The global material handling equipment market, driven by rising automation in logistics and warehousing, is experiencing robust growth—projected to expand at a CAGR of 6.8% from 2024 to 2030, according to Grand View Research. Within this landscape, ramp jacks have emerged as critical support tools in construction, industrial, and transportation sectors, ensuring safe elevation and stabilization of mobile access ramps and platforms. As demand for durable, high-capacity lifting solutions increases, manufacturers are innovating with enhanced load ratings, corrosion-resistant materials, and modular designs. Fueled by infrastructure development and stringent workplace safety regulations, the industrial lifting equipment segment continues to gain traction. Leveraging market insights and performance metrics, here are the top 9 ramp jack manufacturers shaping the industry’s future.

Top 9 Ramp Jacks Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Car Ramp

Domain Est. 2012

Website: jacksall.com

Key Highlights: We are professional Car Ramp manufacturers and factory.We can produce Car Ramp according to your requirements.More types of Car Ramp wanted,please ……

#2 RAMPS & STANDS

Domain Est. 1997

Website: farmking.com

Key Highlights: RAMP, ALUMINUM BI-FOLD 1500LB. 1228281. Farm King Price: $141.59. Farm King SKU: 1228281; Manufacturer: ERICKSON B. MANUFACTURING; Manufacturer Part#:: 07458 ……

#3 Pallet Jack Curb Ramp

Domain Est. 1997

Website: bpmfg.com

Key Highlights: B&P Manufacturing Curb Ramps allow pallet jacks to travel up over curbs, fitting most pallet jacks. Double apron ends, lightweight aluminum, ……

#4 Beacon Industries Material Handling Equipment

Domain Est. 1998

Website: beacontechnology.com

Key Highlights: Beacon Industries is a world leading material handling equipment company providing loading dock equipment, lift tables, steel pipe guards, drum equipment, ……

#5 HD Ramps

Domain Est. 2008

Website: hdramps.com

Key Highlights: We develop innovative, lightweight aluminum products for loading, hauling and transportation needs. Our in-house engineering team has many years of experience….

#6 Jumpack Portable Bike Ramp

Domain Est. 2015

Website: jumpack.com

Key Highlights: 15-day returns* GENUINELY PORTABLE AT JUST 6KG! * SETS UP IN 20 SECONDS. * GOPRO COMPATIBLE. * INCLUDES BACKPACK. Suitable for all ages and levels of experience. £219.99 GBP….

#7 Car Ramp

Domain Est. 2016

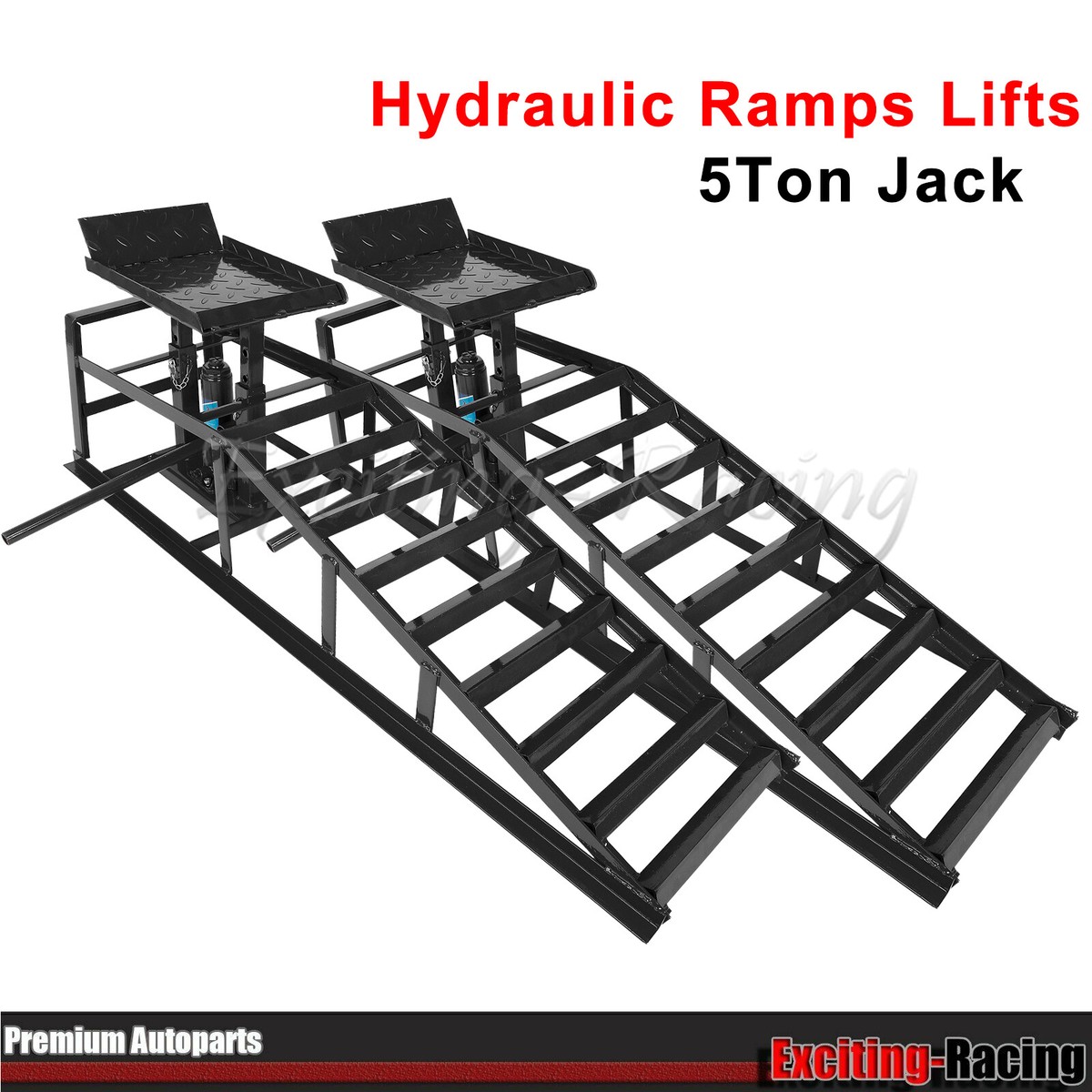

#8 GARVEE Hydraulic Car Ramps

Domain Est. 2022

Website: garvee.com

Key Highlights: Out of stock Rating 4.9 (108) Experience safe and efficient vehicle maintenance with GARVEE’s 10000 lbs hydraulic car ramps. Built for durability, perfect for low clearance vehic…

#9 Jacks, Ramps & Stands

Domain Est. 1996

Expert Sourcing Insights for Ramp Jacks

H2 2026 Market Trends for Ramp Jacks

The ramp jack market in the second half of 2026 is poised for continued evolution, shaped by broader industrial, construction, and logistics trends. Driven by infrastructure investment, automation, and sustainability demands, key developments are expected across technology, regional demand, and product innovation.

1. Accelerated Adoption of Smart and Automated Ramp Jacks

By H2 2026, smart ramp jacks integrated with IoT sensors and wireless monitoring will gain significant traction. Manufacturers are increasingly embedding load-sensing technology, tilt detection, and remote diagnostics into hydraulic and mechanical ramp jacks. These features enhance safety compliance and enable predictive maintenance—critical in high-utilization sectors like warehousing and aerospace. Fleet managers in logistics and construction will prioritize jacks with connectivity to central maintenance platforms, reducing downtime and improving operational efficiency.

2. Strong Regional Growth in Emerging Markets

Asia-Pacific—particularly India, Indonesia, and Vietnam—will lead global demand growth in H2 2026, driven by large-scale infrastructure projects and expanding manufacturing hubs. Government investments in transportation networks and industrial parks are increasing the need for reliable material handling equipment, including high-capacity ramp jacks. Meanwhile, Latin America and parts of Africa will see moderate growth, supported by urbanization and foreign direct investment in construction.

3. Sustainability and Lightweight Material Innovation

Environmental regulations and corporate ESG goals are pushing manufacturers to adopt lightweight, recyclable materials such as high-strength aluminum alloys and composite components. This shift not only reduces the carbon footprint of production but also improves portability and fuel efficiency in transport applications. By H2 2026, leading brands will likely market eco-certified ramp jacks with improved lifecycle sustainability, appealing to green procurement policies in both public and private sectors.

4. Rising Demand in E-Commerce and Last-Mile Logistics

The continued expansion of e-commerce is fueling need for efficient loading/unloading solutions at distribution centers and last-mile delivery depots. Compact, portable ramp jacks capable of rapid deployment are seeing increased adoption. In H2 2026, expect modular designs that integrate with electric delivery vans and urban micro-fulfillment centers, emphasizing ease of use and space efficiency.

5. Consolidation and Competitive Pricing Pressures

The market may experience consolidation as larger industrial equipment manufacturers acquire niche ramp jack producers to expand product portfolios. This could lead to standardized features and downward pressure on prices, especially for mid-tier mechanical models. However, premium segments—especially hydraulic and smart jacks—will maintain higher margins due to advanced technology and safety certifications.

6. Regulatory and Safety Standard Harmonization

With global trade increasing, H2 2026 will likely see greater alignment of safety standards (e.g., ISO, ANSI, CE) across regions. Manufacturers will invest in dual-certified products to streamline exports. Enhanced safety features—such as automatic locking mechanisms and overload alarms—will become baseline expectations, driven by stricter workplace safety regulations in North America and Europe.

Conclusion:

In H2 2026, the ramp jack market will be characterized by technological advancement, regional diversification, and sustainability focus. Companies that innovate in smart integration, lightweight design, and global compliance will be best positioned to capture growth, particularly in infrastructure-heavy and logistics-driven economies.

Common Pitfalls When Sourcing Ramp Jacks: Quality and Intellectual Property Risks

Sourcing ramp jacks—especially from lower-cost regions or unfamiliar suppliers—can expose buyers to significant risks related to product quality and intellectual property (IP) infringement. Being aware of these pitfalls is crucial for ensuring safety, compliance, and long-term reliability.

Quality Concerns in Ramp Jack Construction

One of the most prevalent issues when sourcing ramp jacks is inconsistent or substandard product quality. Ramp jacks are load-bearing components used in formwork systems, and failures can lead to serious safety hazards. Common quality pitfalls include:

- Use of Inferior Materials: Suppliers may use low-grade steel or subpar welding techniques to cut costs, compromising structural integrity and load capacity.

- Inaccurate Manufacturing Tolerances: Poorly machined components may not fit properly with other formwork elements, leading to instability or increased assembly time.

- Lack of Certification or Testing: Some suppliers provide products without valid third-party testing, load certification, or compliance with international standards (e.g., EN 12811, OSHA, or local building codes).

- Inconsistent Finish and Corrosion Resistance: Inadequate surface treatment (such as galvanization) can lead to premature rust and reduced lifespan, especially in harsh environments.

Buyers should demand material test reports, perform on-site audits, and request sample testing before placing bulk orders.

Intellectual Property Infringement Risks

Another critical risk when sourcing ramp jacks—particularly from manufacturers in regions with lax IP enforcement—is the potential for counterfeit or copied designs:

- Design Copying: Many ramp jacks are protected by patents or design rights. Unscrupulous suppliers may reverse-engineer and replicate branded products (e.g., Doka, Peri, Ulma) without authorization.

- Trademark Violations: Fake products may bear logos or branding indistinguishable from original equipment manufacturers (OEMs), misleading buyers and exposing them to legal liability.

- Lack of Legal Recourse: If infringing products are imported, the buyer—not just the supplier—may face legal action, customs seizures, or reputational damage.

To mitigate IP risks, conduct due diligence on suppliers, verify product authenticity, and include IP indemnity clauses in procurement contracts.

Conclusion

Sourcing ramp jacks requires careful attention to both quality assurance and intellectual property compliance. Prioritizing certified suppliers, conducting thorough audits, and verifying legal rights to designs can prevent costly delays, safety issues, and legal complications.

Logistics & Compliance Guide for Ramp Jacks

Overview

Ramp jacks are essential tools in material handling, commonly used in conjunction with loading docks, trailers, and warehouse operations to facilitate the safe movement of pallets and equipment. Proper logistics planning and compliance with safety standards are critical to avoid accidents, ensure efficiency, and meet regulatory requirements.

Equipment Specifications

- Load Capacity: Typically ranges from 2,000 to 6,000 lbs; confirm load limits per model.

- Construction: Steel frame with non-slip deck surfaces; often foldable for storage.

- Height Adjustability: Features adjustable legs to accommodate varying trailer or dock heights.

- Wheels: Equipped with swivel and rigid casters for mobility and stability.

Safety Compliance Requirements

- OSHA Standards: Comply with OSHA 29 CFR 1910.176 (material handling) and 1910.132 (personal protective equipment).

- ANSI/RMU 1-2020: Adhere to safety standards for industrial ramp jacks and dock plates.

- Load Limit Markings: Clearly labeled with maximum weight capacity in visible locations.

- Anti-Slip Surfaces: Required on walking/rolling surfaces to prevent slips and falls.

Transportation & Storage Logistics

- Securing During Transit: Ramp jacks must be fastened securely during transport using straps or chains to prevent shifting.

- Stacking and Storage: Store vertically or on racks to avoid deformation; avoid outdoor exposure to prevent rust.

- Forklift Handling: Use appropriate forklift procedures when moving ramp jacks—center the load and maintain stability.

Operational Best Practices

- Pre-Use Inspection: Check for structural damage, loose bolts, worn casters, or hydraulic leaks (if applicable).

- Proper Deployment: Ensure ramp jacks are fully locked in position and level before use.

- Alignment with Trailer: Confirm the ramp is properly seated on the trailer bed and dock to prevent tipping.

- Operator Training: Only trained personnel should operate or position ramp jacks; include in safety onboarding.

Maintenance & Inspection Schedule

- Daily: Visual inspection for damage and secure fasteners.

- Weekly: Check caster movement, locking mechanisms, and hydraulic function (if applicable).

- Monthly: Lubricate moving parts and inspect weld points.

- Annual: Professional inspection and load testing as needed.

Regulatory Documentation & Recordkeeping

- Maintain logs of inspections, maintenance, and repairs.

- Retain equipment manuals and compliance certificates on-site.

- Train staff on ramp jack use and document training sessions.

Emergency Procedures

- In Case of Failure: Immediately cease use, tag equipment as unsafe, and remove from service.

- Reporting: Notify supervisor and safety officer of any incidents or near misses.

- Replacement Protocol: Replace damaged or non-compliant units promptly; do not attempt field repairs unless certified.

Conclusion

Adhering to this logistics and compliance guide ensures the safe, efficient use of ramp jacks across operations. Prioritizing compliance, maintenance, and training reduces risk, enhances productivity, and supports a culture of workplace safety.

In conclusion, sourcing ramp jacks requires a careful evaluation of quality, load capacity, durability, and compliance with safety standards. It is essential to select suppliers or manufacturers that offer reliable products tested for structural integrity and suited to the intended application—whether for industrial, marine, or construction use. Factors such as material (typically steel or aluminum), ease of adjustability, portability, and customer support should also be considered. By prioritizing safety, performance, and long-term value over initial cost, organizations can ensure they procure ramp jacks that enhance operational efficiency, support worker safety, and provide a strong return on investment. Establishing relationships with reputable suppliers and conducting regular maintenance checks further ensures sustained reliability and optimal performance in the field.