The global ramen noodle machine market is experiencing robust growth, driven by rising demand for instant noodles across Asia-Pacific, North America, and emerging markets. According to a 2023 report by Mordor Intelligence, the global noodle and pasta processing equipment market—of which ramen noodle machines are a key segment—is projected to grow at a CAGR of 6.8% from 2023 to 2028. This expansion is fueled by increasing automation in food processing, consumer preference for convenient meals, and the scalability needs of large-scale noodle producers. Complementing this, Grand View Research valued the global instant noodles market at USD 58.7 billion in 2022, with continued expansion expected to stimulate investment in efficient, high-capacity production machinery. As manufacturers seek consistent quality, energy efficiency, and throughput, demand for advanced ramen noodle machines has surged. In this competitive landscape, identifying the top machine manufacturers has become critical for producers aiming to optimize output and maintain product integrity. Based on market presence, technological innovation, and customer feedback, the following ten companies represent the industry leaders shaping the future of ramen noodle production.

Top 10 Ramen Noodle Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Heshan Noodle Machinery for Wheat Ramen and Rice Noodle …

Domain Est. 1999

Website: heshan.com

Key Highlights: We are a Chinese noodle machine manufacturer. We make instant noodle machinery, noodle factory machines that produce rice noodles and starch cellophane glass ……

#2 Heshan Machinery

Domain Est. 2001

Website: noodle-machines.com

Key Highlights: Zhanjiang Heshan Machinery Co., Ltd. is a leading manufacturer of ramen and rice noodle making machines. Heshan provides noodle making plant turnkey ……

#3 Nongshim USA

Domain Est. 2005

Website: nongshimusa.com

Key Highlights: Discover Nongshim America:leading producer of authentic Korean instant noodles and snacks, including the famous Shin Ramyun. Taste the tradition!…

#4 Ramen Machine and Production Solution

Domain Est. 1998

Website: anko.com.tw

Key Highlights: ANKO NDL-100 Commercial Ramen Machine produces authentic Japanese ramen, udon, soba noodles at 100kg/hr. Compact design, quick mold changes, gluten-free ……

#5 Richmen Series

Domain Est. 2010

Website: yamatonoodle.com

Key Highlights: A professional noodle machine, specifically designed for use in commercial settings. This state-of-the-art machine produces authentic Japanese ramen noodles, ……

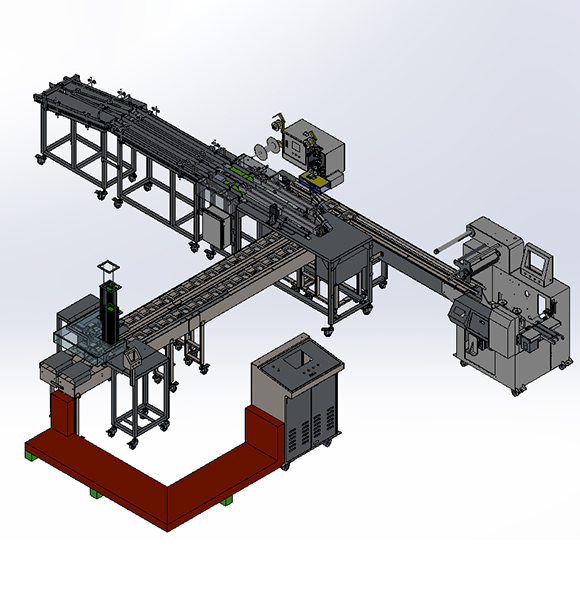

#6 Ramen Noodle Packaging Line

Domain Est. 2011

Website: taidragon.com

Key Highlights: Connected with noodle making system, it automaticly delivers noodles to packaging machine. The system consists of automatic alignment unit and distribution….

#7 Yamato Noodle Company

Domain Est. 2015

Website: ramenmachine.com

Key Highlights: It is a machine to make authentic udon noodles – high in water content. (Udon, soba, ramen, pasta, etc.) 1. Solid durable machine that lasts and is easy to use ……

#8 Yo

Domain Est. 2016

Website: yokaiexpress.com

Key Highlights: Yo-Kai Express is the revolutionary high tech company who develope future autonomous restaurant to serve people gourmet food 24/7….

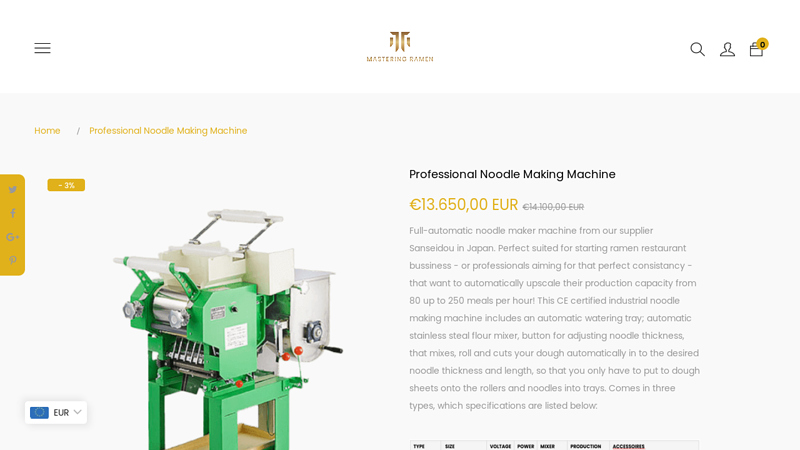

#9 Professional Noodle Making Machine

Domain Est. 2022

#10 Instant Noodle Production Line

Domain Est. 2024

Website: loyalmachines.com

Key Highlights: Discover high-quality instant noodle production lines manufactured in China, designed for efficiency and reliability. Partner with us for loyal service and ……

Expert Sourcing Insights for Ramen Noodle Machine

H2: 2026 Market Trends for Ramen Noodle Machines

The global ramen noodle machine market is poised for significant transformation by 2026, driven by evolving consumer demands, technological advancements, and shifting production landscapes. Here are the key trends shaping the industry:

1. Surge in Demand for Premium & Artisanal Machines:

With the global rise of premium and gourmet ramen experiences, there’s increasing demand for high-end ramen noodle machines capable of producing authentic, hand-pulled or traditionally textured noodles. Manufacturers are focusing on machines that replicate artisanal techniques—such as precise kneading, laminating, and cutting—while maintaining scalability. In 2026, expect advanced models with customizable settings for moisture, gluten tension, and cutting width, catering to specialty restaurants and boutique producers.

2. Automation and Smart Manufacturing Integration:

Automation is no longer optional. By 2026, fully automated ramen noodle production lines with IoT connectivity will dominate industrial segments. These machines feature real-time monitoring, predictive maintenance, and AI-driven quality control to minimize waste and ensure consistency. Integration with ERP and MES systems allows seamless data flow from production to inventory, enhancing efficiency for large-scale food processors.

3. Growth in Compact and Modular Designs for SMEs:

Small and medium-sized enterprises (SMEs), including cloud kitchens and local ramen shops, are driving demand for compact, modular noodle machines. These units offer space efficiency, lower capital investment, and ease of operation. The 2026 market will see more plug-and-play models with quick changeover capabilities, enabling operators to switch between noodle types (e.g., thin, thick, wavy) with minimal downtime.

4. Emphasis on Food Safety and Hygienic Design:

Regulatory scrutiny and consumer awareness are pushing manufacturers to adopt hygienic engineering principles. Ramen noodle machines in 2026 will increasingly feature stainless steel construction, seamless welds, self-cleaning functions, and certifications like EHEDG or 3-A. These features reduce contamination risks and comply with global food safety standards, especially in North America and Europe.

5. Sustainability and Energy Efficiency:

Eco-consciousness is influencing equipment design. Machines with energy-efficient motors, water recycling systems, and reduced material waste are gaining traction. By 2026, suppliers will highlight low carbon footprints and sustainable lifecycle management as competitive advantages, aligning with corporate ESG goals.

6. Regional Expansion and Localization:

While Asia-Pacific remains the largest market, North America and Europe are experiencing rapid growth due to ramen’s popularity. Equipment manufacturers are localizing support services, offering machines compatible with regional flour types (e.g., durum wheat in Europe), and adapting to local voltage and safety standards. This localization strategy will accelerate market penetration.

7. Rise of Plant-Based and Alternative Ingredient Compatibility:

As plant-based diets expand, ramen noodle machines must handle alternative flours (e.g., chickpea, buckwheat, gluten-free blends). By 2026, multi-functional machines with adjustable torque and hydration systems will be essential to accommodate diverse dough rheologies, supporting innovation in health-focused noodle products.

In summary, the 2026 ramen noodle machine market will be characterized by technological sophistication, customization, and alignment with sustainability and food safety imperatives. Producers who embrace automation, flexibility, and hygiene will lead in an increasingly competitive and globalized landscape.

Common Pitfalls When Sourcing a Ramen Noodle Machine: Quality and Intellectual Property Concerns

Sourcing a ramen noodle machine, especially from international suppliers, involves several risks that can impact product quality, operational efficiency, and legal compliance. Two major areas of concern are machine quality and intellectual property (IP) protection. Being aware of these pitfalls helps ensure a reliable, cost-effective, and legally sound procurement process.

1. Compromised Machine Quality

One of the most frequent issues when sourcing ramen noodle machines is receiving equipment that fails to meet performance or durability standards. Common quality-related pitfalls include:

-

Inconsistent Noodle Output: Poorly calibrated or low-grade machines may produce noodles with inconsistent thickness, texture, or shape, affecting the final product’s quality and customer satisfaction.

-

Substandard Materials and Construction: Machines made with inferior stainless steel or non-food-grade components can corrode, contaminate food, or break down prematurely, increasing maintenance costs and downtime.

-

Lack of Precision in Automation: Automated ramen machines require precise control over dough mixing, sheeting, cutting, and steaming. Low-quality controllers or sensors can lead to inefficiencies and inconsistent production.

-

Insufficient After-Sales Support: Many overseas suppliers offer limited technical support, spare parts availability, or training, making repairs difficult and costly.

-

Misleading Specifications: Some manufacturers exaggerate machine capacity, speed, or automation level, leading to performance shortfalls once installed.

To mitigate these risks, conduct factory audits, request third-party quality inspections, and ask for operational references or video demonstrations before purchase.

2. Intellectual Property (IP) Risks

When sourcing specialized ramen noodle machines—particularly those with unique automation or patented processes—IP infringement is a serious concern:

-

Counterfeit or Copycat Machines: Some suppliers reverse-engineer patented machinery from reputable brands without authorization. Purchasing such equipment can expose your business to legal liability, especially if used commercially.

-

Use of Unauthorized Software or Controls: Machines may include pirated PLC (Programmable Logic Controller) software or copied user interfaces, violating international software licensing agreements.

-

Lack of IP Documentation: Reputable manufacturers should provide proof of IP ownership or licensing for proprietary technologies. Absence of such documentation increases the risk of unknowingly acquiring infringing equipment.

-

Export and Import Legal Complications: Importing machines that violate IP rights can result in customs seizures, fines, or lawsuits, particularly in regions with strong IP enforcement (e.g., EU, U.S., Japan).

To protect your business, verify the supplier’s IP credentials, request documentation of patents or licenses, and consider involving legal counsel when purchasing high-tech or proprietary equipment.

Conclusion

Sourcing a ramen noodle machine requires due diligence beyond price and delivery terms. Prioritizing quality assurance and IP compliance helps avoid long-term operational disruptions, legal exposure, and reputational damage. Engaging independent inspectors, verifying supplier credentials, and conducting thorough contract reviews are essential steps in a successful sourcing strategy.

Logistics & Compliance Guide for Ramen Noodle Machine

Product Classification & HS Code

Identify the Harmonized System (HS) Code for the ramen noodle machine to ensure correct customs classification. Typical classifications fall under machinery for food processing (e.g., HS 8438.80 or 8438.10, depending on specific function). Accurate classification affects import duties, taxes, and regulatory requirements in the destination country.

Import Regulations & Permits

Verify import regulations in the target market. Some countries require permits, pre-shipment inspections, or product registration for food-processing equipment. Ensure compliance with local food safety and machinery safety standards (e.g., FDA in the U.S., CE in the EU, or JIS in Japan).

Packaging & Shipping Requirements

Use robust, export-grade packaging to protect the machine during transit. Include moisture barriers and shock-absorbing materials. Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include essential product details. Choose shipping method (air, sea, or land) based on cost, lead time, and machine size.

Electrical & Safety Compliance

Confirm the machine meets electrical standards of the destination country (e.g., voltage: 110V/60Hz vs. 220-240V/50Hz). Adaptors or transformers may be needed. Ensure the machine complies with safety certifications such as CE, UL, or EAC, and includes required safety guards, emergency stops, and grounding.

Documentation for Customs Clearance

Prepare complete documentation, including:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Safety and Compliance Certificates

– Technical Specifications and User Manual (translated if required)

Incomplete paperwork may result in delays or seizure.

Sanitation & Food-Grade Materials Compliance

Ensure all components in contact with food are made from food-grade materials (e.g., stainless steel 304 or 316) and comply with food safety regulations such as FDA 21 CFR or EU Regulation (EC) No 1935/2004. Provide documentation confirming material compliance.

After-Sales Support & Warranty Logistics

Establish a service and spare parts supply chain in the target market. Include warranty terms in the sales contract and clarify responsibilities for repairs and technical support. Consider local service partners to reduce downtime.

Environmental & Disposal Regulations

Be aware of environmental regulations regarding the disposal of packaging materials and end-of-life equipment. Some regions require producers to comply with extended producer responsibility (EPR) rules for industrial machinery.

Training & Installation Support

Plan for on-site or remote installation and operator training, especially for complex machinery. Provide manuals in the local language and comply with occupational health and safety standards during installation.

Risk Management & Insurance

Secure comprehensive cargo insurance covering transit risks (e.g., damage, loss, delay). Consider product liability insurance, especially when selling to commercial food operators. Conduct a risk assessment for supply chain vulnerabilities.

In conclusion, sourcing a ramen noodle machine requires careful consideration of several key factors including production capacity, automation level, budget, maintenance requirements, and supplier reliability. Whether for a small-scale restaurant or a large commercial operation, selecting the right machine directly impacts noodle quality, consistency, and operational efficiency. Conducting thorough research, comparing multiple suppliers, evaluating after-sales support, and possibly testing the machine before purchase will ensure a sound investment. Additionally, prioritizing food safety standards and ease of cleaning will contribute to long-term success. By aligning the machine specifications with your business needs, sourcing a ramen noodle machine can significantly enhance productivity and product quality, ultimately supporting business growth and customer satisfaction.