The industrial and consumer demand for reliable power tools continues to rise, driven by growth in construction, woodworking, and DIY markets. According to Grand View Research, the global electric motors market was valued at USD 154.7 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.3% from 2024 to 2030. This growth is fueled by increasing automation, efficiency standards, and the need for durable replacement components across power tool applications. Among these, table saws remain a staple in workshops worldwide, creating sustained demand for high-performance replacement electric motors. As aging motors fail or users upgrade for power and efficiency, manufacturers are responding with innovative, compatible alternatives. Drawing on industry trends and performance metrics, this overview highlights the top nine replacement electric motor manufacturers catering specifically to table saws—companies leading the charge in durability, energy efficiency, and seamless integration.

Top 9 Replacement Electric Motors For Table Saws Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

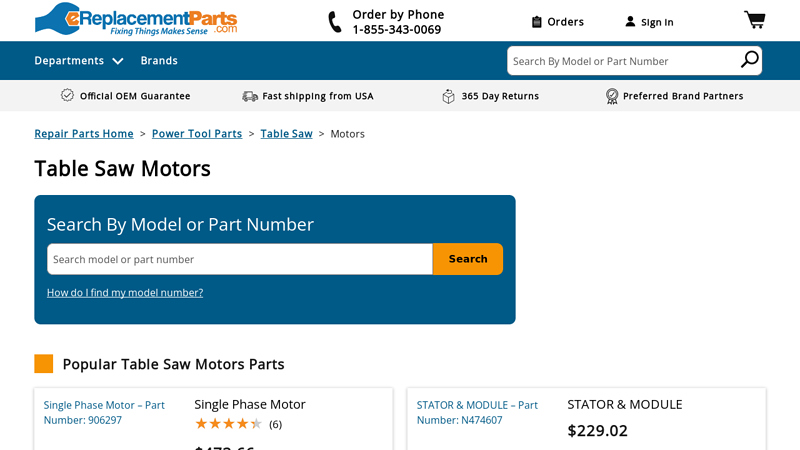

#1 Table Saw Motors

Domain Est. 2004

Website: ereplacementparts.com

Key Highlights: 1–2 day delivery · 365-day returnsShop for the OEM replacement Motors you need to repair your Table Saw. eReplacementParts.com offers genuine manufacturer parts, repair help, and …

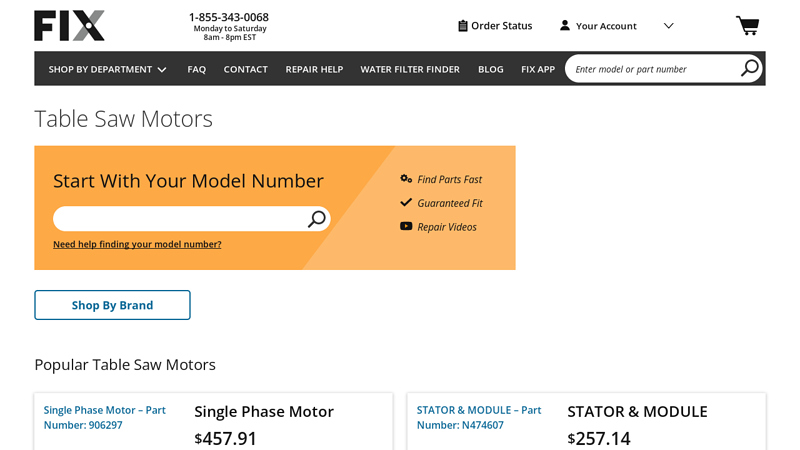

#2 Shop OEM Table Saw Motors

Domain Est. 1995

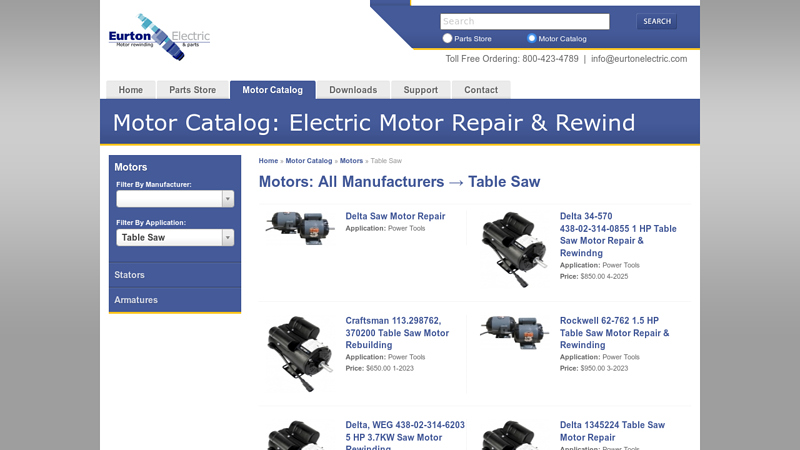

#3 All Manufacturers » Table Saw

Domain Est. 1999

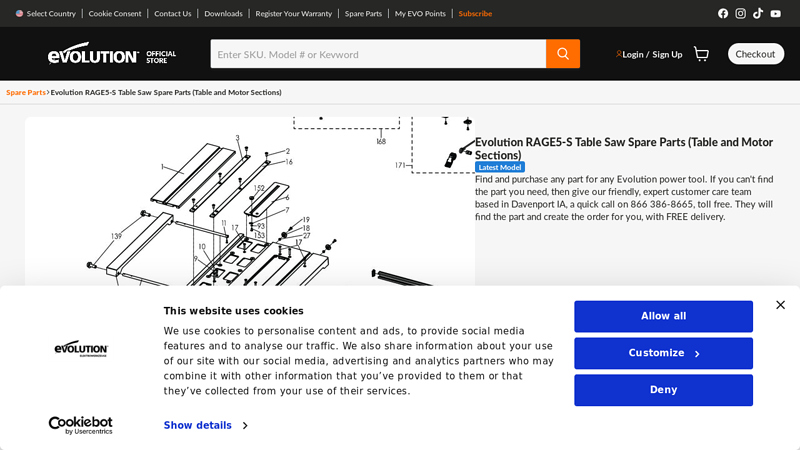

#4 Evolution RAGE5

Domain Est. 2000

Website: store.evolutionpowertools.com

Key Highlights: In stock Free deliveryEvolution RAGE5-S Table Saw Spare Parts (Table and Motor Sections). Latest Model. Find and purchase any part for any Evolution power tool. If you can’t find t…

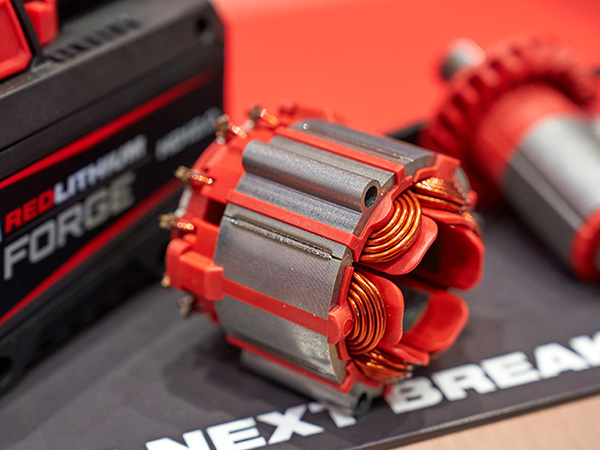

#5 Milwaukee® Tool

Domain Est. 2000

Website: milwaukeetool.com

Key Highlights: Milwaukee Tool is the most respected manufacturer of heavy-duty power tools, hand tools, instruments, and accessories….

#6 Replacement motor on dewalt table saw

Domain Est. 1995

Website: doityourself.com

Key Highlights: I replaced the armature in the saw motor I use at work for $75. I use either ereplacementparts or toolpartsdirect dot com for all my tool parts needs….

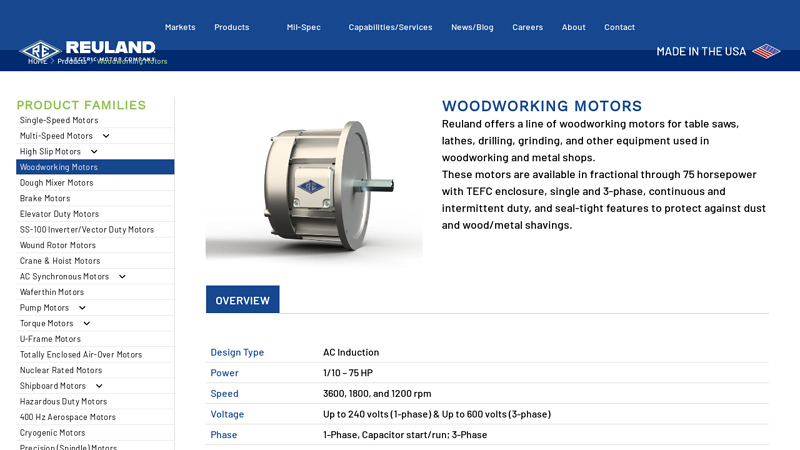

#7 Woodworking Motors

Domain Est. 1996

Website: reuland.com

Key Highlights: Reuland offers a line of woodworking motors for table saws, lathes, drilling, grinding, and other equipment used in woodworking and metal shops….

#8 Mayer Electric

Domain Est. 1997

Website: mayerelectric.com

Key Highlights: Mayer is one of the nation’s largest wholesale distributors of electrical products and equipment, connected solutions, lighting, digital tools, ……

#9 Woodworking Electric Motors

Domain Est. 1999

Expert Sourcing Insights for Replacement Electric Motors For Table Saws

H2: Emerging Market Trends for Replacement Electric Motors for Table Saws in 2026

The market for replacement electric motors for table saws is poised for notable transformation by 2026, driven by technological advancements, sustainability demands, and evolving user expectations across professional and DIY sectors. Key trends shaping this niche segment include:

-

Increased Demand for Energy-Efficient Motors

As energy regulations tighten globally, manufacturers are prioritizing high-efficiency motors such as premium efficiency (IE3 and IE4) models. These motors reduce power consumption and heat generation, appealing to both commercial woodworking shops aiming to lower operational costs and environmentally conscious consumers. -

Rise of Smart and IoT-Integrated Motors

By 2026, integration of smart technology into replacement motors is expected to accelerate. Motors equipped with sensors for temperature monitoring, load balancing, and predictive maintenance alerts are becoming more common. These features enhance safety and uptime, particularly in industrial settings. -

Growth in E-Commerce and Direct-to-Consumer Sales

Online platforms are increasingly becoming the primary channel for purchasing replacement motors. Enhanced product descriptions, compatibility tools, and customer reviews help users identify the correct motor quickly. This shift is driving competition among suppliers to offer faster shipping, better warranties, and detailed installation support. -

Standardization and Interchangeability

To meet growing demand for plug-and-play replacements, motor manufacturers are aligning with standardized mounting configurations, shaft dimensions, and electrical ratings. This trend simplifies the replacement process and reduces downtime for users, making it easier to upgrade or repair older table saw models. -

Shift Toward Brushless DC (BLDC) Motors

Although traditionally used in portable tools, brushless DC motor technology is gaining ground in stationary equipment due to its superior efficiency, longer lifespan, and reduced maintenance. By 2026, BLDC motors are expected to represent a growing share of high-end replacement options, especially in hybrid or retrofit applications. -

Sustainability and Circular Economy Influence

The push for sustainability is encouraging repair over replacement. As a result, the market for durable, repairable, and recyclable motor components is expanding. Manufacturers are responding with modular designs and longer product lifecycles, aligning with circular economy principles. -

Regional Market Diversification

While North America and Western Europe remain strong markets due to high ownership of power tools, emerging economies in Asia-Pacific and Latin America are showing increased demand for industrial woodworking equipment, fueling growth in replacement parts, including motors. -

Aftermarket Innovation and Brand Competition

Independent motor manufacturers are challenging OEMs by offering cost-effective, high-performance alternatives with improved warranties and technical support. This competitive landscape is driving innovation and value for end users.

In conclusion, the 2026 market for replacement electric motors for table saws will be defined by efficiency, connectivity, and accessibility. As woodworking industries modernize and consumers demand smarter, greener solutions, the replacement motor sector will continue to evolve as a critical enabler of equipment longevity and performance.

Common Pitfalls When Sourcing Replacement Electric Motors for Table Saws (Quality and IP Considerations)

When replacing the electric motor on a table saw, selecting the wrong unit can lead to poor performance, safety hazards, or premature failure. Two critical areas where buyers often encounter issues are motor quality and Ingress Protection (IP) rating. Being aware of these common pitfalls helps ensure a reliable and safe replacement.

Overlooking Motor Build Quality and Materials

One of the most frequent mistakes is choosing a replacement motor based solely on price or basic specifications without evaluating build quality. Low-cost motors may use inferior materials such as aluminum windings instead of copper, lower-grade bearings, or substandard insulation. These compromises reduce efficiency, increase operating temperatures, and shorten motor lifespan. Always verify that the motor uses copper windings, high-quality bearings, and thermal protection mechanisms. Reputable brands typically provide detailed construction information, while generic or off-brand motors may obscure these details.

Ignoring IP (Ingress Protection) Rating for Workshop Environment

Table saws are commonly used in dusty, debris-filled environments where sawdust and moisture can infiltrate the motor. A common pitfall is selecting a motor with an insufficient IP rating—such as IP20 or no rating at all—which offers little protection against dust and liquids. For table saw applications, a minimum of IP54 or higher is generally recommended. This ensures protection against dust ingress (preventing internal buildup and overheating) and splashing water. Using an under-protected motor in a workshop setting increases the risk of electrical shorts, corrosion, and fire hazards.

Assuming All Motors Are Interchangeable Without Verifying Specifications

Even if a motor appears to fit physically, differences in shaft size, rotation direction (clockwise vs. counterclockwise), mounting configuration, or electrical specs (voltage, phase, RPM) can render it incompatible. Mismatched motors may vibrate excessively, overheat, or fail to deliver the required torque. Always cross-reference the original motor’s nameplate data and confirm mechanical and electrical compatibility before purchasing.

Failing to Check for Thermal and Overload Protection

Many replacement motors—particularly budget models—lack built-in thermal overload protection. Without this safeguard, the motor is more susceptible to damage from prolonged use or stalling, which is common when cutting dense materials. Overheating can degrade insulation, damage windings, and create fire risks. Ensure the replacement motor includes thermal cut-off or overload protection suited for intermittent heavy-duty use.

Prioritizing Cost Over Long-Term Reliability

While it’s tempting to choose the cheapest available motor, this often leads to higher long-term costs due to frequent replacements and potential damage to the table saw. Investing in a high-quality, appropriately rated motor from a trusted manufacturer typically offers better performance, durability, and safety, ultimately providing greater value over time.

Logistics & Compliance Guide for Replacement Electric Motors for Table Saws

Overview

Replacement electric motors for table saws are critical components in both industrial and consumer woodworking equipment. Proper logistics planning and adherence to compliance regulations are essential to ensure safe, timely, and legal distribution. This guide outlines key considerations for shipping, handling, regulatory requirements, and international trade compliance.

Product Classification & Harmonized System (HS) Code

Identifying the correct HS code is crucial for customs clearance and tariff assessment. Replacement electric motors for table saws generally fall under:

HS Code: 8501.31 or 8501.32 – Electric motors of an output not exceeding 750 W or over 750 W but not exceeding 75 kW, respectively.

Note: Classification may vary by country and specific motor specifications (e.g., voltage, power output). Always verify with local customs authorities or a licensed customs broker.

Packaging & Handling Requirements

- Secure Packaging: Motors must be packed in sturdy, corrugated boxes with internal cushioning (e.g., foam inserts or molded pulp) to prevent damage during transit.

- Moisture Protection: Include desiccant packs and moisture barriers, especially for ocean freight, to prevent corrosion.

- Labeling: Clearly label packages with:

- Product description and model number

- Net weight and gross weight

- “Fragile” and “This Side Up” indicators

- Manufacturer and supplier contact information

- Palletization: Use standard pallet sizes (e.g., 48” x 40” in North America) and secure with stretch wrap. Stack height must not exceed safe limits.

Domestic & International Shipping

- Mode of Transport:

- Air freight: Recommended for urgent shipments; higher cost but faster delivery.

- Ocean freight: Cost-effective for large volumes; use FCL (Full Container Load) or LCL (Less than Container Load) based on volume.

- Ground transport: Suitable for regional distribution within the U.S., EU, or other land-connected regions.

- Freight Documentation:

- Commercial Invoice

- Packing List

- Bill of Lading (B/L) or Air Waybill (AWB)

- Certificate of Origin (if required for preferential tariffs)

Regulatory Compliance

United States (U.S.)

- FCC Compliance: Motors with electronic speed controls or wireless features may require FCC certification under Part 15.

- UL/ETL Listing: Replacement motors should be UL or ETL listed (e.g., UL 1004) to meet safety standards for electric motors.

- CPSC Regulations: Ensure compliance with Consumer Product Safety Commission guidelines if intended for consumer-use tools.

European Union (EU)

- CE Marking: Mandatory under the Machinery Directive (2006/42/EC) and Low Voltage Directive (2014/35/EU).

- RoHS Compliance: Restriction of Hazardous Substances – must not contain lead, mercury, cadmium, etc., above permitted levels.

- REACH: Registration, Evaluation, Authorization, and Restriction of Chemicals – declare any Substances of Very High Concern (SVHC).

- Ecodesign (ErP Directive): Energy efficiency requirements may apply depending on motor type and power.

Canada

- CSA Certification: Required under Canadian Electrical Code (CSA C22.2 No. 100).

- ISED Certification: For electromagnetic compatibility (similar to FCC).

Other Markets

- UKCA Marking: Required for sale in Great Britain (post-Brexit).

- Australia/New Zealand: RCM (Regulatory Compliance Mark) and AS/NZS 60034 standards.

- China: CCC (China Compulsory Certification) may be required depending on motor power and application.

Import Duties & Taxes

- Duty Rates: Vary by country. Example: U.S. duty on electric motors under HTS 8501.31 is generally 2.5%.

- VAT/GST: Applicable on landed cost in most countries (e.g., 20% VAT in the UK, 10% GST in Australia).

- De Minimis Thresholds: Shipments below a certain value may be exempt from duties (e.g., $800 in the U.S. under Section 321).

Warranty & Returns Logistics

- Warranty Period: Clearly state warranty terms (e.g., 1–2 years) on packaging and documentation.

- Returns Process: Establish a reverse logistics protocol, including RMA (Return Merchandise Authorization) numbers and inspection procedures.

- Defective Unit Handling: Segregate and dispose of or repair returned motors per environmental regulations (e.g., WEEE in EU).

Environmental & Safety Regulations

- WEEE (EU): Producers may be responsible for recycling end-of-life motors. Register with national WEEE authorities if applicable.

- Battery-Operated Motors: If applicable, comply with IATA regulations for lithium batteries (UN 3480 or 3481).

- Hazardous Materials: Confirm motors do not contain PCBs or other regulated substances.

Recordkeeping & Audit Readiness

Maintain records for at least 5 years, including:

– Test reports (safety, EMC, efficiency)

– Certifications (UL, CE, CSA)

– Import/export documentation

– Supplier compliance statements

Conclusion

Efficient logistics and strict compliance are vital for successfully distributing replacement electric motors for table saws. Understanding classification, packaging, transport, and regulatory requirements across target markets reduces delays, avoids penalties, and ensures product safety and customer satisfaction. Always consult with legal and logistics experts to stay updated on evolving regulations.

In conclusion, sourcing replacement electric motors for table saws requires careful consideration of several key factors to ensure compatibility, performance, safety, and long-term reliability. It is essential to match motor specifications—such as horsepower, voltage, phase, RPM, rotation direction, and shaft dimensions—to the original equipment manufacturer (OEM) requirements or the saw’s design parameters. Utilizing OEM motors ensures guaranteed fit and function, while aftermarket or universal motors can offer cost savings if selected with due diligence.

When evaluating suppliers, prioritize reputable manufacturers and distributors with proven quality control and customer support. Assess warranty terms, availability of technical documentation, and adherence to electrical and safety standards (e.g., NEMA, UL, CE). Additionally, consider the ease of installation and availability of mounting hardware or adapters, as mismatched mounting configurations can complicate integration.

Ultimately, the goal is to restore the table saw to optimal working condition with a motor that delivers consistent power and durability. Taking time to research, compare options, and consult product manuals or experts will help avoid operational issues and ensure user safety. A well-chosen replacement motor not only extends the life of the tool but also maintains the precision and efficiency required for professional and DIY woodworking applications.