The global exhaust system market, driven by increasing vehicle production and stringent emission regulations, is projected to grow at a CAGR of 5.8% between 2023 and 2028, according to Mordor Intelligence. With performance and acoustic engineering becoming pivotal in both OEM and aftermarket applications, resonator exhaust pipes have emerged as critical components in optimizing engine efficiency and reducing noise. As demand rises across automotive and industrial sectors, manufacturers are investing in advanced materials and acoustic tuning technologies to meet evolving regulatory and consumer standards. In this competitive landscape, nine key players have distinguished themselves through innovation, scale, and technical expertise—shaping the future of exhaust system performance worldwide.

Top 9 Resonator Exhaust Pipe Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

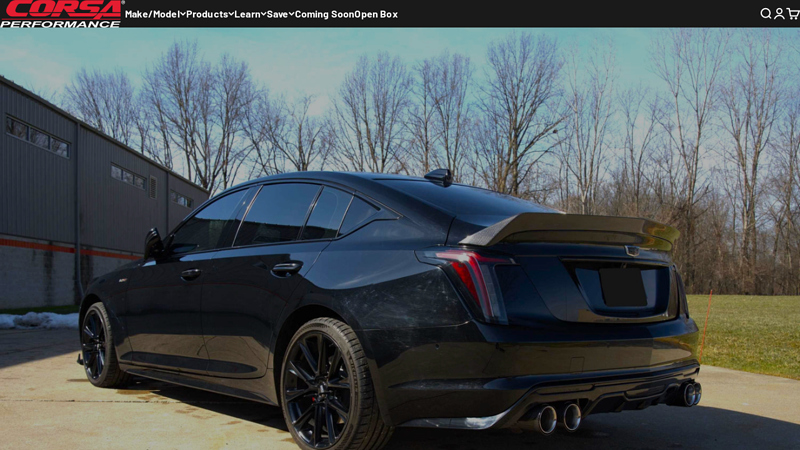

#1 CORSA Performance exhaust systems, mufflers, headers and air …

Domain Est. 1999

Website: corsaperformance.com

Key Highlights: CORSA Performance is an American Manufacturer of high performance exhaust systems, headers and air intakes … Pipes, resonator deletes and performance mufflers….

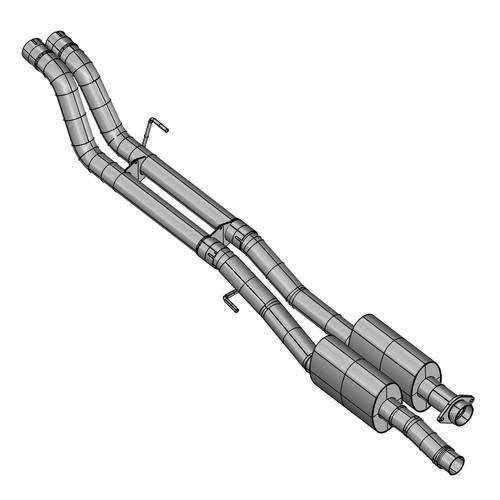

#2 Exhaust Systems, Cat

Domain Est. 1997

Website: dynomax.com

Key Highlights: DynoMax® Performance Exhaust is a leading brand of stainless steel exhaust systems, cat-back systems, axle-back systems and stainless steel muffler ……

#3 Walker Exhaust Systems

Domain Est. 1999

Website: walkerexhaust.com

Key Highlights: Providing performance-grade mufflers and exhaust kits for a wide variety of makes and models, Walker is the name to trust in OE-quality exhaust parts….

#4 Mufflers and Resonators

Domain Est. 2000

Website: vibrantperformance.com

Key Highlights: We offer one of the most complete offerings of Mufflers & Resonators in the industry, providing the ideal upgrade for virtually any type of car or truck, ……

#5 Exhaust Resonator Pipe, X & H Pipes Products

Domain Est. 2003

#6 My Store

Domain Est. 2003

Website: invidia-usa.com

Key Highlights: Invidia Exhaust—exceptional craftsmanship, premium materials, and cutting-edge design. Our meticulously engineered systems reduce back pressure, boost engine ……

#7 to AP Emissions Technologies

Domain Est. 2006

Website: apemissions.com

Key Highlights: AP Emissions Technologies is your source for aftermarket exhaust and emissions parts for virtually every type of on-road and off-road passenger vehicle, fleet ……

#8 ARK Performance Inc

Domain Est. 2006

Website: arkperformance.com

Key Highlights: 4-day deliveryXtreme Quality Makes Xtreme Performance. From high-performance exhaust systems to precision-engineered suspension, stylish wheels and aerodynamic components ……

#9 xforce performance exhaust

Domain Est. 2014

Expert Sourcing Insights for Resonator Exhaust Pipe

H2: 2026 Market Trends for Resonator Exhaust Pipes

The global market for resonator exhaust pipes is projected to experience notable transformation by 2026, driven by evolving automotive technologies, stricter emissions regulations, and shifting consumer preferences. As a critical component of vehicle exhaust systems, resonator pipes are designed to reduce noise and improve exhaust flow, enhancing both performance and acoustic comfort. The following are key trends expected to shape the resonator exhaust pipe market through 2026:

-

Growing Demand for Performance and Luxury Vehicles

The rising global popularity of performance-oriented and luxury vehicles is significantly boosting the demand for high-efficiency resonator exhaust systems. Enthusiasts and premium automakers are increasingly integrating performance exhausts—including advanced resonators—into vehicle designs to improve sound quality and engine efficiency. This trend is particularly strong in North America, Europe, and parts of Asia-Pacific, where aftermarket customization is on the rise. -

Expansion of the Automotive Aftermarket

The aftermarket segment is expected to dominate the resonator exhaust pipe market by 2026. Consumers are more frequently replacing or upgrading stock exhaust components to enhance vehicle acoustics and performance. Online retail platforms and DIY culture are accelerating this trend, enabling broader access to specialized resonator products from both OEM and aftermarket brands. -

Stringent Noise and Emission Regulations

Governments worldwide are enforcing tighter regulations on vehicle noise pollution and emissions. Resonator exhaust pipes play a crucial role in meeting noise compliance standards without compromising engine performance. As automakers seek quieter yet efficient exhaust solutions, demand for precisely engineered resonators will increase—particularly in urban-centric markets and regions with strict environmental policies (e.g., EU’s Euro 7 standards). -

Adoption of Lightweight and Corrosion-Resistant Materials

The shift toward lightweight, durable materials such as aluminized steel and stainless steel is a key trend in resonator manufacturing. These materials enhance longevity and performance, especially in harsh environments. Additionally, advancements in coating and manufacturing processes are improving resistance to thermal fatigue and corrosion—critical for maintaining acoustic efficacy over time. -

Electric Vehicle (EV) Impact and Niche Opportunities

While the rise of electric vehicles (EVs), which do not require traditional exhaust systems, may limit overall market growth, hybrid vehicles still rely on internal combustion engines (ICE) and thus on exhaust components like resonators. Moreover, some EV manufacturers are exploring artificial sound systems, but this does not directly replace resonator demand. The ICE vehicle fleet will remain substantial through 2026, ensuring continued need for resonator exhaust pipes. -

Regional Market Dynamics

- Asia-Pacific is expected to witness the highest growth due to expanding automotive production in China, India, and Southeast Asia, alongside rising disposable incomes and vehicle ownership.

- North America maintains strong demand due to a robust car culture and high adoption of aftermarket performance parts.

-

Europe emphasizes emissions and noise compliance, driving innovation in compact and efficient resonator designs.

-

Technological Integration and Smart Exhaust Systems

Emerging trends include the integration of variable valve control and active noise cancellation technologies in exhaust systems. While still in early adoption, these smart systems may incorporate adaptive resonators that adjust sound profiles based on driving mode, further increasing the sophistication and value of resonator components.

Conclusion

By 2026, the resonator exhaust pipe market will be shaped by a convergence of regulatory demands, performance aspirations, and material innovation. While electrification poses a long-term challenge, the continued dominance of ICE and hybrid vehicles ensures sustained relevance. Manufacturers that invest in advanced acoustics engineering, lightweight materials, and compliance-focused designs will be best positioned to capture growth in this evolving market.

Common Pitfalls Sourcing Resonator Exhaust Pipes (Quality, IP)

Sourcing resonator exhaust pipes, especially from overseas suppliers, presents significant challenges related to both product quality and intellectual property (IP) protection. Overlooking these pitfalls can lead to costly recalls, legal disputes, reputational damage, and lost market share.

Quality Inconsistencies and Defects

One of the most prevalent issues is inconsistent or substandard quality. Many suppliers, particularly in low-cost manufacturing regions, may lack robust quality control systems, leading to variability between batches. Common defects include poor weld integrity (leading to leaks or failures under thermal cycling), incorrect dimensions (causing fitment issues), and use of inferior-grade stainless steel that corrodes prematurely. Surface finish and internal geometry are critical for acoustic performance; deviations can result in unacceptable noise levels or reduced engine efficiency. Without rigorous incoming inspection and ongoing quality audits, buyers risk receiving non-conforming parts that fail in the field.

Intellectual Property Infringement Risks

Sourcing resonator exhaust pipes carries substantial IP risks, especially when dealing with suppliers who may replicate designs without authorization. Many aftermarket or OEM-specific resonator designs are protected by patents (utility or design) and trademarks. Unwittingly sourcing a copycat product can expose the buyer to infringement claims from original manufacturers. Furthermore, suppliers may reverse-engineer proprietary designs and sell them to competitors, eroding market advantage. Contract manufacturers might also overproduce and divert parts to gray markets. Failure to conduct due diligence on a supplier’s IP compliance history or to secure appropriate legal agreements (e.g. confidentiality, IP ownership clauses) significantly increases legal and financial exposure.

Mitigation Strategies

To mitigate these risks, buyers should implement stringent supplier qualification processes, including on-site audits, sample testing, and verification of material certifications. Clear technical specifications and performance requirements must be documented and enforced. Legally, contracts should explicitly address IP ownership, prohibit reverse engineering, and include indemnification clauses. Where possible, working with authorized partners or OEM-approved suppliers reduces both quality and IP risks. Regular monitoring and strong supply chain governance are essential to maintain product integrity and protect proprietary designs.

H2: Logistics & Compliance Guide for Resonator Exhaust Pipe

This guide outlines the key logistics considerations and compliance requirements for the international shipping, handling, and regulatory approval of Resonator Exhaust Pipes.

H3: Product Classification & Identification

- HS Code: Typically 8708.91 (Parts and accessories of the motor vehicles of headings 8701 to 8705, for exhaust systems). Verify locally (e.g., 8708.91.00 in the US HTS; 8708 91 00 in EU CN). Accuracy is critical for duties and regulations.

- UN Number: Not applicable (NA) – Resonator exhaust pipes are not classified as hazardous goods under normal transport conditions.

- Product Description: Clearly state “Resonator Exhaust Pipe Assembly” or “Automotive Exhaust Resonator” on all documentation. Specify material (e.g., “Stainless Steel 304 Resonator”).

- SKU/Part Number: Include unique identifiers for traceability.

H3: Packaging & Labeling Requirements

- Packaging:

- Use robust, protective packaging (e.g., heavy-duty corrugated cardboard boxes, wooden crates for large/fragile units) to prevent dents, scratches, and corrosion during transit.

- Securely pack to prevent movement within the container/box.

- Use internal padding (bubble wrap, foam inserts, cardboard dividers).

- Consider moisture barriers (VCI paper, desiccants) for sea freight, especially for steel components.

- Ensure packaging is suitable for stacking and standard palletization.

- Labeling (External Package/Carton):

- Shipping Marks: Consignee, Consignor, PO Number, Country of Origin (“Made in [Country]”).

- Handling Labels: “Fragile,” “This Side Up,” “Do Not Stack,” weight, dimensions.

- Compliance Marks: Any required national safety or environmental marks (e.g., E-Mark if applicable – see below).

- Barcodes/QR Codes: For scanning and tracking.

H3: Transportation & Logistics

- Mode of Transport: Primarily containerized ocean freight (FCL/LCL) or air freight for urgent/low-volume shipments. Overland trucking for regional/domestic moves.

- Incoterms: Clearly define responsibilities (e.g., EXW, FOB, CIF, DDP). DDP (Delivered Duty Paid) simplifies import for the buyer but increases exporter responsibility/cost.

- Palletization: Standard pallet sizes (e.g., EUR/EPAL, US 48″x40″). Securely strap and band packages to the pallet. Max weight per pallet per carrier limits.

- Handling: Avoid dropping, dragging, or excessive force. Use appropriate lifting equipment.

- Storage: Store in a dry, covered area, off the ground. Protect from direct sunlight, rain, snow, and extreme temperatures. Prevent moisture accumulation.

H3: Regulatory Compliance & Documentation

- Essential Documents:

- Commercial Invoice: Detailed description, HS Code, value (FOB/CIF), currency, Incoterms, buyer/seller details, country of origin.

- Packing List: Itemized list per package, weights, dimensions, carton/pallet counts, marks & numbers.

- Bill of Lading (B/L) or Air Waybill (AWB): Contract of carriage.

- Certificate of Origin (CoO): Required for preferential duty rates under trade agreements (e.g., USMCA, RCEP). Often mandatory.

- Key Regulatory Requirements:

- Emissions & Noise Regulations (Critical):

- USA: Not subject to EPA certification as a standalone part if replacing an original resonator in kind. However, modifications affecting the overall exhaust system’s noise or emissions (e.g., removing a resonator entirely, drastic design changes) can violate the Clean Air Act (CAA) and state laws (e.g., California’s CARB). CARB Executive Order (EO) number required if marketed as a legal replacement part in CA.

- EU: Must comply with EU Whole Vehicle Type Approval (WVTA) framework. Replacement parts should not invalidate the vehicle’s type approval. May require E-Mark certification (ECE Regulation No. 51 or 59 for noise, depending on vehicle type) if replacing a type-approved component. National type approval may also apply.

- Other Markets: Check local noise and emissions regulations (e.g., Japan JIS D 5501, Australia ADR 28/xx). Modifications often face restrictions.

- Material Restrictions:

- RoHS (EU & similar): Restricts lead, mercury, cadmium, etc. Primarily applies to electrical/electronic components. Generally not applicable to pure metal exhaust pipes/resonators, but verify if any coatings or attached sensors contain restricted substances.

- REACH (EU): Requires notification of Substances of Very High Concern (SVHC) if present above thresholds. Metal alloys (e.g., stainless steel) may contain SVHCs like Chromium (VI) compounds (formed during welding). Provide a declaration if requested.

- Prop 65 (California, USA): Requires warning labels if the product contains chemicals known to cause cancer or reproductive harm (e.g., certain metals in stainless steel like Chromium). Assessment and labeling may be necessary.

- Product Safety: General product liability laws apply. Ensure design/manufacturing meets reasonable safety standards.

- Emissions & Noise Regulations (Critical):

H3: Import Procedures & Duties

- Customs Clearance: Provide accurate HS Code, CoO, and all other required documents to the importer or their customs broker.

- Duty & Taxes: Payable by the importer (unless DDP). Rate depends on the HS Code, country of origin, and trade agreements. VAT/GST also applies.

- Import Licenses/Permits: Generally not required for exhaust resonators, but verify with the destination country’s customs authority.

H3: Best Practices

- Verify HS Code: Consult a customs expert or official tariff database for the destination country.

- Understand Destination Laws: Research specific noise, emissions, and safety regulations in the final market.

- Clear Documentation: Ensure all paperwork is complete, accurate, and consistent.

- Robust Packaging: Prevent damage in transit to avoid claims and returns.

- Compliance Declarations: Be prepared to provide RoHS, REACH, or Prop 65 declarations if requested.

- Consult Experts: Engage freight forwarders, customs brokers, and legal advisors familiar with automotive parts regulations in target markets.

Disclaimer: Regulations change frequently. This guide provides general information. Always consult with legal, compliance, and logistics professionals for specific shipments and target markets.

In conclusion, sourcing a resonator exhaust pipe requires careful consideration of vehicle specifications, desired sound profile, material quality, and local regulations. It is essential to select a resonator that matches your vehicle’s make and model to ensure proper fitment and optimal performance. High-quality materials such as stainless steel offer improved durability and resistance to corrosion, contributing to long-term reliability. Additionally, choosing the right resonator can enhance engine efficiency, reduce unwanted noise, and provide a more balanced exhaust tone without the excessive volume of a straight-pipe system. Whether purchased from OEM suppliers, aftermarket manufacturers, or reputable online retailers, verifying compatibility and product certifications ensures a successful installation. Ultimately, investing time in sourcing the correct resonator exhaust pipe leads to improved driving experience, better exhaust system performance, and compliance with noise and emissions standards.