The global fasteners market, driven by rising demand in apparel, automotive, and industrial sectors, is projected to grow at a CAGR of 5.2% from 2023 to 2028, according to Mordor Intelligence. Within this expanding landscape, snap buttons—critical components in clothing, accessories, and safety gear—have seen increased demand for durable, corrosion-resistant, and aesthetically versatile alternatives. As sustainability and supply chain resilience gain priority, manufacturers are turning to replacement snap button suppliers that offer innovation in materials, automation, and eco-friendly production. With the Asia-Pacific region leading both in production and consumption due to its robust textile industry, the competition among manufacturers has intensified. Based on production capacity, global reach, product innovation, and compliance with international standards, here are the top 9 replacement snap button manufacturers shaping the future of the fasteners market.

Top 9 Replacement Snap Buttons Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

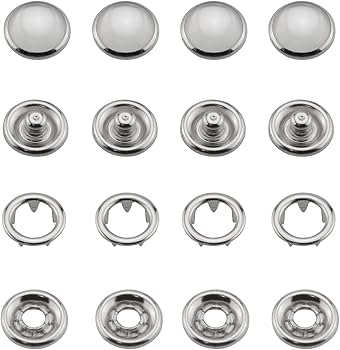

#1 China Snap Buttons Suppliers, Manufacturers, Factory

Domain Est. 2022

Website: jfbutton.com

Key Highlights: KUNSHUO is one of the most professional snap buttons manufacturers and suppliers in China, specialized in providing high quality custom service….

#2 Pearl Snaps • Snap Button Supplier • Snap Fastener Manufacturer

Domain Est. 2006

Website: buttoncare.com

Key Highlights: We developed in a variety of shapes and sizes from hexagon to diamond shaped. Most importantly, pearl snaps have a distinctive look….

#3 Buttons

Domain Est. 1996

Website: prym.com

Key Highlights: Buttons 2-hole Prym 1530, recycled hemp, 28mm, light brown. Select options. Buttons 2-hole Prym 1530, recycled hemp, 28mm, light brown….

#4 Snap Fastener Kit

Domain Est. 1997

Website: generaltools.com

Key Highlights: Snap Fasteners can be used to connect two tarps, fix a tent or replace a jacket button. Snaps are made of brass and are nickel plated for added durability….

#5 page

Domain Est. 1997

Website: fasnap.com

Key Highlights: Button Machines · Dies and Adapters and Replacement Parts · Baby Snap Dies · Press-n-Snap Replacement Parts · Replacement Parts · Self-Piercing Grommet Dies ……

#6 Snap Buttons, Snaps for Clothing & Sewing Snaps …

Domain Est. 2002

Website: wawak.com

Key Highlights: Free delivery over $99 · Free 90-day returnsSnap Buttons are lightweight, easy-to-use closures suitable for a variety of applications. Choose from a variety of sewing snap fastene…

#7 High Quality Plastic & Metal Snap Fasteners, Grommets & Rivets

Domain Est. 2008

Website: kamsnaps.com

Key Highlights: Shop CPSIA-compliant plastic snaps, metal snap fasteners, grommets, rivets, and clips at wholesale prices from KAMsnaps®. Perfect for clothing, cloth ……

#8 Press buttons for clothes and metal snap fasteners

Domain Est. 2016

Website: spring85buttons.com

Key Highlights: We create customized snap buttons with care and attention to make unique your clothes. For over thirty years, Spring ’85 has specialized in the production ……

#9 Snap button

Domain Est. 2002

Website: ipros.com

Key Highlights: We provide total support including technical guidance! Our company mainly manufactures and sells snap buttons for apparel, as well as installation machines, ……

Expert Sourcing Insights for Replacement Snap Buttons

H2: 2026 Market Trends for Replacement Snap Buttons

The global market for replacement snap buttons is poised for steady growth and transformation by 2026, driven by evolving consumer preferences, advancements in manufacturing technologies, and increasing demand across fashion, outdoor gear, and medical apparel sectors. Several key trends are expected to shape the industry landscape in the coming years.

1. Rising Demand in the Fashion and Apparel Industry

The fast fashion sector continues to be a major driver for replacement snap buttons, as brands seek cost-effective and durable fastening solutions. With an increasing focus on repairability and sustainable fashion, consumers are more likely to repair garments rather than discard them, boosting demand for replacement hardware such as snap buttons. This shift supports a growing aftermarket segment for spare and compatible fasteners.

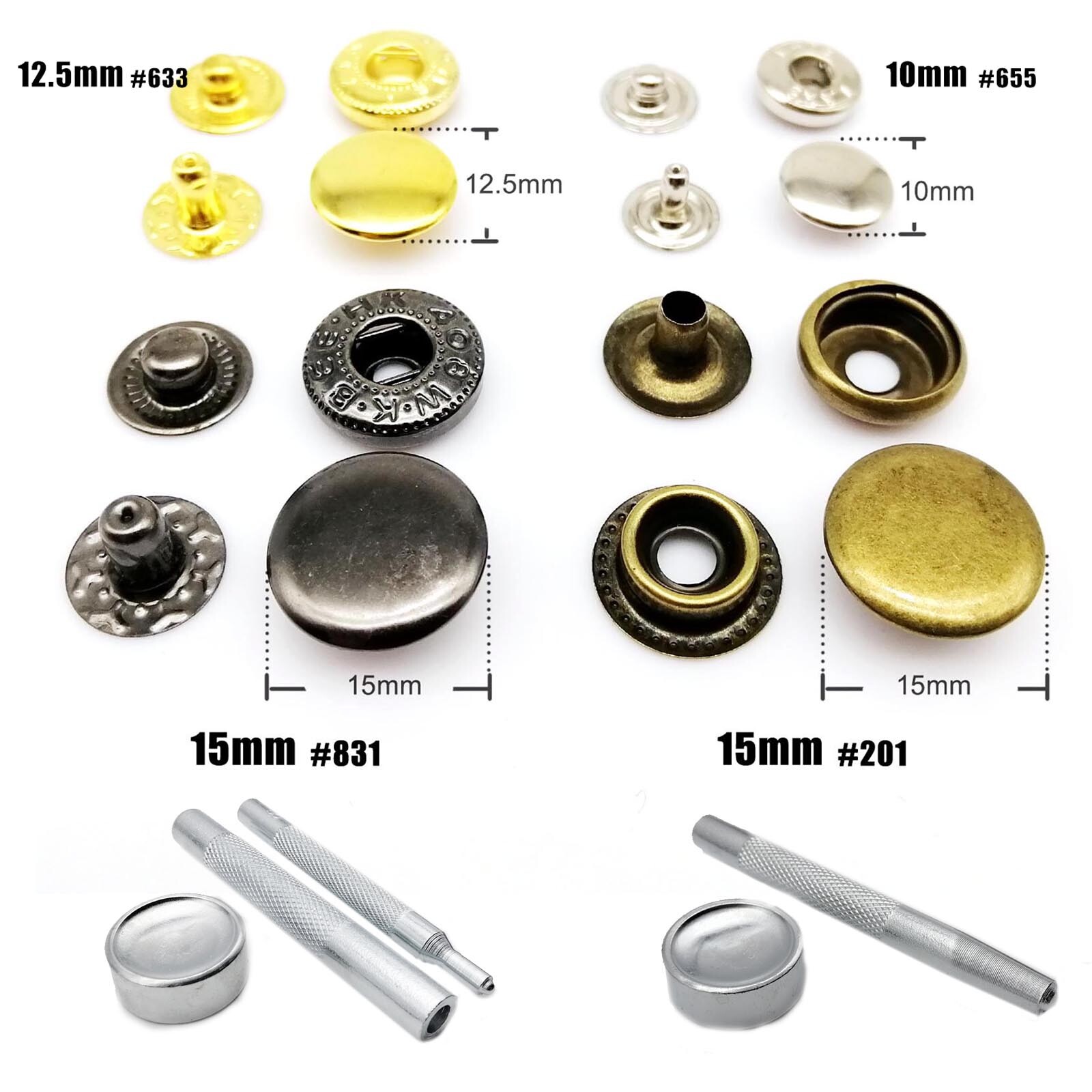

2. Growth in Outdoor and Workwear Markets

Outdoor apparel, tactical gear, and industrial workwear often rely on durable snap buttons for functionality and ease of use. As participation in outdoor recreation and demand for high-performance clothing rises, so does the need for robust, replaceable fasteners. Manufacturers are responding with corrosion-resistant and high-tensile snap buttons made from materials like brass, nickel, and reinforced polymers.

3. Expansion of E-Commerce and DIY Repair Culture

Online marketplaces such as Amazon, Etsy, and Alibaba have made replacement snap buttons more accessible to consumers and small businesses. The DIY clothing repair trend, amplified by social media and sustainability influencers, encourages consumers to purchase individual snap buttons for home repairs. This trend is expected to accelerate through 2026, especially in North America and Europe.

4. Innovation in Materials and Design

By 2026, manufacturers are increasingly adopting eco-friendly materials and low-impact production methods. Recyclable metals, bio-based polymers, and lead-free coatings are becoming standard in response to environmental regulations and consumer demand. Additionally, customizable designs, color-matching options, and easy-apply mechanisms (e.g., self-piercing snaps) are gaining popularity among both professionals and hobbyists.

5. Regional Market Dynamics

Asia-Pacific, particularly China and India, remains the dominant manufacturing hub for snap buttons, benefiting from established supply chains and low production costs. However, reshoring trends in North America and Europe may lead to localized production for premium or sustainable product lines. Emerging markets in Southeast Asia and Africa are also expected to see rising domestic demand due to growing textile industries and urbanization.

6. Integration with Smart Textiles (Niche Growth)

While still in early stages, a niche segment involves snap buttons designed for integration with smart clothing—serving as both functional fasteners and connection points for wearable electronics. Though not mainstream by 2026, this innovation could open new opportunities in healthcare and fitness apparel.

In conclusion, the 2026 market for replacement snap buttons will be characterized by sustainability, accessibility, and innovation. As repair culture strengthens and industries demand higher performance, suppliers that offer durable, eco-conscious, and user-friendly solutions will be best positioned to capture market share.

Common Pitfalls When Sourcing Replacement Snap Buttons (Quality, IP)

Sourcing replacement snap buttons may seem straightforward, but businesses often encounter significant challenges related to quality inconsistencies and intellectual property (IP) risks. Overlooking these pitfalls can lead to product failures, customer dissatisfaction, and legal liabilities. Below are key issues to watch for:

Quality Inconsistencies and Material Defects

One of the most frequent problems when sourcing snap buttons—especially from low-cost or unverified suppliers—is inconsistent quality. Buttons may vary in plating thickness, material composition (e.g., brass vs. zinc alloy), or structural integrity. Poor-quality snaps can break easily, corrode, or fail to secure properly, compromising the functionality and longevity of the end product. Inconsistent sizing or misaligned male/female components also lead to assembly difficulties during manufacturing.

Counterfeit or IP-Infringing Components

Snap button designs, particularly proprietary or branded fasteners, may be protected under patents, trademarks, or design rights. Sourcing replacements without verifying IP clearance risks using counterfeit or copied components. Suppliers in certain regions may offer “compatible” snaps that infringe on existing IP, exposing the buyer to legal action, shipment seizures, or reputational damage. Always confirm that the snap design does not violate existing patents—especially for well-known systems like Prym, Kam, or Snaply.

Lack of Durability and Environmental Resistance

Low-quality snap buttons often lack proper surface treatments (e.g., nickel or lacquer coatings), making them prone to tarnishing, oxidation, or skin irritation from metal leaching. Inadequate resistance to washing, dry cleaning, or UV exposure can result in premature failure. Ensure that replacements meet required durability standards (e.g., ASTM or ISO testing for tensile strength and corrosion resistance), particularly for apparel or outdoor gear.

Inadequate Supplier Verification and Traceability

Many buyers source snap buttons through intermediaries or online marketplaces without fully vetting suppliers. This lack of transparency makes it difficult to trace material origins, verify compliance with regulations (e.g., REACH, CPSIA), or ensure ethical manufacturing practices. Always request certifications, material test reports, and conduct supplier audits when possible.

Mismatched Specifications and Fit Issues

Replacement snaps must precisely match the original in size, shape, and installation method (e.g., prong diameter, cap depth). Even minor deviations can prevent proper tooling installation or cause gaps and misalignment. Always obtain physical samples and conduct fit tests before bulk ordering.

Avoiding these pitfalls requires due diligence: verify supplier credentials, request samples, conduct quality testing, and consult legal experts when necessary to ensure compliance with IP and safety standards.

Logistics & Compliance Guide for Replacement Snap Buttons

This guide outlines key logistics and compliance considerations when sourcing, shipping, and distributing replacement snap buttons. Ensuring adherence to regulations and efficient supply chain management is essential for product safety, customer satisfaction, and legal compliance.

Product Classification & Tariff Codes

Identify the correct Harmonized System (HS) code for snap buttons to ensure accurate international customs declarations. Common classifications include 9606.22 (snap fasteners of base metal) or 9606.29 (other fasteners), depending on material and composition. Accurate coding affects import duties, taxes, and trade compliance.

Material & Safety Compliance

Replacement snap buttons must comply with regional safety and environmental regulations:

– REACH (EU): Ensure no restricted substances (e.g., lead, nickel, phthalates) exceed allowable limits.

– RoHS (Electronics-Adjacent Products): If used in electronic textiles or smart garments, compliance may be required.

– CPSIA (USA): For children’s apparel, buttons must meet lead and phthalate content standards.

– Prop 65 (California): Disclose if components contain listed carcinogens or reproductive toxins.

Packaging & Labeling Requirements

Use packaging that prevents damage during transit and complies with labeling laws:

– Include manufacturer details, material composition, and country of origin.

– For retail sales, comply with FTC textile labeling rules (USA) or EU Textile Regulation (No 1007/2011).

– Clearly mark warning labels if applicable (e.g., small parts choking hazard).

Shipping & Inventory Management

Optimize logistics with the following practices:

– Use moisture-resistant, tamper-evident packaging to maintain quality.

– Store in cool, dry environments to prevent corrosion (especially for metal components).

– Implement barcode or RFID tracking for inventory accuracy and traceability.

– Consider bulk vs. retail-ready packaging based on distribution channel.

Import/Export Documentation

Prepare essential documentation for international trade:

– Commercial invoice with detailed product description and value.

– Packing list with quantities, weights, and dimensions.

– Certificate of Origin (if required for preferential tariffs).

– Safety or conformity certificates (e.g., EU Declaration of Conformity).

Sustainability & End-of-Life Considerations

Promote environmental responsibility by:

– Using recyclable or biodegradable packaging materials.

– Sourcing from suppliers with certified environmental management systems (e.g., ISO 14001).

– Providing disposal guidance for metal and plastic components.

Supplier Audits & Due Diligence

Conduct regular audits of suppliers to verify:

– Ethical labor practices (aligned with standards like SMETA or SA8000).

– Consistent quality control and compliance with material specifications.

– Valid certifications for relevant safety and environmental regulations.

Following this guide ensures that replacement snap buttons are handled safely, legally, and efficiently throughout the supply chain. Regular review of regulations and logistics performance supports long-term compliance and operational excellence.

Conclusion for Sourcing Replacement Snap Buttons:

After evaluating various suppliers, material options, cost considerations, and quality requirements, it is clear that sourcing replacement snap buttons requires a balanced approach focusing on durability, compatibility, and cost-efficiency. Reliable suppliers offering consistent quality, reasonable minimum order quantities, and strong customer support should be prioritized. Whether sourcing domestically or internationally, factors such as lead times, customization capabilities, and compliance with industry standards must be taken into account. By establishing strong relationships with vetted vendors and maintaining quality control processes, we can ensure a sustainable supply of snap buttons that meet product specifications and support long-term manufacturing needs. Ultimately, a strategic sourcing plan will enhance production efficiency, reduce downtime, and contribute to overall product reliability and customer satisfaction.