The global power tools market, propelled by rising demand in construction, manufacturing, and metalworking industries, is experiencing robust growth. According to Grand View Research, the global power tools market size was valued at USD 41.2 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. A key driver within this segment is the increasing need for high-performance cutting tools capable of handling tough materials like metal, where precision, durability, and efficiency are paramount. Reciprocating saws, in particular, have become indispensable in metal fabrication due to their versatility in demolition, repair, and industrial cutting applications. As manufacturing operations demand more reliable and powerful solutions, leading tool manufacturers are innovating with advanced motor technologies, enhanced blade systems, and ergonomic designs tailored for metal cutting. In this competitive landscape, selecting the right reciprocating saw can significantly impact productivity and operational cost-efficiency. Based on performance metrics, user reviews, and technical specifications, the following nine manufacturers stand out for delivering top-tier reciprocating saws engineered specifically for metalworking applications.

Top 9 Reciprocating Saw For Metal Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Reciprocating Saws

Domain Est. 1996

Website: skil.com

Key Highlights: SKIL reciprocating saws are must-have, multi-purpose powerhouses for cutting through wood, fiberglass, plaster, drywall, and more….

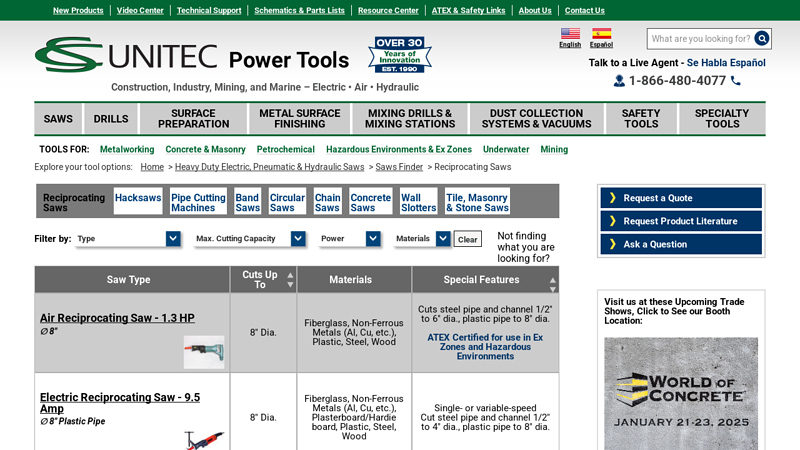

#2 Reciprocating Saws

Domain Est. 1997

Website: csunitec.com

Key Highlights: Special Features: Marine, mining, utility and construction applications. Cut pipe up to 6″ dia., wood up to 8″ dia., metal plate up to 3/4″ dia….

#3 Reciprocating Saw

Domain Est. 1997

Website: greenlee.com

Key Highlights: Shop now! Greenlee power tool accessories, hole-making tools, reciprocating saw blades & more. For the professional electrician….

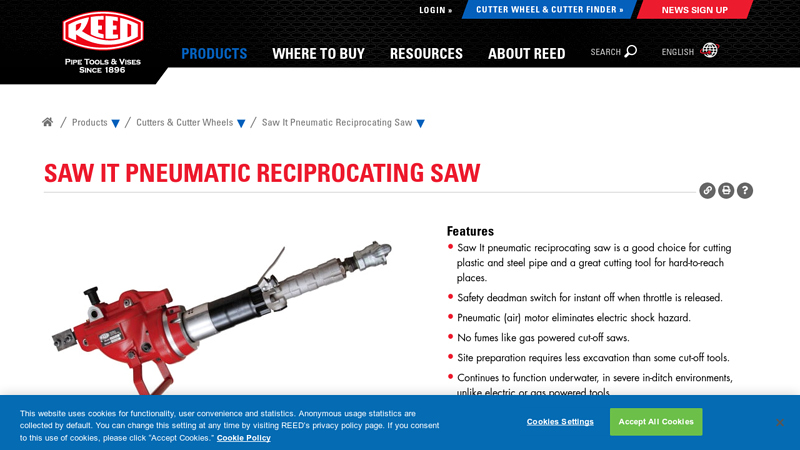

#4 Saw It Pneumatic Reciprocating Saw

Domain Est. 1997

Website: reedmfgco.com

Key Highlights: Features. Saw It pneumatic reciprocating saw is a good choice for cutting plastic and steel pipe and a great cutting tool for hard-to-reach places….

#5 Reciprocating saw blades

Domain Est. 1997

Website: metabo.com

Key Highlights: Reciprocating saw blades from Metabo – High-quality, reliable and long-lasting. Learn about professional power tools from Metabo now….

#6 SHOP Reciprocating Saw Blades Sets

Domain Est. 1998

Website: starrett.com

Key Highlights: 15-day returnsMetal-cutting Reciprocating Saw Blades. Tough, long-lasting and fast cutting Starrett reciprocating saw blades offer market-leading performance….

#7 Reciprocating Saws

Domain Est. 2000

Website: store.evolutionpowertools.com

Key Highlights: Free delivery · Free 45-day returns…

#8 Reciprocating Blade Long

Domain Est. 2012

#9 LENOX®

Domain Est. 2017

Website: cutwithlenox.com

Key Highlights: Eat metal for breakfast with the new LENOX® hole saw and reciprocating saw blades. Now available at a retailer near you….

Expert Sourcing Insights for Reciprocating Saw For Metal

H2: 2026 Market Trends for Reciprocating Saw for Metal

The global market for reciprocating saws designed specifically for metal cutting is poised for significant transformation by 2026, driven by technological advancements, rising industrial demand, and a growing emphasis on precision and efficiency. Key trends shaping the landscape include:

-

Increased Adoption of Cordless and Lithium-Ion Powered Models

By 2026, cordless reciprocating saws are expected to dominate the metal-cutting segment due to advancements in battery technology. Lithium-ion batteries now offer longer run times, faster charging, and improved power delivery—critical for metal cutting applications. Professionals in construction, demolition, and metal fabrication increasingly favor cordless models for their portability and performance, reducing reliance on corded tools. -

Integration of Smart Technology and IoT Features

Leading manufacturers are incorporating smart sensors and connectivity features into reciprocating saws. By 2026, expect models with real-time performance monitoring, tool health diagnostics, and usage analytics via Bluetooth or Wi-Fi. These features enhance maintenance predictability and optimize tool life, especially in high-intensity industrial environments. -

Demand for High-Performance Blades and Material-Specific Optimization

There is a rising trend toward specialized blades engineered for cutting various metals, including steel, aluminum, and stainless steel. Carbide-tipped and bi-metal blades with enhanced heat resistance and durability are becoming standard. Saw designs are increasingly optimized to accommodate these advanced blade types, improving cut quality and speed. -

Growth in Industrial and Infrastructure Sectors

Expanding infrastructure projects in North America, Europe, and Asia-Pacific are driving demand for metal-cutting tools. The construction of renewable energy facilities, transportation systems, and industrial plants requires robust cutting solutions, positioning reciprocating saws as essential equipment in metal fabrication and demolition workflows. -

Focus on Ergonomics and Operator Safety

Ongoing improvements in tool design prioritize user comfort and safety. Anti-vibration technology, soft-grip handles, and improved weight distribution reduce operator fatigue during prolonged use. In 2026, compliance with stringent global safety standards (such as ISO and ANSI) will be a key differentiator among brands. -

Sustainability and Energy Efficiency

Environmental regulations and corporate sustainability goals are prompting manufacturers to design energy-efficient tools with recyclable components. Lightweight materials and energy-saving motor technologies are expected to become standard, aligning with broader green manufacturing initiatives. -

Regional Market Expansion and Competitive Dynamics

Emerging markets in Southeast Asia, Latin America, and Africa are witnessing increased adoption of power tools due to urbanization and industrialization. This growth is attracting investments from global players and fostering competition, which will drive innovation and affordability in the reciprocating saw market.

In conclusion, the 2026 outlook for reciprocating saws for metal is marked by technological innovation, evolving user needs, and expanding applications across industries. Companies that invest in R&D, sustainability, and user-centric design are likely to gain a competitive edge in this dynamic market.

Common Pitfalls When Sourcing a Reciprocating Saw for Metal (Quality and IP Considerations)

Sourcing a reciprocating saw specifically designed for metal cutting involves several critical factors related to quality and intellectual property (IP). Overlooking these can lead to performance issues, safety hazards, or legal complications. Below are common pitfalls to avoid:

Poor Build Quality and Durability

Many low-cost reciprocating saws marketed for metal cutting lack the robust construction needed to withstand continuous heavy-duty use. Inferior materials in the gearbox, motor housing, or blade clamp can lead to premature failure, especially under high torque and vibration. Always verify the saw’s duty cycle, motor type (brushed vs. brushless), and component materials before purchase.

Inadequate Motor Power and Stroke Performance

A common mistake is selecting a saw with insufficient power (measured in amps or watts) or stroke rate (SPM – strokes per minute) for metal applications. Underpowered motors bog down when cutting through steel or pipes, reducing efficiency and increasing blade wear. Ensure the motor delivers consistent power across various thicknesses and types of metal.

Substandard Blade Compatibility and Quality

Some budget saws use proprietary blade systems or low-quality clamps that limit blade choice and reduce cutting precision. Poor blade retention can cause slippage during operation, creating safety risks. Additionally, sourcing compatible high-performance bi-metal or carbide-tipped blades may be difficult or expensive if the saw uses non-standard fittings.

Lack of Overheating Protection

Cutting metal generates significant heat, and saws without proper thermal protection or efficient cooling systems are prone to motor burnout. Look for models with built-in thermal overload protection and adequate ventilation to ensure sustained operation.

Misleading IP (Ingress Protection) Ratings

Some suppliers falsely advertise high IP ratings (e.g., IP54 or IP65) without independent certification. An inaccurate IP rating can mislead buyers into believing the tool is dustproof or water-resistant when it is not. This is especially problematic in harsh job site environments. Always request documentation or certification from a recognized testing body to verify the IP claim.

Intellectual Property Infringement Risks

Sourcing from unverified manufacturers, especially in regions with lax IP enforcement, increases the risk of purchasing counterfeit or cloned tools. These products may mimic well-known brands in design and performance claims but lack safety certifications and reliability. Using such tools can expose businesses to legal liability, warranty issues, and reputational damage.

Absence of Safety and Compliance Certifications

Reputable reciprocating saws should carry safety certifications such as CE, UL, or ETL. Tools lacking these may not meet minimum electrical or mechanical safety standards, posing risks to users. Always validate certifications and avoid suppliers who cannot provide compliance documentation.

By carefully evaluating build quality, performance specs, blade compatibility, accurate IP ratings, and IP compliance, buyers can avoid costly mistakes and ensure they source a reliable, safe, and legally compliant reciprocating saw for metal cutting applications.

Logistics & Compliance Guide for Reciprocating Saw For Metal

This guide outlines the essential logistics and compliance considerations for the international shipment, distribution, and use of reciprocating saws designed for metal cutting. Proper handling ensures adherence to regulatory standards, safety, and efficient supply chain operations.

1. Product Classification & HS Code

Reciprocating saws for metal are typically classified under the Harmonized System (HS) for customs purposes. The recommended HS code is:

- 8467.21.00 – Electric circular saws, chain saws, and other electric saws; reciprocating saws (e.g., jigsaws, sabre saws), powered by an electric motor.

Note: Confirm the exact HS code with local customs authorities, as classifications may vary by country and specific product features (e.g., motor type, voltage, or intended industrial use).

2. Import/Export Regulations

- Export Controls: Reciprocating saws generally do not fall under strict export control regimes (e.g., ITAR or EAR), but verify if the product contains dual-use technologies or components subject to national regulations.

- Import Duties & Taxes: Duties vary by destination country. Consult local tariff schedules to determine applicable rates and any preferential treatment under trade agreements.

- Documentation Required:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (if claiming preferential tariffs)

- Import License (if required by the destination country)

3. Packaging & Labeling Requirements

- Packaging: Use robust, corrugated cardboard with internal cushioning to protect the saw and accessories during transit. Ensure compliance with ISTA or ISO shipping standards where applicable.

- Labeling:

- Product name and model number

- Manufacturer name and address

- Voltage, frequency, and power rating (e.g., 120V ~ 60Hz, 1200W)

- Safety warnings in the local language(s) of the destination market

- CE, UKCA, FCC, or other applicable conformity marks

- Battery labeling (if cordless): UN38.3 certification for lithium-ion batteries

4. Safety & Regulatory Compliance

- CE Marking (EU): Comply with the Machinery Directive (2006/42/EC) and Low Voltage Directive (2014/35/EU). Include a Declaration of Conformity (DoC).

- UKCA Marking (UK): Required for products sold in Great Britain; conform to UK supply of machinery regulations.

- FCC Compliance (USA): If the saw includes electronic components that may emit radio frequency interference, FCC Part 15 compliance may be required.

- UL/CSA Certification (North America): Recommended for safety certification. UL 174 or CSA C22.2 No. 68 may apply.

- RoHS & REACH (EU): Ensure the product is free from restricted hazardous substances (e.g., lead, cadmium, phthalates).

5. Battery & Motor Compliance (if applicable)

- Lithium-Ion Batteries:

- Must comply with IEC 62133

- Packaged per UN Recommendations on the Transport of Dangerous Goods (UN 3480 or UN 3481)

- Accompanied by a Material Safety Data Sheet (MSDS/SDS)

- Labeled with Class 9 hazardous material labels when shipped separately

6. Transportation & Logistics

- Mode of Transport: Suitable for air, sea, or ground freight. Air transport of lithium-ion batteries may require special handling and documentation.

- Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, CIF, DDP).

- Temperature & Humidity Control: Store and transport in dry, temperate conditions to prevent damage to electrical components.

- Stacking & Weight Limits: Adhere to pallet weight and stacking guidelines to prevent damage during warehousing and shipping.

7. Warranty & After-Sales Compliance

- Provide multilingual user manuals and safety instructions.

- Include warranty information compliant with local consumer protection laws (e.g., 2-year warranty in the EU).

- Establish a process for handling product recalls or non-compliance issues.

8. Environmental & Disposal Regulations

- Comply with WEEE (Waste Electrical and Electronic Equipment) Directive in the EU for end-of-life take-back and recycling.

- Inform distributors and end-users about proper disposal procedures and recycling options.

9. Country-Specific Considerations

- USA: Comply with OSHA and ANSI safety standards for power tools.

- Canada: Meet requirements of the Canadian Electrical Code and require CSA or cULus certification.

- Australia/NZ: Must meet AS/NZS 61037.1 for hand-held motor-operated tools.

- China: Requires CCC (China Compulsory Certification) for certain electric tools.

Conclusion

Proper logistics planning and regulatory compliance are critical for the successful global distribution of reciprocating saws for metal. Always verify regional requirements and maintain accurate documentation to ensure smooth customs clearance and market access.

Conclusion: Sourcing a Reciprocating Saw for Metal Cutting

In conclusion, sourcing a reciprocating saw specifically designed for metal cutting requires careful consideration of power, blade compatibility, durability, and intended application. Industrial-grade models with high strokes-per-minute (SPM), variable speed controls, and robust motors—whether corded for continuous use or cordless for portability—are essential for effectively cutting through metal materials such as steel, aluminum, or piping. Compatibility with carbide- or bi-metal blades ensures clean, efficient cuts and extended tool life.

Additionally, ergonomic design, brand reliability, warranty, and availability of service support should factor into the purchasing decision, especially for professional or high-volume use. After evaluating product specifications, user reviews, and supplier credibility, it is recommended to source from reputable manufacturers or authorized distributors to ensure quality, safety compliance, and access to technical support.

Ultimately, selecting the right reciprocating saw for metal applications enhances productivity, reduces downtime, and ensures long-term cost efficiency in construction, demolition, or metal fabrication environments.