The global truck accessories market, driven by rising commercial vehicle production and increasing demand for cargo security and efficiency, is projected to grow at a CAGR of 4.8% from 2023 to 2030, according to Grand View Research. Within this landscape, ratchet bars—essential for securing loads in truck beds—have become a critical component in fleet safety and operational compliance. As logistical standards tighten and e-commerce fuel freight demand, the need for durable, high-performance ratchet bars has surged. This growing demand has spurred innovation and competition among manufacturers worldwide. Based on market presence, product performance, certifications, and customer reviews, we’ve compiled a data-driven overview of the top 10 ratchet bar manufacturers for truck beds, offering insights into the companies leading this expanding segment.

Top 10 Ratchet Bar For Truck Bed Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cargo Bar

Domain Est. 1999

Website: ericksonmfg.com

Key Highlights: 89″ to 104″ Lever Action Industrial Cargo Bars · New Products · The North American leader in tie-down straps and load securement related items….

#2 Cargo Bars & Accessories

Domain Est. 2017

Website: ancracargo.com

Key Highlights: Made of galvanized steel tubing and high-quality aluminum, our bars help to prevent cargo from shifting and becoming damaged, saving you money on damage claims …Missing: bed man…

#3 Cargo Bars

Domain Est. 1995

Website: peerlesschain.com

Key Highlights: SuperSox. For passenger car and light truck applications. Learn more How to Buy · Light Truck Tire Chain · Overview. Light Truck Tire Chain. LIGHT TRUCK TIRE ……

#4 Kinedyne

Domain Est. 1997

Website: kinedyne.com

Key Highlights: We manufacture several flatbed cargo securement solutions, including ratchet straps, winch straps, and winches, to name a few. Additionally, we also specialize ……

#5 Wright Tool

Domain Est. 1997

Website: wrighttool.com

Key Highlights: Wright forges the most proven and highest quality wrenches, ratchets, sockets and attachments. We are American made, privately-owned, and committed to a ……

#6 Knapheide Parts: Knapheide Replacement Parts

Domain Est. 1998

Website: parts.knapheide.com

Key Highlights: Shop Knapheide repair and replacement parts, and all the top truck equipment brands, at Knapheide Truck Equipment Center’s online truck body parts store….

#7 Cargo Bars for Secure Cargo Control

Domain Est. 2000

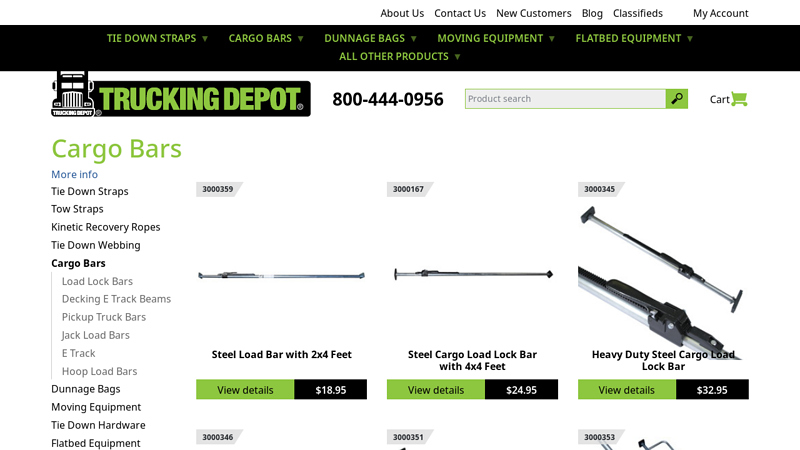

#8 Cargo Bars for Cargo Securement and Load Stabilization

Domain Est. 2004

Website: truckingdepot.com

Key Highlights: 6-day delivery 15-day returnsSome of the most popular types of cargo bars include Load Lock Bars, Decking E Track Shoring Beams, Pickup Truck Cargo Bars, Jack Load Bars, and Hoop L…

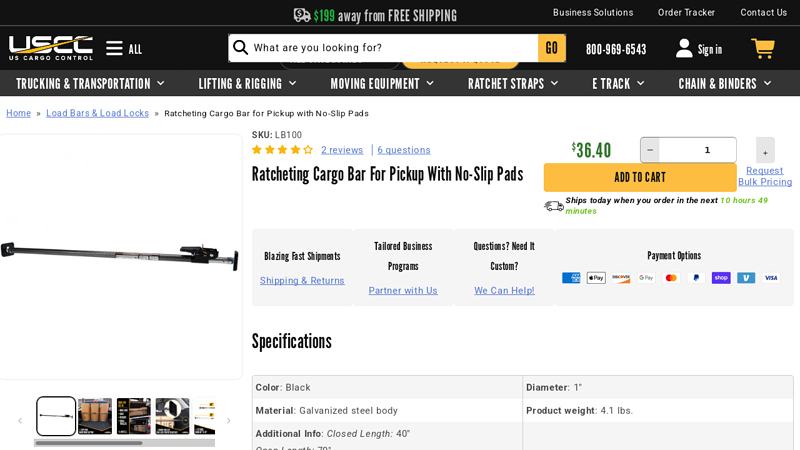

#9 Ratcheting Cargo Bar for Pickup with No

Domain Est. 2005

Website: uscargocontrol.com

Key Highlights: In stock Rating 4.0 (2) Adjustable pickup truck load bar adjusts from 40″ to 70″ and has no-slip feet for a secure hold. Ideal for pick-up trucks, mini vans, and more….

#10 Adjustable Ratcheting Cargo Bar

Domain Est. 2010

Expert Sourcing Insights for Ratchet Bar For Truck Bed

H2: 2026 Market Trends for Ratchet Bars for Truck Beds

The global market for ratchet bars for truck beds is poised for steady growth through 2026, driven by increasing demand for secure cargo transportation, rising e-commerce logistics, and advancements in material technology. As the transportation and logistics industries continue to expand—especially in emerging markets—the need for reliable load-securing solutions like ratchet bars is becoming more critical. This analysis explores key trends shaping the ratchet bar market for truck beds in 2026.

1. Growth in Commercial Vehicle Production and Aftermarket Sales

The steady rise in commercial vehicle production, especially in North America, Europe, and Asia-Pacific, is a primary driver for ratchet bar adoption. As fleet operators prioritize cargo safety and compliance with transportation regulations, demand for durable and easy-to-use ratchet systems is increasing. Additionally, the aftermarket segment is expanding, with truck owners upgrading or replacing worn-out tie-down systems, further fueling market growth.

2. Emphasis on Lightweight and Corrosion-Resistant Materials

Manufacturers are increasingly using high-strength aluminum alloys and polymer-coated steel to produce ratchet bars that are both lightweight and resistant to rust and wear. These materials improve fuel efficiency by reducing overall vehicle weight while enhancing product longevity—key selling points in 2026’s competitive market landscape.

3. Integration with Smart Cargo Management Systems

A notable trend emerging by 2026 is the integration of ratchet bars with smart load-monitoring technologies. Some advanced systems now include tension sensors and IoT connectivity, providing real-time feedback on strap tension and potential load shifts. While still in early adoption, this innovation is gaining traction among logistics companies seeking to minimize cargo damage and enhance safety.

4. Regulatory and Safety Standards Driving Adoption

Stringent government regulations on cargo securement—such as FMCSA guidelines in the U.S. and ECE R27 in Europe—are compelling fleet operators to invest in certified ratchet systems. Compliance is no longer optional, making ratchet bars a standard fixture in modern truck beds. This regulatory push is accelerating market penetration, especially in long-haul and heavy-duty transport sectors.

5. Sustainability and Eco-Friendly Manufacturing

Environmental concerns are influencing production processes. By 2026, leading manufacturers are adopting sustainable practices, such as recycling scrap metal, reducing energy consumption in production, and offering recyclable product packaging. Consumers and B2B buyers alike are showing preference for brands that demonstrate environmental responsibility.

6. Regional Market Dynamics

North America remains the largest market due to high truck ownership and strict safety enforcement. However, Asia-Pacific is expected to witness the fastest growth, driven by expanding infrastructure, rising freight volumes, and increased government investment in transportation networks—particularly in India and Southeast Asia.

7. E-Commerce and Last-Mile Delivery Expansion

The boom in e-commerce has led to a surge in last-mile delivery vehicles, many of which are equipped with truck beds requiring effective load retention. Small businesses and delivery services are investing in affordable, user-friendly ratchet bars, creating new opportunities for mid-tier and budget product lines.

Conclusion

By 2026, the ratchet bar for truck bed market will be characterized by innovation, regulatory compliance, and a strong focus on durability and smart integration. Manufacturers who invest in advanced materials, sustainability, and digital enhancements will be best positioned to capture market share. With global logistics demands on the rise, ratchet bars will remain an essential component in safe and efficient cargo transport.

Common Pitfalls When Sourcing Ratchet Bars for Truck Beds (Quality and Intellectual Property)

Sourcing ratchet bars for truck beds—essential components used in cargo tie-down systems—requires careful attention to both product quality and intellectual property (IP) considerations. Failure to evaluate these aspects thoroughly can lead to operational risks, legal liabilities, and reputational damage. Below are key pitfalls to avoid.

1. Compromising on Material Quality and Durability

One of the most frequent issues is selecting ratchet bars made from substandard materials. Low-grade steel or poorly plated components may corrode quickly, especially in harsh weather conditions, leading to premature failure. Buyers should ensure that sourced ratchet bars meet industry standards for tensile strength, corrosion resistance (e.g., zinc or powder coating), and load ratings (typically 5,000 lbs or more for truck applications).

2. Inconsistent Manufacturing Tolerances

Poorly manufactured ratchet bars may have inconsistent dimensions or misaligned components, leading to improper fitment with truck bed rails or compatibility issues with tie-down straps. Always request product samples and verify dimensional accuracy against specifications before placing bulk orders.

3. Lack of Compliance with Safety Standards

Ratchet bars must comply with safety regulations such as those from the Department of Transportation (DOT) or standards like WSTDA (Web Sling & Tie Down Association). Sourcing non-compliant products can result in failed inspections, fines, or liability in the event of cargo shifting or accidents.

4. Ignoring Intellectual Property Rights

Many reputable ratchet bar designs are protected by patents, trademarks, or trade dress. Sourcing generic copies that mimic branded products (e.g., those resembling well-known brands like Erickson or Mac’s) can lead to IP infringement claims. Importers and distributors may face shipment seizures, legal action, or forced recalls.

5. Overlooking Patent Landscapes in Target Markets

Even if a product appears freely available overseas, it may still be protected by active patents in the destination country (e.g., the U.S., EU, or Canada). Conducting a freedom-to-operate (FTO) search before sourcing helps mitigate the risk of infringing existing patents, especially design or utility patents related to ratcheting mechanisms or mounting systems.

6. Relying on Unverified Suppliers

Sourcing from suppliers without proper audits or certifications increases the risk of receiving counterfeit or non-compliant products. Always verify supplier credentials, request test certifications (e.g., third-party load testing), and consider on-site factory inspections, especially when dealing with overseas manufacturers.

7. Failing to Secure Proper Documentation

Ensure suppliers provide documentation such as material certifications, test reports, and IP indemnification clauses in contracts. This protects your business in case of disputes related to quality failures or IP claims.

Conclusion

To avoid quality and IP pitfalls when sourcing ratchet bars for truck beds, conduct thorough due diligence on materials, compliance, supplier reliability, and intellectual property status. Proactive evaluation not only ensures product performance and safety but also safeguards your business from legal and financial risks.

Logistics & Compliance Guide for Ratchet Bar For Truck Bed

Product Overview and Classification

The ratchet bar for truck bed is a cargo control device designed to secure loads on pickup trucks and trailers. It typically consists of a steel or alloy bar with a ratcheting mechanism used in conjunction with tie-down straps. Proper classification is essential for compliance and logistics planning.

HTS Code and Import/Export Classification

The Harmonized Tariff Schedule (HTS) code for ratchet bars used in cargo securement generally falls under 7326.90.86 – “Other articles of iron or steel: Other: Other.” This classification may vary by country, so it is critical to confirm the correct HTS code with local customs authorities. Accurate classification ensures correct duty assessment and avoids delays.

Regulatory Compliance (U.S. Focus)

Ratchet bars must comply with U.S. Department of Transportation (DOT) and Federal Motor Carrier Safety Administration (FMCSA) regulations under 49 CFR Part 393, Subpart I – Cargo Securement. Key requirements include:

– Minimum Working Load Limit (WLL) of 50% of the cargo weight being secured.

– Proper labeling of WLL and manufacturer information on each ratchet bar.

– Compliance with the North American Cargo Securement Standard (based on FMCSA and CVSA guidelines).

Non-compliant products may be rejected at customs or result in fines during roadside inspections.

Packaging and Labeling Requirements

Each ratchet bar must be individually packaged to prevent damage during transit. Standard packaging includes:

– Corrugated cardboard boxes with internal padding.

– Bulk packaging in master cartons (e.g., 10–20 units per box) for efficient shipping.

Labels must include:

– Product name and model number.

– Working Load Limit (WLL) and Safe Working Load (SWL).

– Manufacturer or importer name and contact information.

– Country of origin (e.g., “Made in China”).

– Any required safety warnings (e.g., “Inspect before each use”).

Shipping and Transportation Logistics

Ratchet bars are typically shipped via Less-Than-Truckload (LTL), Full Truckload (FTL), or ocean freight (for international shipments). Key considerations:

– Use palletized loads secured with stretch wrap.

– Stack master cartons uniformly to prevent crushing.

– Include a packing list and commercial invoice with each shipment.

For international shipping, ensure Incoterms (e.g., FOB, CIF) are clearly defined in contracts.

Customs Documentation

Required documentation for import/export includes:

– Commercial Invoice (with itemized description, HTS code, value, and origin).

– Bill of Lading (BOL) or Air Waybill (AWB).

– Packing List (detailing weight, dimensions, and quantity).

– Certificate of Origin (if claiming preferential duty treatment under trade agreements).

Ensure all documents are consistent to prevent customs delays.

Quality and Safety Standards

Manufacturers should adhere to recognized quality standards such as:

– ISO 9001 for quality management.

– FMVSS No. 108 (if applicable for visibility-related components).

– Third-party certification (e.g., CVSA compliance verification) may enhance market acceptance.

Storage and Handling

Store ratchet bars in a dry, indoor environment to prevent rust and corrosion. Avoid exposure to moisture or extreme temperatures. Handle with care to avoid damaging ratcheting mechanisms during loading/unloading.

Environmental and Disposal Considerations

Ratchet bars are made primarily of recyclable metals. At end-of-life, they should be disposed of in accordance with local recycling regulations. Packaging materials should use recyclable cardboard and minimal plastic.

Conclusion

Compliance with logistics and regulatory standards ensures smooth distribution and legal use of ratchet bars for truck beds. By adhering to HTS classifications, FMCSA cargo securement rules, proper labeling, and shipping protocols, businesses can avoid fines, delays, and safety risks. Regular audits of compliance procedures are recommended.

Conclusion:

After evaluating various options for sourcing a ratchet bar for a truck bed, it is clear that selecting the right product involves balancing durability, compatibility, ease of installation, and cost. Ratchet tie-down bars are essential for securing cargo safely and preventing shifting during transit, making reliability a top priority. Based on research and user feedback, investing in a high-quality ratchet bar from reputable suppliers—whether purchased online through trusted retailers (such as Amazon, Home Depot, or specialized trucking supply stores) or through local automotive or hardware outlets—ensures better longevity and performance.

Additionally, key factors such as load capacity, material strength (typically steel or reinforced composite), corrosion resistance, and user-friendly ratcheting mechanisms should guide the final decision. Sourcing from suppliers that offer warranties and customer support further enhances value and peace of mind.

In summary, the optimal approach is to source a durable, well-rated ratchet bar that matches the truck bed’s specifications and intended use, prioritizing safety and long-term reliability over initial cost savings. This ensures secure cargo transportation and minimizes maintenance or replacement needs over time.