit may meet nominal size requirements but falls short in mechanical strength, making it prone to crushing, denting, or deformation during installation or under load. Always verify compliance with relevant standards (e.g., EN 61386, IEC 61386-1) and confirm the specified gauge or metric thickness matches project specifications.

Poor Galvanization Quality

The protective zinc coating is critical for corrosion resistance. Poorly galvanized conduit can exhibit thin, uneven, or patchy coatings, leading to premature rust and reduced service life—especially in humid or corrosive environments. Look for conduit that meets ASTM A53 or ISO 1461 standards for hot-dip galvanizing and request mill test certificates to verify coating thickness (typically ≥50–80 µm).

Non-Compliance with IP Ratings

A key oversight is assuming RGS conduit automatically provides high IP protection. While metal conduit inherently offers good mechanical and environmental protection, the overall IP rating depends on proper installation with compatible fittings, seals, and couplings. Sourcing conduit without verifying compatibility with IP-rated accessories (e.g., sealed connectors, watertight couplings) can result in failed IP65, IP66, or higher requirements. Ensure the full system—not just the conduit—meets the required IP classification.

Use of Substandard or Non-Certified Fittings

Even high-quality conduit can be undermined by inferior couplings, boxes, or connectors. Low-grade fittings may lack proper threading, corrosion resistance, or sealing capabilities, compromising both mechanical integrity and IP performance. Always source fittings from the same reputable manufacturer or ensure third-party fittings are certified for use with RGS conduit and compliant with relevant standards.

Lack of Traceability and Certification

Procuring conduit without proper documentation—such as test reports, CE marking, or third-party certifications—increases the risk of counterfeit or non-compliant products. Insist on mill test certificates, conformity declarations, and batch traceability to ensure authenticity and performance consistency.

Ignoring Environmental and Application Requirements

RGS conduit performance varies depending on the environment. Using standard galvanized conduit in coastal, chemical, or high-moisture areas without additional protective measures (e.g., supplemental coatings) can lead to rapid degradation. Always assess the operating environment and select conduit with appropriate corrosion protection for the intended service life.

Inconsistent Dimensional Tolerances

Off-spec conduit can cause fitting misalignment, difficulty in pulling cables, or improper grounding continuity. Poor dimensional control leads to gaps in connections, reducing both mechanical stability and IP performance. Verify that conduit dimensions adhere to standard tolerances and are compatible with installed accessories.

By recognizing and addressing these common pitfalls, procurement teams and project managers can ensure the reliable, safe, and code-compliant installation of RGS electrical conduit systems.

Logistics & Compliance Guide for RGS Electrical Conduit

This guide outlines the key logistics and compliance considerations for handling, transporting, storing, and using RGS Electrical Conduit to ensure safety, regulatory adherence, and product integrity.

Product Overview

RGS Electrical Conduit, typically referring to Rigid Galvanized Steel conduit, is a heavy-duty, corrosion-resistant raceway used to protect and route electrical wiring in commercial, industrial, and utility applications. It complies with relevant national and international standards, including but not limited to UL 6, ASTM A53, and NEC Article 344.

Regulatory Compliance

RGS conduit must meet specific regulatory standards to ensure safety and performance:

- UL Certification: RGS conduit is UL Listed under category “Electrical Metallic Tubing – Steel” (QCMZ) and complies with UL 6, the Standard for Steel Electric Conduit.

- NEC Compliance: Meets requirements of the National Electrical Code (NEC) Article 344, covering installation, bonding, and grounding.

- ASTM Standards: Conforms to ASTM A53 for structural steel pipe and ASTM A123 for zinc (galvanized) coatings.

- RoHS & REACH: Compliant with Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulations where applicable.

Ensure all supplied products include proper certification markings (e.g., UL logo, manufacturer ID, trade size, wall thickness) and are accompanied by compliance documentation upon request.

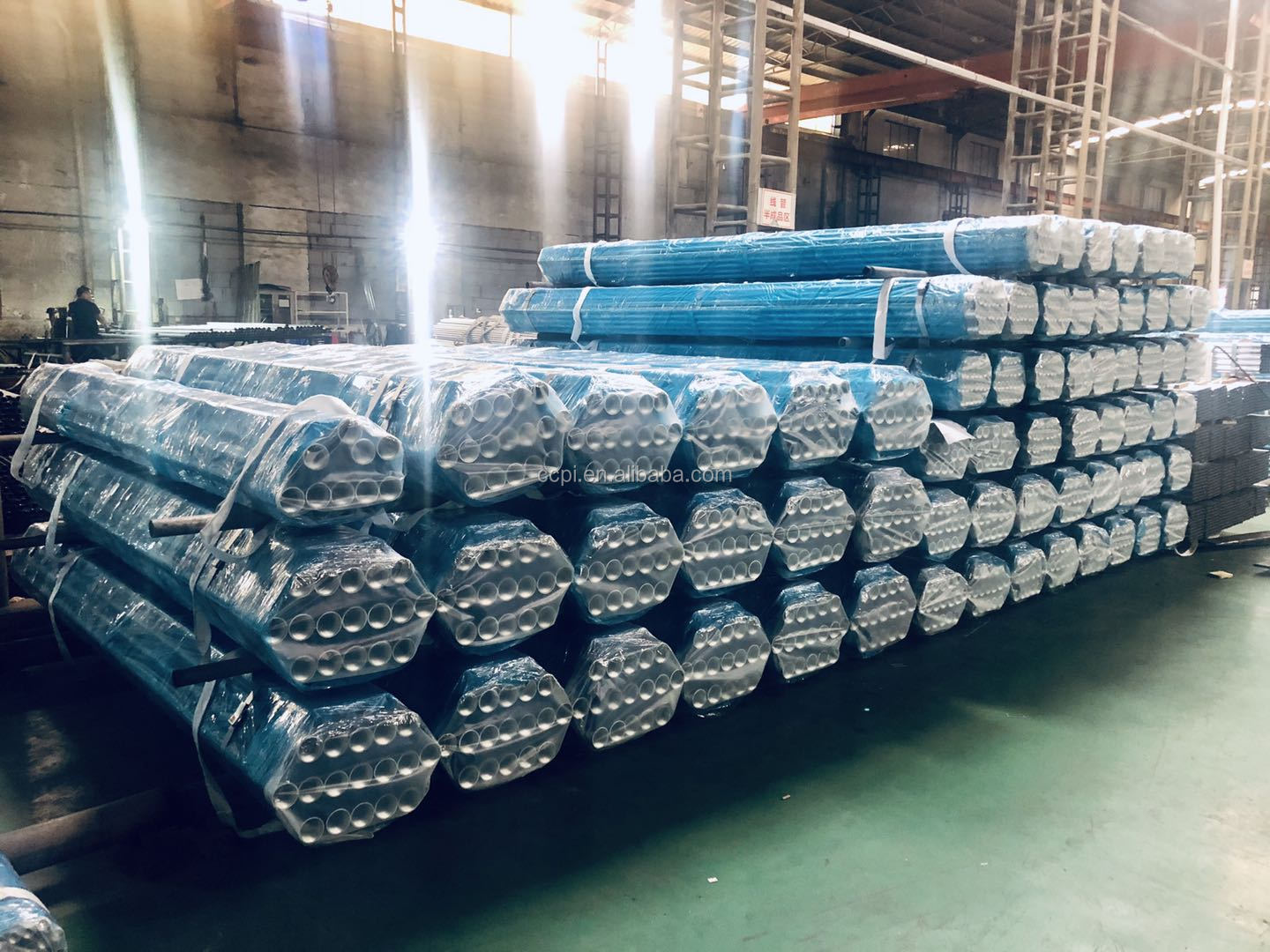

Packaging & Handling

Proper packaging and handling are essential to prevent damage and maintain product quality:

- Standard Packaging: Conduit is typically bundled in lengths of 10 ft or 20 ft, secured with steel or nylon strapping. Bundles are labeled with product type, size, length, and batch number.

- Lifting & Transport: Use forklifts or cranes with padded slings to lift bundles. Avoid dragging or dropping, which can deform conduit or damage galvanization.

- Handling Precautions: Wear protective gloves to prevent cuts from sharp edges. Avoid rolling conduit on unprotected surfaces to minimize coating abrasion.

Transportation Guidelines

Ensure safe and secure transit to prevent damage and maintain compliance:

- Load Securing: Secure bundles on flatbed or enclosed trucks using ratchet straps or chains. Prevent shifting during transport.

- Weather Protection: Cover loads with waterproof tarps if transported in open vehicles to prevent moisture exposure and rust formation.

- Stacking Limits: Do not stack conduit bundles more than two high during transport unless specifically designed for multi-level stacking.

- Documentation: Include a packing slip, bill of lading, and compliance certificates with each shipment.

Storage Requirements

Proper storage extends the life of RGS conduit and preserves its protective coating:

- Indoor Storage: Store in a dry, covered area whenever possible to avoid prolonged exposure to moisture and precipitation.

- Outdoor Storage: If stored outdoors, elevate bundles off the ground using wooden skids and cover completely with UV-resistant plastic. Ensure adequate airflow to prevent condensation.

- Stacking: Limit stack height to three bundles high. Use dunnage between layers to prevent crushing and deformation.

- Separation: Keep conduit away from corrosive chemicals, salts, and high-humidity zones.

Installation & Field Use Compliance

Ensure proper installation practices in accordance with codes and standards:

- Cutting & Threading: Use appropriate tools (e.g., pipe threaders, cutoff saws) to avoid damaging galvanized coating. Deburr all cut ends.

- Grounding & Bonding: RGS conduit can serve as an equipment grounding conductor per NEC 250.118(2), provided it is properly coupled and bonded.

- Support & Securing: Follow NEC 344.30 for maximum support intervals (typically every 3 ft for ½”–1” conduit, up to 10 ft for 2” and larger).

- Bending: Use hydraulic or mechanical benders designed for rigid steel conduit to maintain structural integrity and inner diameter.

Environmental & Safety Considerations

Adhere to environmental and occupational safety standards:

- Galvanized Coating Hazards: Avoid grinding or welding galvanized steel without proper ventilation and respiratory protection (zinc oxide fumes can cause “metal fume fever”).

- Recycling: Steel conduit is 100% recyclable. Dispose of scrap material through approved metal recycling channels.

- Spill & Waste Management: Collect and dispose of metal shavings and cutting fluids in accordance with local environmental regulations.

Documentation & Traceability

Maintain full traceability and compliance records:

- Batch Records: Each shipment should include a lot or batch number for traceability.

- Certificates of Compliance (CoC): Available upon request; include material test reports and certification statements.

- Retention: Retain compliance and shipping documents for a minimum of five years, or as required by project or jurisdictional standards.

By following this guide, stakeholders ensure that RGS Electrical Conduit is handled, stored, transported, and installed in full compliance with applicable standards, promoting safety, durability, and regulatory acceptance.

Conclusion for Sourcing RGS Electrical Conduit

In conclusion, sourcing rigid galvanized steel (RGS) electrical conduit requires a strategic approach that balances quality, compliance, cost-efficiency, and supply chain reliability. RGS conduit remains a preferred choice for electrical installations in demanding environments due to its durability, fire resistance, and mechanical protection for wiring systems. When selecting suppliers, it is essential to prioritize those that adhere to recognized industry standards such as ASTM A53 or AS/NZS 2053, ensuring the product meets required specifications for thickness, corrosion resistance, and structural integrity.

Key considerations include evaluating supplier reputation, material certifications, lead times, and logistical capabilities. Partnering with established manufacturers or distributors with a proven track record helps mitigate risks related to substandard materials or project delays. Additionally, conducting periodic quality audits and requesting sample testing can further ensure long-term performance and compliance, particularly in commercial, industrial, or infrastructure projects where safety and reliability are paramount.

Ultimately, effective sourcing of RGS electrical conduit supports safer electrical installations, reduces lifecycle maintenance costs, and contributes to the overall success and compliance of construction and electrical projects. A well-informed procurement strategy ensures that the chosen conduit meets both technical requirements and project-specific demands.