The global LED lighting market is experiencing robust expansion, driven by rising energy efficiency demands, falling LED prices, and supportive government regulations phasing out traditional lighting technologies. According to Grand View Research, the global LED lighting market size was valued at USD 82.8 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 11.3% from 2024 to 2030. A pivotal factor fueling this growth is the widespread replacement of fluorescent lights with LED alternatives across commercial, industrial, and residential sectors. Fluorescent lamps, once the backbone of energy-efficient lighting, are increasingly being displaced due to LEDs’ superior lifespan, lower energy consumption, and reduced maintenance costs. With businesses and municipalities aiming to cut carbon emissions and operational expenses, the transition to LED technology has become a strategic priority. As demand surges, a select group of manufacturers has emerged at the forefront, offering innovative, reliable, and cost-effective LED retrofit solutions. These top eight companies are shaping the future of sustainable illumination by delivering high-performance replacements that seamlessly integrate into existing fluorescent fixtures, accelerating the global shift toward smarter, greener lighting infrastructure.

Top 8 Replacement Of Fluorescent Lights With Led Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 H.E. Williams, Inc.

Domain Est. 1995

Website: hew.com

Key Highlights: HE Williams, Inc. designs and builds the most extensive line of American-made luminaires featuring advanced LED technologies and integrated lighting controls….

#2 SATCO

Domain Est. 1996

Website: satco.com

Key Highlights: A leading supplier of lighting products, with solutions for nearly every lighting market across the commercial, residential and industrial landscape….

#3 LED Fluorescent Tube Replacements

Domain Est. 2024

Website: industrialcommerciallighting.com

Key Highlights: Free delivery over $300 · 45-day returnsLED tube lights are an excellent choice for replacing traditional fluorescent tubes. We carry a wide variety of bulb types and ballast comp…

#4 LED light tubes

Domain Est. 1987

Website: lighting.philips.com

Key Highlights: It replaces your current fluorescent tube or LED tube directly and offers immediately great energy cost reduction as well as a much longer lifetime! Download ……

#5 LED Tubes

Domain Est. 1996

Website: sunco.com

Key Highlights: Free delivery over $100Replace your fluorescent tubes with commercial LED Tubes. These 4ft LED tubes are more energy efficient and reduce maintenance costs….

#6 LED Lighting

Domain Est. 1999

Website: energy.gov

Key Highlights: Quality LED light bulbs last longer, are more durable, and offer comparable or better light quality than other types of lighting. LED lightbulb. Energy Savings….

#7 LED Tube Lights

Domain Est. 2011

Website: eledlights.com

Key Highlights: Free 30-day returnsLED tube lights are high-efficiency replacements for traditional fluorescent tubes. Designed to fit into existing fluorescent fixtures, LED tubes provide bright …

#8 Sylvania

Domain Est. 2015

Website: sylvania-automotive.com

Key Highlights: For over 100 years, SYLVANIA has delivered lighting expertise with reliable headlights and enhanced visibility—putting light where you need it. Shop LED ……

Expert Sourcing Insights for Replacement Of Fluorescent Lights With Led

H2: 2026 Market Trends for the Replacement of Fluorescent Lights with LED

By 2026, the global market for replacing fluorescent lighting with LED technology is poised for significant transformation, driven by technological advancements, regulatory shifts, cost efficiencies, and growing environmental awareness. The transition from fluorescent to LED lighting—already well underway—will accelerate across commercial, industrial, residential, and municipal sectors. Below are the key trends shaping this market in 2026:

1. Regulatory Mandates Accelerating Phase-Out of Fluorescent Lamps

Governments worldwide are tightening regulations on mercury-containing fluorescent lamps, aligning with environmental treaties such as the Minamata Convention. By 2026, bans or restrictions on the sale and import of fluorescent tubes (especially T12 and T8 models) will be widespread across the EU, North America, and parts of Asia-Pacific. These policies are pushing organizations to adopt mercury-free LED alternatives, making LED retrofits not just economically beneficial but legally necessary.

2. Cost Parity and Lower Total Cost of Ownership (TCO)

LED lighting has achieved cost parity with fluorescent systems in most applications, and by 2026, the total cost of ownership will be decisively in favor of LEDs. With lifespans exceeding 50,000 hours (compared to 10,000–20,000 for fluorescents) and energy efficiency improvements (up to 50–70% energy savings), businesses and municipalities will prioritize LED retrofits to reduce long-term operational costs. Financing models such as Energy-as-a-Service (EaaS) will further lower upfront barriers.

3. Smart Lighting Integration Driving Adoption

LEDs are the foundational technology for smart lighting systems. By 2026, demand for connected LED fixtures with sensors, occupancy detection, daylight harvesting, and IoT integration will surge—particularly in smart buildings and industrial facilities. These systems offer granular control, predictive maintenance, and integration with building management systems (BMS), enhancing energy savings and operational efficiency beyond simple lamp replacement.

4. Rapid Growth in Retrofit Solutions

Plug-and-play LED tube retrofits (Type A, Type B, and hybrid) will dominate the market, enabling easy replacement of fluorescent tubes without rewiring. By 2026, advancements in driver technology and compatibility will make retrofits safer and more reliable, encouraging widespread adoption in existing infrastructure. Ballast-bypass (Type B) installations will gain favor due to higher efficiency and longevity.

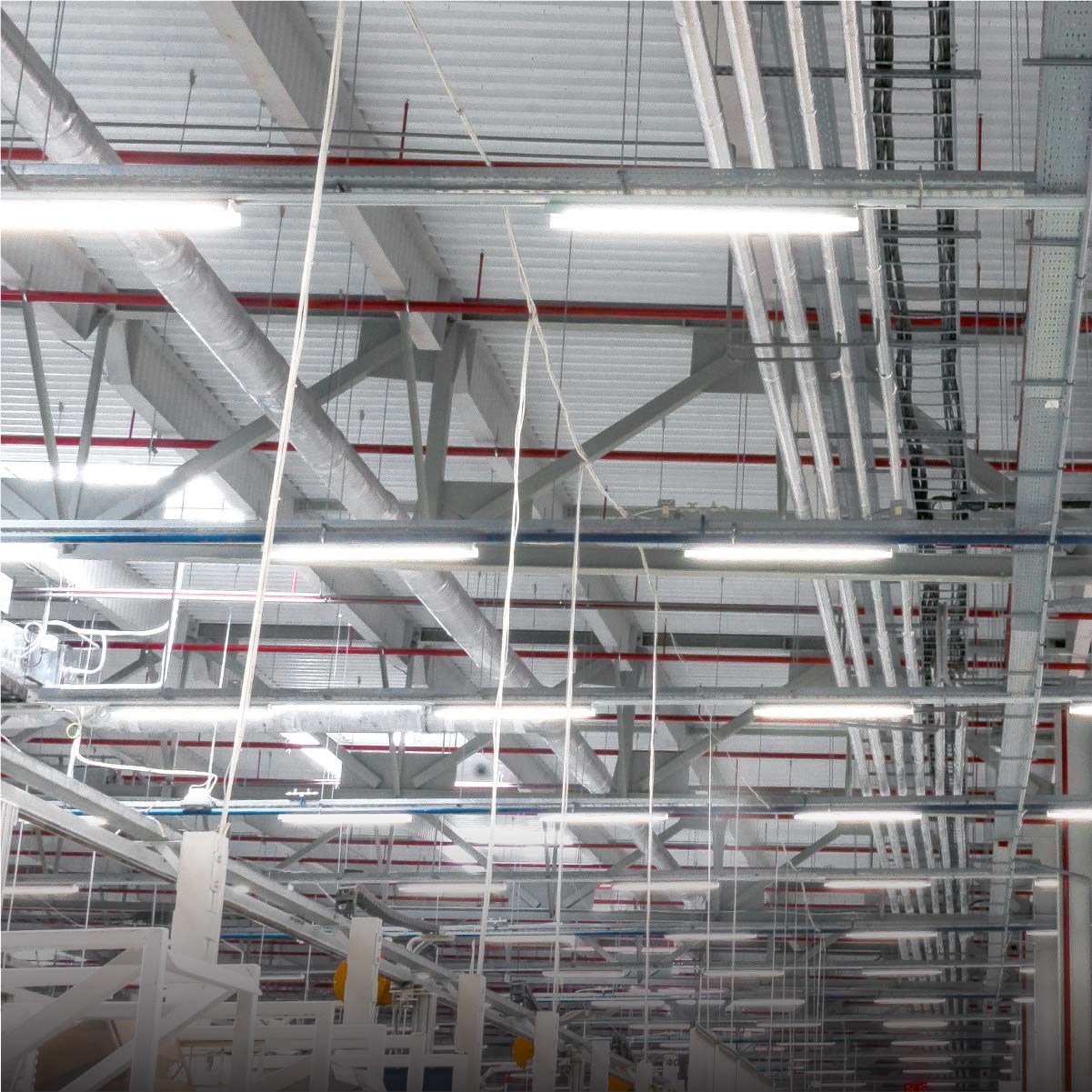

5. Expansion in Industrial and Commercial Sectors

Warehouses, factories, offices, and retail spaces will represent the largest share of LED replacements by 2026. High-bay and low-bay LED fixtures are replacing fluorescent high-output (FHO) and very-high-output (VHO) systems, offering better lumen maintenance, instant-on capability, and improved light quality (higher CRI). The push for LEED certification and ESG compliance will further incentivize upgrades.

6. Municipal and Street Lighting Modernization

Cities globally will continue large-scale LED streetlight conversion projects by 2026, driven by energy savings, reduced maintenance costs, and climate action plans. Many urban centers will integrate adaptive controls (dimming schedules, remote monitoring) into municipal LED networks, creating smart city infrastructure and reducing carbon emissions.

7. Advancements in LED Quality and Performance

By 2026, LEDs will offer superior color rendering (CRI >90), tunable white light, and reduced flicker—addressing previous concerns about light quality. Improvements in thermal management and phosphor technology will enhance reliability and performance in extreme environments, making LEDs viable for cold storage, outdoor, and high-humidity applications where fluorescents once dominated.

8. Sustainability and ESG as Key Drivers

Corporate sustainability goals will play a major role in fluorescent-to-LED transitions. Reducing carbon footprints, achieving energy efficiency targets, and improving indoor environmental quality will make LED retrofits a cornerstone of ESG (Environmental, Social, and Governance) strategies. Lifecycle assessments increasingly favor LEDs due to lower emissions and recyclability.

9. Supply Chain Maturity and Regional Growth

Asia-Pacific will remain the largest market due to rapid urbanization and government-led energy efficiency programs (e.g., India’s UJALA scheme, China’s Green Lighting Initiative). North America and Europe will see steady growth driven by aging infrastructure and decarbonization policies. Supply chains for LED components will be more resilient and localized by 2026, reducing lead times and costs.

10. Decline of Fluorescent Manufacturing and Support

By 2026, major lighting manufacturers will have largely exited the fluorescent market, shifting focus entirely to LED and smart lighting solutions. Spare parts and ballasts for fluorescent systems will become scarcer and more expensive, creating a “last call” effect that accelerates LED adoption before obsolescence.

Conclusion

The replacement of fluorescent lights with LED technology will be a defining trend in the global lighting market by 2026. Driven by regulatory pressure, economic advantages, smart technology integration, and sustainability imperatives, the transition will be nearly complete in developed markets and well advanced in emerging economies. Stakeholders—包括 manufacturers, contractors, facility managers, and policymakers—must act now to capitalize on the energy, environmental, and financial benefits of this shift.

Common Pitfalls When Sourcing Replacement of Fluorescent Lights with LED: Quality and IP Rating Concerns

When upgrading from fluorescent lighting to LED, organizations often focus on energy savings and longevity but overlook critical quality and environmental protection factors—particularly Ingress Protection (IP) ratings. Below are common pitfalls related to quality and IP when sourcing LED replacements:

1. Prioritizing Low Cost Over Long-Term Quality

One of the most frequent mistakes is selecting the cheapest available LED tubes without evaluating build quality. Low-cost LEDs may use inferior components such as poor heat sinks, substandard drivers, or low-grade LEDs, leading to premature failure, inconsistent light output, and increased maintenance costs. Investing in high-quality LEDs from reputable manufacturers ensures reliability and long-term savings.

2. Ignoring IP Ratings for the Application Environment

IP ratings define the level of protection against dust and water ingress. A common pitfall is using indoor-rated LED tubes (e.g., IP20) in damp or outdoor environments such as garages, warehouses, or outdoor canopies. Without appropriate IP ratings (e.g., IP65 or higher), moisture and dust can damage internal components, leading to safety hazards and reduced lifespan.

3. Mismatched Fixture Compatibility

Not all LED tubes are compatible with existing fluorescent ballasts. Some require ballast bypass (direct wire), while others are ballast-compatible. Sourcing the wrong type can lead to flickering, reduced efficiency, or complete failure. Additionally, improper installation due to mismatched bases (e.g., G5 vs. G13) or lengths can compromise both performance and safety.

4. Overlooking Thermal Management and Build Quality

LED performance degrades with heat. Poorly designed LED tubes with inadequate heat dissipation reduce lumen output and shorten lifespan. Thin aluminum housings or lack of proper thermal pathways are red flags. High-quality LEDs feature robust heat sinks and materials that ensure stable operation under continuous use.

5. Inadequate Light Quality and Color Consistency

Low-quality LEDs often have poor Color Rendering Index (CRI < 80) and inconsistent color temperatures (e.g., mixing 3000K and 4000K in the same area). This results in an unprofessional appearance and eye strain. Always verify CRI (>80 recommended) and ensure batch consistency to maintain uniform lighting.

6. Assuming All “Waterproof” LEDs Meet Required Standards

Marketing terms like “waterproof” or “dustproof” can be misleading. Always check the actual IP rating—such as IP65 (dust-tight and protected against water jets) or IP67 (protected against temporary immersion). Without verified certifications, claims may not hold up in real-world conditions.

7. Neglecting Certifications and Compliance

Reputable LED products should carry certifications such as UL, CE, or Energy Star. Sourcing non-certified LEDs increases risk of fire, electrical failure, or non-compliance with local safety codes. Always verify compliance with regional standards before procurement.

By addressing these pitfalls—focusing on quality components, correct IP ratings, compatibility, and certifications—organizations can ensure a successful, safe, and cost-effective transition from fluorescent to LED lighting.

Logistics & Compliance Guide for Replacement of Fluorescent Lights with LED

Planning and Assessment

Before initiating the replacement of fluorescent lighting with LED, a comprehensive assessment of the existing lighting infrastructure is required. This includes evaluating the number and types of fluorescent fixtures (e.g., T12, T8, T5), identifying fixture locations, and determining compatibility with LED retrofit options (tube replacements or complete fixture upgrades). A site audit helps establish project scope, budget estimates, and timelines. Additionally, consider lighting requirements such as lumens, color temperature (CCT), and dimming capabilities to ensure the new LED system meets operational and safety standards.

Regulatory and Environmental Compliance

Ensure compliance with local, state, and federal regulations regarding lighting upgrades and hazardous material handling. Fluorescent lamps contain mercury, a hazardous substance regulated under the Environmental Protection Agency (EPA) and local environmental agencies. Used fluorescent tubes must be properly removed, stored, and disposed of according to Universal Waste Rule (40 CFR Part 273) guidelines. Partner with certified e-waste recyclers for safe disposal and obtain documentation (e.g., waste manifests) for compliance records. Upgrading to LED reduces environmental impact and supports sustainability goals, potentially qualifying for utility rebates or tax incentives under Energy Policy Act (EPAct) Section 179D or similar programs.

Procurement and Supply Chain Management

Develop a procurement strategy that includes sourcing high-quality LED lighting products meeting ENERGY STAR, DLC (DesignLights Consortium), or other relevant certifications. Verify product specifications such as lifespan (typically 50,000+ hours), energy efficiency (lumens per watt), and warranty terms. Coordinate with suppliers for timely delivery and consider bulk ordering to reduce costs. Maintain accurate inventory of old fluorescent lamps and new LED components to prevent project delays. Ensure product compatibility with existing electrical systems, especially if using plug-and-play LED tubes that may require ballast bypass or compatible ballasts.

Installation Logistics and Safety Protocols

Plan installation activities to minimize disruption to operations. Schedule work during off-hours or low-occupancy periods when possible. Certified electricians should perform installations in accordance with the National Electrical Code (NEC) and OSHA safety standards. De-energize circuits before removing fluorescent fixtures, and follow lockout/tagout (LOTO) procedures. For ballast bypass LED tubes, ensure wiring modifications are correctly executed to avoid electrical hazards. Provide training or instructions to maintenance staff on new system operation and safety procedures. Maintain detailed records of installed locations, dates, and materials used.

Waste Management and Recycling

Implement a structured waste handling process for decommissioned fluorescent lamps. Use labeled, shatter-resistant containers for storage and transport. Retain records of disposal through licensed hazardous waste handlers to demonstrate regulatory compliance. Avoid landfill disposal, as it violates environmental regulations. Consider tracking metrics such as total lamps recycled and mercury content diverted to highlight environmental benefits.

Documentation and Reporting

Maintain comprehensive documentation throughout the project, including:

– Pre- and post-installation lighting assessments

– Disposal manifests and recycling certificates

– Product specifications and warranties

– Energy savings calculations and utility incentive applications

This documentation supports audits, sustainability reporting, and potential future inspections. Use project data to calculate return on investment (ROI), energy savings (kWh), and carbon emissions reductions.

Post-Implementation Review and Maintenance

After installation, conduct a post-implementation review to verify performance, identify any issues, and ensure all fixtures operate correctly. Establish a preventive maintenance schedule for LED systems, which typically require minimal upkeep but may benefit from periodic cleaning and inspection. Monitor energy consumption to validate expected savings. Gather user feedback to assess improvements in light quality and workplace comfort. Update facility lighting plans and asset registers to reflect the new LED infrastructure.

Conclusion:

The replacement of fluorescent lighting with LED lighting presents a strategic, cost-effective, and environmentally responsible decision for both commercial and residential applications. LEDs offer superior energy efficiency, consuming up to 50–70% less electricity than traditional fluorescent lamps, leading to significant reductions in energy costs and carbon emissions. With a longer lifespan—typically 25,000 to 50,000 hours or more—LEDs drastically reduce maintenance and replacement frequency, lowering long-term operational expenses.

Additionally, LED technology provides better light quality, instant illumination without flicker or warm-up time, and greater design flexibility with dimming and color control options. Unlike fluorescent lamps, LEDs contain no hazardous materials such as mercury, making them safer to handle and easier to dispose of or recycle.

Although the initial investment in LED fixtures may be higher, the total cost of ownership is considerably lower due to energy savings, reduced maintenance, and extended lifespan. Incentives and rebates from utility companies and government programs further improve the return on investment.

In conclusion, sourcing the replacement of fluorescent lights with LED lighting is a forward-thinking initiative that enhances sustainability, improves lighting performance, and delivers substantial financial benefits over time. It is a recommended upgrade for any organization seeking to reduce its environmental footprint and operate more efficiently.