The global RFID in textiles market is experiencing robust growth, driven by increasing demand for inventory automation, brand protection, and supply chain transparency across the fashion, retail, and healthcare sectors. According to Grand View Research, the global RFID market size was valued at USD 13.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 13.4% from 2023 to 2030. A significant portion of this growth is attributed to the integration of RFID technology into textile manufacturing, where smart fabrics and tagged garments enable real-time tracking, reduce counterfeiting, and improve operational efficiency. Mordor Intelligence further projects that the RFID in retail market—where apparel is a dominant segment—will witness accelerated adoption, with the overall RFID market anticipated to grow at a CAGR of over 12% during the forecast period. As brands increasingly digitize their supply chains and embrace circular economy models, the demand for reliable, high-performance RFID cloth manufacturers has surged. In this evolving landscape, identifying manufacturers who combine technical innovation, scalability, and quality assurance is critical for enterprise success. The following list highlights the top 10 RFID cloth manufacturers leading this transformation.

Top 10 Rfid Cloth Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 RFID Technology for Textile Goods Tracking

Domain Est. 1999

Website: rfidlabel.com

Key Highlights: RFID tags offer several opportunities to track the stock of garments, guest hospitality services, large laundry facilities, fabrics, apparel….

#2 Positek RFID

Domain Est. 2001

Website: positekrfid.com

Key Highlights: Positek RFID is the most experienced RFID solutions provider to the textile industry. Positek RFID’s tracking technology and solutions are used on a wide ……

#3 Textile RFID Tags

Domain Est. 2005

Website: hidglobal.com

Key Highlights: Textile RFID tags from HID® are built to withstand industrial laundry environments so you can maintain efficiency and accurate operations….

#4 Datamars

Domain Est. 2014

Website: textile-id.com

Key Highlights: Datamars Textile ID: the leading global supplier of specialized RFID solutions for the textile laundry business. With over 10.000 installations in 65 countries….

#5 laundry rfid tags

Domain Est. 2016

Website: tjnfctag.com

Key Highlights: This guide explores how specialized RFID systems transform chaotic textile inventories into precision-managed resources, reducing labor costs by 81% while ……

#6 AD TexTrace Connected Textiles – Avery Dennison

Domain Est. 1993

Website: rfid.averydennison.com

Key Highlights: Welcome to AD TexTrace™, our integrated RFID solutions for connected textiles. By connecting physical garments with the digital world we are unlocking new ……

#7 RFID Systems for Fabric & Textile Mills, Leather & Hide Tanning

Domain Est. 2006

Website: gaorfid.com

Key Highlights: Textile mill machine operators can scan multiple machines with an RFID Reader that alerts them when machines require routine maintenance and servicing offline….

#8 HF and UHF Tag for textiles’ identification and traceability

Domain Est. 2007

Website: abgsys.com

Key Highlights: The RFid TAG from ABG Systems are designed to provide advanced tracking and efficient management of textiles in professional environments such as hospitals, ……

#9 Smart RFID Threads for Sustainable Textile Traceability

Domain Est. 2012

Website: primo1d.com

Key Highlights: Discover Primo1D’s smart RFID threads for sustainable textile traceability, boosting visibility, inventory accuracy & circularity across sectors….

#10 Highly Sensitive RFID Apparel Tags Making from Arizon

Domain Est. 2018

Website: arizonrfid.com

Key Highlights: In Arizon, we can offer you the best RFID tags for clothes, our RFID apparel tags technologies can be applied to production, distribution, retail, and inventory ……

Expert Sourcing Insights for Rfid Cloth

H2: 2026 Market Trends for RFID Cloth

The RFID (Radio-Frequency Identification) cloth market is poised for significant transformation and growth by 2026, driven by advancements in smart textiles, increasing demand for supply chain transparency, and the integration of IoT (Internet of Things) in everyday products. The convergence of technology and textile manufacturing has positioned RFID-enabled fabrics at the forefront of innovation across industries such as fashion, logistics, healthcare, and retail.

One of the key trends shaping the 2026 RFID cloth market is the rising adoption of smart inventory management systems. Retailers and apparel brands are increasingly embedding RFID tags into garments during production, enabling real-time tracking from manufacturing to point of sale. This trend enhances inventory accuracy, reduces shrinkage, and improves omnichannel fulfillment—directly addressing consumer expectations for faster delivery and product availability.

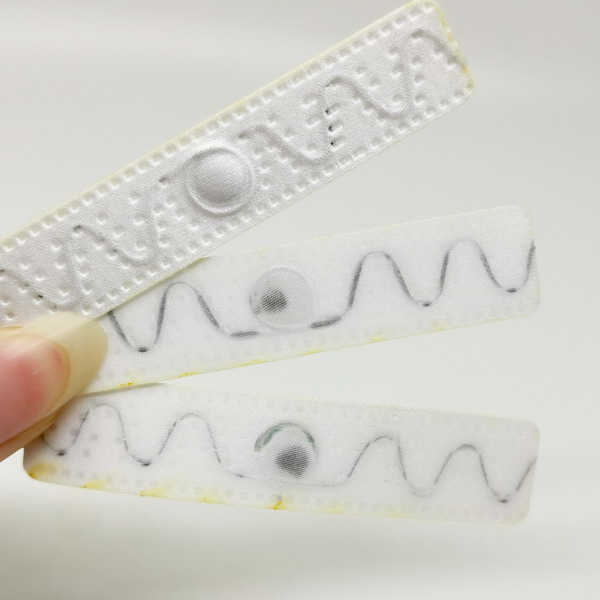

Another notable trend is the miniaturization and durability of RFID components. By 2026, advancements in flexible electronics and conductive inks are enabling seamless integration of RFID antennas and chips into fabric without compromising comfort or washability. This progress supports broader adoption in wearable technology and high-performance apparel, including sportswear and military uniforms.

Sustainability is also emerging as a major driver. As consumers and regulators demand greater transparency in sourcing and production, RFID cloth enables end-to-end traceability. Brands can provide digital passports for garments, verifying ethical labor practices, material origins, and recyclability—aligning with circular economy goals and enhancing brand trust.

Furthermore, the healthcare sector is exploring RFID-integrated textiles for patient monitoring and asset tracking. Smart hospital gowns and linens with embedded RFID tags can streamline patient identification, reduce equipment loss, and support infection control protocols—applications expected to grow steadily by 2026.

Regionally, North America and Europe lead in RFID cloth adoption due to mature retail ecosystems and strong regulatory support for data transparency. However, Asia-Pacific is anticipated to witness the fastest growth, fueled by booming e-commerce, government initiatives in smart manufacturing, and a robust textile production base in countries like China, India, and South Korea.

In conclusion, by 2026, the RFID cloth market will be defined by technological integration, operational efficiency, and sustainability. As costs decrease and performance improves, RFID-enabled textiles are set to transition from niche applications to mainstream use, fundamentally reshaping how industries manage, authenticate, and interact with fabric-based products.

Common Pitfalls When Sourcing RFID Cloth: Quality and Intellectual Property Issues

Logistics & Compliance Guide for RFID-Embedded Cloth

Product Overview and Identification

RFID-embedded cloth refers to textiles integrated with Radio-Frequency Identification (RFID) tags, typically used for inventory tracking, supply chain visibility, anti-counterfeiting, and smart retail applications. These garments or textile products contain small electronic components (chip and antenna) embedded during manufacturing. Understanding the composition is critical for safe handling, transportation, and regulatory compliance.

Regulatory Compliance Considerations

RFID-enabled textiles must comply with multiple international regulations due to their dual nature as both textile products and electronic devices. Key compliance areas include:

– Radio Frequency Regulations: Ensure RFID modules comply with local RF emission standards (e.g., FCC Part 15 in the U.S., ETSI EN 300 220 in the EU, MIC in Japan). Frequency bands (e.g., 860–960 MHz UHF) must be approved for use in destination markets.

– REACH and RoHS: Comply with the EU’s REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives, which regulate hazardous materials in electronics and textiles.

– Textile Labeling Laws: Follow country-specific labeling requirements (e.g., fiber content, care instructions, country of origin) while ensuring RFID tags do not interfere with mandatory labels.

– Data Privacy (GDPR, CCPA): If RFID tags store or transmit personal data (e.g., unique user identifiers), compliance with data protection laws is required. Ensure data minimization, encryption, and opt-out mechanisms where applicable.

Packaging and Handling Guidelines

Proper packaging protects both the textile and the embedded RFID functionality during transit:

– Use non-metallic packaging materials to prevent interference with RFID signal performance.

– Avoid excessive folding or compression near the RFID tag location to prevent damage to the antenna or chip.

– Clearly label packages as containing electronic components (e.g., “Contains RFID Tag – Handle with Care”).

– Implement ESD (electrostatic discharge) protective measures if handling in bulk or warehouse environments.

Transportation and Storage Requirements

- Temperature and Humidity: Store and transport RFID cloth within 0–40°C and 20–75% relative humidity unless otherwise specified by the manufacturer. Exposure to extreme conditions may degrade electronic components.

- Magnetic and RF Interference: Keep shipments away from strong magnetic fields, large metal objects, or high-power RF sources that could damage or prematurely activate RFID tags.

- Stacking and Weight Limits: Follow manufacturer guidelines for stacking to prevent crushing of garments, especially at tag-embedded seams or labels.

Import and Export Documentation

Ensure accurate customs declarations that reflect the dual nature of RFID cloth:

– Classify products under appropriate HS codes (e.g., 6217.10 for other made-up clothing accessories, potentially with electronic components). Consult local customs authorities for precise classification.

– Declare the presence of embedded electronics in shipping manifests and commercial invoices.

– Provide technical specifications of RFID components (frequency, power output, chip type) for regulatory inspection if required.

End-of-Life and Disposal Compliance

RFID-embedded cloth presents unique waste management challenges:

– Do not dispose of in regular textile recycling streams due to electronic content.

– Follow WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions for proper e-waste handling.

– Provide clear end-user guidance on responsible disposal or return programs.

Quality Assurance and Testing Protocols

- Conduct pre-shipment testing to verify RFID read range, data integrity, and durability through simulated logistics conditions (e.g., folding, washing, vibration).

- Perform batch-level compliance audits for regulatory standards (RF, chemical, safety).

- Maintain records of test results and certifications for traceability and audit purposes.

Conclusion

Managing the logistics and compliance of RFID-embedded cloth requires a multidisciplinary approach that bridges textile manufacturing, electronics regulation, and supply chain best practices. Proactive planning, accurate documentation, and adherence to regional requirements are essential to ensure smooth global distribution and regulatory acceptance.

Conclusion for Sourcing RFID-Embedded Cloth

Sourcing RFID-embedded cloth represents a strategic advancement in integrating smart textile technology across industries such as apparel, healthcare, logistics, and retail. By embedding RFID tags directly into fabric, businesses can enable seamless inventory tracking, enhance supply chain transparency, improve anti-counterfeiting measures, and offer enhanced customer experiences through smart garments.

Successful sourcing requires careful evaluation of suppliers based on technical expertise, material quality, customization capabilities, and cost-efficiency. Compatibility with existing RFID systems, durability through washing and wear, and adherence to privacy and regulatory standards are critical factors in selecting the right solution.

Furthermore, long-term partnerships with innovative and scalable manufacturers ensure reliability and adaptability as technology evolves. As demand for connected textiles grows, early adoption and strategic sourcing of RFID cloth can provide a significant competitive advantage, driving operational efficiency and opening new avenues for digital integration in textile applications.

In conclusion, sourcing RFID cloth is not just a procurement decision—it’s an investment in innovation, traceability, and future-ready product development.