The global reach truck market is experiencing robust growth, driven by rising demand for warehouse automation, e-commerce expansion, and the need for efficient material handling in constrained spaces. According to Grand View Research, the global material handling equipment market was valued at USD 178.7 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030, with reach trucks representing a key segment due to their vertical lift capabilities and space-saving design. This surge is further amplified by increasing investments in logistics infrastructure and smart warehousing across North America, Europe, and Asia Pacific. As competition intensifies, manufacturers are focusing on electrification, advanced guidance systems, and operator ergonomics to differentiate their offerings. In this evolving landscape, nine manufacturers have emerged as leaders, combining technological innovation, global reach, and strong performance metrics to dominate the reach truck sector.

Top 9 Reach Truck Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 UniCarriers Forklifts

Domain Est. 2020

Website: logisnextamericas.com

Key Highlights: As an American forklift manufacturer that’s proudly part of a global corporation, UniCarriers is committed to enabling our customers to efficiently move goods ……

#2 Yale Lift Truck Technologies

Domain Est. 1994

Website: yale.com

Key Highlights: Yale’s forklifts and lift trucks are designed to tackle your biggest challenges. Discover how our technology can boost your warehouse productivity!…

#3 Forklift Trucks – Fleet & Warehouse Solutions

Domain Est. 1995

Website: raymondcorp.com

Key Highlights: Raymond is a leading manufacturer of forklift trucks and pallet jacks, as well as a provider of telematics and material handling solutions to improve ……

#4 Crown Equipment Corporation

Domain Est. 1998

Website: crown.com

Key Highlights: Crown Equipment Corporation is a global manufacturer of material handling equipment, lift trucks … Internal Combustion Forklifts · Reach Trucks · Man-up ……

#5 Hyster

Domain Est. 2012

Website: hyster-yale.com

Key Highlights: Comprised of two synergistic businesses, with leading powerhouse brands, our combined strengths meet diverse customer needs and deliver exceptional value….

#6 Reach Truck

Domain Est. 1996

Website: toyotaforklift.com

Key Highlights: Toyota’s Electric Reach Truck provides optimal visibility when needing to reach high thanks to its open-view mast. Learn more about this forklift today!…

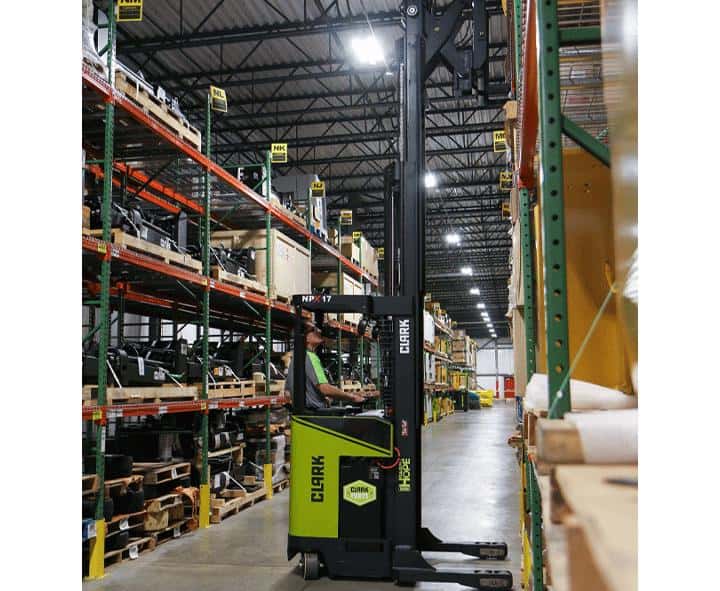

#7 CLARK Material Handling Company

Domain Est. 1996

Website: clarkmhc.com

Key Highlights: We also provide specialized equipment such as order picker forklifts, reach truck forklifts, and tow tractors for heavy-duty hauling. For pallet handling ……

#8 Mitsubishi Forklift Trucks

Domain Est. 1999

Website: mitforklift.com

Key Highlights: Our class-leading diesel and LPG forklifts trucks deliver powerful, efficient and reliable performance. Handling up to 16.0 tonnes….

#9 Linde Material Handling

Domain Est. 2008

Website: linde-mh.us

Key Highlights: Welcome to Linde Material Handling. Outfit your operation with innovative solutions for material handling, warehouse automation, fleet management, and more….

Expert Sourcing Insights for Reach Truck

H2: 2026 Market Trends for Reach Trucks

The global reach truck market is poised for significant transformation by 2026, driven by advancements in automation, sustainability imperatives, and the continued expansion of e-commerce logistics. As warehouses become more sophisticated and space-constrained, reach trucks—known for their ability to operate efficiently in narrow aisles and handle high stacking—will play a critical role in material handling solutions. The following key trends are expected to shape the reach truck market in 2026:

1. Electrification and Zero-Emission Technologies

By 2026, the transition from internal combustion (IC) to electric reach trucks will accelerate. Stricter environmental regulations, corporate sustainability goals, and lower lifecycle costs are pushing demand for lithium-ion (Li-ion) battery-powered models. Li-ion technology offers faster charging, longer operational hours, and reduced maintenance compared to traditional lead-acid batteries. Major manufacturers are expected to phase out or significantly reduce production of IC reach trucks in key markets like Europe and North America.

2. Integration of Automation and Smart Features

Reach trucks will increasingly incorporate advanced telematics, IoT connectivity, and AI-driven analytics. Fleet management systems will allow real-time monitoring of truck performance, battery status, operator behavior, and maintenance needs. By 2026, semi-autonomous reach trucks capable of assisted navigation and load handling will gain traction, especially in high-throughput distribution centers. Integration with warehouse management systems (WMS) will optimize inventory movement and reduce operational downtime.

3. Growth in E-Commerce and Urban Warehousing

The rise of e-commerce continues to fuel demand for compact, high-density storage solutions. Reach trucks are ideal for narrow-aisle racking systems commonly used in urban fulfillment centers where space is at a premium. As last-mile logistics expand, the need for efficient, agile material handling equipment in smaller, decentralized warehouses will boost reach truck adoption.

4. Focus on Operator Comfort and Safety

Ergonomics will remain a key differentiator among manufacturers. By 2026, reach trucks will feature enhanced operator cabins with improved visibility, climate control, and intuitive controls to reduce fatigue and increase productivity. Advanced safety systems such as collision avoidance, load stability sensors, and 360-degree cameras will become standard, especially in automated or mixed-traffic environments.

5. Regional Market Dynamics

Asia-Pacific is expected to lead market growth due to rapid industrialization, infrastructure development, and expansion of logistics hubs in countries like China, India, and Vietnam. Europe will maintain strong demand driven by green logistics initiatives and high automation rates. North America will see steady growth, supported by reshoring of manufacturing and investments in smart warehouses.

6. Servitization and Aftermarket Opportunities

Equipment manufacturers are shifting toward service-based business models, offering leasing, maintenance-as-a-service, and predictive maintenance solutions. By 2026, these value-added services will represent a growing share of revenue, enhancing customer retention and lifecycle profitability.

In conclusion, the 2026 reach truck market will be defined by smarter, cleaner, and more efficient machines tailored to the evolving needs of modern logistics. Companies that embrace innovation in electrification, automation, and digital integration will gain a competitive edge in this dynamic landscape.

Common Pitfalls Sourcing Reach Trucks (Quality, IP)

Sourcing reach trucks—especially from overseas suppliers or new vendors—comes with significant risks if due diligence is not performed. Two critical areas where companies often encounter problems are quality assurance and intellectual property (IP) protection. Failing to address these can lead to operational delays, safety hazards, financial loss, and legal exposure.

Poor Quality Control and Inconsistent Build Standards

One of the most frequent issues when sourcing reach trucks is receiving units that do not meet expected quality or safety standards. This often stems from:

- Lack of adherence to international standards (e.g., ISO, CE, ANSI): Some suppliers may claim compliance but fail to implement proper manufacturing processes or testing.

- Inconsistent component quality: Substandard hydraulic systems, electrical components, or structural materials can result in frequent breakdowns and safety risks.

- Insufficient testing and certification: Suppliers may skip load testing, stability checks, or third-party certifications, increasing the risk of equipment failure.

- Inadequate after-sales support: Poorly built trucks often require frequent maintenance, and sourcing replacement parts or technical support may be difficult with low-tier suppliers.

Recommendation: Conduct factory audits, request test reports, and insist on third-party inspections before shipment. Work with suppliers who provide full traceability and documented quality management systems (e.g., ISO 9001 certified).

Intellectual Property (IP) Infringement and Brand Cloning

Another major pitfall is unintentionally sourcing reach trucks that infringe on intellectual property rights. This is especially common when dealing with suppliers in regions with weak IP enforcement:

- Counterfeit or cloned designs: Some manufacturers replicate the外观 (appearance), branding, or patented features of well-known brands (e.g., Toyota, Jungheinrich, Crown), risking legal action if imported.

- Use of unlicensed technology: Embedded software, control systems, or patented mast designs may be copied without authorization.

- Grey market or rebranded units: Trucks may be genuine but diverted from authorized markets, voiding warranties and support.

Recommendation: Perform IP due diligence by verifying design rights and trademarks. Avoid suppliers offering “compatible” or “copy” models of premium brands. Include IP indemnity clauses in contracts and work with reputable manufacturers who respect IP laws.

By proactively addressing quality and IP risks, businesses can ensure reliable, safe, and legally compliant reach truck procurement.

Logistics & Compliance Guide for Reach Truck Operations

Overview of Reach Truck Functionality

Reach trucks are narrow-aisle forklifts designed specifically for high-density warehouse environments. Their primary purpose is to lift and transport palletized loads to elevated storage locations, typically in racking systems. With a pantograph or scissor mechanism enabling forward reach, these trucks allow operators to place and retrieve loads without needing to move the entire vehicle forward, optimizing space utilization in confined aisles.

Key Logistics Considerations

Efficient logistics with reach trucks depend on proper warehouse layout planning, load compatibility, and operational workflow integration. Ensure aisle widths are suitable (typically 2.4–3 meters) to allow safe maneuvering. Prioritize load center compatibility—most reach trucks are rated for standard 1,000–1,500 mm load centers—and avoid overloading or extending beyond rated capacities. Maintain clear floor markings, adequate lighting, and unobstructed access to racking to support smooth operations.

Operator Training and Certification

Only trained and certified personnel should operate reach trucks. Training must cover pre-operational inspections, safe lifting and lowering techniques, stability principles, and emergency procedures. Certification should comply with local regulations, such as OSHA standards in the U.S. or PUWER in the UK. Refresher training is recommended annually or after any safety incident.

Maintenance and Equipment Checks

Implement a preventive maintenance schedule as per manufacturer guidelines. Daily pre-use inspections should include checking hydraulic systems, brakes, forks, steering, and warning devices (horn, lights). Document all maintenance activities and address defects immediately. Keep fluid levels, tire conditions, and battery charge (for electric models) within operational specifications.

Compliance with Safety Regulations

Reach truck operations must adhere to regional and international safety standards. In the EU, compliance with the Machinery Directive (2006/42/EC) and adherence to EN 16307-5 (industrial trucks safety) are mandatory. In North America, follow ANSI/ITSDF B56.1 safety standards. Ensure equipment carries required CE or ANSI markings and that safety features such as emergency stop buttons, load backrests, and overhead guards are functional and undamaged.

Load Handling and Stability

Always observe the truck’s load capacity chart, which varies with lift height and load center. Never exceed the rated capacity. Ensure loads are stable and uniformly stacked; use load restraints when necessary. Avoid sudden movements, sharp turns, or excessive speeds, especially at height, to prevent tip-overs. Operate with the load tilted slightly backward during travel.

Workplace Safety and Signage

Designate pedestrian-free zones in high-traffic reach truck areas and use clear floor markings and warning signs. Install mirrors at blind corners and use audible alarms when reversing. Provide adequate lighting at all storage levels. Implement traffic management protocols to prevent collisions between multiple trucks operating in the same zone.

Battery and Charging Safety (Electric Models)

For electric reach trucks, charging stations must be in well-ventilated areas, away from ignition sources. Use only approved chargers and follow lockout/tagout procedures during battery changes. Personnel handling batteries should wear appropriate PPE, including gloves and eye protection, due to the risk of acid exposure and electrical hazards.

Incident Reporting and Documentation

Establish a formal procedure for reporting near-misses, accidents, or equipment malfunctions. Investigate all incidents promptly to identify root causes and implement corrective actions. Maintain logs of operator certifications, maintenance records, inspections, and incident reports for audit and compliance purposes.

Environmental and Ergonomic Considerations

Electric reach trucks produce zero emissions, making them ideal for indoor environments. Ensure proper disposal of batteries and hydraulic fluids in accordance with environmental regulations. Optimize cab design and controls for operator comfort to reduce fatigue and improve long-term productivity and safety.

Conclusion for Sourcing a Reach Truck:

Sourcing a reach truck is a strategic decision that significantly impacts warehouse efficiency, operational productivity, and long-term cost management. After evaluating key factors such as load capacity, lift height, maneuverability, energy efficiency, and maintenance requirements, it becomes clear that selecting the right reach truck must align closely with specific operational needs and facility layout.

Opting for reputable suppliers or manufacturers ensures reliability, warranty support, and access to timely service and parts. Whether choosing between electric or IC models, new or used units, or purchasing versus leasing, each option presents trade-offs that should be weighed against budget constraints and usage frequency.

Furthermore, incorporating operator safety features, ergonomic design, and smart technologies such as fleet management systems can enhance performance and reduce downtime. In conclusion, a well-informed sourcing strategy—grounded in thorough needs assessment, total cost of ownership analysis, and supplier evaluation—will deliver optimal material handling solutions, improving both productivity and return on investment in the long term.