The global automotive safety components market, driven by increasing regulatory mandates and consumer demand for enhanced vehicle safety, is witnessing steady growth, with the seat belt segment playing a pivotal role. According to a report by Mordor Intelligence, the global automotive seat belt market was valued at USD 6.34 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. This growth is fueled by rising vehicle production, stricter safety regulations from bodies such as NHTSA and Euro NCAP, and the increasing adoption of advanced restraint systems in both passenger and commercial vehicles. With original seat belts subject to wear and tear, and post-accident replacements becoming essential, the demand for high-quality replacement seat belts has surged. This has led to a competitive landscape among manufacturers who combine compliance, durability, and innovative engineering. The following list highlights the top 10 replacement seat belt manufacturers for cars, selected based on industry reputation, product compliance, innovation, customer reviews, and market presence, reflecting the evolving standards in automotive safety.

Top 10 Replacement Seat Belts For Cars Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SeatBeltsPlus

Domain Est. 2006

Website: seatbeltsplus.com

Key Highlights: Replacement seat belts: lap belts, 3 point seat belts, universal seat belts, direct fit belts, classic car seat belts, industrial belts, racing harnesses, ……

#2 GWR Safety Systems

Domain Est. 2014

Website: gwrco.com

Key Highlights: GWR is a global seat belt manufacturer known for automotive seat belts, seat belts for commercial and specialty vehicles, and custom safety systems….

#3 Seat Belt

Domain Est. 1994

Website: autoparts.toyota.com

Key Highlights: Free deliveryEnsure safety with genuine Toyota seat belts. Explore a range of quality seat belt parts for your vehicle’s protection and comfort….

#4 Replacement

Domain Est. 1996

Website: setina.com

Key Highlights: Setina’s unique Center Pull Seat Belt Systems are Professionally Designed and Laboratory tested to meet the rigorous 207/210 FMVSS, Federal Seat Belt Safety ……

#5 Seatbelts

Domain Est. 1998

Website: autoliv.com

Key Highlights: The Autoliv seatbelt systems work together to save more lives: retractors, buckles, load limiters, pretensioners, pre-pretensioners, hardware and active ……

#6 Seatbelt Belts

Domain Est. 1999

Website: buckle-down.com

Key Highlights: Free delivery over $99 30-day returnsInspired by 1980 Cadillac seatbelts, these belts feature a push-button release and bold prints. Shop officially licensed styles from Honda, For…

#7 Replacement Seat Belts

Domain Est. 2001

Website: wescoperformance.com

Key Highlights: 1–2 day delivery · 30-day returnsChoose our replacement belts for your car, truck, van or RV either retractable or non-retractable. And all of our seat belts work for both passeng…

#8 Aftermarket & Replacement Seat Belts

Domain Est. 2008

Website: seatbeltplanet.com

Key Highlights: Shop our collection of aftermarket seat belts for your vehicle online at SeatbeltPlanet. We offer replacement seat belts, mounting hardware, and more….

#9 APV Safety Products

Domain Est. 2011

Website: apvsafetyproducts.com

Key Highlights: APV Safety Products designs, manufactures and certifies seat belts and restraints for a wide range of vehicles and specialist applications. On site is a ……

#10 Trust Shield

Domain Est. 2012

Website: trustshield.com

Key Highlights: SHIELD produces a variety of products for use in and around all manner of vehicles ranging from simple seatbelts to complex occupant and cargo control devices….

Expert Sourcing Insights for Replacement Seat Belts For Cars

H2: 2026 Market Trends for Replacement Seat Belts for Cars

The global market for replacement seat belts for cars is poised for steady growth and transformation by 2026, driven by a confluence of regulatory mandates, technological advancements, rising vehicle ownership, and increasing focus on occupant safety. As automotive safety standards evolve and older vehicles remain on the road, the demand for high-quality, reliable replacement seat belts is expected to rise significantly.

1. Regulatory and Safety Compliance Driving Demand

Stringent government regulations on vehicle safety across North America, Europe, and parts of Asia-Pacific continue to shape the replacement seat belt market. Organizations such as the National Highway Traffic Safety Administration (NHTSA) in the U.S. and the European New Car Assessment Programme (Euro NCAP) mandate minimum safety standards, compelling vehicle owners to replace worn or damaged seat belts. By 2026, non-compliance penalties and mandatory safety inspections in many countries are expected to boost the aftermarket demand for certified replacement seat belts.

2. Growth in the Aftermarket and DIY Repairs

The increasing average age of vehicles on the road—particularly in developed markets like the U.S. and Western Europe—is a key driver for replacement parts, including seat belts. As vehicles surpass the 10–15-year mark, components such as seat belts experience wear and tear, leading to higher demand for replacements. Simultaneously, the rise of do-it-yourself (DIY) automotive repair culture, supported by online tutorials and e-commerce platforms, is making it easier for consumers to purchase and install replacement seat belts without relying on dealerships.

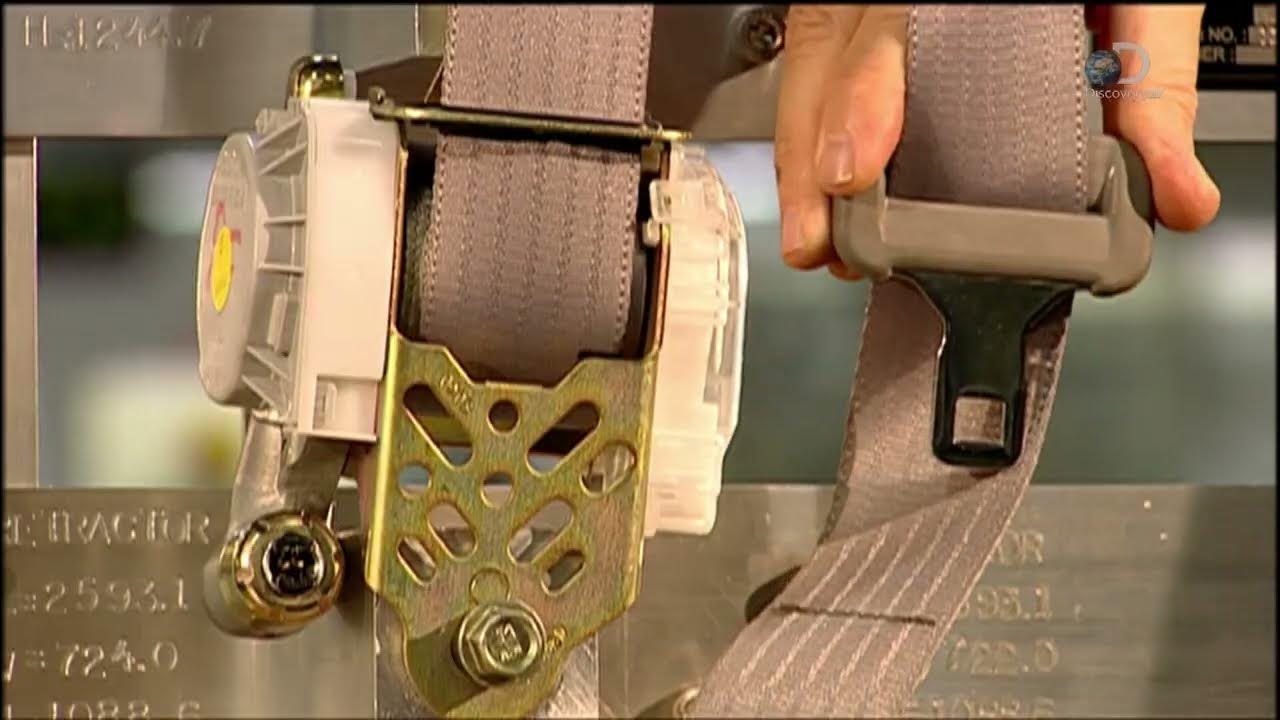

3. Technological Advancements and Smart Seat Belts

By 2026, integration of smart technologies into seat belt systems is expected to influence the replacement market. Features such as pretensioners, load limiters, and seat belt reminder systems are becoming standard even in mid-tier vehicles. Replacement seat belts will increasingly need to support these advanced functionalities, prompting consumers and repair shops to upgrade to OEM-equivalent or enhanced aftermarket versions. Additionally, some manufacturers are exploring smart seat belts with embedded sensors to monitor occupant presence, posture, and health metrics—features that may gradually filter into the replacement segment.

4. Rise in E-Commerce and Online Distribution

The shift toward online shopping is reshaping how consumers purchase automotive parts. By 2026, e-commerce platforms such as Amazon, eBay, and specialized auto parts websites are expected to dominate the distribution of replacement seat belts. These platforms offer competitive pricing, user reviews, and compatibility filters, making it easier for consumers to find the right product. OEM and aftermarket brands are investing in digital marketing and direct-to-consumer models to capture this growing channel.

5. Sustainability and Material Innovation

Environmental concerns are beginning to influence material choices in the automotive aftermarket. Replacement seat belts made from recycled or sustainable materials, while still niche, are gaining attention. Manufacturers are exploring high-tenacity, eco-friendly webbing materials that maintain strength and durability without increasing environmental impact. By 2026, sustainability could become a differentiating factor in the competitive aftermarket landscape.

6. Regional Market Dynamics

North America and Europe are expected to lead the replacement seat belt market due to aging vehicle fleets and strict safety regulations. Meanwhile, emerging markets in Asia-Pacific—especially India and Southeast Asia—are witnessing rapid growth in car ownership, leading to increased demand for affordable replacement parts. Latin America and Africa present untapped potential, although economic and infrastructural challenges may limit adoption in the short term.

7. Competitive Landscape and Brand Differentiation

The market is highly fragmented, with a mix of OEM suppliers (e.g., Autoliv, ZF TRW, Takata) and third-party aftermarket brands. By 2026, competition will center on product quality, certification (such as ISO and FMVSS compliance), and compatibility across vehicle models. Brands that offer extended warranties, easy installation, and clear compliance documentation will gain consumer trust and market share.

In conclusion, the 2026 replacement seat belt market will be shaped by safety regulations, aging vehicles, technological integration, and digital commerce. As consumers become more safety-conscious and environmentally aware, manufacturers and distributors must adapt to deliver reliable, compliant, and innovative solutions in a competitive global marketplace.

Common Pitfalls When Sourcing Replacement Seat Belts for Cars (Quality, IP)

Sourcing replacement seat belts for vehicles requires careful attention due to the critical role they play in occupant safety. Cutting corners can lead to serious risks, including compromised performance in a crash, legal liabilities, and intellectual property (IP) violations. Below are key pitfalls to avoid:

1. Prioritizing Cost Over Safety and Quality

One of the most dangerous mistakes is selecting seat belts based solely on price. Low-cost aftermarket or counterfeit belts may use substandard materials—such as weak webbing, inferior retractor mechanisms, or poorly welded hardware—that fail under stress. These components may not meet federal safety standards (e.g., FMVSS 209 and 210 in the U.S.), leading to catastrophic failure during an accident.

2. Ignoring Compliance with Safety Standards

Replacement seat belts must comply with regional safety regulations. Sourcing parts that lack proper certification (such as DOT, ECE, or SAE markings) puts both the installer and end user at risk. Non-compliant belts may not have undergone crash testing, dynamic load evaluation, or proper quality control, making them unreliable in real-world scenarios.

3. Purchasing Counterfeit or Imitation OEM Parts

Counterfeit seat belts often mimic the branding and appearance of original equipment manufacturer (OEM) parts but lack the engineering, materials, and rigorous testing of genuine components. These fakes infringe on OEM intellectual property and can be difficult to distinguish without close inspection. Using them exposes buyers and installers to legal risk and undermines vehicle safety.

4. Overlooking Intellectual Property (IP) Infringement

Many OEM seat belt designs are protected by patents, trademarks, and design rights. Sourcing aftermarket belts that replicate patented mechanisms (e.g., specific pretensioner or load limiter designs) without licensing can result in IP violations. Distributors and repair shops caught using or selling infringing parts may face lawsuits, fines, or damage to reputation.

5. Relying on Unverified Suppliers or Online Marketplaces

Purchasing seat belts from unverified vendors—especially on third-party e-commerce platforms—increases the risk of receiving counterfeit, used, or non-compliant products. These sellers often lack transparency about manufacturing origins, quality control, or compliance documentation, making it difficult to trace parts or ensure reliability.

6. Failing to Verify Compatibility and Fitment

Not all seat belts are interchangeable, even within the same vehicle make and model. Differences in mounting points, retractor types, buckle configurations, and integrated sensors (e.g., for airbag systems) can lead to improper installation or system malfunction. Using incompatible belts may disable critical safety features or create installation hazards.

7. Neglecting Traceability and Documentation

Reputable seat belt suppliers should provide traceable part numbers, compliance certificates, and batch information. Lack of documentation makes it impossible to verify authenticity, initiate recalls if needed, or defend against liability claims in the event of a failure. Always require proper paperwork when sourcing safety-critical components.

8. Underestimating the Role of Integrated Safety Systems

Modern seat belts often work in conjunction with airbags, seat occupancy sensors, and crash detection systems. Aftermarket or non-OEM belts may not interface correctly with these systems, leading to warning lights, disabled safety features, or improper deployment timing during a collision.

By avoiding these common pitfalls, buyers and technicians can ensure they source high-quality, compliant, and legally sound replacement seat belts that maintain the integrity of a vehicle’s safety systems. Always prioritize certified suppliers, verify compliance, and respect intellectual property rights when replacing life-critical components.

Logistics & Compliance Guide for Replacement Seat Belts for Cars

Product Classification and Regulatory Framework

Replacement seat belts for cars are classified as automotive safety components and are subject to stringent safety standards and regulatory oversight. In most jurisdictions, these products are governed by motor vehicle safety regulations, such as the Federal Motor Vehicle Safety Standards (FMVSS) in the United States (specifically FMVSS No. 209 and FMVSS No. 210), the United Nations Economic Commission for Europe (UNECE) Regulations (e.g., Regulation No. 16) in Europe and many other regions, and equivalent national standards. Compliance with these regulations is mandatory for legal sale and installation.

Certification and Testing Requirements

All replacement seat belts must undergo rigorous testing to ensure they meet strength, durability, and performance benchmarks. Manufacturers and importers must obtain certification from authorized bodies, such as the Department of Transportation (DOT) in the U.S. or through ECE approval in Europe. Each product must bear a permanent label indicating compliance, including the regulatory standard met, manufacturer ID, date of production, and unique identification number. Third-party testing by accredited laboratories is typically required to validate performance under dynamic crash simulations and static load tests.

Import and Export Compliance

When shipping replacement seat belts internationally, adherence to customs regulations and trade compliance is essential. Harmonized System (HS) codes must be correctly applied—typically falling under 8708.29 for safety belts in vehicles. Importers must ensure that products meet destination country standards and that all required documentation, such as certificates of conformity (CoC), test reports, and letters of authorization, are submitted. Tariffs, import duties, and potential anti-dumping measures should be assessed in advance. Products must also comply with regional labeling requirements, including language, safety warnings, and traceability data.

Packaging and Labeling Standards

Proper packaging is critical to prevent damage during transit and ensure product integrity. Replacement seat belts should be securely packaged to protect webbing, retractors, and hardware from moisture, abrasion, and deformation. Packaging must include compliance labels, installation instructions in the local language, and safety warnings. Counterfeit prevention measures such as tamper-evident seals and serialized labels are recommended. Environmentally compliant packaging materials may be required in certain markets (e.g., EU Packaging Waste Directive).

Supply Chain and Inventory Management

Due to the safety-critical nature of seat belts, inventory management systems should support full traceability from manufacturing batch to end customer. Serialization and batch tracking are vital for effective recall management. Logistics partners should provide temperature-controlled and secure storage where necessary, and transportation should minimize vibration and shock. Just-in-time (JIT) delivery models may be used in OEM or aftermarket distribution networks, but safety stock levels must be maintained to avoid supply disruptions.

Installation and Aftermarket Guidelines

Replacement seat belts must be designed to match the specifications of original equipment manufacturer (OEM) systems. Compatibility with vehicle make, model, and year must be clearly documented. Installation should ideally be performed by certified technicians following manufacturer guidelines to ensure proper anchoring and functionality. Selling non-OEM-compliant or universal-fit seat belts without proper fitment verification may result in liability and regulatory penalties.

Recall Preparedness and Reporting

Companies distributing replacement seat belts must have a robust recall management system in place. Any defect indicating non-compliance or safety risk must be reported to relevant authorities (e.g., NHTSA in the U.S., RAPEX in the EU) within mandated timeframes. A clear communication plan should be established to notify distributors, retailers, and end users. Regular internal audits and quality control checks help minimize the risk of recalls.

Environmental and End-of-Life Compliance

Seat belts contain mixed materials (webbing, metal components, plastic housings), requiring proper end-of-life handling. Compliance with environmental regulations such as the EU End-of-Life Vehicles (ELV) Directive may require take-back programs or reporting of hazardous substances. Recycling partnerships and waste management protocols should be established to meet sustainability goals and legal obligations.

Liability and Insurance Considerations

Given the life-saving function of seat belts, distributors and manufacturers face significant liability risks. Product liability insurance is essential and should cover defects, improper installation guidance, and failure to warn. Legal counsel should review terms of sale, disclaimers, and warranty provisions to ensure enforceability and regulatory alignment.

In conclusion, sourcing replacement seat belts for cars requires careful consideration of safety, compatibility, quality, and regulatory compliance. It is essential to choose seat belts that meet or exceed original equipment manufacturer (OEM) specifications and comply with national and international safety standards, such as FMVSS 209 in the U.S. or ECE R16 in Europe. Purchasing from reputable suppliers, authorized dealers, or certified aftermarket brands helps ensure authenticity and reliability. Additionally, proper installation by a qualified professional is crucial to maintain the effectiveness of the restraint system. Ultimately, investing in high-quality, correctly fitted replacement seat belts not only restores vehicle safety but also protects occupants in the event of a collision, underscoring the importance of diligence and informed decision-making throughout the sourcing process.