The global reusable spray can market is experiencing robust growth, driven by increasing environmental awareness and demand for sustainable packaging solutions across personal care, household, and industrial sectors. According to a 2023 report by Grand View Research, the global aerosol sprays market size was valued at USD 97.8 billion and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030, with reusable and refillable systems emerging as a key growth segment. Similarly, Mordor Intelligence projects steady momentum in the aerosol packaging market, citing innovation in pressure-assisted reusable containers as a critical driver. As brands prioritize circular economy principles and regulatory bodies tighten restrictions on single-use aerosols, reusable spray can manufacturers are stepping in with durable, eco-friendly alternatives. This shift has elevated the prominence of specialized manufacturers who combine engineering precision with sustainability. Below, we spotlight the top 10 reusable spray can manufacturers leading this transformation, selected based on production capacity, innovation, global distribution, and material sustainability credentials.

Top 10 Reusable Spray Can Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 OEM Refillable Aerosol Spray Can Factory, Pricelist

Domain Est. 2024

Website: sailon-can.com

Key Highlights: Looking for Refillable Aerosol Spray Cans? Foshan SAILON Tinplate Printing & Can Making Co., Ltd. offers high-quality, customizable options for your needs….

#2 Refillable Seamless Aluminum Aerosol Can Personalized Printing

Domain Est. 2021

Website: mgaerosolcan.com

Key Highlights: Leading aerosol cans factory in China, Mgaerosolcan supply best custom Refillable Seamless Aluminum Aerosol Can Personalized Printing with your design….

#3 Refillable Spray Can

Domain Est. 2023

Website: vim-ent.com

Key Highlights: Smarter Spray Solutions – 4 Ways to Choose Between Refillable and Disposable Spray Cans · How to Repair and Maintain Refillable Spray Cans for Longevity : VIM ……

#4 Aluminum Aerosol Cans

Domain Est. 1991

Website: ball.com

Key Highlights: Ball’s aluminum aerosol cans, which can be recycled again and again. From personal care to household products, high-definition designs and award-winning ……

#5 YouCAN

Domain Est. 1997

Website: jacquardproducts.com

Key Highlights: 5-day delivery 14-day returnsJacquard’s YouCAN is the first ever refillable air powered spray can that looks and feels just like a regular aerosol can. It can be filled with ANY li…

#6 Refillable Aerosol Can

Domain Est. 1998

Website: roberlo.com

Key Highlights: At Roberlo, we offer innovative solutions for every need. Discover the Disolac range and find the refillable aerosol can suitable for your project….

#7 Refillo®mat: Refilling spray cans

Domain Est. 1999

Website: wuerth-industrie.com

Key Highlights: With our Refillo®mat you can automatically refill spray cans, canisters & drums with substances & compressed air! Cost-effective & environmentally friendly….

#8 A1638Y5 Patented 620ml Thickened Aluminum Refillable Fluid …

Domain Est. 2010

Website: firstinfo.com.tw

Key Highlights: This pressure aerosol can with the sufficient force for you to spray from any angles without the limitation of space. 【 Universal Air Valve Stem/ Must Keep ……

#9 Refillable Spray Can

Domain Est. 2017

Website: sihai-aerosolcan.com

Key Highlights: The high-quality Tinplate Empty Aerosol Cans made by Sihai can be applied to various industry. We introduced advanced equipment to make the cans, which ……

#10 Discover which refillable sprays can we have

Domain Est. 1998

Website: montanacolors.com

Key Highlights: The MTN PRO range includes a line of refillable spray cans. Three aerosols are available, which are all operative once filled with the paint you want….

Expert Sourcing Insights for Reusable Spray Can

H2: Projected 2026 Market Trends for Reusable Spray Cans

The reusable spray can market is poised for significant transformation by 2026, driven by growing environmental awareness, regulatory shifts, and advancements in sustainable packaging technologies. As consumers and industries alike prioritize eco-conscious alternatives, reusable spray cans are emerging as a viable solution to reduce single-use aerosol waste. Below are key market trends expected to shape the reusable spray can sector in 2026:

-

Increased Consumer Demand for Sustainable Packaging

By 2026, consumer preference for sustainable and refillable products is expected to surge, particularly in personal care, household cleaning, and automotive care segments. Reusable spray cans, which eliminate the need for disposable metal aerosols, will benefit from this shift. Brands emphasizing circular economy principles—such as refill stations, returnable canisters, and closed-loop systems—are likely to capture greater market share. -

Regulatory Pressure and Extended Producer Responsibility (EPR)

Governments worldwide are tightening regulations on single-use plastics and pressurized containers. The EU’s Green Deal and similar initiatives in North America and Asia-Pacific will incentivize or mandate the adoption of reusable and refillable packaging. By 2026, Extended Producer Responsibility (EPR) schemes may require manufacturers to design for reusability, pushing investment into durable, refillable spray systems. -

Technological Innovations in Valve and Propellant Systems

Advances in non-aerosol pump technologies and air-powered dispensing systems will enhance the functionality and user experience of reusable spray cans. By 2026, expect widespread adoption of hand-pump, electrostatic, and compressed-air spray mechanisms that eliminate harmful propellants (e.g., VOCs) while maintaining consistent spray performance. Integration with smart caps for dosage control or connectivity could further differentiate premium products. -

Growth in B2B and Industrial Applications

Beyond consumer goods, reusable spray cans will gain traction in industrial, automotive, and maintenance sectors. Companies seeking to reduce operational waste and comply with environmental standards will adopt refillable systems for lubricants, cleaners, and coatings. Customizable canister sizes and bulk refill options will support scalability in these markets. -

Expansion of Refill Infrastructure and Retail Partnerships

By 2026, a growing network of refill stations in supermarkets, pharmacies, and specialty stores will make reusable spray cans more accessible. Strategic partnerships between reusable can manufacturers and major CPG brands (e.g., Seventh Generation, Method, or Unilever) will drive mainstream adoption. Subscription-based refill delivery models may also emerge, enhancing convenience. -

Material Innovation and Design for Durability

Reusable cans will increasingly use recycled aluminum, bioplastics, or hybrid materials designed for long-term use and safe refilling. Lightweighting, impact resistance, and aesthetic customization will be critical differentiators. Brands may adopt QR codes or NFC tags for tracking usage, refills, and recycling, supporting transparency and consumer engagement. -

Regional Market Growth and Urban Adoption Hubs

Europe and North America will lead in adoption due to strong environmental policies and consumer readiness. However, urban centers in Asia-Pacific (e.g., Tokyo, Seoul, Singapore) and Latin America (e.g., São Paulo, Mexico City) will see accelerated growth as sustainability becomes a priority among younger demographics.

In summary, by 2026, the reusable spray can market will be shaped by sustainability mandates, technological innovation, and evolving consumer behavior. Companies that invest in scalable refill systems, eco-friendly design, and circular business models will be well-positioned to lead this emerging segment.

Common Pitfalls When Sourcing Reusable Spray Cans (Quality and Intellectual Property)

Sourcing reusable spray cans offers environmental and cost-saving benefits, but it comes with significant challenges related to product quality and intellectual property (IP) risks. Failing to address these pitfalls can lead to poor performance, customer dissatisfaction, legal disputes, and reputational damage.

Quality-Related Pitfalls

Inconsistent Spray Performance

Many low-cost reusable spray cans suffer from inconsistent spray patterns, clogging, or weak pressure due to substandard valve systems or poor nozzle design. This undermines user experience and can damage brand credibility, especially if the product is marketed as a premium or professional solution.

Material Durability and Leakage

Reusable canisters must withstand repeated pressurization and cleaning cycles. Sourcing from manufacturers using low-grade plastics or metals can result in cracking, corrosion, or seal failure, leading to leaks and potential safety hazards. Inadequate testing for long-term durability is a common oversight.

Poor Refill Compatibility

Not all reusable spray cans are compatible with various types of liquids (e.g., water-based, oil-based, solvents). Sourcing without verifying chemical resistance or proper sealing mechanisms can lead to degradation of the can or valve components over time.

Lack of Quality Control and Certification

Suppliers, particularly in low-cost regions, may lack robust quality assurance processes. Absence of certifications (e.g., ISO standards, pressure safety testing) increases the risk of receiving inconsistent batches or non-compliant products.

Intellectual Property (IP) Pitfalls

Design and Mechanism Infringement

Many reusable spray can designs—especially innovative locking mechanisms, valve systems, or ergonomic features—are protected by patents. Sourcing generic versions without conducting thorough IP due diligence can result in unintentional infringement, leading to legal action, product seizures, or forced redesigns.

Copycat Products and Brand Confusion

Some suppliers offer near-identical replicas of patented designs under private labels. While appealing for cost reasons, these products expose buyers to litigation and reputational harm, especially if consumers associate the knockoff with an established brand.

Lack of IP Ownership in Custom Designs

When working with manufacturers to develop custom reusable spray cans, businesses may assume they own the design rights. However, without clear contractual agreements, the supplier may retain IP rights, limiting exclusivity or enabling them to sell the same design to competitors.

Insufficient Documentation and Traceability

Failing to obtain proper documentation—such as design patents, freedom-to-operate opinions, or supplier warranties—leaves companies vulnerable. In the event of an IP dispute, lack of evidence can weaken legal defenses and increase liability.

Mitigation Strategies

To avoid these pitfalls, conduct thorough due diligence: verify supplier credentials, request product testing data, perform IP searches, and secure written agreements that assign IP rights. Partnering with reputable manufacturers and involving legal counsel early in the sourcing process can significantly reduce risks.

Logistics & Compliance Guide for Reusable Spray Can

Product Overview

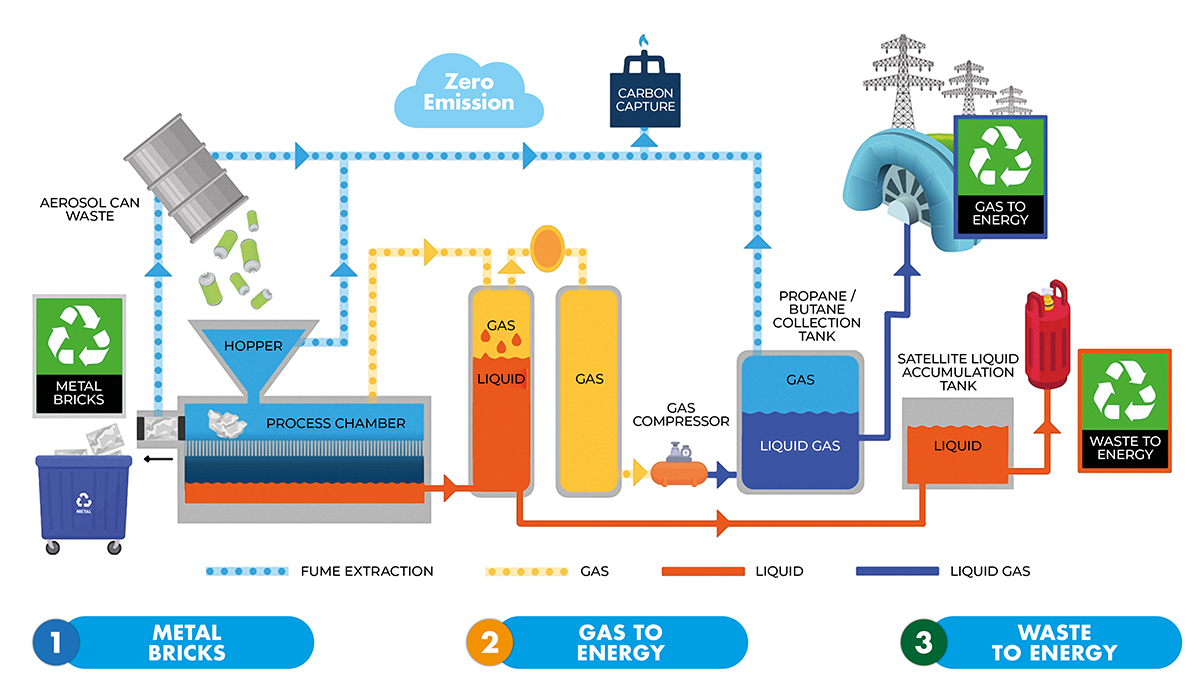

The Reusable Spray Can is an innovative, environmentally friendly alternative to single-use aerosol cans. It is designed for repeated refilling and reuse with various non-hazardous liquids such as cleaning agents, lubricants, or personal care products. This guide outlines the logistics handling, storage, transportation, and regulatory compliance considerations for the safe and legal distribution of the Reusable Spray Can.

Regulatory Classification

Aerosol or Non-Aerosol?

Unlike traditional aerosol cans that contain pressurized propellants, the Reusable Spray Can operates via manual pump or user-pressurized mechanisms and does not contain flammable or compressed gas propellants. As such, it typically does not fall under hazardous materials (dangerous goods) regulations when empty or filled with non-hazardous substances.

Note: Classification depends on the liquid contents. Always assess the chemical composition of the refill liquid per applicable regulations (e.g., UN TDG, GHS, 49 CFR, ADR/RID/ADN, IATA/IMDG).

Transportation & Shipping

Domestic (e.g., U.S. & Canada)

- Non-Hazardous Contents: If filled with non-flammable, non-toxic, non-reactive liquids, the product can be shipped as a general commodity under standard parcel or freight shipping (e.g., FedEx, UPS, LTL).

- Hazardous Contents: If filled with regulated substances (e.g., flammable cleaners), it may be subject to DOT 49 CFR or Transportation of Dangerous Goods (TDG) Regulations. Proper classification, labeling, packaging, and documentation are required.

International Shipping

- IATA (Air): If the filled product contains hazardous materials, it must comply with IATA Dangerous Goods Regulations. Most reusable spray cans with non-pressurized, non-flammable contents are exempt.

- IMDG (Sea): Similar to air, marine transport requires classification under the IMDG Code if hazardous.

- ADR (Europe – Road): Applies to road transport in Europe. Non-pressurized, non-hazardous reusable sprays are typically ADR-exempt.

Best Practice: Ship reusable spray cans unfilled to avoid classification issues. Provide refills separately if they are regulated.

Packaging & Labeling

Primary Packaging

- Ensure the spray can is securely sealed to prevent leakage during transit.

- Use child-resistant closures if applicable (e.g., for household cleaners).

- Include clear usage instructions and material compatibility warnings.

Secondary Packaging

- Use rigid outer packaging with cushioning to protect the can during handling.

- Include absorbent material if shipping with liquid (even non-hazardous) to contain potential leaks.

Labeling Requirements

- GHS Compliance: If the liquid is classified as hazardous, apply GHS-compliant labels (pictograms, signal words, hazard statements).

- Product Identification: Include product name, model number, manufacturer details, and batch/lot number.

- Recycling & Reuse Symbols: Display appropriate eco-labels (e.g., recycling logo, “Refillable” icon).

- Country-Specific Labels: Comply with local requirements (e.g., CE mark in EU, CPC in U.S. for consumer products).

Storage Guidelines

- Environment: Store in a cool, dry, well-ventilated area away from direct sunlight and heat sources.

- Segregation: If storing with refills, separate flammable or reactive liquids according to local fire codes.

- Shelf Life: While the can itself is durable, monitor the integrity of seals and gaskets. Recommend inspection every 12–24 months for optimal performance.

Environmental & Compliance Standards

REACH & RoHS (EU)

- Ensure all materials (plastic, metal, seals) comply with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances).

- Provide SVHC (Substances of Very High Concern) declarations if requested.

Proposition 65 (California, USA)

- Evaluate all materials and formulations for listed chemicals. Provide warning labels if required.

EPA & FTC Guidelines (USA)

- Avoid unsubstantiated “eco-friendly” or “green” claims. Use qualifying language such as “reusable design reduces single-use waste.”

- Comply with EPA Safer Choice Program if marketing environmental attributes.

End-of-Life & Circular Economy

- Return & Refill Programs: Encourage take-back systems to promote reuse and reduce plastic waste.

- Recycling Instructions: Clearly label disassembly steps (e.g., remove pump before recycling).

- Compliance with EPR Schemes: In regions with Extended Producer Responsibility (e.g., EU, Canada), register and report as required.

Summary of Key Actions

| Action | Responsibility | Frequency |

|——-|—————-|———|

| Classify contents per transport regulations | Product Safety Team | Per new formulation |

| Apply correct labels and markings | Packaging/Compliance | Per shipment |

| Audit storage conditions | Warehouse Manager | Monthly |

| Review regulatory updates | Compliance Officer | Quarterly |

| Train logistics staff on handling procedures | Operations | Annually |

Conclusion

The Reusable Spray Can offers a sustainable solution with simplified logistics when shipped unfilled or with non-hazardous contents. Proactive classification, compliant labeling, and adherence to regional regulations are essential for smooth global distribution. By prioritizing reuse and lifecycle management, manufacturers can meet both environmental goals and regulatory obligations.

In conclusion, sourcing reusable spray cans presents a sustainable, cost-effective, and environmentally responsible solution for businesses and consumers alike. By investing in high-quality, durable reusable alternatives, organizations can significantly reduce single-use waste, lower long-term packaging costs, and align with growing consumer demand for eco-friendly products. Careful consideration of suppliers, material quality, compatibility with various liquids, and ease of cleaning and refilling is essential to ensure performance and safety. Additionally, partnering with manufacturers that prioritize innovation and sustainability strengthens supply chain resilience and supports broader environmental goals. As regulatory pressures and environmental awareness continue to rise, transitioning to reusable spray cans is not only a practical procurement decision but also a strategic move toward a more sustainable future.