The global ratchet extender bar market is experiencing steady growth, driven by rising demand from the automotive, industrial, and DIY tool sectors. According to Grand View Research, the global hand tools market—under which ratchet extender bars fall—was valued at USD 10.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing automotive repair and maintenance activities, alongside a surge in demand for precision tools in manufacturing and construction. Mordor Intelligence further highlights that advancements in tool ergonomics and material durability are pushing manufacturers to innovate, particularly in socket wrench systems where extender bars play a critical role. As demand for high-quality, corrosion-resistant, and high-torque ratchet accessories grows, a select group of manufacturers has emerged as leaders in performance, innovation, and global reach. Here are the top 10 ratchet extender bar manufacturers shaping the industry.

Top 10 Ratchet Extender Bar Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Socket Extensions

Domain Est. 1998

Website: craftsman.com

Key Highlights: Discover CRAFTSMAN®’s Socket Extensions for tools that provide extra reach and flexibility in tight spaces. Our durable extensions ensure seamless …Missing: extender manufacture…

#2 Extension Bars

Domain Est. 2006

Website: bgstechnic.com

Key Highlights: Ratchets, Extensions, Adapters & Accessories – Extension Bars. BGS technic.Missing: extender manufacturer…

#3 Extensions

Domain Est. 1997

Website: wrighttool.com

Key Highlights: Designed for superior performance in a variety of lengths for hard-to-reach applications. Forged and Machined for Best Fit and Unyielding Strength….

#4 Ratchets, Breaker/Power Bars, Extensions

Domain Est. 1999

Website: clarkeinternational.com

Key Highlights: Clarkes professional use polished chrome extendable ratchet is ideal for working in tight spaces or hard to reach areas. It provides three ……

#5 Ratchet and Extension

Domain Est. 2000

Website: ernstmfg.com

Key Highlights: Free delivery over $75 60-day returnsEasily add on sockets, ratchets, and extensions to Ernst socket rails. Clips snap into place and can adjust position for customization….

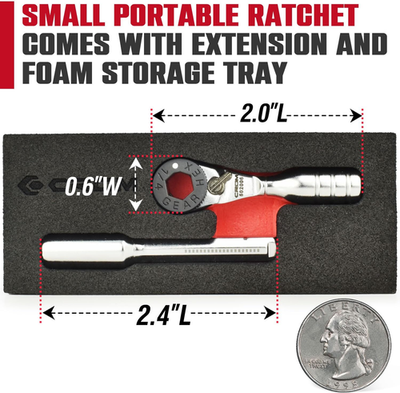

#6 MINI Ratchet Extensions

Domain Est. 2001

#7 RATCHET ACCESSORIES

Domain Est. 2005

Website: licotatools.com

Key Highlights: An extension bar increases the reach and gets the access around obstructions. An extendable handle provides greater torque to make sure the job can be done with ……

#8 Eastwood 31894K

Domain Est. 2008

#9 F32291C Ratchet Extension Drive Bar and Low Profile Socket Set

Domain Est. 2010

Website: firstinfo.com.tw

Key Highlights: 【Complete Set for Conveniently Use】 Includes 10 pieces low profile sockets ranging from 8 to 17 mm in 3/8” drive, 3 pieces square drive adapters in 1/4” and 3 ……

#10 3/8″ Drive Ratchets & Extension Bars

Domain Est. 2017

Expert Sourcing Insights for Ratchet Extender Bar

H2: 2026 Market Trends for Ratchet Extender Bars

The ratchet extender bar market in 2026 is poised for steady growth, driven by evolving user demands, technological advancements, and broader shifts in the automotive and industrial sectors. Key trends shaping the market include:

1. Rising Demand for Ergonomic and User-Centric Designs:

As awareness of workplace safety and repetitive strain injuries grows, manufacturers are prioritizing ergonomics. Expect wider adoption of extender bars with anti-slip knurling, reduced vibration features, and lightweight composite materials. These improvements enhance comfort during prolonged use, particularly in automotive repair and manufacturing settings.

2. Expansion in E-Commerce and Direct-to-Consumer Channels:

Online platforms continue to dominate tool sales. In 2026, brands are leveraging digital marketplaces and subscription tool services to reach DIY enthusiasts and professional technicians alike. Enhanced product visualization (e.g., 3D models and AR previews) and customer reviews will influence purchasing decisions significantly.

3. Growth in the Automotive Aftermarket and EV Maintenance:

With increasing vehicle ownership and longer vehicle lifespans, the aftermarket repair industry remains robust. While electric vehicles (EVs) require fewer traditional powertrain repairs, they still demand specialized underbody and battery pack maintenance—applications where ratchet extender bars are essential. This sustains demand despite shifting powertrain technologies.

4. Integration with Smart Tool Ecosystems:

Emerging trends involve connectivity. While still in early stages, some premium extender bars may incorporate torque sensors or compatibility with smart ratchets that log usage data. This appeals to professional workshops focused on quality control and maintenance tracking.

5. Emphasis on Durability and Material Innovation:

High-tensile chrome vanadium (Cr-V) steel remains standard, but advancements in heat treatment and coatings (e.g., anti-corrosion black oxide or ceramic finishes) extend product life. Demand for durable, long-lasting tools supports premium pricing and brand loyalty.

6. Sustainability and Circular Economy Considerations:

Environmental concerns are prompting brands to explore recyclable packaging and modular designs that allow for part replacement (e.g., swappable drive ends). Although not yet mainstream, sustainability is becoming a differentiating factor, especially among younger consumers and corporate procurement teams.

7. Regional Market Diversification:

Growth is strongest in emerging markets across Asia-Pacific and Latin America, where infrastructure development and rising disposable income boost demand for automotive tools. Localized manufacturing and distribution partnerships will play a critical role in capturing this expansion.

In summary, the 2026 ratchet extender bar market will be characterized by innovation in design and materials, digital sales dominance, and sustained demand from both traditional and evolving service sectors—ensuring its relevance in modern toolkits.

Common Pitfalls When Sourcing Ratchet Extender Bars (Quality and IP)

Sourcing ratchet extender bars may seem straightforward, but overlooking key quality and intellectual property (IP) concerns can lead to performance issues, safety risks, and legal complications. Here are the most common pitfalls to avoid:

1. Prioritizing Low Cost Over Material Quality

Choosing the cheapest extender bars often means compromising on material strength. Low-grade steel or improper heat treatment can result in bending, cracking, or snapping under load—posing serious safety hazards. Always verify material specifications (e.g., chrome vanadium steel) and request test reports for tensile strength and durability.

2. Ignoring Manufacturing Tolerances and Fit

Poorly manufactured extenders may not maintain precise tolerances, leading to wobble or incomplete engagement with the ratchet and socket. This can cause slippage, rounding of fasteners, or tool damage. Ensure compatibility with industry-standard drive sizes (e.g., 1/4″, 3/8″, 1/2″) and check for tight manufacturing tolerances.

3. Overlooking Surface Finish and Corrosion Resistance

Inadequate plating or coating (e.g., substandard chrome plating) can result in premature rusting and reduced lifespan, especially in humid or industrial environments. Inspect for consistent, smooth finishes and confirm corrosion resistance through salt spray testing if used in harsh conditions.

4. Assuming All Suppliers Comply with IP Regulations

Many ratchet extender designs are protected by patents or trade dress laws. Sourcing from manufacturers that copy branded designs (e.g., mimicking patented knurling patterns or locking mechanisms) exposes buyers to intellectual property infringement risks. Always verify that products are either licensed or designed independently to avoid legal disputes and shipment seizures.

5. Failing to Audit Supplier Capabilities and Certifications

Not all factories have the tooling or quality control systems to produce reliable extenders. Avoid suppliers without certifications like ISO 9001 or proven experience in precision tool manufacturing. Conduct factory audits or third-party inspections to assess production processes and QC protocols.

6. Neglecting Load and Torque Specifications

Extender bars reduce effective torque and introduce leverage stress. Using an undersized or improperly rated extender can lead to failure during high-torque applications. Confirm the maximum torque rating and ensure it aligns with your intended use—especially for automotive or industrial maintenance.

7. Skipping Sample Testing Before Bulk Orders

Relying solely on supplier claims without physical testing is risky. Always request pre-production samples and perform real-world torque, fit, and durability tests to validate performance and safety before committing to large volumes.

Avoiding these pitfalls ensures you source ratchet extender bars that are safe, reliable, and free from legal complications. Prioritize quality validation and IP compliance throughout the sourcing process.

Logistics & Compliance Guide for Ratchet Extender Bar

Product Classification & HS Code

The Ratchet Extender Bar is typically classified under Harmonized System (HS) Code 8207.90, which covers interchangeable tools for hand-operated tools. Final classification may vary by country; consult local customs authorities for precise code assignment based on material and design.

Packaging & Labeling Requirements

Ensure extender bars are securely packaged to prevent damage during transit. Use durable, recyclable materials such as corrugated cardboard with internal dividers or blister packs. Each unit must be labeled with:

– Product name and model number

– Manufacturer or brand name

– Country of origin

– Safety warnings (e.g., “Use with compatible ratchet tools only”)

– Compliance marks (e.g., CE, UKCA if applicable)

Bulk shipments should include outer carton labels with barcodes, quantity, weight, and handling symbols (e.g., “Do not stack,” “Fragile”).

Import/Export Regulations

Verify export controls based on the country of manufacture and destination. Most ratchet extender bars are not subject to ITAR or EAR restrictions, but confirm with a trade compliance officer. Required export documentation includes:

– Commercial invoice

– Packing list

– Bill of lading or air waybill

– Certificate of origin (if claiming preferential tariff treatment)

Some countries may require product conformity certification or registration prior to import.

Safety & Compliance Standards

Ratchet extender bars must comply with mechanical and safety standards in target markets:

– European Union: Comply with the Machinery Directive (2006/42/EC) and carry CE marking. Perform a conformity assessment and maintain technical documentation.

– United Kingdom: Adhere to UKCA marking requirements; UKCA replaces CE for goods placed on the UK market.

– United States: No federal certification required, but products should meet ANSI or ASME design standards for mechanical tools. Comply with OSHA safety guidelines for tool usage.

Ensure products are free from hazardous substances per RoHS (EU) and REACH regulations.

Transportation & Handling

Use standard freight containers or palletized shipments secured with stretch wrap. Avoid exposure to moisture and extreme temperatures. Follow IATA and IMDG regulations if shipping by air or sea, though extender bars are generally non-hazardous. Confirm carrier-specific requirements for tool shipments.

Customs Clearance

Provide accurate product descriptions and declared values to avoid delays. Duties and taxes vary by country; leverage trade agreements (e.g., USMCA, RCEP) where applicable. Retain all compliance documents for a minimum of five years.

End-of-Life & Environmental Compliance

Design for recyclability. Comply with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions, even if not electric, as metal tool disposal may fall under industrial scrap regulations. Provide disposal guidance in user documentation.

Recordkeeping & Audits

Maintain detailed records of compliance certifications, test reports, shipping documents, and supplier declarations. Conduct annual audits to ensure ongoing adherence to international logistics and regulatory standards.

Conclusion: Sourcing Ratchet Extender Bars

In conclusion, sourcing ratchet extender bars requires careful evaluation of quality, material durability, compatibility with existing tools, and supplier reliability. These essential automotive and industrial accessories enhance torque reach and improve access in tight spaces, making their performance and safety critical. Opting for extender bars made from high-strength chrome vanadium steel with standardized drive sizes (such as 1/4″, 3/8″, or 1/2″) ensures optimal compatibility and longevity. Additionally, choosing suppliers with certifications, positive customer feedback, and clear compliance with industry standards helps mitigate risks related to counterfeit or substandard products.

Whether sourcing locally or internationally, balancing cost-efficiency with product reliability is key. Bulk purchasing, long-term supplier partnerships, and periodic quality audits can further enhance supply chain efficiency and product consistency. Ultimately, investing in high-quality ratchet extender bars from trusted sources contributes to improved tool performance, user safety, and operational efficiency across mechanical and maintenance applications.