The global reflective tape market is experiencing robust growth, driven by increasing demand for high-visibility safety solutions across automotive, construction, transportation, and personal protective equipment (PPE) sectors. According to Grand View Research, the global reflective material market was valued at USD 7.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by stringent regulatory standards for nighttime visibility, rising road safety initiatives, and the expansion of smart infrastructure projects worldwide. As demand intensifies, manufacturers are investing in advanced retroreflective technologies, including prismatic and glass bead-based tapes, to improve performance and durability. In this competitive landscape, nine key players have emerged as leaders, combining innovation, global reach, and compliance with international safety standards to dominate market share and shape the future of reflective solutions.

Top 9 Reflecting Tape Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 tesa – global manufacturer of tapes and self

Domain Est. 1997

Website: tesa.com

Key Highlights: tesa creates adhesive solutions that improve the work, products and lives of our customers. We support industry partners, craftspeople and consumer….

#2 The Reflective Store

Domain Est. 2007

Website: reflectivestore.com

Key Highlights: We carry a comprehensive stock of Oralite and Nikkalite Self-Adhesive Reflective Films, providing a diverse range of types, colors, widths, and lengths….

#3 Top Manufacturer of Reflective Fabric And Safety Vest

Domain Est. 2014

Website: chinareflective.com

Key Highlights: Chinastars is the largest reflective material and safety vest manufacturer and exporter in China. Products include reflective fabric, reflective tape, ……

#4 Tape Finder Online Store

Domain Est. 2014

Website: tapefinder.com

Key Highlights: We carry a Large Variety of Retro Reflective Tapes in Multiple Sizes and Colors, Each with Unique Qualities to Match the Needs of your Project or Application….

#5 3M Scotchlite Reflective Material Overview

Domain Est. 1988

Website: 3m.com

Key Highlights: Discover the versatility of 3M™ Scotchlite™ Reflective Material, ideal for enhancing visibility in a variety industries and consumer applications….

#6 Reflective Tapes

Domain Est. 1993

Website: graphics.averydennison.com

Key Highlights: Avery Dennison V-5720 Series Conspicuity Tape is a high quality and durable metalized microprismatic tape offering easy repositionable application with its ……

#7 Reflomax

Domain Est. 2001

Website: reflomax.com

Key Highlights: Reflomax – retro-reflective film, micro-prismatic, traffic sign, car license plate, vehicle conspicuity, Garment Tape, reflective film, traffic sign, ……

#8 Reflective Tape: Stripe Colors (PTM814BKYL)

Domain Est. 2002

#9 Best Reflective Tapes Manufacturer and Suppliers

Domain Est. 2024

Website: reflectivesafetyjackets.com

Key Highlights: Our Reflective Tapes are designed to provide high visibility, ensuring your team stays safe and seen, no matter the circumstances….

Expert Sourcing Insights for Reflecting Tape

H2: 2026 Market Trends for Reflecting Tape

The global reflecting tape market is projected to experience steady growth by 2026, driven by increasing demand across multiple industries, regulatory developments, and technological advancements. Below are key trends shaping the reflecting tape market in 2026:

-

Rising Safety Regulations and Standards

Governments and regulatory bodies worldwide are tightening safety standards for high-visibility apparel and equipment, particularly in transportation, construction, and emergency services. Mandates requiring reflective materials on workwear, school uniforms, and personal protective equipment (PPE) are fueling demand. In 2026, compliance with ISO 20471 and ANSI/ISEA 107 standards continues to be a major driver for market expansion. -

Growth in Automotive and Road Safety Applications

The automotive sector is increasingly using reflective tapes for vehicle conspicuity, especially in commercial fleets, emergency vehicles, and construction machinery. With the global push for road safety and reduced nighttime accidents, regulatory bodies in North America, Europe, and Asia-Pacific are mandating reflective striping on trucks and trailers. This trend is expected to significantly boost market demand by 2026. -

Expansion in Consumer and Lifestyle Applications

Beyond industrial and safety uses, reflecting tape is gaining popularity in consumer products such as sportswear, outdoor gear, footwear, and fashion accessories. Athletes and outdoor enthusiasts are demanding high-visibility apparel for nighttime running, cycling, and hiking. Brands are integrating aesthetic reflective elements into designs, combining style with safety—a trend expected to grow through 2026. -

Sustainability and Eco-Friendly Materials

Environmental concerns are driving innovation in eco-conscious reflective tapes. By 2026, manufacturers are increasingly adopting recyclable backings, water-based adhesives, and reduced-VOC (volatile organic compound) production methods. Demand for sustainable alternatives is especially strong in Europe and North America, where corporate social responsibility (CSR) initiatives are influencing procurement decisions. -

Technological Advancements in Reflective Performance

Innovation in micro-prismatic and glass bead technologies has enhanced the brightness, durability, and wash resistance of reflective tapes. In 2026, smart reflective materials with integrated sensors or temperature-reactive elements are emerging in niche markets. Additionally, improved adhesion to diverse substrates (e.g., fabrics, plastics, metals) is expanding application possibilities. -

Asia-Pacific as a Key Growth Region

The Asia-Pacific region is becoming a major hub for both production and consumption of reflecting tape. Rapid urbanization, infrastructure development, and increasing awareness of occupational safety in countries like China, India, and Vietnam are driving regional market growth. Local manufacturers are also investing in R&D to compete with Western brands. -

E-Commerce and Direct-to-Consumer Sales Channels

Online platforms are playing a growing role in the distribution of reflecting tape, particularly for DIY, craft, and small-scale commercial users. By 2026, digital marketplaces offer wider product variety, competitive pricing, and faster delivery, contributing to market accessibility and consumer adoption. -

Impact of Supply Chain Resilience

Post-pandemic supply chain adjustments continue to influence the reflecting tape market. Companies are diversifying sourcing and manufacturing locations to mitigate risks. Regionalization of supply chains, especially in North America and Europe, supports faster delivery and reduces dependency on single-source suppliers.

In conclusion, the reflecting tape market in 2026 is characterized by regulatory momentum, technological innovation, and expanding application scopes. As safety remains a global priority and consumer preferences evolve, stakeholders who invest in sustainable, high-performance, and versatile reflective solutions are poised for competitive advantage.

Common Pitfalls Sourcing Reflecting Tape (Quality, IP)

When procuring reflecting tape—commonly used in safety gear, vehicle markings, and industrial applications—organizations often encounter challenges related to quality inconsistencies and intellectual property (IP) concerns. Being aware of these pitfalls helps ensure reliable performance and legal compliance.

Inconsistent or Substandard Material Quality

One of the most frequent issues is receiving reflecting tape that fails to meet specified performance standards. Common quality shortcomings include poor retroreflectivity, inadequate durability under UV exposure, insufficient adhesion, or degradation in extreme temperatures. These deficiencies compromise safety and lead to higher long-term costs due to frequent replacements. Buyers may inadvertently source from suppliers using inferior glass beads or prismatic films, or those skipping proper quality control protocols.

Misrepresentation of Compliance and Certifications

Many suppliers claim compliance with international standards such as EN 471, ASTM D4956, or CSA Z96, but fail to provide verifiable test reports or third-party certifications. This misrepresentation can result in non-compliant products being used in regulated environments, exposing the buyer to liability risks, failed audits, or recalls.

Lack of Intellectual Property Verification

Reflecting tape technology—especially high-performance prismatic or micro-optical designs—is often protected by patents and trademarks. Sourcing from unauthorized manufacturers or suppliers may lead to inadvertent IP infringement. This is particularly common when dealing with low-cost suppliers from regions with lax IP enforcement. Using counterfeit or cloned products not only risks legal action but also undermines safety due to untested performance.

Inadequate Supply Chain Transparency

Opaqueness in the supply chain makes it difficult to trace the origin of materials and verify manufacturing processes. Without transparency, buyers cannot ensure ethical sourcing, consistent quality, or authenticity. This also complicates efforts to respond to quality failures or recall events.

Overreliance on Price as the Primary Selection Criterion

Prioritizing low cost over performance and reliability often results in sourcing inferior products. While budget constraints are real, excessively cheap reflecting tape typically sacrifices optical efficiency, longevity, and regulatory compliance—leading to higher total cost of ownership and potential safety hazards.

Failure to Conduct Proper Supplier Qualification

Skipping due diligence—such as on-site audits, sample testing, or verification of manufacturing capabilities—increases the risk of partnering with unreliable suppliers. Without proper vetting, buyers are more vulnerable to supply disruptions, quality lapses, and IP issues.

Avoiding these pitfalls requires a strategic sourcing approach that emphasizes technical specifications, verified certifications, IP compliance, and long-term supplier relationships built on transparency and accountability.

Logistics & Compliance Guide for Reflecting Tape

Product Classification & Regulatory Overview

Reflecting tape, also known as retroreflective tape, is commonly used for safety, visibility, and identification in transportation, construction, and industrial applications. Its classification for logistics and compliance purposes depends on composition, intended use, and regional regulations. Key regulatory standards include:

- DOT (Department of Transportation, USA): FMVSS No. 108 for motor vehicle safety standards; applies to tape used on commercial vehicles.

- ANSI/ISEA 107 (USA): Specifies performance requirements for high-visibility safety apparel and accessories.

- EN 13356 / EN 471 (Europe): European standards for high-visibility clothing; affects imported products.

- IMDG Code (International Maritime): Governs transport of hazardous goods by sea, if applicable (e.g., solvent-based adhesives).

- REACH & RoHS (EU): Chemical compliance requirements for restricted substances.

Ensure product specifications meet the standards of the destination market.

Packaging & Labeling Requirements

Proper packaging and labeling are essential for compliance and efficient logistics:

- Primary Packaging: Use moisture-resistant, durable materials to prevent adhesive degradation or surface damage.

- Labeling: Include:

- Product name and specifications (e.g., “Class C Reflective Tape, 5 cm x 50 m”)

- Batch or lot number

- Manufacturer and importer details

- Compliance markings (e.g., ANSI/ISEA 107, CE mark)

- Country of origin

- Hazard Labels: Required only if components are classified as hazardous (e.g., flammable solvents). Check SDS (Safety Data Sheet) for classification.

Transport & Handling Guidelines

Reflecting tape is generally non-hazardous, but proper handling ensures quality and regulatory compliance:

- Temperature Control: Store and transport between 10°C and 30°C; avoid freezing or extreme heat to prevent adhesive failure.

- Humidity: Maintain low humidity to avoid moisture absorption, especially for rolls with paper liners.

- Stacking & Palletization: Stack vertically to prevent deformation; use edge protectors and secure stretch-wrapping.

- Mode-Specific Regulations:

- Air (IATA): Non-restricted if non-hazardous; check adhesive composition.

- Sea (IMDG): Declare accurately; most reflective tapes are UN 3082, environmentally hazardous (if applicable).

- Road/Rail (ADR/RID): Usually exempt unless classified as dangerous goods.

Customs Documentation & Duties

Accurate documentation is critical for international shipments:

- Commercial Invoice: Include detailed product description, HTS code, value, and origin.

- Packing List: Specify quantity per package, gross/net weight, dimensions.

- Certificate of Conformity (CoC): Required in EU, GCC, and other regions; confirm product meets local standards.

- HTS Code Guidance:

- US: Typically 3919.90 (self-adhesive plates, sheets, film) or 8708.29 (for vehicle safety use).

- EU: 3919 90 80 (other self-adhesive film).

- Verify with local customs for precise classification.

Storage & Shelf Life

- Storage Conditions: Keep in a dry, cool warehouse (15–25°C), away from direct sunlight and ozone sources (e.g., motors).

- Shelf Life: Typically 12–24 months; monitor expiration dates and follow FIFO (First In, First Out) practices.

- Roll Orientation: Store vertically to prevent edge damage or deformation.

Environmental & Disposal Compliance

- Recyclability: Most reflective tapes are composite materials (plastic, glass beads, adhesive) and not widely recyclable.

- Disposal: Treat as non-hazardous solid waste unless adhesives contain regulated substances.

- Waste Management: Follow local regulations (e.g., EPA in USA, WEEE in EU) and provide SDS upon request.

Quality Assurance & Traceability

- Batch Tracking: Maintain records of raw materials, production dates, and distribution for recall readiness.

- Testing Documentation: Retain test reports for reflectivity (e.g., coefficient of retroreflection), adhesion, and durability.

- Supplier Compliance: Audit suppliers for REACH, RoHS, and conflict minerals compliance where applicable.

Special Considerations for High-Visibility Applications

- Police, Emergency, and Worker Safety Gear: Products may require third-party certification (e.g., NFPA, CSA).

- Military/Defense Contracts: May require DFARS compliance and specific testing (e.g., MIL-PRF-32309).

- Export Controls: Rare, but verify if tape contains controlled materials or dual-use technologies.

Follow this guide to ensure safe, compliant, and efficient logistics operations for reflecting tape across global supply chains. Always consult local regulations and update procedures based on product formulation and end-use.

Conclusion for Sourcing Reflecting Tape:

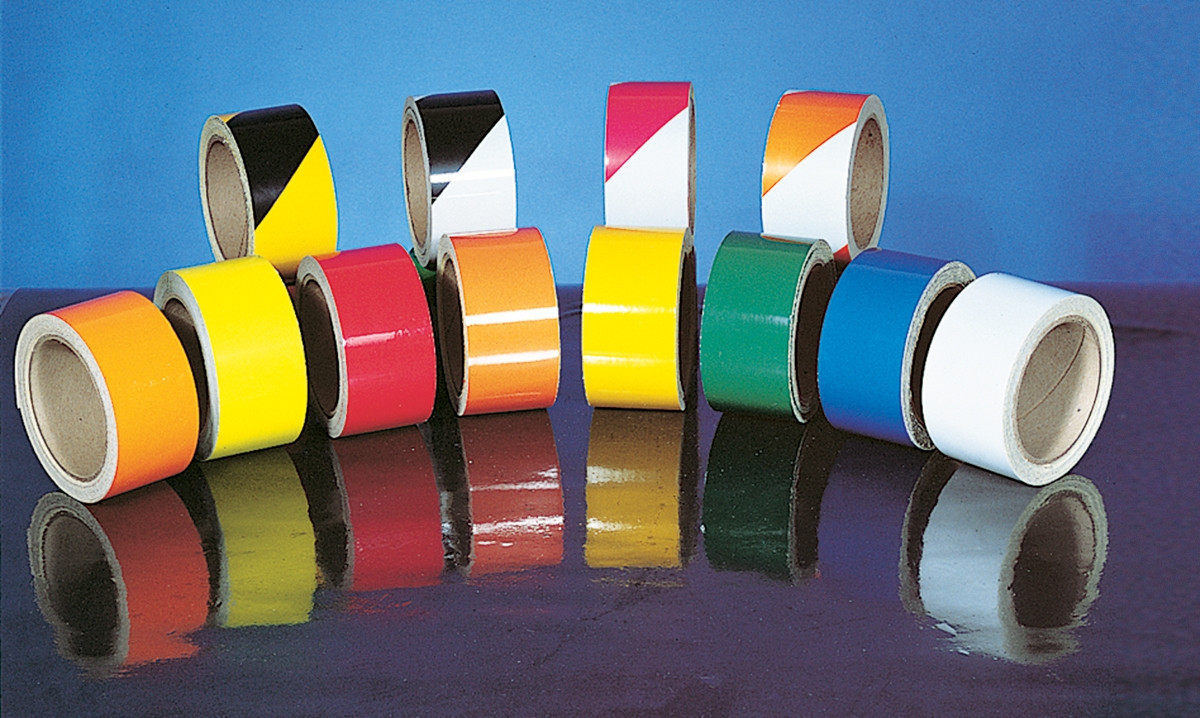

After a thorough evaluation of potential suppliers, product specifications, and market options, the sourcing of reflecting tape has been strategically aligned with quality, cost-efficiency, and compliance requirements. The selected supplier offers durable, high-performance reflecting tape that meets international safety standards (such as ASTM or EN-13356), ensuring optimal visibility and reliability for intended applications in traffic safety, personal protective equipment, or industrial use.

Key factors such as material reflectivity (prismatic vs. glass bead), adhesive strength, weather resistance, and customization options (width, color, length) were prioritized during the selection process. Additionally, the chosen vendor provides competitive pricing, consistent lead times, and scalable supply capacity, supporting both immediate needs and future demand growth.

In conclusion, the sourcing decision ensures a reliable, cost-effective, and compliant supply of reflecting tape that enhances safety and operational effectiveness. Continued supplier performance monitoring and periodic market reviews will be implemented to maintain quality and explore opportunities for further optimization.