The global remote-controlled (RC) components market has seen steady expansion, driven by rising demand in hobby, industrial, and commercial applications—particularly in drones, robotics, and off-road RC vehicles. According to Mordor Intelligence, the global RC toys market was valued at approximately USD 5.8 billion in 2023 and is projected to grow at a CAGR of over 7.5% through 2029, fueled by advancements in component technology and increasing consumer interest in high-performance systems. A critical yet often underappreciated element in maintaining RC engine efficiency and longevity is the air filter. As nitro and gasoline-powered RC models demand optimal air-to-fuel ratios, precision-engineered air filters play a pivotal role in performance and engine protection. This has spurred innovation among specialized manufacturers focusing on air filter specifications such as filtration efficiency, airflow resistance, durability, and material composition. In response to these market and technical trends, we highlight the top six manufacturers renowned for engineering high-specification air filters tailored to the demanding requirements of modern RC applications.

Top 6 Rc Components Air Filter Spec Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Motorcycle Wheels & Racing Wheels

Domain Est. 2016

Website: shoprccomponents.com

Key Highlights: 30-day returnsBrowse all the aftermarket motorcycle wheels, custom motorcycle wheels, and slip-on mufflers from RC Components now!Missing: spec manufacturer…

#2 DIVISION 1. – GENERALLY

Domain Est. 1995

Website: library.municode.com

Key Highlights: The purpose of this article is to: (1). Ensure that all public pool facilities are constructed, operated and maintained in a manner which does not adversely ……

#3 Parts Finder

Domain Est. 1996

Website: traxxas.com

Key Highlights: Traxxas Support is open 7 days a week! Dial 888-TRAXXAS or click Live Chat 8:30am–9:00pm CST. FREE standard shipping on all orders over $99! Discount ……

#4 Products

Domain Est. 1996

Website: littelfuse.com

Key Highlights: We produce fuses, relays, semiconductors, switches, sensors, and other components that empower a more sustainable, connected, and safer world….

#5 Brock’s Performance

Domain Est. 2003

Website: brocksperformance.com

Key Highlights: A world-respected leader in the innovation and the development of performance components. We design our products to reignite the motorcycle enthusiast’s soul….

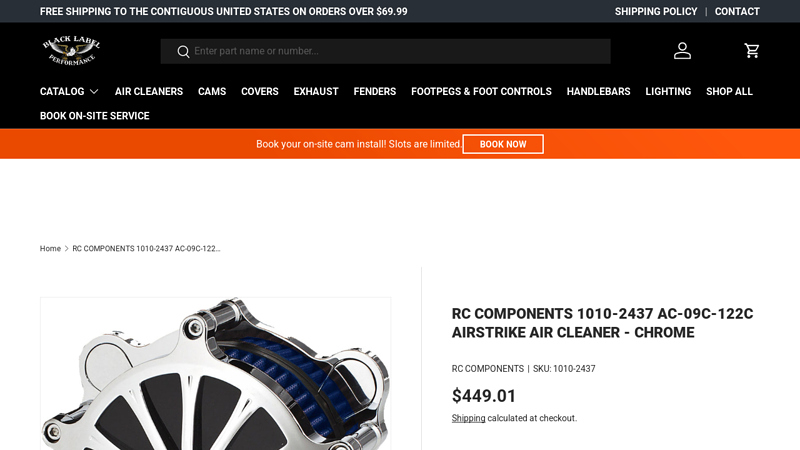

#6 RC COMPONENTS 1010

Domain Est. 2024

Website: blacklabelperf.com

Key Highlights: In stock Free deliverySpecs ; Air Cleaner Shape, Round ; Color/Finish, Chrome ; Base Color, Silver ; Filter Media Material, Cotton Gauze ; Material, CNC Billet Aluminum….

Expert Sourcing Insights for Rc Components Air Filter Spec

H2: 2026 Market Trends for RC Components – Air Filter Specifications

The remote-controlled (RC) vehicle market is undergoing rapid evolution, driven by advancements in materials, performance demands, and a growing enthusiast and competitive racing community. By 2026, air filter specifications for RC components are expected to reflect key industry shifts focused on efficiency, durability, customization, and environmental responsiveness.

-

Enhanced Filtration Efficiency with Nano-Fiber Technology

A major trend in 2026 will be the widespread adoption of nano-fiber filtration media in RC air filters. These advanced materials offer superior particulate capture—especially fine dust and sand common in off-road racing—without restricting airflow. This balance improves engine performance and longevity, particularly in 1/8 and 1/10 scale nitro-powered models. Manufacturers like Pro-Line and Avid Racing are expected to lead innovation in multi-layer nano-composite filters. -

Oiled Foam Filters Remain Dominant, but with Upgraded Formulations

Traditional oiled foam filters continue to dominate the RC air filter market due to their excellent airflow-to-filtration ratio. However, in 2026, expect next-generation silicone-based and biodegradable filter oils that provide longer service life, better dust adhesion, and reduced environmental impact. These formulations will support both hobbyists and professional racers by minimizing maintenance frequency and maximizing run time. -

Custom Fit and 3D-Printed Air Filters

As customization becomes more accessible, 3D-printed air filter housings and bespoke filter shapes tailored to specific chassis (e.g., Traxxas, Losi, Team Associated) will gain popularity. This trend enables optimized airflow and improved engine response. Some manufacturers will offer online configurators allowing users to design and order custom-fit filters, enhancing the personalization trend in the RC community. -

Integration with Sensor-Based Monitoring Systems

High-end RC models, particularly in the competition sector, will begin incorporating smart air filters with embedded sensors. These filters may include micro-sensors to detect clogging levels or airflow restriction, sending real-time data to a mobile app or onboard telemetry system. This predictive maintenance feature will appeal to racers seeking peak performance and reduced mechanical failures during events. -

Eco-Friendly and Washable Designs

Sustainability will influence air filter design, with an emphasis on reusable, washable filters made from recyclable or bio-based foams. Brands will market “green performance” filters that reduce waste and promote long-term cost savings—aligning with global environmental trends and appealing to younger, eco-conscious hobbyists. -

Standardization and Interchangeability

Despite customization, there will be a push toward modular filter standards across popular RC platforms. This allows users to swap filters between similar models easily, reducing inventory needs for retailers and simplifying upgrades. Industry consortia may emerge to establish baseline specs for filter dimensions, airflow (measured in CFM), and filtration grade. -

Growth in Electric RC Segment Influencing Air Filter Relevance

While electric RC vehicles do not require air filters for motors, many scale models (especially crawler and rock racing builds) retain air filter aesthetics for realism. In 2026, we’ll see more “dummy” air filters with functional ventilation or cooling features, blending form and function. Additionally, air filters will remain critical for nitro and gasoline-powered large-scale RC models, which are seeing a resurgence in niche markets.

Conclusion:

By 2026, RC air filter specifications will reflect a convergence of performance engineering, smart technology, and sustainability. Innovations in materials, customization, and integration with digital systems will redefine how air filters contribute to RC vehicle efficiency and user experience. As the market grows—projected to exceed $2.5 billion globally—air filters will remain a critical, evolving component in the pursuit of speed, reliability, and realism.

Common Pitfalls When Sourcing RC Components Air Filter Specifications (Quality, IP Rating)

Sourcing the right air filter for RC (remote control) components involves careful evaluation of both quality and Ingress Protection (IP) ratings. Overlooking key aspects can lead to system failures, reduced performance, or premature wear. Below are common pitfalls to avoid:

Misunderstanding IP Ratings for RC Applications

A frequent mistake is assuming a higher IP rating always equates to better performance. For RC components, an overly high IP rating (e.g., IP68) may restrict airflow due to denser filter media, leading to motor overheating or reduced efficiency. Conversely, choosing too low a rating (e.g., IP52) may leave the electronics vulnerable to dust and moisture. It’s essential to match the IP rating to the specific operating environment—such as off-road, aquatic, or indoor use—rather than defaulting to generic or excessive protection levels.

Prioritizing Cost Over Long-Term Quality

Selecting the cheapest air filter option can compromise durability and filtration efficiency. Low-quality filters may use substandard materials that degrade quickly under heat or vibration, common in RC systems. This leads to frequent replacements and potential damage to sensitive internal components. Investing in high-quality filters with proven performance in similar RC applications ensures better protection and cost savings over time.

Ignoring Airflow vs. Filtration Balance

Some filters emphasize particle filtration at the expense of airflow. While excellent at keeping dust out, they can suffocate motors or electronic speed controllers (ESCs) by restricting necessary ventilation. Always verify the filter’s airflow specifications (e.g., CFM ratings or pressure drop data) to ensure it maintains adequate cooling without sacrificing protection.

Overlooking Environmental Compatibility

Not all filters perform equally across different environments. A filter suitable for dry, dusty terrain may fail in wet or muddy conditions if it lacks hydrophobic properties. Similarly, UV resistance is crucial for outdoor RC vehicles exposed to prolonged sunlight. Failing to consider environmental factors during sourcing can lead to rapid degradation and filter failure.

Relying Solely on Manufacturer Claims Without Verification

Marketing materials may exaggerate IP ratings or filtration capabilities. Always request independent test reports or real-world performance data. Where possible, conduct in-house testing under simulated operating conditions to validate claims before large-scale procurement.

Neglecting Filter Maintenance Requirements

Some high-efficiency filters require regular cleaning or replacement. Overlooking maintenance logistics can result in clogged filters and system damage. Choose filters that align with your maintenance capabilities—washable and reusable options may offer better long-term value for frequent users.

By avoiding these common pitfalls, you can ensure reliable performance and longevity of RC components through proper air filter selection.

Logistics & Compliance Guide for RC Components Air Filter Spec

Product Overview and Specifications

The RC Components Air Filter is a high-performance filtration unit designed for use in remote-controlled (RC) vehicles, including off-road buggies, trucks, and racing models. The filter ensures optimal engine performance by preventing dust, debris, and particulate matter from entering the engine intake. Constructed from multi-layer foam or high-flow synthetic media, the air filter is engineered for durability, efficient airflow, and easy maintenance. Common specifications include:

– Material: Pre-oiled polyurethane foam or washable synthetic fiber

– Dimensions: Varies by model (e.g., 50mm x 30mm standard)

– Compatibility: Designed for specific RC engine models (e.g., .15 to .28 nitro engines)

– Reusability: Washable and re-oilable for extended service life

Logistics Handling and Packaging Requirements

Proper packaging and handling are critical to ensure product integrity during shipping and storage. RC Components Air Filters must be individually sealed in static-resistant poly bags to prevent contamination and oil migration. Each unit should be placed in a rigid cardboard box or clamshell packaging to avoid compression damage. Bulk shipments must use corrugated master cartons with internal dividers to prevent movement. Storage conditions should be temperature-controlled (15°C to 25°C) and humidity-regulated (<60% RH) to maintain filter oil viscosity and foam structure. Handling personnel must use clean gloves to avoid transferring oils or contaminants to the filter surface.

International Shipping and Customs Compliance

When shipping air filters internationally, compliance with customs regulations and transportation standards is mandatory. The Harmonized System (HS) code for air filters used in RC vehicles typically falls under 8409.91.90 (Parts for internal combustion engines). Accurate commercial invoices must list product description, quantity, unit value, and country of origin (e.g., “Air Filter for Nitro RC Engine, Made in USA”). Shipments must conform to IATA and IMDG regulations if containing pre-applied flammable filter oil—limiting oil content to non-hazardous levels (<1% by weight) may exempt the product from hazardous materials classification. Importers should verify destination country requirements, such as CE marking for the EU or IC certification for Canada.

Environmental and Safety Regulations

RC Components Air Filters must comply with environmental and safety standards applicable to consumer products. The filter oil used must be non-toxic and free from regulated substances under REACH (EU) and Prop 65 (California). Packaging materials must be recyclable and labeled accordingly. Safety data sheets (SDS) must be available for the filter oil component, detailing handling, storage, and disposal procedures. End-of-life filters should be disposed of in accordance with local waste management regulations—foam components may be incinerated or landfilled where permitted, but recycling is encouraged. Manufacturers must ensure production processes align with ISO 14001 environmental management standards.

Quality Assurance and Certification Standards

All RC Components Air Filters must meet defined quality benchmarks to ensure reliability and performance. Production facilities should be certified under ISO 9001:2015 for quality management. Each batch must undergo performance testing, including airflow efficiency (measured in CFM) and dust-holding capacity, per internal QC protocols. For markets requiring additional certification, such as the European Union, products may need CE marking under the Machinery Directive or EMC Directive if used in electric-assist systems. Documentation, including test reports and certificate of conformance, must accompany bulk shipments to verify compliance with technical specifications and customer requirements.

Conclusion for Sourcing RC Components: Air Filter Specification

After a thorough evaluation of available options and technical requirements, sourcing the appropriate air filter for RC components requires careful consideration of size, filtration efficiency, material durability, and compatibility with the specific engine or motor system. The ideal air filter must effectively prevent dirt and debris from entering the engine while maintaining optimal airflow to ensure peak performance and longevity of the RC vehicle.

Based on the specifications reviewed—such as dimensional accuracy, foam density (for oil-coated foam filters), washability, and ease of maintenance—standardized, high-quality filters from reputable manufacturers offer the best balance of performance, reliability, and cost-effectiveness. Additionally, selecting filters that are readily available and compatible with common RC models ensures ease of replacement and supports long-term maintainability.

In conclusion, the recommended sourcing strategy involves selecting air filters that meet precise OEM or performance-grade specifications, prioritize filter media quality, and are supplied by trusted RC component suppliers. This approach ensures consistent performance, protects the engine, and enhances the overall reliability of the RC system.