The global retaining wall block market is experiencing robust growth, driven by increasing urbanization, infrastructure development, and demand for erosion control solutions in residential and commercial construction. According to Grand View Research, the global segment of concrete masonry products, which includes retaining wall blocks, was valued at USD 178.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Similarly, Mordor Intelligence projects that the precast concrete products market—which encompasses retaining wall systems—will grow at a CAGR of over 6.2% during the forecast period of 2023–2028, fueled by advancements in modular construction and rising adoption in transportation and water management infrastructure. As the demand for durable, aesthetically pleasing, and engineered retaining solutions intensifies, a select group of manufacturers have emerged as industry leaders, combining innovation, scalability, and technical expertise to meet evolving market needs. The following list highlights the top nine retaining wall block manufacturers shaping the future of civil and landscape engineering worldwide.

Top 9 Retaining Wall Block Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pavers, Retaining Walls, Masonry Block

Domain Est. 1996

Website: superliteblock.com

Key Highlights: Belgard has defined itself among brick and concrete paver manufacturers by offering distinct pavers for stone hardscapes, retaining walls and more. Belgard ……

#2 Belgard Pavers & Hardscapes Manufacturer

Domain Est. 1997

Website: belgard.com

Key Highlights: Belgard has defined itself among brick and concrete paver manufacturers by offering distinct pavers for stone hardscapes, retaining walls, and more……

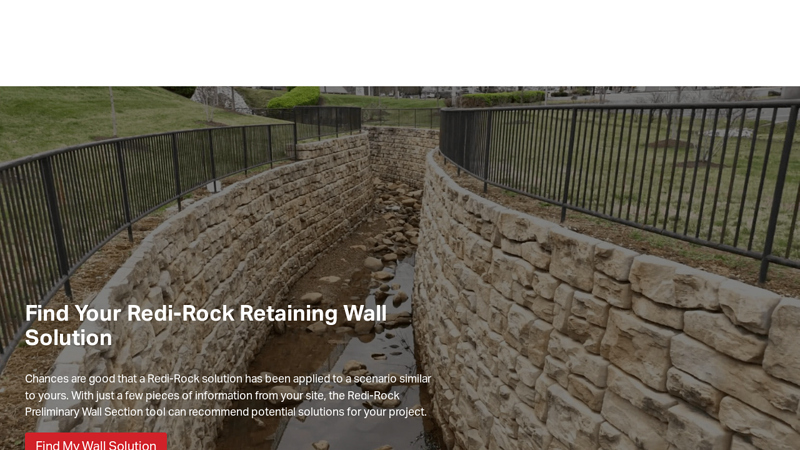

#3 Redi

Domain Est. 2000

Website: redi-rock.com

Key Highlights: Redi-Rock designs, manufactures, and licenses premium-grade steel forms and molds to a network of more than 130 local producers around the world….

#4 Basalite Concrete Products

Domain Est. 2000

Website: basalite.com

Key Highlights: Basalite Building Products, LLC is one of the largest manufacturers of concrete masonry products in the Western United States. Product lines include structural ……

#5 Retaining Wall Blocks & Systems, Patio Block, and Sound Barrier …

Domain Est. 1995

Website: allanblock.com

Key Highlights: Allan Block is your trusted partner for innovative retaining wall solutions. Explore our durable, easy-to-install blocks, comprehensive design resources, ……

#6 Retaining Wall Blocks for Every Landscaping Need; Reliable and …

Domain Est. 1996

Website: versa-lok.com

Key Highlights: VERSA-LOK retaining walls deliver flexibility, attractive facing options, and cost-effectiveness, making them the perfect solution for residential landscaping….

#7 Retaining Wall Blocks

Domain Est. 1996

Website: rcpblock.com

Key Highlights: Retaining Wall Blocks and Landscape Wall Blocks are designed to retain soil or create yard division. Available retaining wall blocks for all project needs….

#8 Recon Wall Systems

Domain Est. 2001

Website: reconwalls.com

Key Highlights: With over twenty-million square feet of Recon retaining walls installed around the world, we are proud to be a leader in the big block retaining wall industry….

#9 Wall Systems

Domain Est. 2002

Website: hub.countymaterials.com

Key Highlights: Durable Interlocking Concrete Blocks for Retaining and Freestanding Walls. Retaining wall blocks are a durable and aesthetically pleasing building material ……

Expert Sourcing Insights for Retaining Wall Block

2026 Market Trends for Retaining Wall Blocks

The global retaining wall block market is poised for significant evolution by 2026, driven by shifting construction priorities, technological advancements, and growing environmental awareness. Key trends shaping the industry include:

Sustainable and Eco-Friendly Materials

Demand for environmentally responsible construction solutions is accelerating. By 2026, manufacturers are expected to increasingly adopt recycled aggregates, low-carbon cement alternatives, and permeable block designs that support stormwater management. Green building certifications like LEED and BREEAM are pushing projects to prioritize sustainable hardscaping, favoring retaining wall blocks with verifiable environmental credentials.

Design Innovation and Aesthetic Versatility

Homeowners and landscape architects are seeking retaining wall blocks that blend functionality with visual appeal. The market will see a rise in blocks mimicking natural stone, wood, and textured finishes, available in diverse colors, shapes, and modular patterns. Customization options and interlocking systems that allow for curved and tiered installations will gain popularity, especially in residential and urban landscaping.

Growth in Residential and Urban Infrastructure

Expanding suburban developments and urban densification are driving demand for space-efficient landscaping solutions. Retaining wall blocks are increasingly used in residential projects for creating usable outdoor spaces on sloped lots, basement walls, and garden terraces. Additionally, municipal infrastructure projects—such as greenways, flood control systems, and roadside stabilization—are adopting segmental retaining wall (SRW) systems for their cost-effectiveness and rapid installation.

Advancements in Engineering and Installation Efficiency

By 2026, innovation in block design and geosynthetic reinforcement will enhance structural performance and ease of installation. Pre-engineered systems with integrated drainage and alignment features will reduce labor costs and project timelines. The use of BIM (Building Information Modeling) and digital design tools will improve precision in planning and material estimation, minimizing waste.

Regional Market Expansion

Emerging economies in Asia-Pacific, Latin America, and Africa are expected to see robust growth due to urbanization and infrastructure development. In contrast, mature markets like North America and Western Europe will focus on renovation, retrofitting, and sustainable redevelopment, supporting steady demand for high-performance and aesthetically refined retaining wall solutions.

Consolidation and Brand Differentiation

Market consolidation among major manufacturers is likely as companies seek economies of scale and broader distribution networks. At the same time, differentiation through proprietary technologies, design patents, and sustainability claims will become critical for competitive advantage. Brands that offer comprehensive support—including engineering services, design software, and installer training—will gain market share.

In summary, the 2026 retaining wall block market will be characterized by a convergence of sustainability, design, engineering performance, and efficiency—catering to both residential aesthetics and large-scale infrastructure resilience.

Common Pitfalls When Sourcing Retaining Wall Blocks (Quality and Intellectual Property)

Sourcing retaining wall blocks involves more than just selecting an attractive design and competitive price. Overlooking key quality and intellectual property (IP) considerations can lead to structural failures, legal disputes, and reputational damage. Below are common pitfalls to avoid.

Poor Material Quality and Inconsistent Manufacturing

One of the most frequent issues is selecting blocks made from substandard concrete or aggregates. Blocks with low compressive strength, high water absorption, or inconsistent curing processes are prone to cracking, spalling, and premature deterioration—especially in freeze-thaw climates. Additionally, inconsistent sizing or finish across production batches can result in poor fit during installation, compromising both aesthetics and structural integrity.

Lack of Compliance with Industry Standards

Many suppliers fail to adhere to relevant standards such as ASTM C1372 (Standard Specification for Dry-Cast Concrete Masonry Units) or local building codes. Sourcing blocks without verification of compliance increases the risk of using non-engineered products unsuitable for load-bearing applications. Always request test reports and certifications to confirm performance metrics.

Inadequate Drainage and Structural Design Features

High-quality retaining wall blocks are engineered with integrated features like set-backs, interlocking mechanisms, and weep holes to ensure stability and water management. Sourcing blocks without these design elements—or using them incorrectly—can lead to hydrostatic pressure buildup, wall tilting, or catastrophic failure over time.

Counterfeit or Knock-Off Products Infringing on IP

A significant but often overlooked pitfall is purchasing counterfeit or imitation retaining wall blocks that infringe on patented designs. Many reputable manufacturers hold design and utility patents on block shapes, interlocking systems, and surface textures. Using unauthorized copies not only violates intellectual property rights but may also result in inferior performance due to poor reverse engineering.

Failure to Verify Licensing and IP Rights

When sourcing from third-party suppliers or overseas manufacturers, it’s crucial to confirm whether they are licensed to produce patented block designs. Unlicensed production can expose contractors, developers, and distributors to legal liability, including cease-and-desist orders, fines, or project stoppages.

Insufficient Documentation and Traceability

Lack of proper documentation—such as material test reports, batch numbers, or IP licensing proof—makes it difficult to trace product origins and verify authenticity. This opacity complicates quality assurance and increases risk in the event of a failure or legal challenge.

Prioritizing Cost Over Long-Term Performance

Choosing the cheapest available option often leads to higher lifecycle costs due to maintenance, repairs, or complete wall replacement. Low-cost blocks may cut corners on mix design, reinforcement, or finishing processes, sacrificing durability and safety.

Overlooking Aesthetic Consistency

For visible landscapes or commercial projects, inconsistent color, texture, or finish can undermine design intent. Poor quality control in pigment application or surface treatment leads to patchy appearances that degrade the project’s visual appeal.

By carefully evaluating both quality attributes and intellectual property compliance, buyers can avoid these common pitfalls and ensure the longevity, safety, and legal integrity of their retaining wall installations.

Logistics & Compliance Guide for Retaining Wall Blocks

Product Overview and Handling Requirements

Retaining wall blocks are precast concrete or segmental units designed to construct stable, erosion-resistant retaining structures. Due to their weight and bulk, proper handling, storage, and transportation are critical to ensure product integrity and job site safety. These blocks typically range from 30 to 100+ pounds per unit and are often shipped on wooden pallets or in bulk loads. Always assess block dimensions, weight, and edge sensitivity before planning logistics.

Transportation and Delivery

Ensure all shipments are secured using straps, edge protectors, and dunnage to prevent shifting during transit. Use flatbed trucks or enclosed trailers equipped with forklifts or cranes for unloading. Coordinate delivery schedules with the job site to minimize double-handling and exposure to weather. Confirm site access for large vehicles and ensure a clear, level unloading area free of obstructions.

On-Site Storage Best Practices

Store blocks on a level, well-drained surface to avoid shifting or water damage. Keep pallets intact and stacked no higher than recommended by the manufacturer (typically 2–3 high) to prevent collapse. Avoid placing blocks directly on soil or grass; use gravel or plywood pads. Protect from prolonged exposure to moisture, especially in freeze-thaw climates, to prevent spalling or cracking.

Safety and Handling Procedures

Only trained personnel should handle retaining wall blocks using appropriate equipment such as forklifts, skid steers, or suction lifters. Always wear personal protective equipment (PPE), including steel-toed boots, gloves, and eye protection. Use mechanical aids whenever possible—never attempt to manually lift heavy units. Follow safe lifting techniques and maintain clear communication during unloading and placement.

Regulatory and Compliance Considerations

Retaining wall blocks must meet relevant standards such as ASTM C1372 (Standard Specification for Segmental Concrete Retaining Wall Units) and local building codes. Verify that products are certified by recognized testing laboratories and that documentation (e.g., material test reports) is available upon request. Imported blocks may require compliance with customs regulations, including ISPM 15 for wooden pallets.

Environmental and Sustainability Compliance

Ensure transportation and storage practices minimize environmental impact. Avoid stacking blocks near waterways or drainage areas to prevent sediment runoff. Recycle packaging materials such as pallets and plastic wraps where possible. Consider specifying blocks made with recycled content or low-carbon concrete mixes to meet green building standards (e.g., LEED).

Documentation and Traceability

Maintain detailed records of delivery receipts, batch numbers, and inspection reports. This traceability is essential for quality assurance and compliance audits. Report any damaged or non-conforming units immediately to the supplier with photographic evidence and documentation.

Installation and Job Site Coordination

Coordinate logistics with the installation team to ensure a steady supply of blocks without overstocking. Verify that the blocks match project specifications in color, texture, and size prior to installation. Store blocks near the work area but out of the primary construction zone to reduce trip hazards and maintain workflow efficiency.

Emergency and Damage Response

Establish a protocol for handling damaged blocks during shipping or handling. Isolate damaged units and document the issue for insurance or warranty claims. In case of accidents or injuries during handling, follow OSHA guidelines and report incidents promptly according to company policy.

Conclusion: Sourcing Retaining Wall Block Manufacturers

In conclusion, sourcing retaining wall block manufacturers requires a strategic approach that balances quality, cost, reliability, and sustainability. A thorough evaluation of potential suppliers—based on manufacturing capabilities, material standards, production capacity, and compliance with industry regulations—is essential to ensure the durability and performance of the retaining wall systems. Additionally, factors such as lead times, logistics, customization options, and after-sales support play a crucial role in long-term project success.

By prioritizing manufacturers with proven track records, certifications (such as ISO or ASTM compliance), and environmental responsibility, businesses can secure reliable partnerships that enhance project efficiency and structural integrity. Leveraging both domestic and international suppliers may offer cost advantages and access to innovative designs, provided quality control and communication are effectively managed.

Ultimately, a well-researched and diversified sourcing strategy not only mitigates risks but also supports sustainable construction practices and long-term value for clients and stakeholders. Establishing strong relationships with reputable retaining wall block manufacturers is a key step toward delivering successful civil and landscaping infrastructure projects.