The global radiofrequency (RF) machine market is witnessing robust expansion, driven by rising demand for minimally invasive aesthetic and medical procedures. According to Grand View Research, the global aesthetic devices market, which includes RF machines, was valued at USD 13.2 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 10.4% from 2023 to 2030. This growth is fueled by increasing consumer preference for non-surgical cosmetic treatments, technological advancements in skin tightening and body contouring devices, and expanding applications across dermatology and physiotherapy. Additionally, Mordor Intelligence projects steady growth in the medical RF device sector, citing innovations in radiofrequency ablation and increasing adoption in emerging economies. As demand surges, a core group of professional RF machine manufacturers are leading the industry through R&D investment, regulatory compliance, and global distribution networks—setting the benchmark for performance, safety, and clinical efficacy.

Top 7 Rf Machine Professional Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

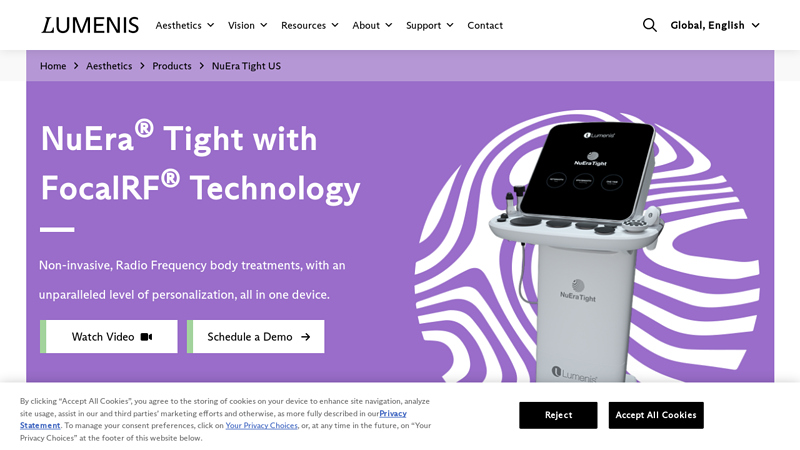

#1 NuEra®: All-in-One RF Skin Tightening Machine

Domain Est. 1999

Website: lumenis.com

Key Highlights: NuEra Tight’s groundbreaking technology offers unparalleled treatment depth control: it targets tissue at the exact depth which yields the best results….

#2 InMode

Domain Est. 2012

Website: inmodemd.com

Key Highlights: InMode advanced aesthetic medical devices. Innovative radiofrequency technology for face, body, and wellness treatments….

#3 Matrix™ RF Microneedling Device

Domain Est. 2018

Website: candelamedical.com

Key Highlights: Discover a multi-technology skin renewal system combining RF, microneedling, and infrared light to treat volume loss, skin laxity, fine lines, and wrinkles….

#4 Thermage

Domain Est. 1997

Website: thermage.com

Key Highlights: The Thermage® system is a non-invasive radiofrequency (RF) treatment that can smooth, tighten and contour skin for an overall younger-looking appearance….

#5 Secret™ RF

Domain Est. 2003

Website: cutera.com

Key Highlights: Secret RF is an innovative fractional radiofrequency (RF) microneedling system for tissue coagulation and hemostasis designed to stimulate and remodel collagen….

#6 Vivace Microneedling

Domain Est. 2016

Website: vivaceexperience.com

Key Highlights: The Vivace® Microneedle RF device is the newest generation of radiofrequency microneedling and is FDA-cleared for your safety. This minimally-invasive treatment ……

#7 VirtueRF: Versatile RF Microneedling Platform

Domain Est. 2017

Website: cartessaaesthetics.com

Key Highlights: VirtueRF combines radiofrequency (RF) energy and microneedling technologies to create micro-injuries in the skin and stimulate the natural healing process ……

Expert Sourcing Insights for Rf Machine Professional

H2: 2026 Market Trends for RF Machine Professionals

The global market for Radio Frequency (RF) machine professionals is poised for significant transformation by 2026, driven by technological advancements, increasing demand in healthcare and industrial applications, and evolving workforce needs. This analysis explores key trends shaping the profession and industry landscape.

1. Expansion in Aesthetic and Medical Applications

The aesthetic medicine sector continues to be a primary growth driver for RF technology. By 2026, non-invasive skin tightening, body contouring, and anti-aging treatments are expected to dominate demand for RF-based devices. Innovations such as multi-polar RF, combined modalities (e.g., RF with microneedling or ultrasound), and AI-driven treatment personalization will increase efficacy and safety, elevating the role of RF machine professionals in clinical settings. Additionally, therapeutic applications in dermatology, physiotherapy, and pain management are expanding, requiring skilled operators with medical training and certification.

2. Rising Demand for Skilled RF Technicians and Specialists

As RF equipment becomes more sophisticated, there is a growing need for trained professionals who understand both the technical operation and physiological effects of RF energy. By 2026, certification programs and continuing education in RF technology are expected to become standardized, particularly in regulated markets such as North America, Europe, and parts of Asia-Pacific. Employers will increasingly favor professionals with dual expertise in technology and patient care.

3. Technological Integration and Automation

RF machines are integrating advanced sensors, real-time feedback systems, and machine learning algorithms to optimize energy delivery and treatment outcomes. Professionals will need to adapt to smart devices that require data interpretation, device calibration, and troubleshooting. Automation may reduce manual operation time but will elevate the importance of technical oversight and customization skills, reinforcing the value of human expertise.

4. Regulatory and Safety Standards Tightening

With increased use of RF devices, regulatory bodies are expected to enforce stricter safety protocols and operator qualifications by 2026. Regions like the EU and the U.S. are likely to mandate professional licensing or accreditation for RF machine operators, particularly in medical spas and clinics. This will professionalize the field and potentially limit unregulated or underqualified practitioners.

5. Geographic Market Growth

Emerging markets in Southeast Asia, Latin America, and the Middle East are witnessing rapid adoption of aesthetic technologies, including RF machines. These regions present high growth potential for RF professionals due to rising disposable incomes, urbanization, and increasing awareness of non-surgical cosmetic procedures. Training institutions and equipment providers are anticipated to expand their presence in these areas, creating new job and entrepreneurial opportunities.

6. Shift Toward Preventive and Home-Use Devices

While professional-grade RF machines remain central to clinics, the rise of FDA-cleared at-home RF devices may influence professional services. By 2026, RF professionals may increasingly focus on premium, high-intensity treatments that home devices cannot replicate, emphasizing their role in advanced care and maintenance regimens. Consultative services, including skin health assessments and personalized treatment plans, will become a core part of the professional offering.

7. Sustainability and Equipment Lifecycle Management

As environmental concerns grow, manufacturers and clinics are prioritizing energy-efficient RF devices and sustainable practices. RF machine professionals may take on roles in equipment maintenance, calibration, and lifecycle management to reduce waste and improve cost-efficiency—skills that will be increasingly valued in eco-conscious healthcare environments.

Conclusion

By 2026, RF machine professionals will operate in a more specialized, regulated, and technologically advanced environment. Success in the field will depend on continuous learning, technical adaptability, and a strong foundation in both safety and client outcomes. The convergence of medical science, digital health, and consumer demand will position RF professionals as key contributors to the future of non-invasive therapies.

Common Pitfalls When Sourcing RF Machine Professionals (Quality, IP)

Hiring or outsourcing to RF (Radio Frequency) machine professionals—such as engineers, technicians, or consultants—requires careful due diligence. Missteps can lead to compromised product quality, project delays, and serious intellectual property (IP) risks. Below are key pitfalls to avoid:

Inadequate Technical Expertise and Experience

Many professionals may claim RF proficiency, but lack hands-on experience with specific applications (e.g., 5G, radar, IoT, medical devices). Be wary of candidates who cannot demonstrate proven success in designing, testing, or troubleshooting RF systems under real-world conditions. Always verify their project history, tools used (e.g., HFSS, ADS), and familiarity with regulatory standards (e.g., FCC, CE).

Poor Quality Control and Documentation

RF systems demand precision and repeatability. Professionals who skip proper testing protocols, fail to document design iterations, or neglect simulation validation can introduce hidden flaws. Ensure candidates follow structured development processes, including design reviews, prototyping, and performance validation. Lack of thorough documentation also complicates future troubleshooting and compliance audits.

Insufficient Understanding of Electromagnetic Interference (EMI) and Shielding

A common technical shortcoming is underestimating EMI/EMC challenges. Professionals who ignore proper grounding, filtering, or PCB layout techniques risk creating non-compliant or unreliable systems. Evaluate their approach to system integration and susceptibility testing to avoid costly redesigns post-production.

Intellectual Property (IP) Ownership Ambiguity

One of the biggest legal risks is unclear IP rights. If an RF professional develops circuit designs, antenna configurations, or firmware as part of your project, failing to secure written agreements on IP ownership can result in disputes or loss of proprietary technology. Always use clear contracts that assign all work product to your organization.

Use of Third-Party or Unlicensed IP

Some professionals may incorporate third-party designs, libraries, or reference circuits without proper licensing. This can expose your company to infringement claims or compliance violations. Require full disclosure of all external IP used and verify licensing compliance upfront.

Lack of Confidentiality and Data Security Measures

RF designs often contain sensitive information. Professionals without NDAs or secure data handling practices risk leaking critical information. Ensure all parties sign robust confidentiality agreements and follow secure communication and storage protocols (e.g., encrypted files, access controls).

Overreliance on Simulation Without Real-World Validation

While simulation tools are essential, some professionals rely too heavily on models without validating through physical testing. Real-world factors like material tolerances, environmental conditions, and assembly variations can significantly impact performance. Prioritize candidates who balance simulation with empirical testing and measurement (e.g., using VNA, spectrum analyzers).

Failure to Plan for Scalability and Manufacturing

An RF design that works in the lab may fail in mass production. Professionals who don’t consider manufacturability, component availability, or testability risk costly production delays. Look for experience in Design for Manufacturing (DFM) and collaboration with production teams.

Avoiding these pitfalls requires thorough vetting, clear contracts, and ongoing oversight. Investing time upfront in selecting the right RF machine professional protects both your product quality and intellectual assets.

Logistics & Compliance Guide for RF Machine Professionals

Introduction

Radio Frequency (RF) machines—used in industries such as telecommunications, medical aesthetics, broadcasting, and industrial heating—require careful handling throughout their lifecycle. As an RF machine professional, understanding logistics and compliance protocols is essential to ensure safety, legal adherence, and operational efficiency.

Regulatory Compliance Overview

RF equipment is subject to multiple international, national, and sector-specific regulations. Key compliance areas include electromagnetic compatibility (EMC), radio spectrum usage, safety standards, and environmental directives.

- FCC (USA): The Federal Communications Commission regulates RF emissions under Part 15 and Part 18. Certification is mandatory for most RF-emitting devices.

- CE Marking (EU): Compliance with the EMC Directive (2014/30/EU), Radio Equipment Directive (RED) 2014/53/EU, and Low Voltage Directive (2014/35/EU) is required for market access.

- IC (Canada): Industry Canada sets RF exposure and emission standards similar to FCC rules.

- Other Regions: Countries may have local equivalents (e.g., MIC in Japan, SRRC in China). Always verify destination-specific requirements.

Ensure all machines have valid certifications and test reports before shipment.

International Shipping & Transportation

Shipping RF equipment globally involves navigating customs, export controls, and carrier-specific rules.

- Export Controls: Some high-power or dual-use RF systems may be subject to export restrictions under regulations like the U.S. Export Administration Regulations (EAR) or the International Traffic in Arms Regulations (ITAR). Verify classification (e.g., ECCN) before shipping.

- Documentation: Prepare commercial invoices, packing lists, certificates of origin, and compliance declarations. Include technical specifications and certification details.

- Hazardous Materials: While most RF machines are not classified as hazardous, certain components (e.g., lithium batteries, high-voltage capacitors) may require special handling or labeling.

- Packaging: Use anti-static, shock-resistant packaging to protect sensitive circuitry. Clearly label equipment with handling instructions and regulatory marks.

Import & Customs Clearance

Successful customs clearance depends on accurate classification and documentation.

- HS Codes: Assign the correct Harmonized System (HS) code (e.g., 8517.62 for transmission apparatus) to determine duties and taxes.

- Duty & Tax Liability: Be aware of import tariffs, VAT, or GST in the destination country. Use Incoterms (e.g., DDP, DAP) to clarify responsibility.

- Local Approval: Some countries require pre-approval or local registration (e.g., SRRC approval in China, ANATEL in Brazil). Factor in lead times.

Installation & Site Compliance

On-site deployment requires adherence to safety and operational standards.

- EMF Exposure Limits: Ensure RF emissions comply with occupational and public exposure limits set by bodies such as ICNIRP or IEEE C95.1.

- Zoning & Licensing: For broadcast or telecom RF systems, verify frequency licensing and zoning permits with national regulators.

- Grounding & Shielding: Follow manufacturer guidelines for proper installation, grounding, and RF shielding to prevent interference and ensure safety.

- Environmental Controls: Install in areas with appropriate temperature, humidity, and ventilation as specified.

Maintenance & Servicing Logistics

Ongoing compliance and performance depend on regular maintenance and proper handling of spare parts.

- Calibration & Certification: Maintain records of periodic calibration and re-certification, especially for medical or measurement RF devices.

- Spare Parts Compliance: Replacement components must meet original certification standards. Avoid unauthorized modifications.

- Service Documentation: Keep logs of repairs, software updates, and compliance checks for audit purposes.

End-of-Life & Disposal

RF machines contain electronic components subject to environmental regulations.

- WEEE Compliance (EU): Follow Waste Electrical and Electronic Equipment directives for proper recycling.

- RoHS Compliance: Ensure disposal adheres to restrictions on hazardous substances (e.g., lead, cadmium).

- Data Security: For machines with embedded systems, securely erase configuration files or sensitive data before disposal.

- Certified Recyclers: Use licensed e-waste handlers to dismantle and recycle components responsibly.

Training & Personnel Certification

Ensure all personnel involved in handling, installing, or maintaining RF equipment are properly trained.

- RF Safety Training: Provide education on RF exposure risks and safe work practices.

- Compliance Awareness: Train staff on relevant regulations and documentation requirements.

- Certifications: Encourage professional certifications such as ETA RF Certification or vendor-specific training.

Recordkeeping & Audits

Maintain comprehensive documentation to support compliance and facilitate audits.

- Retention Period: Keep compliance certificates, shipping records, maintenance logs, and disposal receipts for at least 5–7 years.

- Audit Preparedness: Organize documents systematically to respond quickly to regulatory or customer audits.

Conclusion

RF machine professionals must integrate logistics and compliance into every phase—from procurement to disposal. By following this guide, you ensure operational safety, regulatory adherence, and smooth international operations. Stay updated on evolving standards and consult legal or compliance experts when in doubt.

Conclusion: Sourcing an RF (Radio Frequency) Machine – A Professional Approach

Sourcing a professional RF (Radio Frequency) machine requires thorough due diligence, technical understanding, and a clear alignment with your specific application needs—whether for aesthetic treatments, medical procedures, or industrial use. A successful sourcing strategy begins with identifying key performance criteria such as frequency range, power output, safety features, regulatory compliance (e.g., FDA, CE), and service support. Engaging with reputable manufacturers or certified distributors ensures product quality, reliability, and access to technical training and after-sales service.

It is essential to compare multiple vendors, evaluate machine durability and user-friendliness, and consider long-term maintenance costs. Additionally, verifying certifications and conducting site visits or product demonstrations can further mitigate risks. By taking a professional and systematic approach to sourcing, organizations can secure an RF machine that delivers optimal performance, ensures safety, and provides a strong return on investment. Ultimately, the right RF machine enhances operational efficiency and supports high standards of service delivery in any specialized field.