The global reinforced plastic tanks market is experiencing robust growth, driven by increasing demand for corrosion-resistant and durable storage solutions across industries such as water treatment, chemical processing, and oil & gas. According to Grand View Research, the global FRP (Fiberglass-Reinforced Plastic) tanks market size was valued at USD 5.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.7% from 2023 to 2030. This growth is fueled by rising infrastructure investments, stringent environmental regulations, and the shift toward lightweight, maintenance-free materials. As industries prioritize longevity and chemical resistance in fluid storage, reinforced plastic tanks have emerged as a preferred alternative to traditional steel and concrete solutions. In this competitive landscape, a select group of manufacturers have distinguished themselves through innovation, scale, and product reliability—shaping the future of industrial storage. The following list highlights the top 10 reinforced plastic tank manufacturers leading this transformation.

Top 10 Reinforced Plastic Tanks Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 LF Manufacturing – Manufacturer of fiberglass

Domain Est. 1997 | Founded: 1974

Website: lfm-frp.com

Key Highlights: LFM has been building fiberglass reinforced plastic tanks and process vessels for a wide range of applications since 1974. We utilize the ……

#2 Fiberglass Tanks • Fiberglass Tank Manufacturer, Fiberglass Pipe …

Domain Est. 1999

Website: augustafiberglass.com

Key Highlights: The world’s leading manufacturer of custom designed and fabricated fiberglass reinforced plastic (FRP) tanks and equipment….

#3 Tanks

Domain Est. 2002

Website: allplastics-fiberglass.com

Key Highlights: Our extensive experience in design and fabrication of Fiberglass Reinforced Plastics ( FRP) tanks give us the ability to fabricate tanks up to 50 ft in ……

#4 Plastic Tank Manufacturers

Website: plastictankcompanies.com

Key Highlights: Manufacturers typically use fiberglass reinforced plastic (also known as glass reinforced plastic or FRP) and molded polyethylene to fabricate them….

#5 Belco Tanks

Domain Est. 1995

Website: nov.com

Key Highlights: Our Fiberglass Reinforced Plastic (FRP) tanks and vessels are lightweight, corrosion resistant and essentially maintenance free. Belco is ASME RTP-1 accredited ……

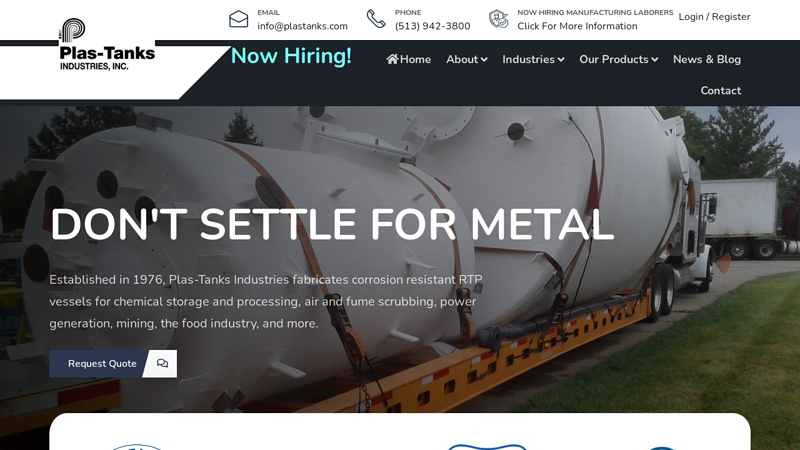

#6 Plas

Domain Est. 1997 | Founded: 1976

Website: plastanks.com

Key Highlights: Established in 1976, Plas-Tanks Industries fabricates corrosion resistant RTP vessels for chemical storage and processing, air and fume scrubbing, power ……

#7 Snyder Industries: Poly Tanks

Domain Est. 1998

Website: snydernet.com

Key Highlights: Snyder Industries manufactures plastic & steel tanks, IBC totes, bins, containers, pallets & more including custom products….

#8 Our Tanks

Domain Est. 2004

Website: designtanks.com

Key Highlights: Our customizable fiberglass reinforced plastic (FRP) tanks deliver 20+ years of worry-free service, reducing maintenance costs and replacement needs and ……

#9 Plasticon Projects

Domain Est. 2019

Website: plasticonprojects.com

Key Highlights: On-site tank fabrication. Plasticon Projects on-site production of large FRP tanks and equipment, exceeding transport limits, offers unparalleled advantages….

#10 Reinforced Plastic Storage Tank Manufacturing

Domain Est. 2020

Website: allenfrp.com

Key Highlights: We design, engineer, manufacture, and deliver every fiber-reinforced plastic storage container. So as our team grows, we continue to strictly adhere to quality ……

Expert Sourcing Insights for Reinforced Plastic Tanks

H2: 2026 Market Trends for Reinforced Plastic Tanks

The global market for reinforced plastic tanks is poised for significant transformation by 2026, driven by advancements in material science, evolving regulatory standards, and increasing demand across key industries. Reinforced plastic tanks—primarily manufactured using fiberglass-reinforced plastic (FRP) or advanced composites—are valued for their corrosion resistance, lightweight properties, and durability in storing aggressive chemicals, water, and industrial fluids.

-

Growing Demand in Water and Wastewater Treatment

By 2026, the water and wastewater treatment sector is expected to remain a major growth driver. Governments worldwide are investing heavily in infrastructure to address water scarcity and pollution. Reinforced plastic tanks offer a cost-effective, long-lasting solution for water storage, desalination, and sewage treatment, especially in regions with corrosive soil or saline environments. -

Expansion in the Chemical and Petrochemical Industries

The chemical processing and petrochemical sectors continue to prioritize safe, chemically resistant storage solutions. FRP tanks are increasingly favored over traditional steel tanks due to their resistance to corrosion and lower lifecycle costs. Rising industrial activity in Asia-Pacific and the Middle East is expected to boost demand, with countries like China, India, and Saudi Arabia expanding refining and chemical production capacity. -

Adoption of Advanced Composite Materials

Innovation in resin formulations and reinforcement techniques—such as vinyl ester resins and carbon fiber integration—is enhancing the performance of reinforced plastic tanks. These advancements allow tanks to withstand higher pressures, temperatures, and UV exposure, making them suitable for extreme environments. By 2026, smart tanks embedded with IoT sensors for real-time monitoring of tank integrity and fluid levels are anticipated to gain traction. -

Sustainability and Regulatory Push

Environmental regulations are tightening, particularly around leak prevention and secondary containment. Reinforced plastic tanks meet stringent EPA and ISO standards for environmental safety. Additionally, the recyclability of certain composite materials and the reduction in maintenance-related emissions contribute to their appeal in ESG (Environmental, Social, and Governance)-driven markets. -

Regional Market Dynamics

North America and Europe will maintain strong demand due to infrastructure upgrades and regulatory compliance needs. However, the fastest growth is expected in the Asia-Pacific region, driven by urbanization, industrialization, and government initiatives in water management and clean energy. Latin America and Africa are also emerging as potential growth markets, especially in mining and agriculture applications. -

Competitive Landscape and Consolidation

The market is witnessing increased consolidation among manufacturers, with key players investing in R&D and expanding their global footprint. Companies like National Tank Company, CST Industries, and Advanced Polymer Solutions are leveraging automation and modular designs to reduce production time and costs.

In summary, the 2026 outlook for reinforced plastic tanks is highly positive, characterized by technological innovation, regulatory support, and cross-sectoral demand. Market players who focus on sustainability, digital integration, and regional customization are likely to lead the next phase of growth.

Common Pitfalls When Sourcing Reinforced Plastic Tanks (Quality and Intellectual Property)

Sourcing reinforced plastic tanks—such as those made from fiberglass-reinforced plastic (FRP) or advanced composites—requires careful evaluation to avoid compromising on quality, performance, and legal integrity. Below are key pitfalls related to quality assurance and intellectual property (IP) that buyers often encounter.

Inadequate Quality Control and Material Verification

One of the most frequent issues is receiving tanks that do not meet specified performance standards due to poor manufacturing practices. Suppliers may use substandard resins, insufficient fiber reinforcement, or inconsistent lamination techniques, leading to premature failure, leaks, or structural weaknesses. Buyers often assume certifications (e.g., ISO, ASTM, or ASME RTP-1) are sufficient, but without independent verification or factory audits, compliance can be superficial.

Additionally, lack of proper testing—such as hydrostatic, chemical resistance, or burst pressure tests—can result in tanks unsuitable for intended operating conditions. Always demand third-party inspection reports and batch-specific material certifications to validate quality claims.

Non-Compliance with Industry Standards and Specifications

Many reinforced plastic tanks are designed for specific applications (e.g., storing corrosive chemicals, potable water, or wastewater), each governed by distinct standards. A common pitfall is sourcing tanks that claim compliance but fail to meet required specifications such as ASTM D4021 (for vertical storage tanks), BS 4994 (for FRP vessels), or AWWA D120 (for water storage). This can lead to regulatory non-compliance, safety hazards, and costly replacements.

Ensure that the supplier clearly documents adherence to applicable standards and provides engineering drawings and calculations for review prior to production.

Intellectual Property Infringement Risks

Reinforced plastic tank designs often incorporate proprietary engineering, such as unique laminate schedules, joint configurations, or structural reinforcements protected by patents or design rights. Sourcing from unauthorized or unlicensed manufacturers—especially in regions with weak IP enforcement—can expose buyers to legal liability, including injunctions, fines, or seizure of goods.

Be cautious of suppliers offering “equivalent” or “compatible” designs at significantly lower prices, as these may be unauthorized copies. Always verify that the manufacturer holds proper licenses for patented technologies and request documentation confirming freedom to operate.

Lack of Traceability and Documentation

Poor record-keeping by suppliers can hinder quality assurance and accountability. Without batch traceability, material data sheets, or as-built documentation, it becomes difficult to investigate failures, ensure regulatory compliance, or support warranty claims. This is particularly critical in regulated industries such as pharmaceuticals, food & beverage, or environmental infrastructure.

Require comprehensive documentation packages, including resin certificates, laminate logs, QA/QC records, and compliance statements, as part of the procurement agreement.

Hidden Costs from Poor Long-Term Performance

Low initial pricing can be misleading if the tank degrades prematurely due to UV exposure, chemical incompatibility, or mechanical stress. Inferior surface coatings, inadequate UV stabilization, or poor design for thermal cycling can drastically reduce service life. These hidden costs—including downtime, environmental remediation, and replacement—often outweigh initial savings.

Invest in lifecycle cost analysis and prioritize suppliers with proven field performance and long-term warranties backed by real-world data.

Conclusion

To mitigate these pitfalls, conduct thorough due diligence: audit potential suppliers, verify certifications, demand full documentation, and consult independent engineering experts when necessary. Protecting both quality and intellectual property integrity ensures reliable, compliant, and legally sound procurement of reinforced plastic tanks.

Logistics & Compliance Guide for Reinforced Plastic Tanks

Overview and Scope

This guide outlines key logistics and compliance considerations for the safe and legal handling, transportation, storage, and use of reinforced plastic tanks. These tanks—commonly made from fiberglass-reinforced plastic (FRP) or other composite materials—are widely used for storing corrosive, hazardous, or non-hazardous liquids in industries such as chemical processing, water treatment, and agriculture. Proper logistics planning and regulatory compliance are essential to prevent damage, ensure worker safety, and meet legal requirements.

Regulatory Compliance

International and National Regulations

Reinforced plastic tanks used for transporting or storing hazardous materials must comply with relevant regulations, including:

– DOT (U.S. Department of Transportation): For domestic transport in the United States, tanks transporting hazardous materials must meet 49 CFR requirements, including specifications for tank design, labeling, and placarding.

– ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road): Applies to cross-border shipments within Europe.

– ISO Standards: ISO 9001 (quality management) and ISO 14001 (environmental management) may apply depending on manufacturing and handling processes.

– UN Recommendations on the Transport of Dangerous Goods (UN Model Regulations): Provides the foundation for many regional regulations and includes performance testing standards for packaging.

Environmental and Safety Standards

- EPA Regulations (U.S.): Tanks storing regulated substances must comply with Spill Prevention, Control, and Countermeasure (SPCC) rules under the Clean Water Act and Resource Conservation and Recovery Act (RCRA) if handling hazardous waste.

- OSHA Standards: Ensure worker safety during handling, installation, and maintenance. Includes requirements for fall protection, confined space entry, and chemical exposure limits.

- FM Global or Factory Mutual Approvals: Often required for fire protection and property loss prevention in industrial applications.

Certification and Documentation

- Tanks must be certified by recognized bodies (e.g., ASME RTP-1, ASTM standards) to verify structural integrity and chemical resistance.

- Maintain documentation including Material Safety Data Sheets (MSDS/SDS), tank certification, test reports (hydrostatic, burst), and compliance declarations.

Handling and Transportation

Pre-Transportation Checks

- Verify tank integrity: inspect for cracks, stress points, or degradation.

- Confirm compatibility with transported material—ensure resin type (e.g., vinyl ester, polyester) resists the chemical being stored.

- Secure all fittings, valves, and manways. Empty and clean tanks properly if previously used for hazardous substances.

Loading and Securing

- Use proper lifting equipment with spreader bars to avoid stress on the tank shell. Never lift using fittings or manways.

- Secure tanks on transport vehicles with straps, cradles, or custom supports to prevent shifting. Isolate from direct metal-to-plastic contact using protective padding.

- Protect tanks from UV exposure during transport by covering with tarps if necessary.

Transport Restrictions

- Follow all regional hazardous materials transportation rules when applicable.

- Avoid extreme temperatures during transit, which may affect resin integrity or cause internal pressure buildup.

- Do not stack tanks unless specifically designed and certified for vertical stacking.

Storage Requirements

Indoor vs. Outdoor Storage

- Store tanks on a level, load-bearing surface. Concrete pads or steel support cradles are recommended.

- Outdoor storage: Shield from direct sunlight with covers or shelters to reduce UV degradation. Ensure proper drainage to prevent water accumulation under the tank.

- Indoor storage: Ensure adequate ventilation, especially if storing residual chemicals or volatile compounds.

Environmental Considerations

- Maintain safe distances from ignition sources, high-traffic areas, and incompatible materials.

- Implement secondary containment (e.g., bund walls or containment pallets) capable of holding 110% of tank capacity to prevent environmental spills.

Installation and Site Compliance

Foundation and Support

- Install tanks on a uniformly supported, flat foundation (e.g., concrete slab) to prevent stress cracking.

- Use manufacturer-recommended support cradles that distribute weight evenly and provide cushioning.

Piping and Connections

- Use flexible connectors to accommodate minor movement and reduce stress on tank nozzles.

- Follow local plumbing and pressure codes (e.g., ASME B31.3) for piping systems.

Grounding and Static Protection

- Ground tanks when storing flammable or combustible liquids to dissipate static electricity, especially during filling or emptying.

Inspection, Maintenance, and Decommissioning

Routine Inspections

- Conduct visual and structural inspections at regular intervals (e.g., every 6–12 months) for signs of wear, corrosion, or deformation.

- Perform non-destructive testing (NDT) such as ultrasonic thickness testing if required by regulation or risk assessment.

Maintenance Procedures

- Clean tanks according to chemical compatibility guidelines. Avoid abrasive cleaning methods.

- Repair only using manufacturer-approved materials and certified technicians. Patch repairs should follow ASME RTP-1 standards.

Decommissioning and Disposal

- Safely empty and decontaminate tanks before removal. Follow local, state, or national waste disposal regulations.

- Recycle plastic components where possible. Dispose of fiberglass waste in accordance with environmental regulations.

Training and Documentation

Personnel Training

- Train staff on proper handling, emergency response, and compliance requirements. Include procedures for spill containment and personal protective equipment (PPE) use.

Recordkeeping

- Maintain logs of inspections, maintenance, modifications, and regulatory audits. Retain documentation for a minimum of five years or as required by jurisdiction.

Emergency Preparedness

Spill Response

- Equip storage and transport sites with spill kits, absorbents, and neutralizing agents appropriate for stored chemicals.

- Establish emergency shutdown and evacuation procedures.

Reporting Obligations

- Report accidental releases to appropriate authorities (e.g., EPA, NRC, local environmental agencies) per regulatory thresholds (e.g., CERCLA, EPCRA in the U.S.).

Conclusion

Effective logistics and compliance for reinforced plastic tanks require a proactive approach integrating regulatory knowledge, safe handling practices, and thorough documentation. Adhering to this guide helps ensure operational safety, environmental protection, and legal compliance across the tank lifecycle. Always consult the tank manufacturer and regulatory agencies for application-specific requirements.

In conclusion, sourcing reinforced plastic tanks requires a comprehensive evaluation of material quality, manufacturer expertise, compliance with industry standards, and long-term performance requirements. Reinforced plastic tanks offer significant advantages such as corrosion resistance, lightweight construction, and durability, making them ideal for storing aggressive chemicals, wastewater, or potable water in various industrial, municipal, and commercial applications. When selecting a supplier, it is essential to prioritize manufacturers with proven experience, stringent quality control processes, and the ability to customize tanks according to specific capacity, design, and environmental conditions. Additionally, considering lifecycle costs, warranty terms, and after-sales support ensures optimal value and reliability. By carefully assessing these factors, organizations can make informed sourcing decisions that enhance operational efficiency, safety, and sustainability.