The global fasteners market, driven by robust demand from automotive, aerospace, construction, and industrial machinery sectors, is experiencing steady expansion. According to Mordor Intelligence, the market was valued at USD 111.87 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. A key segment within this landscape is rectangular nuts—engineered fasteners designed to provide enhanced resistance to loosening under vibration and dynamic loads. Their specialized geometry makes them critical in high-performance applications, particularly in rail infrastructure, heavy machinery, and electronic enclosures. As industries prioritize reliability and durability, demand for precision-engineered rectangular nuts continues to rise. This growing need has positioned several manufacturers at the forefront of innovation, quality, and global supply. Below, we explore the top nine rectangular nuts manufacturers shaping the future of industrial fastening solutions.

Top 9 Rectangular Nuts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 NEFCO

Domain Est. 1999

Website: gonefco.com

Key Highlights: Approved Manufacturer · 3/8-16 Hex Finish Nut Grade-2 Zinc Plated Package 100/Bx. SKU: 37CHFN2Z/P100. NEFCO ID: 27836. Log In for Pricing and Availability….

#2 McMaster

Domain Est. 1994

Website: mcmaster.com

Key Highlights: McMaster-Carr is the complete source for your plant with over 700000 products. 98% of products ordered ship from stock and deliver same or next day….

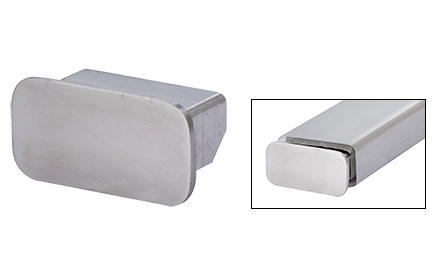

#3 CRL

Domain Est. 1995

Website: crlaurence.com

Key Highlights: The leading full-service provider of architectural metals, glass fittings & professional-grade glazing supplies. Shop CRL’s architectural hardware today….

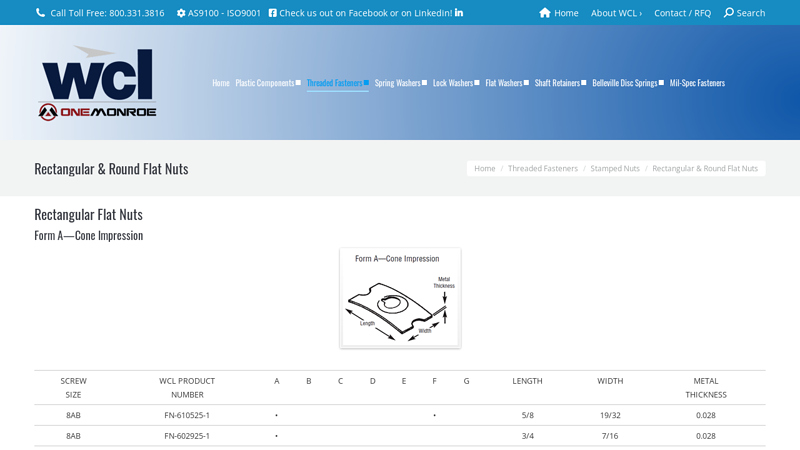

#4 Rectangular & Round Flat Nuts

Domain Est. 1997

Website: wclco.com

Key Highlights: Rectangular & Round Flat Nuts · Rectangular Flat Nuts · Round Flat Nuts. Form A—Twin Prong Impression. SCREW SIZE. WCL PRODUCT NUMBER. A. B. C. D. E. F. G….

#5 Bühler Group

Domain Est. 2000

Website: buhlergroup.com

Key Highlights: We strive to create innovations for a better world, with a special focus on healthy, safe, and sustainable solutions….

#6 Nuts

Domain Est. 2002

Website: lisi-automotive.com

Key Highlights: We offer a broad range of automotive-grade, standard and custom-engineered nuts to meet our customers’ most stringent requirements….

#7 Rectangular & Square Nuts – Nuts

Domain Est. 2007

#8 Rectangular nuts

Domain Est. 2012

Website: voehrs-fasteners.com

Key Highlights: We have rectangular nuts, also called sliding nuts, in numerous versions and with different surface coatings. Thread sizes of M2,5 to M12 (1/8″ to 5/16″)….

#9 m5 rectangular nuts with threaded hole online manufacture

Domain Est. 2020

Website: steelnutbolts.com

Key Highlights: m5 rectangular nuts with threaded hole online manufacture · Rectangular Nut 4.8 Plain M5 M6 Non Standard Fasteners · Steel Nut Bolts · Steel Hex Bolt · Carbon Steel ……

Expert Sourcing Insights for Rectangular Nuts

H2: 2026 Market Trends for Rectangular Nuts

The rectangular nuts market in 2026 is poised for steady growth, driven by advancements in key end-use industries and a heightened focus on precision engineering. These specialized fasteners—characterized by their non-round, typically rectangular cross-section—offer distinct advantages in applications requiring alignment, anti-rotation, and high torque transmission. Here are the key trends shaping the market in 2026:

-

Growth in Automotive Electrification and Lightweighting: The rapid expansion of electric vehicle (EV) production is a major driver. Rectangular nuts are increasingly used in EV battery packs, powertrain components, and chassis systems where secure, vibration-resistant fastening is critical. Their ability to prevent rotation without additional locking mechanisms reduces part count and supports lightweighting goals—key priorities in EV design.

-

Adoption in Advanced Manufacturing and Automation: As industries adopt Industry 4.0 principles, the demand for reliable, repeatable fastening solutions rises. Rectangular nuts are favored in automated assembly lines due to their ease of orientation and consistent performance. In robotics and automated machinery, they provide stable mounting points and resist loosening under dynamic loads.

-

Expansion in Renewable Energy Infrastructure: Solar panel mounting systems and wind turbine assemblies increasingly utilize rectangular nuts for their durability and resistance to environmental stress. The push for global renewable energy capacity in 2026 fuels demand, particularly in large-scale installations where long-term reliability and maintenance reduction are essential.

-

Material and Coating Innovations: To meet stringent performance and corrosion resistance requirements, manufacturers are investing in advanced materials such as high-strength alloy steels, stainless steel grades (e.g., A4-80), and non-ferrous options. Enhanced coatings like zinc-nickel, Geomet, and Dacromet are becoming standard, especially in automotive and marine applications.

-

Regional Market Shifts and Supply Chain Localization: Asia-Pacific remains the largest market due to robust manufacturing activity in China, India, and Southeast Asia. However, nearshoring and supply chain resilience initiatives in North America and Europe are boosting regional production. This trend encourages local sourcing of precision fasteners, including rectangular nuts, to mitigate logistics risks.

-

Increased Customization and Design Integration: OEMs are demanding more customized rectangular nut solutions tailored to specific applications. This includes variations in dimensions, threading, and integration with other components (e.g., weld nuts, flanged designs). Digital design tools and rapid prototyping support this trend, enabling faster time-to-market.

-

Sustainability and Circular Economy Pressures: Environmental regulations are pushing manufacturers toward recyclable materials and energy-efficient production processes. Companies offering eco-friendly fastening solutions—such as nuts made from recycled steel or with low-impact coatings—are gaining a competitive edge.

In summary, the 2026 rectangular nuts market is characterized by technological adaptation, industry-specific tailoring, and sustainability integration. As critical components in high-performance sectors—from EVs to renewable energy—their strategic importance continues to rise, ensuring sustained demand and innovation.

Common Pitfalls When Sourcing Rectangular Nuts (Quality, IP)

Sourcing rectangular nuts—especially for high-precision or mission-critical applications—can involve several quality and intellectual property (IP) challenges. Being aware of these pitfalls helps mitigate risks and ensures long-term supply chain reliability.

Poor Material Quality and Non-Compliance

One of the most frequent issues is the use of substandard materials. Suppliers may use inferior grades of steel, stainless steel, or alloys that do not meet specified mechanical or chemical requirements (e.g., ASTM, ISO, or DIN standards). This can lead to premature failure, corrosion, or dimensional instability under load.

Inconsistent Dimensional Accuracy

Rectangular nuts often have tight tolerance requirements, especially when used in linear motion systems or custom machinery. Poor manufacturing processes can result in inconsistent slot widths, thread misalignment, or variations in overall geometry, leading to fitment issues or reduced performance.

Inadequate Surface Treatments and Corrosion Resistance

Improper or omitted surface treatments—such as zinc plating, black oxide, or passivation—can compromise corrosion resistance. Some suppliers may cut corners to reduce cost, leaving the nuts vulnerable to rust or degradation in demanding environments.

Counterfeit or Non-Certified Products

In global supply chains, there’s a risk of receiving counterfeit parts that mimic branded or proprietary designs. These copies often lack proper testing, certification, or traceability, making it difficult to ensure reliability or compliance with industry standards.

Intellectual Property Infringement

Rectangular nuts, particularly those designed for specific systems (e.g., machine tool ways, automation rails), may be protected by patents or design rights. Sourcing generic versions from unauthorized manufacturers can lead to IP violations, legal liability, and supply chain disruptions if enforcement actions occur.

Lack of Traceability and Documentation

Reputable suppliers provide material test reports (MTRs), certificates of conformance (CoC), and full traceability. Many low-cost suppliers fail to supply this documentation, making it difficult to verify quality or meet regulatory requirements in industries like aerospace, medical, or automotive.

Hidden Tooling and Design Copying

When working with contract manufacturers, especially overseas, there’s a risk that your proprietary nut design or tooling may be copied and sold to competitors. Insufficient legal protections or weak IP clauses in manufacturing agreements increase this exposure.

Overlooking Long-Term Supplier Reliability

Focusing only on initial pricing can lead to partnerships with suppliers who lack the capacity, quality systems, or financial stability to support long-term production. This creates risk for future supply continuity and consistent quality.

By addressing these pitfalls through rigorous supplier vetting, quality audits, clear IP agreements, and ongoing compliance checks, buyers can ensure they source rectangular nuts that meet both performance and legal requirements.

Logistics & Compliance Guide for Rectangular Nuts

Product Overview

Rectangular nuts, also known as square nuts or block nuts, are fasteners with a four-sided, non-circular cross-section. They are commonly used in applications requiring high torque resistance and where rotation must be minimized, such as in automotive, construction, and industrial machinery. Their rectangular shape allows for better grip in confined spaces and compatibility with specialized tools and channels.

Packaging Requirements

- Material: Use moisture-resistant, durable packaging such as corrugated cardboard, shrink-wrapped bundles, or plastic-lined containers to prevent corrosion.

- Unitization: Bulk shipments should be palletized with edge protectors and stretch-wrapped for stability. Individual packages must be clearly labeled with product specifications.

- Interior Protection: Include desiccants in sealed containers if shipping to humid environments to prevent oxidation.

Storage Conditions

- Environment: Store in a dry, temperature-controlled area (15–25°C) with relative humidity below 60% to minimize rust and degradation.

- Handling: Keep off concrete floors using pallets or shelving to avoid moisture absorption.

- Segregation: Separate different grades, materials (e.g., stainless steel, carbon steel), and finishes to prevent cross-contamination and ensure traceability.

Transportation Guidelines

- Domestic Shipping: Comply with carrier-specific regulations (e.g., UPS, FedEx, or freight carriers) for weight, dimension, and labeling. Use DOT-compliant packaging for hazardous material classifications, if applicable (e.g., coated with oil).

- International Shipping:

- Ensure packages meet ISPM-15 standards if using wooden pallets (heat-treated and stamped).

- Use Incoterms® clearly defined in contracts (e.g., FOB, CIF) to allocate responsibility.

- Prepare commercial invoices, packing lists, and certificates of origin for customs clearance.

Regulatory Compliance

- Material Standards: Rectangular nuts must conform to recognized industry standards such as:

- ISO 888 (clearance for tapped holes)

- DIN 557 or ANSI/ASME B18.2.2 (dimensions and tolerances)

- ASTM A194 (for high-pressure/high-temperature service, if applicable)

- RoHS & REACH: Ensure compliance if exporting to the EU; verify restricted substances (e.g., lead, cadmium) are within permissible limits.

- Conflict Minerals: Adhere to Section 1502 of the Dodd-Frank Act if sourcing materials from covered regions (e.g., tantalum, tungsten).

Labeling and Documentation

- Packaging Labels: Each unit must display:

- Part number and description

- Material grade (e.g., Grade 8.8, A2-70)

- Quantity per package

- Manufacturer or supplier name

- Lot or batch number for traceability

- Shipping Documents: Include safety data sheets (SDS) if applicable, export declarations, and compliance certificates (e.g., ISO 9001, material test reports).

Import/Export Considerations

- Tariff Classification: Classify under HS Code 7318.15 (other nuts, steel) or country-specific equivalents. Verify current duty rates with local customs authorities.

- Export Controls: Check if nuts fall under dual-use or strategic trade regulations (e.g., Wassenaar Arrangement), especially if intended for military or aerospace use.

- Country-Specific Rules: Some countries require additional certifications (e.g., GOST for Russia, INMETRO for Brazil).

Quality Assurance & Traceability

- Implement lot traceability systems to track raw materials, production batches, and distribution.

- Conduct periodic inspections for dimensional accuracy, thread integrity, and surface finish per ISO 2692 or equivalent.

- Maintain records for at least 5–10 years depending on industry and jurisdiction.

Environmental and Safety Considerations

- Waste Handling: Recycle scrap metal in accordance with local environmental regulations (e.g., EPA in the U.S., WEEE in the EU).

- Worker Safety: Follow OSHA or equivalent guidelines for handling sharp or heavy hardware; provide appropriate PPE during packing and transport.

Conclusion

Proper logistics and compliance management for rectangular nuts ensures product integrity, regulatory adherence, and customer satisfaction. By following standardized packaging, storage, transportation, and documentation practices, manufacturers and distributors can mitigate risks and facilitate smooth global trade operations.

Conclusion for Sourcing Rectangular Nuts:

Sourcing rectangular nuts requires a strategic approach that balances quality, cost, availability, and compatibility with specific application requirements. These specialized fasteners are essential in applications where resistance to rotation and secure anchoring in slots or channels are critical, such as in automotive, aerospace, machinery, and construction industries. When sourcing rectangular nuts, it is important to consider material specifications (e.g., steel, stainless steel, aluminum), plating or coating for corrosion resistance, load-bearing capacity, and compliance with industry standards (e.g., DIN, ISO, or custom specifications).

Establishing relationships with reliable suppliers—whether domestic or international—ensures consistent quality and on-time delivery. Additionally, evaluating total cost of ownership, including shipping, lead times, and potential inventory needs, contributes to a more efficient supply chain. Advances in manufacturing technologies and increasing global supplier competition offer opportunities for cost savings and improved customization options.

In conclusion, successful sourcing of rectangular nuts involves a thorough understanding of technical requirements, rigorous supplier assessment, and continuous supply chain optimization to support product reliability and operational efficiency.