The global fiber optic cable market is experiencing robust expansion, driven by increasing demand for high-speed internet, 5G network deployment, and data center growth. According to a report by Mordor Intelligence, the fiber optic cable market was valued at USD 9.27 billion in 2024 and is projected to reach USD 13.72 billion by 2029, growing at a CAGR of 8.2% during the forecast period. This surge is further fueled by rising broadband penetration and government initiatives to enhance digital infrastructure worldwide. As one of the most widely used coaxial cables for RF signal transmission, RG8 continues to play a critical role in telecommunications, broadcasting, and enterprise networking applications. With escalating demand for reliable and high-performance cabling solutions, a competitive landscape of manufacturers has emerged, focusing on quality, durability, and compliance with international standards. Below, we highlight the top 8 RG8 cable manufacturers leading innovation and market share in this expanding industry.

Top 8 Rg8 Cable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

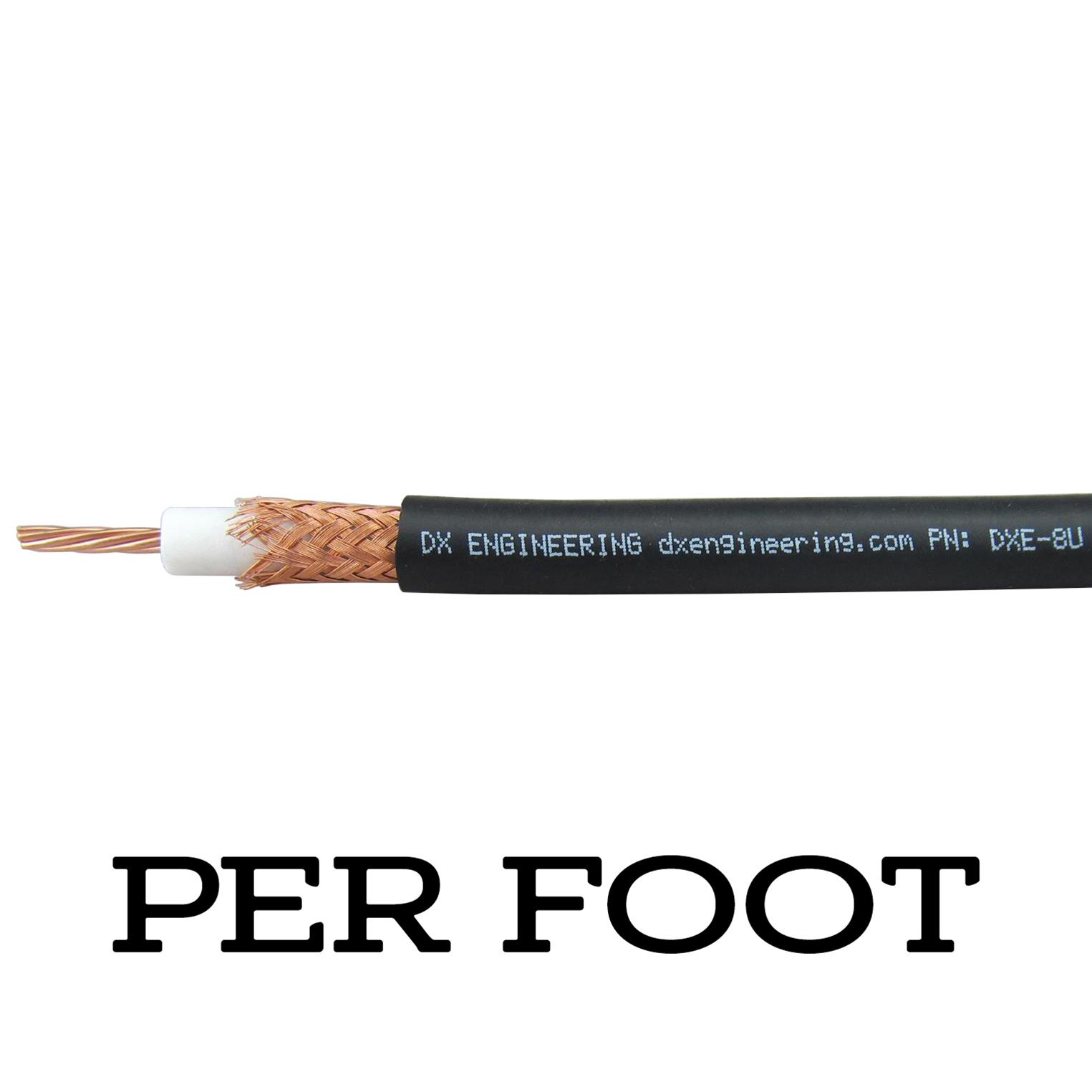

#1 RG 8

Domain Est. 2003

Website: adcable.com

Key Highlights: Advanced Digital Cable Inc. Manufacturer of Electronic, IMSA Traffic, Industrial and RF Wire and Cable. Made In The USA….

#2 LMR-400

Domain Est. 1996

Website: timesmicrowave.com

Key Highlights: The LMR® cable series includes the ultra-flexible LMR-400, 50 Ohms coax cable with UV Resistant jacket. Great drop-in replacement for RG-8/9913 cables….

#3 COAXNTN

Domain Est. 1996

Website: campbellsci.com

Key Highlights: Overview. The COAXNTN consists of an RG8/U, low-loss coaxial cable fitted with a Type N pin (male) connector on each end….

#4 Flexible RG8 Coax Cable Single Shielded with Black PVC (NC) Jacket

Domain Est. 1997

#5 RG8 Coaxial Cable

Domain Est. 1997

Website: awcwire.com

Key Highlights: RG8 coaxial cable is a relatively large diameter, 50-ohm coaxial cable. Its primary applications include broadcasting, amateur radios, and antenna feed cable….

#6 Coaxial Cable 9008

Domain Est. 1997

Website: alphawire.com

Key Highlights: Alpha Essentials Coaxial Cable offers a complete range of 50, 75, 93 and 100 Ohm coaxial, twinaxial and triaxial cables….

#7 RG 8/U Coaxial Cable Cable #CXE11_1483

Domain Est. 1998

Website: omnicable.com

Key Highlights: RG 8/U Coaxial Cable. Part #: E20801. RG 8/U Copper Braid Shield PVC Jacket Conductors. select 1 Gauge select 11. Please enter a minimum total Length of 500 ft….

#8 RG8 Coax Cable

Domain Est. 2002

Website: showmecables.com

Key Highlights: Our bulk RG8 coaxial cable has a stranded and solid conductor type with a bare copper center conductor and bare copper-covered aluminum conductor materials….

Expert Sourcing Insights for Rg8 Cable

H2: Market Trends for RG8 Cable in 2026

As we approach 2026, the market for RG8 coaxial cable—a robust, high-impedance cable traditionally used in radio frequency (RF) transmission, amateur radio, and commercial broadcast applications—is undergoing notable shifts influenced by technological evolution, infrastructure development, and changing communication demands. While the broader coaxial cable industry faces competition from fiber optics and wireless technologies, RG8 maintains a niche presence driven by specific industrial and legacy system requirements.

1. Stabilizing Demand in Niche Applications

By 2026, RG8 cable is expected to see stable, albeit modest, demand in specialized sectors. Its high power-handling capacity and durability make it ideal for high-frequency RF applications in amateur (ham) radio, military communications, and certain industrial settings. These niche markets continue to rely on RG8 for its reliability in environments where signal integrity over short to medium distances is critical. Ham radio communities, in particular, remain a consistent consumer base, especially in regions with active emergency communication networks.

2. Competition from Fiber Optics and Wireless

The expansion of fiber-to-the-home (FTTH), 5G infrastructure, and wireless backhaul technologies continues to displace coaxial solutions in mainstream telecommunications. Unlike RG8, fiber optics offer higher bandwidth, lower loss, and immunity to electromagnetic interference. As a result, RG8 is increasingly sidelined in large-scale telecom deployments. However, in hybrid systems—such as those combining fiber backbone with coaxial last-mile RF distribution—RG8 variants may still be used in intermediate transmission stages.

3. Regional Market Variations

In emerging markets, particularly in parts of Asia, Africa, and Latin America, RG8 demand may experience slight growth due to ongoing deployment of broadcast and radio communication infrastructure. These regions often adopt cost-effective, proven technologies like RG8 for community radio stations, public safety networks, and rural connectivity projects. Conversely, in North America and Western Europe, demand is expected to remain flat or decline slightly, reflecting a shift toward modern alternatives.

4. Product Evolution and Hybrid Solutions

Manufacturers are adapting by enhancing RG8 cable performance through improved shielding, weather-resistant jackets, and low-loss dielectric materials. Some are offering RG8 as part of hybrid connectivity kits that integrate with modern transceivers and antenna systems. These adaptations aim to extend the cable’s relevance in RF-heavy applications where digital signal processing still requires high-quality analog transmission lines.

5. Sustainability and Supply Chain Factors

Environmental regulations and supply chain dynamics are influencing RG8 production. Rising costs of copper—the primary conductor in RG8—are prompting some manufacturers to explore alternative materials or promote recycling programs. Additionally, geopolitical factors affecting raw material availability could influence pricing and availability, particularly in 2026 when global infrastructure spending may peak in certain regions.

Conclusion

While the RG8 cable market is not expected to grow significantly by 2026, it will persist due to its specialized utility and reliability in RF transmission. The cable’s future lies in adaptation—serving legacy systems, supporting emergency and amateur radio, and integrating into hybrid communication architectures. Stakeholders should focus on innovation, regional demand analysis, and sustainability to maintain relevance in an increasingly fiber- and wireless-dominated landscape.

Common Pitfalls When Sourcing RG8 Cable: Quality and Intellectual Property Concerns

Sourcing RG8 coaxial cable, often used in high-frequency RF applications like amateur radio, broadcasting, and military communications, can present several challenges. Buyers must be vigilant to avoid issues related to substandard quality and potential intellectual property (IP) violations. Below are key pitfalls to watch for:

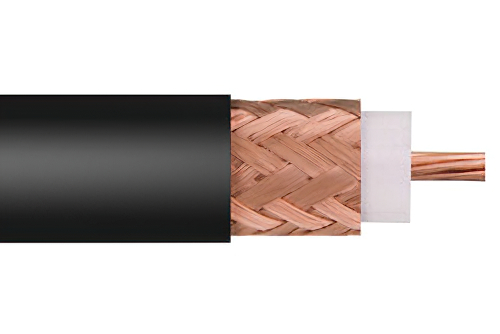

Poor Manufacturing Quality and Material Substitution

One of the most frequent issues is the use of inferior materials and inconsistent manufacturing processes. Many low-cost suppliers, particularly from regions with less stringent oversight, may substitute key components to reduce costs. For example, some cables labeled as RG8 may use copper-clad steel (CCS) conductors instead of the specified solid or stranded bare copper, which increases signal loss and reduces flexibility. Similarly, dielectric foam insulation may be of lower density, leading to impedance instability and higher attenuation. These deviations compromise performance and reliability, especially in critical or long-term installations.

Inaccurate or Inconsistent Impedance and Specifications

RG8 cable is designed for a nominal impedance of 50 ohms. However, poor-quality versions often fail to maintain this standard due to imprecise manufacturing tolerances. Variations in the center conductor diameter, dielectric thickness, or braid coverage can result in impedance mismatches, causing signal reflections, standing wave ratio (SWR) issues, and degraded transmission efficiency. Buyers relying on technical specifications provided by unreliable suppliers may unknowingly install cables that do not meet required RF performance standards.

Mislabeling and Counterfeit Branding

Counterfeiting and mislabeling are serious concerns when sourcing RG8 cable. Some suppliers falsely label generic or lower-grade cables as premium brands (e.g., Times Microwave LMR-400 or Belden 9913), which are sometimes confused with or substituted for traditional RG8. These counterfeit cables may bear fake certifications, incorrect part numbers, or imitation packaging. This not only leads to performance issues but may also expose the buyer to legal or compliance risks, especially in regulated industries.

Lack of Compliance with Industry Standards

Authentic RG8 cable adheres to MIL-DTL-17 military specifications, which define rigorous performance and durability criteria. However, many off-brand cables do not meet these standards but are still marketed as “RG8-type” or “RG8 equivalent.” Without proper certification (such as MIL-PRF-17 or independent test reports), buyers have no assurance of environmental resistance, fire safety (e.g., plenum rating), or long-term durability. This becomes a significant risk in demanding applications or installations requiring regulatory compliance.

Intellectual Property Infringement

Reputable manufacturers invest heavily in R&D and hold intellectual property rights over specific cable designs, materials, and manufacturing techniques. When third-party suppliers replicate these designs without authorization—especially those mimicking patented cable constructions—they may infringe on IP rights. Purchasing such cables, even unknowingly, can entangle buyers in legal disputes, particularly in commercial or government contracts where IP compliance is scrutinized. Additionally, using counterfeit or IP-infringing cables can void warranties and insurance coverage.

Inadequate Documentation and Traceability

Reliable suppliers provide full traceability, including batch numbers, test data, and compliance documentation. A common pitfall is sourcing from vendors who offer little to no documentation, making it difficult to verify authenticity or troubleshoot performance issues. In regulated or mission-critical environments, this lack of traceability can result in failed audits or non-compliance with procurement policies.

Conclusion

To avoid these pitfalls, buyers should source RG8 cable from authorized distributors or directly from reputable manufacturers. Verifying certifications, requesting test reports, and inspecting physical samples before large purchases are essential steps. Awareness of IP rights and insistence on genuine products not only ensures technical performance but also mitigates legal and operational risks.

Logistics & Compliance Guide for RG8 Cable

Overview of RG8 Cable

RG8 is a coaxial cable commonly used in radio frequency (RF) applications such as amateur radio, broadcast systems, and telecommunications. It features a thick center conductor, robust shielding, and low signal loss over long distances, making it suitable for high-power transmission. Understanding proper logistics and compliance requirements is essential for the safe and legal handling, transport, and use of RG8 cable.

Regulatory Compliance Standards

RG8 cable must comply with various regional and international regulations depending on its intended use and destination. Key compliance standards include:

– RoHS (Restriction of Hazardous Substances): Ensures the cable does not contain restricted materials such as lead, mercury, or cadmium. Most RG8 variants sold in the EU and many global markets must be RoHS-compliant.

– REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Applies to chemical substances used in cable manufacturing, requiring full disclosure and risk management.

– FCC Part 15 (USA): Regulates electromagnetic interference (EMI). RG8 used in communication systems must not emit excessive RF interference.

– UL/ETL Listing: Safety certification for cables used in commercial or industrial installations. Look for UL 13 or UL 444 ratings depending on application.

– CE Marking: Required for sale within the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

Packaging and Handling Requirements

Proper packaging ensures that RG8 cables remain undamaged during storage and shipping:

– Cables should be wound on reels or in coils to prevent kinking and deformation.

– Use protective end caps to prevent moisture ingress and damage to connectors.

– Store in a dry, temperature-controlled environment away from direct sunlight and corrosive chemicals.

– Label packaging with product specifications, compliance marks, and handling instructions (e.g., “Do Not Drop” or “Keep Dry”).

Transportation and Shipping Guidelines

When shipping RG8 cable domestically or internationally:

– Use sturdy, corrugated cardboard or wooden reels for large spools to prevent crushing.

– Clearly label shipments with weight, length, and content details (e.g., “Coaxial Cable – 50 Ohm RG8 – 1000 ft”).

– For international shipments, include a commercial invoice, packing list, and bill of lading.

– Declare the correct HS (Harmonized System) code—typically 8544.20 for insulated coaxial cable.

– Ensure compliance with IATA/IMDG regulations if shipping by air or sea, especially for large quantities.

Import/Export Documentation

Key documentation for cross-border logistics includes:

– Certificate of Conformity (CoC): Verifies that RG8 meets required safety and environmental standards.

– Material Safety Data Sheet (MSDS/SDS): Required if the cable contains substances of concern.

– Origin Certificate: May be needed for preferential tariffs under trade agreements.

– FCC Declaration of Conformity: Required when importing into the U.S. for RF equipment applications.

Environmental and Disposal Compliance

At end-of-life, RG8 cable must be disposed of in accordance with environmental regulations:

– Do not incinerate—cable jackets may release toxic fumes.

– Recycle through certified e-waste handlers due to copper content and insulation materials (e.g., PE or PVC).

– Comply with WEEE (Waste Electrical and Electronic Equipment) directives in the EU for proper recycling and disposal.

Best Practices for Compliance and Logistics

- Verify supplier certifications before procurement.

- Maintain records of compliance documentation for audits.

- Train logistics staff on proper handling and regulatory requirements.

- Regularly review updates to regional regulations (e.g., changes to RoHS or REACH).

By adhering to this guide, organizations can ensure efficient, compliant, and safe logistics operations for RG8 coaxial cable across the supply chain.

Conclusion for Sourcing RG8 Cable:

Sourcing RG8 coaxial cable requires careful consideration of application requirements, quality standards, supplier reliability, and cost-effectiveness. RG8 cable, known for its low signal loss and high power-handling capabilities, is ideal for radio frequency (RF) applications such as amateur radio, base station antennas, and other high-frequency transmission needs. When selecting a supplier, it is essential to prioritize cables that meet industry specifications (e.g., MIL-DTL-17 or equivalent) and feature robust construction with proper shielding and low attenuation.

Key factors in the sourcing decision include the authenticity of copper conductors (avoiding copper-clad steel when high conductivity is needed), UV and weather resistance for outdoor installations, and compliance with safety and environmental standards. Evaluating multiple suppliers—balancing reputation, warranty offerings, and customer support—ensures long-term performance and reliability.

Ultimately, while cost is a consideration, investing in high-quality RG8 cable from reputable suppliers reduces signal degradation, minimizes maintenance, and enhances system efficiency. A strategic sourcing approach ensures optimal performance in critical RF communication systems, making it a worthwhile investment for professional and industrial applications.