The global RFID blocking materials market is experiencing robust growth, driven by rising concerns over digital privacy and identity theft. According to a report by Mordor Intelligence, the RFID market — including security and blocking solutions — was valued at USD 18.5 billion in 2023 and is projected to grow at a CAGR of over 11.3% from 2024 to 2029. This surge is fueled by increasing adoption of contactless payment systems, government-issued e-passports, and access control technologies, all of which necessitate effective electromagnetic shielding. As demand for secure personal and corporate data protection grows, manufacturers of RFID blocking materials are scaling innovation in conductive textiles, metal alloys, and composite laminates. In this competitive landscape, ten companies have emerged as leaders, combining material science expertise with scalable production to meet evolving security standards across finance, defense, healthcare, and consumer electronics sectors.

Top 10 Rfid Blocking Material Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 What does RFID

Domain Est. 2016

Website: tjnfctag.com

Key Highlights: Effective RFID-blocking materials include specialized fabrics woven with metallic threads, aluminum foils, and carbon-based composites. When ……

#2 RFID

Domain Est. 1996

Website: chasecorp.com

Key Highlights: Multi-ply laminate that contain a security barrier to prevent RFID detection. This is achieved while offering light-weight, water resistant, durability….

#3 Wallets & Bags by Tatonka with RFID Blocker

Domain Est. 1996

Website: tatonka.com

Key Highlights: The Tatonka RFID Block series for wallets, document folders and pouches offers 100% protection against data theft from wireless card readers….

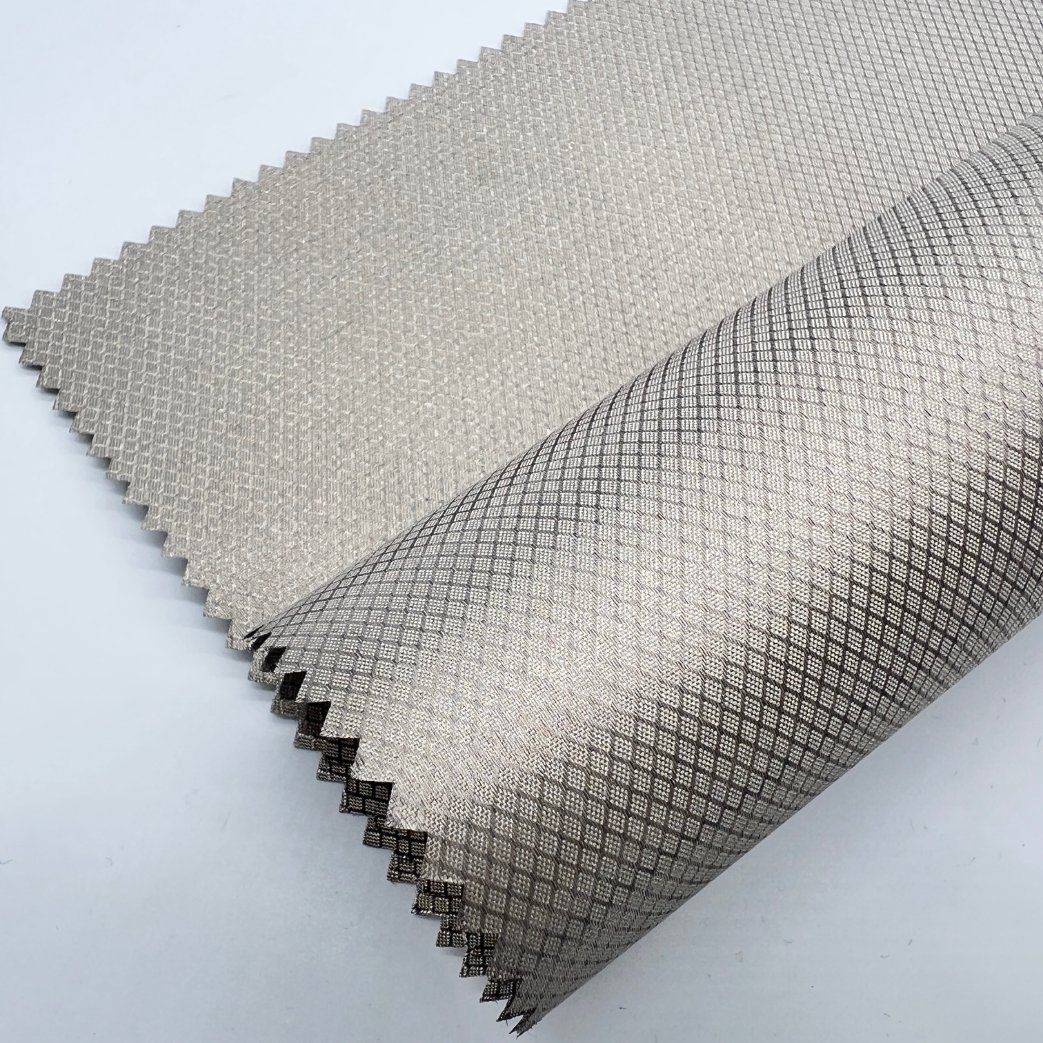

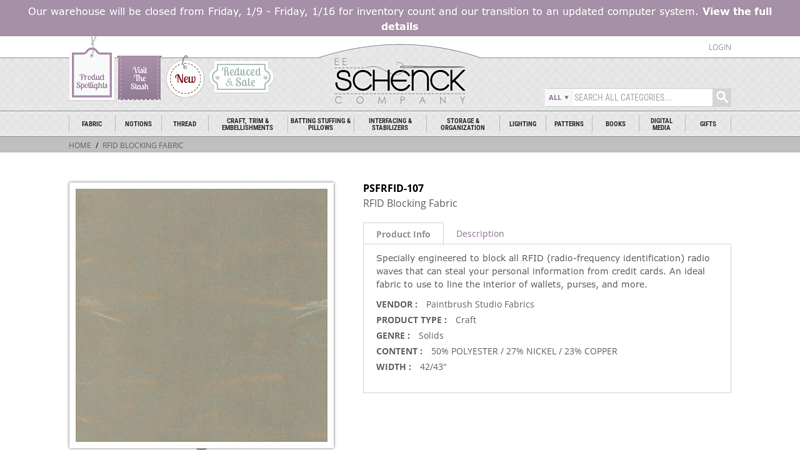

#4 RFID Blocking Fabric

Domain Est. 1999

Website: eeschenck.com

Key Highlights: Specially engineered to block all RFID (radio-frequency identification) radio waves that can steal your personal information from credit cards….

#5 Impinj

Domain Est. 2000

Website: impinj.com

Key Highlights: Impinj wirelessly connects billions of everyday things to applications, delivering real-time information to businesses, and enabling the Internet of Things….

#6 RFID Blocking Wallets

Domain Est. 2011

Website: bas-ip.com

Key Highlights: RFID blocking wallets typically incorporate layers of metal, often aluminum or steel, within the fabric of the wallet itself. These metallic layers work by ……

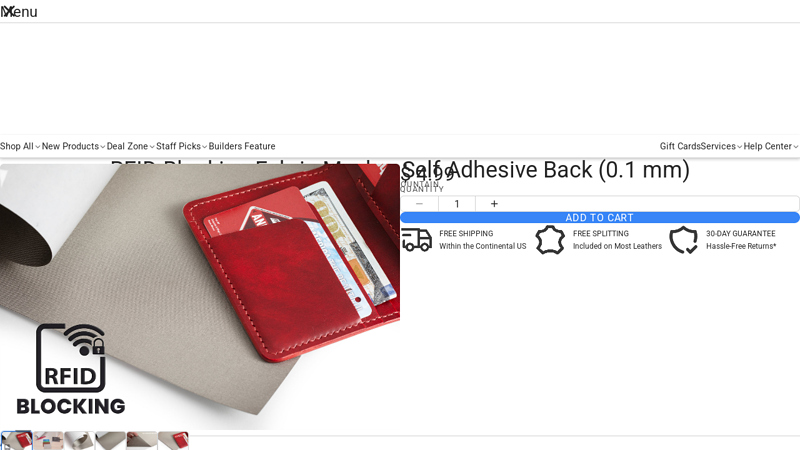

#7 RFID Blocking Fabric Mesh + Self Adhesive Back (0.1 mm)

Domain Est. 2014

Website: rmleathersupply.com

Key Highlights: In stock Free deliveryPRODUCT OVERVIEW. This DIY RFID Blocking Fabric Mesh is made of a special fabric mesh that disrupts RFID signals and protects your cards….

#8 RFID blocking protection for contactless cards, RFID Cloaked

Domain Est. 2015

Website: rfidcloaked.com

Key Highlights: Established in the South West of England in 2015, we manufacture and supply RFID blocking cards for ID cards, contactless payment credit and debit cards. We ……

#9 RFID Solutions

Domain Est. 2015

Website: mwtmaterials.com

Key Highlights: MWT Materials is a full service RF Control Business. We manufacture RFID Portal Isolation Curtains, RF shielding & absorbing products for RFID applications….

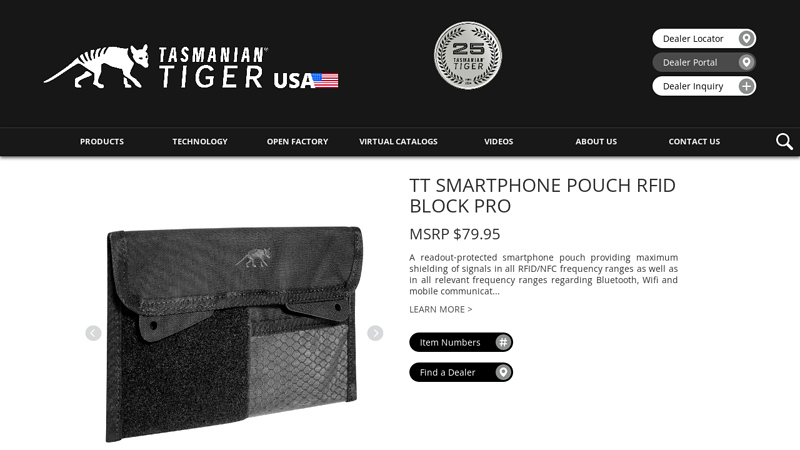

#10 TT SMARTPHONE POUCH RFID BLOCK PRO

Domain Est. 2018

Website: tasmaniantigerusa.com

Key Highlights: A solution against hacker attacks by combining two specially developed materials, Cryptalloy and CryptalloyTex. The Cryptalloy® shielding foil blocks all RFID/ ……

Expert Sourcing Insights for Rfid Blocking Material

2026 Market Trends for RFID Blocking Material

The RFID blocking material market is poised for significant evolution by 2026, driven by rising concerns over digital security, increasing adoption of contactless technologies, and the integration of smart devices in everyday life. As identity theft and wireless data skimming become more prevalent, the demand for effective RFID protection continues to grow across consumer, enterprise, and government sectors.

Rising Security Awareness and Consumer Demand

By 2026, heightened awareness of digital privacy is expected to be a primary driver of the RFID blocking material market. Consumers are increasingly informed about the risks associated with RFID-enabled credit cards, passports, and access cards, prompting a surge in demand for wallets, sleeves, and bags embedded with RFID-blocking technology. Market research indicates that millennials and Gen Z consumers, in particular, are prioritizing security features when purchasing personal accessories, accelerating the integration of RFID shielding into fashion and functional products.

Expansion in Application Segments

The application of RFID blocking materials is expanding beyond personal accessories. By 2026, key industries such as healthcare, logistics, and defense are expected to adopt RFID shielding solutions to protect sensitive data transmitted via RFID tags. For instance, medical records stored on RFID-enabled ID cards require secure handling, and military communications often rely on shielded equipment to prevent signal interception. This diversification of use cases is spurring innovation in material science, with manufacturers developing lightweight, flexible, and durable shielding composites.

Technological Advancements in Materials

Innovation in RFID blocking materials is a critical trend shaping the 2026 landscape. Traditional materials like metalized fabrics and aluminum laminates are being supplemented—or replaced—by advanced nanomaterials, conductive polymers, and meta-materials that offer superior shielding effectiveness (SE) without compromising comfort or design. These next-generation materials enable seamless integration into textiles, smartphone cases, and even building materials, broadening the market potential.

Regulatory and Standardization Developments

Governments and international standards bodies are anticipated to play a larger role in the RFID blocking material market by 2026. As cyber threats evolve, regulatory frameworks may mandate the use of RFID protection in government-issued IDs, financial instruments, and critical infrastructure. Compliance with standards such as ISO/IEC 18000 and EMV will become essential for product certification, driving manufacturers to invest in testing and quality assurance.

Sustainability and Eco-Friendly Solutions

Sustainability is emerging as a key consideration in the development of RFID blocking materials. Consumers and regulators alike are pushing for environmentally responsible production methods and recyclable components. By 2026, leading manufacturers are expected to introduce biodegradable shielding fabrics and low-impact manufacturing processes, aligning with global ESG (Environmental, Social, and Governance) goals.

Competitive Landscape and Market Growth

The global RFID blocking material market is projected to grow at a CAGR of approximately 9–11% from 2021 to 2026, reaching an estimated valuation of USD 1.8–2.2 billion. North America and Europe currently dominate due to strong cybersecurity regulations and high consumer spending, while Asia-Pacific is expected to witness the fastest growth, fueled by rapid urbanization and digitalization in countries like China, India, and South Korea.

Key players such as 3M, Tatsuta Electric Wire & Cable, and Shielding Solutions are investing in R&D and strategic partnerships to capture market share. Startups are also entering the space with innovative, design-forward products targeting niche markets, including luxury fashion and smart apparel.

Conclusion

By 2026, the RFID blocking material market will be shaped by a convergence of security imperatives, technological innovation, and sustainability demands. As contactless transactions and digital identities become ubiquitous, the need for reliable, aesthetically pleasing, and eco-conscious RFID protection will drive continued investment and expansion across multiple industries. Companies that adapt to these trends will be well-positioned to lead in the next generation of personal and data security solutions.

Common Pitfalls Sourcing RFID Blocking Material (Quality, IP)

Sourcing effective RFID blocking material involves navigating several potential pitfalls related to both material quality and intellectual property (IP) concerns. Overlooking these can result in ineffective products, legal risks, and reputational damage.

Inadequate Shielding Performance

One of the most critical pitfalls is assuming all conductive materials offer reliable RFID blocking. Some suppliers market materials that claim to block RFID signals but fail under real-world conditions. Issues include inconsistent shielding across different frequencies (e.g., 13.56 MHz for NFC vs. 900 MHz for UHF RFID), poor durability after folding or washing, or shielding that degrades over time. Always demand third-party test reports (e.g., ISO/IEC 18000 or ASTM D4935) to verify performance across relevant frequency bands.

Misleading Material Specifications

Suppliers may exaggerate technical specifications such as shielding effectiveness (measured in dB) without providing test methodologies or conditions. For example, a material might claim “30 dB blocking,” but only under ideal lab conditions or at a single frequency. Without standardized testing, these claims can mislead buyers. Insist on detailed, transparent technical data sheets backed by verifiable test results.

Lack of Regulatory Compliance and Certifications

RFID blocking materials used in consumer products may need to comply with regional safety and environmental standards (e.g., RoHS, REACH, or California Proposition 65). Sourcing materials without proper compliance documentation can lead to import delays, product recalls, or legal liability. Always verify that the supplier provides up-to-date compliance certificates relevant to your target market.

Intellectual Property Infringement Risks

Using proprietary RFID shielding technologies without proper licensing can expose your company to IP litigation. Some advanced materials (e.g., specialized laminates or nano-coatings) are protected by patents or trade secrets. Sourcing from unauthorized manufacturers or reverse-engineering existing solutions may constitute infringement. Conduct due diligence on the supplier’s IP rights and obtain written assurances of freedom to operate.

Supply Chain Transparency and Material Provenance

Opaque supply chains can hide substandard manufacturing practices or the use of counterfeit materials. For instance, a supplier might source recycled or off-spec conductive fabrics that underperform. Without traceability, it’s difficult to ensure consistency or address quality failures. Establish clear agreements requiring transparency in material sourcing and manufacturing processes.

Poor Durability and Long-Term Reliability

RFID blocking materials must maintain performance through regular use, including bending, abrasion, and exposure to moisture. Some materials lose shielding effectiveness after repeated flexing or laundering. Failing to test for long-term durability can result in customer complaints and high return rates. Request samples for real-world stress testing before full-scale procurement.

Overlooking Integration Challenges

Even high-quality RFID blocking material can fail if not properly integrated into the final product. Issues like seam gaps, improper grounding, or material misalignment can create signal leakage paths. Suppliers may not provide design guidance, leading to ineffective implementation. Engage with suppliers early to ensure technical support and design compatibility.

Logistics & Compliance Guide for RFID Blocking Material

This guide outlines key considerations for the logistics and regulatory compliance associated with RFID blocking materials, including fabrics, sheets, labels, and finished products such as wallets or passport sleeves.

Regulatory Compliance

Material Composition & Safety Standards

Ensure RFID blocking materials comply with relevant chemical and safety regulations based on their composition and target markets. Materials containing metals (e.g., nickel, copper, silver-coated fibers) may be subject to:

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals. Verify compliance, especially for restricted substances like nickel.

– RoHS (EU): Restriction of Hazardous Substances in Electrical and Electronic Equipment, if integrated into electronic devices.

– CPSIA (USA): Consumer Product Safety Improvement Act, particularly for products intended for children.

– TSCA (USA): Toxic Substances Control Act, for chemical substances used in manufacturing.

Product Labeling and Claims

Advertising RFID blocking capabilities must be truthful and substantiated:

– Avoid exaggerated claims (e.g., “100% secure” or “hacker-proof”) unless independently tested and certified.

– Comply with FTC guidelines (USA) and ASA/CAP rules (UK) on advertising standards.

– Include clear usage instructions and limitations (e.g., “Blocks RFID signals up to 13.56 MHz”).

Testing and Certification

Support claims with standardized testing:

– Use recognized methods such as ISO/IEC 18000 or EMVCo protocols to measure shielding effectiveness.

– Consider third-party laboratory testing for credibility.

– Maintain documentation for audits or regulatory inquiries.

Logistics Considerations

Packaging and Handling

– Use packaging that prevents physical damage to RFID shielding layers (e.g., metal foils or conductive textiles).

– Avoid folding or creasing conductive materials during transport, which may degrade performance.

– Consider anti-static packaging if static discharge could affect embedded electronics or user safety.

Storage Conditions

– Store materials in dry, temperature-controlled environments to prevent corrosion (especially for metal-based shields).

– Avoid prolonged exposure to moisture, UV light, or extreme temperatures that could degrade conductive coatings or substrates.

Transportation and Shipping

– Label shipments appropriately if materials contain conductive metals that may trigger security or electronic interference concerns (rare, but advisable for bulk shipments).

– Comply with IATA/IMDG regulations if shipping internationally in large volumes, particularly if materials are classified as containing metal powders or conductive components.

– Declare accurate Harmonized System (HS) codes for customs (e.g., 5903.90 for coated fabrics or 8517.70 for integrated electronic protection items).

Import/Export Compliance

– Verify tariff classifications and country-specific import restrictions.

– Some countries may regulate the sale or import of signal-blocking materials under telecommunications or security laws.

– Maintain documentation for export controls, especially if technology is dual-use or could be perceived as interfering with wireless communications.

End-of-Life and Environmental Responsibility

- Provide guidance for proper disposal, particularly for materials containing metals or conductive coatings.

- Comply with WEEE (EU) or similar e-waste directives if products include electronic components.

- Explore recyclability options and communicate environmental impact to consumers.

Adhering to these logistics and compliance guidelines helps ensure the safe, legal, and effective distribution of RFID blocking materials across global markets.

In conclusion, sourcing RFID blocking material requires careful consideration of effectiveness, material composition, durability, cost, and application-specific needs. Materials such as conductive metals (e.g., aluminum, copper, nickel), specialized fabrics (e.g., carbon-based or metal-infused textiles), and laminated shielding films have proven effective in blocking RFID signals. When selecting a supplier, it’s essential to verify the material’s shielding performance—typically measured in decibels (dB)—through reliable testing standards. Additionally, factors like flexibility, washability, and aesthetic integration are important, especially for consumer products like wallets, passport holders, or clothing. Sourcing from reputable manufacturers or suppliers with certifications and proven track records ensures quality and consistency. Ultimately, the right RFID blocking material balances security, practicality, and cost-efficiency, offering reliable protection against unauthorized scanning and digital theft in an increasingly connected world.