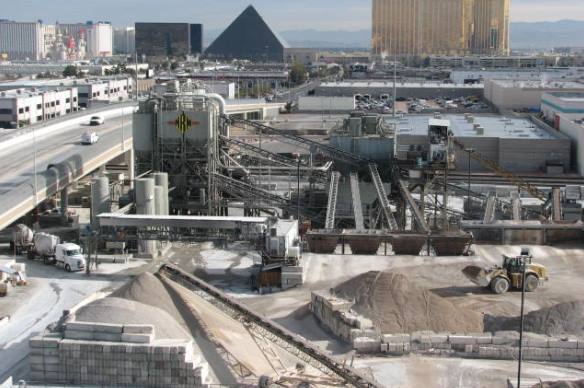

The ready mix concrete market in the United States is experiencing steady growth, driven by increasing infrastructure investment and a surge in residential and commercial construction activity. According to Grand View Research, the U.S. ready mix concrete market size was valued at USD 44.2 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is further amplified in high-construction-demand regions like Las Vegas, Nevada—where rapid urbanization, tourism-driven developments, and large-scale projects such as Allegiant Stadium and the Las Vegas Convention Center District expansion have significantly boosted demand for high-quality, reliable ready mix concrete. Nevada’s construction sector, particularly in Clark County, has seen a 6.4% year-over-year increase in building permits through mid-2023 (U.S. Census Bureau), underscoring the need for scalable and efficient concrete supply. As sustainability and fast project timelines become critical, manufacturers in the Las Vegas area are leveraging centralized batching plants, advanced logistics, and low-carbon mix designs to meet stringent delivery and performance standards. In this competitive environment, the top nine ready mix concrete manufacturers in Las Vegas have distinguished themselves through production capacity, geographic coverage, and innovation in mix technology.

Top 9 Ready Mix Concrete Las Vegas Nevada Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 National Ready Mixed Concrete Association

Domain Est. 1996

Website: nrmca.org

Key Highlights: Find an NRMCA Producer. The National Ready Mixed Concrete Association supports the continued expansion and improvement of the ready mixed concrete industry ……

#2 CalPortland Executive Office

Domain Est. 1997

Website: calportland.com

Key Highlights: CalPortland Company is a major producer of cement, ready mixed concrete, aggregates, concrete products and asphalt in the western United States and Canada….

#3 Mobile Materials Las Vegas

Domain Est. 2018

Website: mobilematerialsmix.com

Key Highlights: We offer over 55 years of experience in the ready – mix industry, and now provide the amazing technology of our volumetric mixer trucks to the Las Vegas market….

#4 Leading Supplier of Concrete & Building Materials

Domain Est. 1996

Website: cemexusa.com

Key Highlights: Ready-Mix Concrete. We provide custom concrete solutions designed to meet your project’s unique requirements, combining the right blend of cement, aggregates ……

#5 Nevada Ready Mix

Domain Est. 2000

Website: nevadareadymix.com

Key Highlights: Highest quality concrete for residential foundations, public works, golf courses, and heavy highway projects….

#6 Sierra Ready Mix

Domain Est. 2000

Website: sierrareadymix.com

Key Highlights: Sierra Ready Mix has been a concrete supplier in the Las Vegas Valley for over 20 years. Our top priority is supplying quality ready mix products and personal ……

#7 Desert Ready Mix

Domain Est. 2014

Website: desertrm.com

Key Highlights: Locally Owned and Operated Concrete Ready Mix Supplier….

#8 Las Vegas Ready Mix

Domain Est. 2016

Website: lasvegasreadymix.com

Key Highlights: Las Vegas Ready mix is a U.S National Ready Mix concrete supply company. Concrete delivery in Las Vegas and surrounding areas. We do concrete delivery from 1…

#9 American Eagle Ready Mix

Domain Est. 2019

Website: aermlv.com

Key Highlights: Delivery of ready mix concrete throughout the Las Vegas valley and surrounding areas. Trusted For Nearly A Decade. The Only Locally And American. Owned And ……

Expert Sourcing Insights for Ready Mix Concrete Las Vegas Nevada

H2: 2026 Market Trends for Ready Mix Concrete in Las Vegas, Nevada

The ready mix concrete market in Las Vegas, Nevada, is poised for significant evolution by 2026, driven by a confluence of infrastructure development, population growth, regulatory changes, and technological innovation. As one of the fastest-growing metropolitan areas in the United States, Las Vegas presents a dynamic landscape for construction materials, with ready mix concrete at the core of both commercial and residential projects.

-

Construction Boom and Population Growth

Las Vegas continues to experience robust population growth, with Clark County projected to add hundreds of thousands of residents over the next decade. This demographic expansion drives demand for housing, commercial developments, and public infrastructure—all of which require substantial volumes of ready mix concrete. By 2026, increased residential construction—especially in master-planned communities on the city’s outskirts—and the expansion of hospitality and entertainment complexes on and near the Strip will sustain strong demand for concrete. -

Infrastructure Modernization and Public Investment

State and federal infrastructure funding, including allocations from the Bipartisan Infrastructure Law, is expected to significantly impact the Las Vegas market. Key projects such as the expansion of the I-11 corridor, improvements to the Las Vegas Convention Center Loop, and upgrades to water and wastewater systems will require large-scale concrete supply. These public works initiatives are anticipated to boost ready mix concrete consumption through 2026. -

Sustainability and Green Building Regulations

Environmental regulations and sustainability goals are reshaping concrete production in Nevada. By 2026, stricter emissions standards and incentives for low-carbon construction materials are likely to push suppliers toward greener alternatives. Ready mix producers are increasingly adopting supplementary cementitious materials (SCMs) like fly ash and slag, as well as carbon capture technologies, to reduce the carbon footprint of concrete. LEED certification requirements for new buildings in Las Vegas will further encourage sustainable concrete practices. -

Technological Advancements in Production and Delivery

The integration of smart technologies—such as real-time tracking of concrete trucks, automated batching systems, and AI-driven quality control—is expected to improve efficiency and reduce waste in the ready mix supply chain. By 2026, leading suppliers in Las Vegas are likely to utilize IoT-enabled sensors to monitor concrete slump, temperature, and curing conditions, ensuring higher quality and compliance with project specifications. -

Labor and Supply Chain Challenges

Despite growth, the industry faces potential headwinds. Ongoing labor shortages in skilled trades and transportation could constrain delivery capacity. Additionally, volatility in raw material prices—especially cement and aggregates—may affect profit margins. Proactive supply chain management and investment in local aggregate sources will be critical for maintaining competitiveness. -

Consolidation and Market Competition

The ready mix concrete market in Las Vegas is expected to see increased consolidation by 2026, as larger national players acquire regional suppliers to gain market share and achieve economies of scale. This could lead to improved service capabilities but may also reduce competition, potentially impacting pricing dynamics. -

Resilience to Economic Cycles

While the Las Vegas economy remains sensitive to tourism and discretionary spending, the diversification into technology, logistics, and healthcare sectors is helping stabilize long-term construction demand. This economic diversification supports a more resilient ready mix concrete market, less vulnerable to downturns in the hospitality industry.

In conclusion, the 2026 outlook for ready mix concrete in Las Vegas is predominantly positive, characterized by strong demand, innovation, and sustainability efforts. However, success will depend on the industry’s ability to adapt to regulatory changes, manage supply chain risks, and embrace technological transformation.

Common Pitfalls When Sourcing Ready Mix Concrete in Las Vegas, Nevada

Sourcing ready mix concrete in Las Vegas, Nevada, presents unique challenges due to the region’s extreme climate, high construction demand, and varying supplier standards. While ready mix concrete offers convenience and consistency, several pitfalls can compromise project quality and intellectual property (IP) protection if not properly managed. Below are key issues to watch for:

Inconsistent Quality Due to Environmental Conditions

Las Vegas experiences extreme temperature fluctuations, with summer highs often exceeding 110°F. These conditions can accelerate concrete setting times and increase the risk of cracking if mix designs aren’t adjusted accordingly. Some suppliers may use generic mix formulations not tailored to desert climates, leading to premature failure, reduced strength, or poor workability. Always verify that the supplier modifies water-cement ratios and uses appropriate admixtures (e.g., retarders, hydration stabilizers) for hot weather.

Lack of Compliance with Local Codes and Standards

Not all ready mix providers in the Las Vegas area adhere strictly to Nevada Department of Transportation (NDOT) or local building codes. Using non-compliant concrete can result in failed inspections, costly rework, or liability issues. Ensure the supplier provides certified test reports (e.g., compressive strength, slump tests) and meets ASTM and ACI standards relevant to your project type.

Poor Delivery and Scheduling Reliability

High demand during peak construction seasons can strain ready mix suppliers’ logistics. Late or inconsistent deliveries disrupt pour schedules, create cold joints, and degrade concrete quality. Confirm the supplier has a strong dispatch system, backup fleet capacity, and experience managing large-scale jobs in the Las Vegas Valley.

Inadequate Technical Support and Mix Design Collaboration

Some suppliers offer limited engineering support, providing only standard mixes without optimization for specific structural or aesthetic needs. This can be a problem for specialized applications like colored concrete, high-strength mixes, or architectural finishes. Choose a supplier that collaborates on mix design and offers technical guidance tailored to your project’s specifications.

Intellectual Property Risks with Custom Mix Designs

If your project involves proprietary or custom concrete formulations (e.g., for unique durability, sustainability, or appearance), there is a risk of IP exposure when working with third-party suppliers. Without proper contracts, a supplier could reuse or disclose your mix design. Always use confidentiality agreements (NDAs) and clearly define IP ownership in procurement contracts.

Hidden Costs and Opaque Pricing Structures

Pricing for ready mix concrete in Las Vegas can vary significantly based on mix complexity, delivery distance, and wait times. Some suppliers include hidden fees for overtime, short loads, or weekend pours. Request detailed, written quotes that outline all potential charges to avoid budget overruns.

Limited Sustainability and Environmental Accountability

With growing emphasis on green building, some developers seek low-carbon or recycled-content concrete. However, not all Las Vegas suppliers offer sustainable options or can provide environmental product declarations (EPDs). Confirm the supplier’s sustainability practices if LEED or similar certifications are project goals.

By being aware of these pitfalls and conducting due diligence in supplier selection, contractors and developers can ensure high-quality concrete delivery while protecting project timelines, budgets, and intellectual property in the Las Vegas market.

Logistics & Compliance Guide for Ready Mix Concrete in Las Vegas, Nevada

Overview of the Ready Mix Concrete Industry in Las Vegas

Las Vegas, Nevada, experiences consistent construction activity due to population growth, tourism infrastructure, and commercial development, making ready mix concrete a critical component of the building supply chain. Efficient logistics and strict compliance with local, state, and federal regulations are essential for timely delivery, project success, and legal operation.

Regulatory Compliance Requirements

Nevada Department of Environmental Protection (NDEP) Regulations

All ready mix concrete producers and haulers in Nevada must comply with NDEP air quality and water pollution control standards. Key requirements include:

- Stormwater Pollution Prevention Plan (SWPPP): Facilities must implement and maintain an SWPPP to prevent runoff contamination from washout water and raw materials.

- Air Quality Permits: Operations with dust-generating activities (e.g., batching, aggregate handling) may require air quality permits, particularly under the National Emissions Standards for Hazardous Air Pollutants (NESHAP).

- Washout Management: Concrete washout water must be properly contained and treated to prevent environmental contamination. Reuse or recycling of washout is encouraged.

Clark County and City of Las Vegas Local Ordinances

- Noise and Dust Control: Local ordinances may impose restrictions on operating hours and require dust suppression measures, especially in residential zones.

- Zoning Permits: Batching plants must be located in appropriately zoned areas, often requiring conditional use permits.

- Vehicle Route Restrictions: Certain roads or neighborhoods may restrict heavy vehicle access during peak hours.

Occupational Safety and Health Administration (OSHA) Standards

- Hazard Communication: Employees must be trained on handling cement and admixtures, which can be caustic or hazardous.

- Personal Protective Equipment (PPE): Mandatory use of gloves, goggles, and respiratory protection where needed.

- Vehicle Safety: Drivers must follow OSHA and Department of Transportation (DOT) standards for commercial vehicle operation.

Transportation and Delivery Logistics

Vehicle Fleet Requirements

- DOT Compliance: All ready mix trucks must be registered with the Federal Motor Carrier Safety Administration (FMCSA), carry proper insurance, and undergo regular inspections.

- Hours of Service (HOS): Drivers must adhere to federal HOS rules, including 11-hour driving limit and mandatory rest periods.

- Weight Restrictions: Nevada enforces legal weight limits (typically 80,000 lbs. gross vehicle weight); overloaded trucks are subject to fines.

Route Planning and Traffic Considerations

- High-Traffic Areas: Las Vegas Strip and downtown areas often have congestion and delivery restrictions. Pre-planning with GPS and real-time traffic apps is essential.

- Permitting for Oversized Loads: If delivering specialty mixes requiring non-standard equipment, special permits may be required.

- Job Site Access: Confirm site access, turning radius, and overhead clearance before dispatch.

Dispatch and Scheduling Best Practices

- Real-Time Tracking: Use GPS-enabled fleet management software to monitor deliveries and respond to delays.

- Batch Plant Coordination: Maintain close communication between dispatchers, batch plant operators, and drivers to avoid over-batching or mix slump loss.

- Delivery Time Windows: Adhere strictly to construction site schedules, especially for large pours requiring multiple trucks.

Environmental and Sustainability Practices

Water Conservation

- Las Vegas operates under water scarcity constraints. Use closed-loop water recycling systems for truck and equipment washout.

- Partner with SNWA (Southern Nevada Water Authority)-approved recycling facilities when possible.

Dust Mitigation

- Use water sprays, windbreaks, and covered storage for raw materials to minimize fugitive dust.

- Regularly maintain site surfaces to reduce dust generation.

Sustainable Mix Designs

- Incorporate supplementary cementitious materials (SCMs) like fly ash or slag to reduce carbon footprint.

- Offer low-carbon or permeable concrete options for environmentally sensitive projects.

Documentation and Recordkeeping

- Batch Tickets: Each delivery must include a detailed batch ticket with mix design, volume, time of batching, and project information.

- Driver Logs: Maintain electronic or paper logs complying with ELD (Electronic Logging Device) rules.

- Inspection Reports: Keep records of vehicle and plant inspections, emissions tests, and environmental compliance audits.

- Incident Reports: Document any spills, accidents, or non-compliance events for regulatory review.

Emergency Response and Spill Management

- Spill Prevention Control and Countermeasure (SPCC) Plan: Required for facilities storing fuels or oils over threshold quantities.

- Concrete Spill Kit: Equip trucks with tools (shovels, absorbent materials, barriers) to manage minor washout or spill incidents.

- Reporting Procedures: Report significant spills to NDEP and local authorities immediately, per Nevada Administrative Code (NAC) 445A.

Conclusion

Operating a ready mix concrete business in Las Vegas demands a proactive approach to logistics coordination and regulatory compliance. By adhering to environmental standards, optimizing delivery operations, and maintaining accurate records, companies can ensure reliable service while minimizing legal and environmental risks. Staying informed about evolving regulations from NDEP, Clark County, and federal agencies is critical for long-term success in this dynamic market.

In conclusion, sourcing ready mix concrete in Las Vegas, Nevada, offers numerous advantages due to the region’s robust construction industry and the presence of reputable suppliers. With a variety of local producers providing high-quality, customizable concrete mixes, contractors and developers can ensure timely delivery, consistent product standards, and compliance with local building codes. Factors such as proximity to project sites, favorable weather conditions for pouring, and competitive pricing further enhance the efficiency and cost-effectiveness of using ready mix concrete in the area. By partnering with established suppliers and planning logistics carefully, construction professionals in Las Vegas can achieve durable, reliable results while maintaining project timelines and budgets. Ultimately, the availability and reliability of ready mix concrete make it an ideal choice for residential, commercial, and infrastructure developments across Southern Nevada.