The global reforestation equipment market is experiencing robust growth, driven by increasing demand for large-scale afforestation and reforestation initiatives in response to climate change and deforestation. According to Mordor Intelligence, the tree planting machinery market is projected to grow at a CAGR of over 7.2% from 2024 to 2029, fueled by advancements in automation and rising government and NGO-led environmental programs. Additionally, data from Grand View Research estimates that the global forestry equipment market, which includes reforestation machinery, was valued at over USD 10 billion in 2023 and is expected to expand significantly through 2030 due to intensified focus on sustainable land management. As demand surges, innovative manufacturers are emerging with advanced, precision-driven replanting machines capable of planting thousands of trees per day. The following list highlights the top nine companies at the forefront of this transformative sector, combining technological innovation, scalability, and proven field performance.

Top 9 Replanting Trees Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

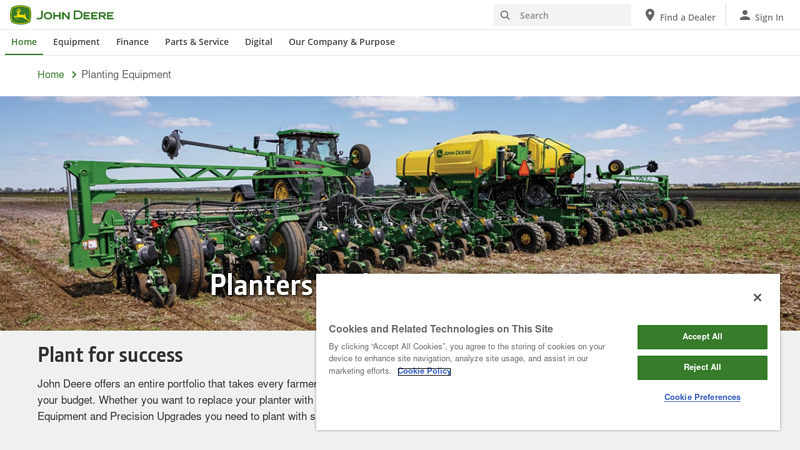

#1 Planting Equipment

Domain Est. 1990

Website: deere.com

Key Highlights: Explore planting equipment and row units from John Deere, including drawn and mounted planters. Visit today to see how to maximize your yield potential….

#2 Tree Spades and Tree Transplanting Equipment in the US

Domain Est. 1996

Website: big-john.com

Key Highlights: At Big John Manufacturing, we’ve delivered quality tree transplanting equipment for over 40 years, all designed and made in the USA….

#3 Precision Planting

Domain Est. 1997

Website: precisionplanting.com

Key Highlights: Connect with a Precision Planting Premier Dealer to evaluate your equipment and future goals to create an upgrade plan for your farm….

#4 Tree Planting

Domain Est. 1998

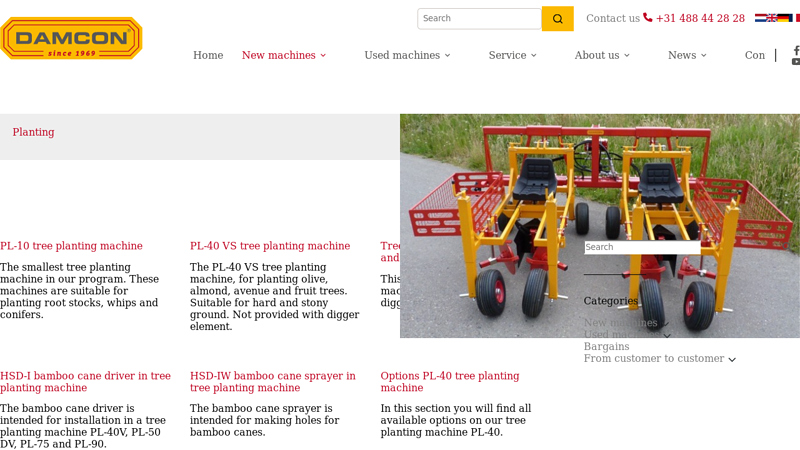

#5 Planting

Domain Est. 2000

Website: damcon.com

Key Highlights: The smallest tree planting machine in our program. These machines are suitable for planting root stocks, whips and conifers….

#6 PlantTape Automated Transplanting System

Domain Est. 2006

Website: planttape.com

Key Highlights: PlantTape is the world’s most advanced, efficient, and flexible process for the sowing, germination, and transplanting of crops….

#7 Land Life

Domain Est. 2013

Website: landlifecompany.com

Key Highlights: Land Life delivers high-integrity nature restoration at scale using innovative science & tech. Invest now in our global nature-based solutions. Learn more….

#8 Flash Forest

Domain Est. 2020

Website: flashforest.com

Key Highlights: We’re a reforestation automation company that uses machine learning and mechanization to produce healthy, resilient forests at scale….

#9 Mayer Planting Systems

Website: mayer.de

Key Highlights: As the inventor of the potting machine, Mayer has been setting new standards in the green sector for over 50 years with innovative automation solutions for ……

Expert Sourcing Insights for Replanting Trees Machine

2026 Market Trends for Replanting Trees Machines

The market for replanting trees machines is poised for significant transformation by 2026, driven by escalating environmental concerns, technological advancements, and strong policy support. These specialized machines—ranging from robotic planters and drone seeders to autonomous tractors equipped with precision planting systems—are transitioning from niche tools to essential components of global reforestation and afforestation strategies.

Key trends shaping the 2026 landscape include the rapid integration of artificial intelligence and machine learning for site assessment and adaptive planting, enabling higher survival rates and ecosystem-specific restoration. Increased demand from large-scale government-led reforestation initiatives, such as the UN Decade on Ecosystem Restoration and national carbon offset programs, is driving public and private investment into scalable planting technologies.

Additionally, advancements in battery efficiency and autonomous navigation are expanding the operational range and reducing the cost of ownership for these machines, making them viable for use in remote or rugged terrains. The rise of carbon credit markets further incentivizes corporations to invest in tech-enabled reforestation, creating a commercial pull for efficient planting solutions.

By 2026, collaboration between agritech firms, environmental NGOs, and forestry agencies is expected to standardize data protocols and improve interoperability among replanting systems, fostering a more cohesive and effective restoration ecosystem. Overall, the replanting trees machine market will likely experience accelerated growth, innovation, and mainstream adoption, positioning automation as a cornerstone of sustainable land management and climate resilience.

Common Pitfalls When Sourcing Replanting Trees Machines: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for Replanting Trees Machine

Overview

This guide outlines the essential logistics and compliance considerations for transporting, operating, and maintaining a Replanting Trees Machine. Whether deployed domestically or internationally, proper planning ensures operational efficiency, legal compliance, and environmental responsibility.

Transportation Logistics

Packaging and Securing the Machine

Ensure the replanting machine is securely crated or palletized for transport. Use weather-resistant packaging and protective padding to prevent damage during transit. Disassemble fragile components if necessary and label all parts clearly.

Domestic Transport

For road transport within a country, confirm the machine complies with local vehicle and cargo regulations (e.g., weight limits, width restrictions). Use flatbed trucks with proper tie-downs and obtain permits for oversized loads if required.

International Shipping

For cross-border shipments:

– Prepare a detailed equipment manifest.

– Comply with International Maritime Organization (IMO) or International Air Transport Association (IATA) standards as applicable.

– Ensure the machine meets import/export documentation requirements (commercial invoice, packing list, certificate of origin).

Customs Clearance

Submit accurate Harmonized System (HS) codes for the machinery (e.g., 8432.40 for agricultural planting equipment). Pay attention to import duties, taxes, and any temporary importation under bond (TIB) options for short-term projects.

Regulatory Compliance

Environmental Regulations

Verify that operation of the replanting machine complies with local environmental protection laws. Avoid planting in protected or ecologically sensitive zones without permits. Follow guidelines from bodies such as the Environmental Protection Agency (EPA) or equivalent regional authorities.

Land Use and Permits

Secure land access permissions from landowners or government agencies before deployment. Obtain necessary forestry or reforestation permits, especially in public or conservation areas.

Safety Standards

Ensure the machine meets occupational safety standards (e.g., OSHA in the U.S., CE marking in the EU). Conduct regular safety inspections and provide operator training to prevent workplace incidents.

Noise and Emissions Compliance

If the machine is engine-powered, confirm compliance with local noise and emissions standards (e.g., EPA Tier 4, EU Stage V). Electric models may have fewer restrictions but still require certification.

Operational Compliance

Operator Certification

Only trained and certified personnel should operate the replanting machine. Maintain records of operator training and machine maintenance.

Species and Seedling Regulations

Use native or approved tree species as required by local forestry departments. Importing seedlings across borders may require phytosanitary certificates and adherence to the International Plant Protection Convention (IPPC).

Monitoring and Reporting

Document replanting activities, including location, species, survival rates, and machine usage. Submit required reports to environmental or forestry agencies to comply with reforestation programs or carbon credit initiatives.

Maintenance and End-of-Life Disposal

Routine Maintenance

Follow the manufacturer’s maintenance schedule. Keep logs of servicing, part replacements, and software/firmware updates for audit purposes.

Waste Disposal

Dispose of worn parts, lubricants, and batteries in accordance with local hazardous waste regulations. Recycle materials whenever possible.

Decommissioning

At end-of-life, follow environmental guidelines for equipment disposal or recycling. Document decommissioning to ensure no residual environmental harm.

Conclusion

Proper logistics planning and regulatory compliance are crucial for the successful deployment of a Replanting Trees Machine. Adhering to this guide supports sustainable reforestation, avoids legal penalties, and enhances project credibility. Always consult local authorities and update procedures as regulations evolve.

Conclusion on Sourcing a Replanting Trees Machine

Sourcing a tree replanting machine represents a strategic and forward-thinking investment in sustainable reforestation and large-scale afforestation efforts. These machines significantly enhance the efficiency, speed, and scalability of tree planting operations compared to traditional manual methods, while also improving seedling survival rates through precise planting techniques. Advances in automation, GPS guidance, and soil compatibility features have made modern replanting machines reliable and adaptable to diverse terrains and environmental conditions.

When sourcing such a machine, it is crucial to evaluate factors including terrain suitability, operational capacity, maintenance requirements, and total cost of ownership. Additionally, aligning the machine’s specifications with environmental goals and local ecological needs ensures long-term success. Partnering with reputable manufacturers and integrating training for operators further supports effective deployment.

Ultimately, investing in a tree replanting machine not only accelerates reforestation goals but also demonstrates a commitment to innovative, climate-resilient solutions. As global demands for carbon sequestration and ecosystem restoration grow, mechanized planting will play an increasingly vital role in restoring forests and combating climate change.