The global performance automotive suspension market is gaining significant traction, driven by rising demand for enhanced vehicle handling and stability in extreme driving conditions. According to Mordor Intelligence, the automotive suspension market is projected to grow at a CAGR of over 4.5% from 2024 to 2029, fueled by advancements in adaptive and performance-tuned suspension systems—particularly in motorsports and high-performance vehicle segments. Rally racing, known for its grueling terrain and dynamic load conditions, places exceptional demands on suspension components, making reliability, adjustability, and durability critical. As competition intensifies and technology evolves, leading manufacturers are investing heavily in R&D to deliver cutting-edge solutions tailored for rally applications. This growing market momentum, supported by data from industry analysts like Mordor Intelligence, underscores the importance of innovation in suspension engineering. In this context, the following list highlights the top 10 suspension manufacturers shaping the future of rally racing through proven performance, technological precision, and race-proven reliability.

Top 10 Rally Racing Suspension Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Öhlins

Domain Est. 1996

Website: ohlins.com

Key Highlights: Racing is in our DNA. Öhlins delivers world-leading suspension technology for MotoGP, Formula 1, Rallycross and performance vehicles worldwide….

#2 H&R Motorsport

Domain Est. 1998

Website: h-r.com

Key Highlights: H&R has been one of the world’s leading manufacturers of sporty suspension components in top international motorsports….

#3 RideFOX

Domain Est. 2009

Website: ridefox.com

Key Highlights: Get your suspension serviced by a professional FOX technician and get back to peak performance. We guarantee the best and most comprehensive service….

#4 to Bos Suspension

Domain Est. 2014

Website: bos-suspension.com

Key Highlights: Designer and manufacturer of suspension for car, motorcycle and mountain bike sports. GAMME MTB. MOUNTAIN BIKE RANGE. GAMME MOTO….

#5 Eibach

Domain Est. 1996

Website: eibach.com

Key Highlights: Renowned for superior engineering, quality and innovation, Eibach offers suspension parts for professional racers, avid enthusiasts, and those seeking the best ……

#6 Race Tech

Domain Est. 1997

Website: racetech.com

Key Highlights: Race Tech Suspension has over 36 years of creating hi-performance suspension solutions for motorcycles, ATVs, UTVs, and snowmobiles….

#7 AST x MOTON Suspension

Domain Est. 1999

Website: ast-suspension.com

Key Highlights: AST and MOTON motorsport suspension systems deliver exceptional performance for competitive drivers. With advanced adjustability and superior damping, they ……

#8 Reiger Suspension

Domain Est. 2000 | Founded: 1977

Website: reigersuspension.com

Key Highlights: Since 1977 Reiger has produced the most capable offroad racing shock absorbers in Hengelo. We won titles in WRC, the Rally Dakar in different classes and many ……

#9 The Perfect Suspension for Every Demand KW suspensions

Domain Est. 2000

Website: kwsuspensions.com

Key Highlights: Welcome to KW suspensions! With us you will find a suspension solution for every use ➤ Whether road, trackday or professional motorsport!…

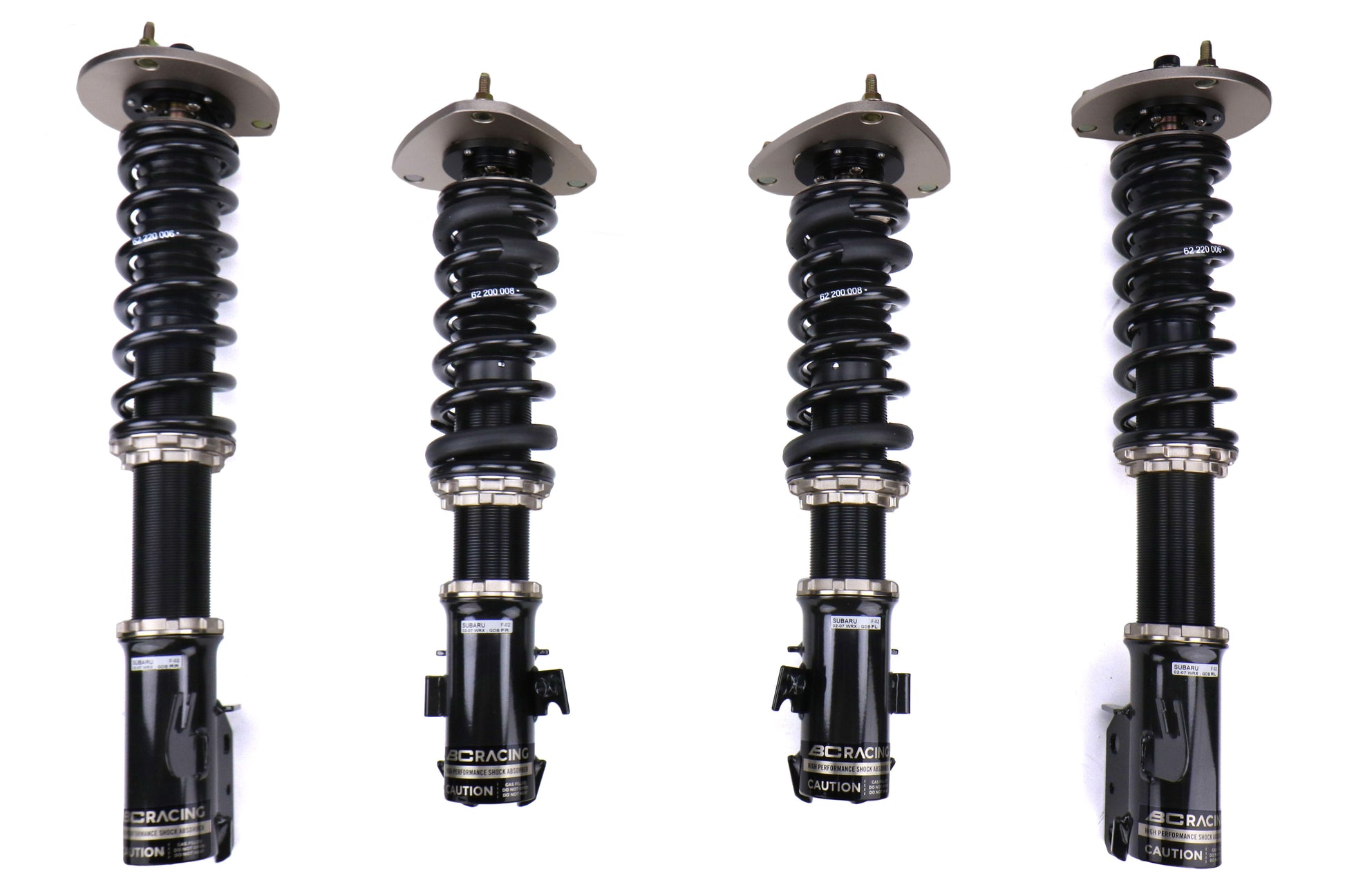

#10 BC Racing

Domain Est. 2006

Website: bcracing-na.com

Key Highlights: BC Racing offers truly bespoke coilover systems for motorsport applications. Motorsport systems require BC Racing engineers to work directly with your team….

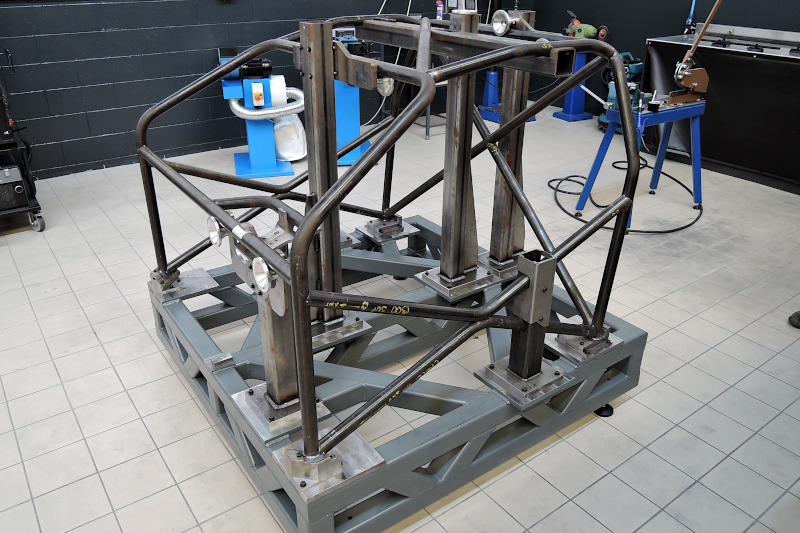

Expert Sourcing Insights for Rally Racing Suspension

H2: 2026 Market Trends for Rally Racing Suspension

By 2026, the rally racing suspension market is poised for significant transformation, driven by technological innovation, evolving competition demands, and broader automotive industry shifts. Key trends shaping the sector include:

1. Advanced Materials & Lightweighting Intensification: The relentless pursuit of performance will accelerate the adoption of next-generation materials. Expect wider use of high-strength, low-density composites (e.g., carbon fiber reinforced polymers in control arms, links), advanced titanium alloys, and sophisticated aluminum alloys. This focus on reducing unsprung mass will enhance handling, acceleration, and fuel efficiency, becoming a critical differentiator especially in top-tier WRC and Rally1 categories.

2. Smart & Adaptive Suspension Systems Maturation: Electromechanical and electro-hydraulic adaptive dampers, already present in prototypes and select high-end applications, will move towards greater sophistication and potential trickle-down. Systems using real-time sensor data (wheel speed, body motion, GPS terrain mapping) to pre-emptively adjust damping rates for upcoming terrain will become more refined. While cost and complexity remain barriers for grassroots, their proven performance benefits will push development, potentially influencing future regulations.

3. Data-Driven Design & Simulation Dominance: High-fidelity simulation (Finite Element Analysis, Multibody Dynamics) will be indispensable. Teams and OEMs will rely heavily on virtual testing to optimize suspension geometry, component strength, and kinematics, significantly reducing physical prototype cycles and development time. Integration of real-world telemetry data from rallies will continuously refine these models, leading to faster iteration and more robust designs.

4. Focus on Durability & Reliability Optimization: As rally stages push limits and regulations demand longer component life (e.g., Rally1 homologation), suspension systems will emphasize extreme durability without sacrificing performance. This involves advanced heat dissipation technologies in dampers, enhanced sealing against mud/water, improved corrosion resistance, and predictive maintenance algorithms based on sensor data to prevent failures.

5. Electrification’s Indirect Influence: While pure electric rally cars (like in Extreme E) have different suspension demands (higher weight, torque characteristics), the broader push for electrification drives innovation in lightweight materials and thermal management applicable to all suspensions. Furthermore, hybrid Rally1 cars necessitate suspension components coping with complex weight distributions and dynamic loads from powertrain integration.

6. Sustainability & Circular Economy Pressures: Environmental regulations and team commitments will increase focus on sustainable manufacturing processes, recyclable materials, and end-of-life component management. This may drive innovations in repairability, modular designs, and the use of bio-based or recycled content in non-structural elements.

7. Cost Containment & Tiered Innovation: While top-tier teams push technological boundaries, the grassroots and regional rally markets will drive demand for cost-effective, reliable, and serviceable suspension solutions. This will foster innovation in durable, simplified designs and the growth of the performance aftermarket offering reliable upgrades accessible to privateers.

In conclusion, the 2026 rally suspension market will be characterized by a convergence of cutting-edge materials science, intelligent systems, and data-centric engineering, all aimed at extracting maximum performance and reliability. While elite competition drives innovation, the broader market will balance these advances with cost, durability, and sustainability demands.

Common Pitfalls When Sourcing Rally Racing Suspension: Quality and Intellectual Property Concerns

Sourcing high-performance suspension components for rally racing involves significant technical and legal challenges. Overlooking key factors related to quality and intellectual property (IP) can lead to poor performance, safety risks, and legal exposure.

Poor Quality Control and Material Integrity

Many suppliers, especially in cost-driven markets, use substandard materials or inconsistent manufacturing processes. Rally suspension systems endure extreme stress, and components made from inferior alloys or with improper heat treatment can fail catastrophically. Buyers often encounter exaggerated performance claims without third-party validation or dyno testing data. Without rigorous quality audits or certifications (e.g., ISO 9001), there’s a high risk of receiving inconsistent or unreliable parts that compromise vehicle handling and driver safety.

Lack of Application-Specific Engineering

Off-the-shelf or generic suspension systems are frequently marketed as “rally-ready” but lack the precise tuning and design needed for specific vehicle dynamics, terrain types, and competition regulations. Sourcing components not engineered for actual rally conditions—such as prolonged high-speed impacts or variable damping requirements—leads to poor performance, increased maintenance, and shortened component lifespan. Always verify that the suspension is developed and tested in real-world rally environments.

Counterfeit or Reverse-Engineered Components

The high cost of genuine performance suspension systems makes the market vulnerable to counterfeit or cloned products. Some suppliers illegally replicate patented designs from reputable brands (e.g., Öhlins, Bilstein, or Moton), offering “look-alike” shocks and struts at lower prices. These copies often lack the precise valving, sealing technology, and durability of authentic units. Purchasing such components not only risks mechanical failure but also exposes teams and suppliers to intellectual property infringement claims.

Intellectual Property Infringement Risks

Using or sourcing suspension components that infringe on patented technologies—such as unique damping systems, adjustability mechanisms, or mounting configurations—can lead to legal action, seizure of equipment, or disqualification from competition. Teams and suppliers must ensure that components are either licensed, original equipment, or independently designed without violating existing IP. Conduct due diligence by requesting documentation on design ownership and licensing, particularly when dealing with lesser-known manufacturers.

Inadequate Documentation and Traceability

Reliable rally suspension systems should come with full documentation, including build sheets, dyno curves, material certifications, and warranty terms. Many low-cost suppliers provide little or no traceability, making it difficult to verify authenticity, perform maintenance, or support warranty claims. This lack of transparency increases long-term costs and operational risks, especially in regulated motorsport environments where component provenance may be scrutinized.

Avoiding these pitfalls requires partnering with reputable, transparent suppliers who prioritize engineering integrity, quality assurance, and IP compliance—ensuring both competitive performance and legal safety.

Logistics & Compliance Guide for Rally Racing Suspension

Overview

This guide outlines key logistics and compliance considerations for the procurement, transportation, installation, and use of suspension systems in rally racing. Adherence ensures safety, regulatory compliance, and competitive eligibility across various rally series and jurisdictions.

Regulatory Compliance

FIA Sporting and Technical Regulations

All suspension components must comply with the Fédération Internationale de l’Automobile (FIA) Appendix J, Article 254 (for Rally 1, Rally2, Rally3, etc.) and applicable homologation requirements. Modifications must not deviate from approved specifications unless permitted under specific technical eligibility forms (TEFs).

National and Regional Regulations

In addition to FIA standards, competitors must adhere to regulations set by national motorsport authorities (e.g., Motorsport UK, ASN in the U.S.). These may include noise limits, safety inspections, and environmental requirements impacting suspension setup or fluid use.

Homologation and Certification

Suspension systems and components (e.g., dampers, control arms) used in regulated rally classes must carry valid FIA homologation or technical passport documentation. Non-homologated parts require pre-approval via TEFs or must fall within permitted development allowances.

Logistics Management

Supply Chain and Procurement

Source suspension components from FIA-approved or reputable suppliers with traceable manufacturing records. Maintain a documented supply chain to support compliance audits and ensure authenticity of parts.

Inventory and Spare Parts

Maintain sufficient inventory of critical suspension spares (e.g., shock absorbers, bushings, control arms) based on rally length, terrain severity, and service intervals. Use serialized tracking for high-value or regulated items.

International Transport

When shipping suspension components internationally:

– Ensure compliance with customs regulations (e.g., HS codes for automotive parts, duty exemptions under ATA Carnet).

– Declare all parts accurately, including homologation status.

– Use shock-resistant packaging with moisture protection to prevent damage during transit.

On-Site Handling and Storage

At service parks or remote locations:

– Store suspension components in clean, dry environments to prevent contamination or corrosion.

– Use protective covers for disassembled parts.

– Label all components clearly to avoid incorrect installation.

Safety and Installation Compliance

Installation Procedures

Follow manufacturer guidelines and FIA technical bulletins for correct suspension assembly and torque specifications. Use calibrated tools and record installation data for traceability during technical checks.

Pre-Race Technical Inspection

Ensure suspension systems are fully compliant before technical scrutineering. Key inspection points include:

– No unauthorized modifications.

– Secure mounting and absence of cracks or leaks.

– Correct ride height and geometry within class limits.

– Valid certification labels or serial numbers visible.

In-Service Modifications

Any suspension adjustments during an event (e.g., ride height, damping settings) must comply with regulations. Adjustable dampers must retain factory seals unless explicitly permitted.

Environmental and Waste Compliance

Fluid Management

Hydraulic fluids (e.g., shock oil) must be handled, stored, and disposed of in accordance with local environmental laws. Use sealed containers and absorbent mats to prevent spills. Recycle used fluids through certified channels.

Hazardous Materials

Be aware of substances regulated under REACH (EU) or similar frameworks. Suspension components may contain restricted materials (e.g., certain chromates); documentation should be available upon request.

Recordkeeping and Documentation

Maintain detailed logs for:

– Component serial numbers and homologation documents.

– Installation, maintenance, and repair history.

– Transport manifests and customs declarations.

– Technical inspection reports and compliance certificates.

Retention period: Minimum of 2 years or as required by sanctioning body.

Conclusion

Effective logistics and strict compliance with technical and safety regulations are essential for competitive rally teams. Proactive management of suspension systems ensures reliability on challenging terrain while maintaining eligibility for competition. Regular review of FIA and national regulations is recommended to adapt to rule changes.

In conclusion, sourcing suspension components for rally racing requires a careful balance of performance, durability, and compatibility with specific vehicle dynamics and terrain demands. High-quality, adjustable coilovers, reinforced control arms, advanced dampers, and performance bushings from reputable manufacturers are essential to withstand the extreme stresses of off-road conditions while providing optimal handling, traction, and driver feedback. Proper research, expert consultation, and consideration of regulations and budget constraints are crucial steps in building a reliable and competitive suspension setup. Ultimately, investing in purpose-built rally suspension not only enhances vehicle performance but also ensures safety and consistency across diverse and challenging rally environments.