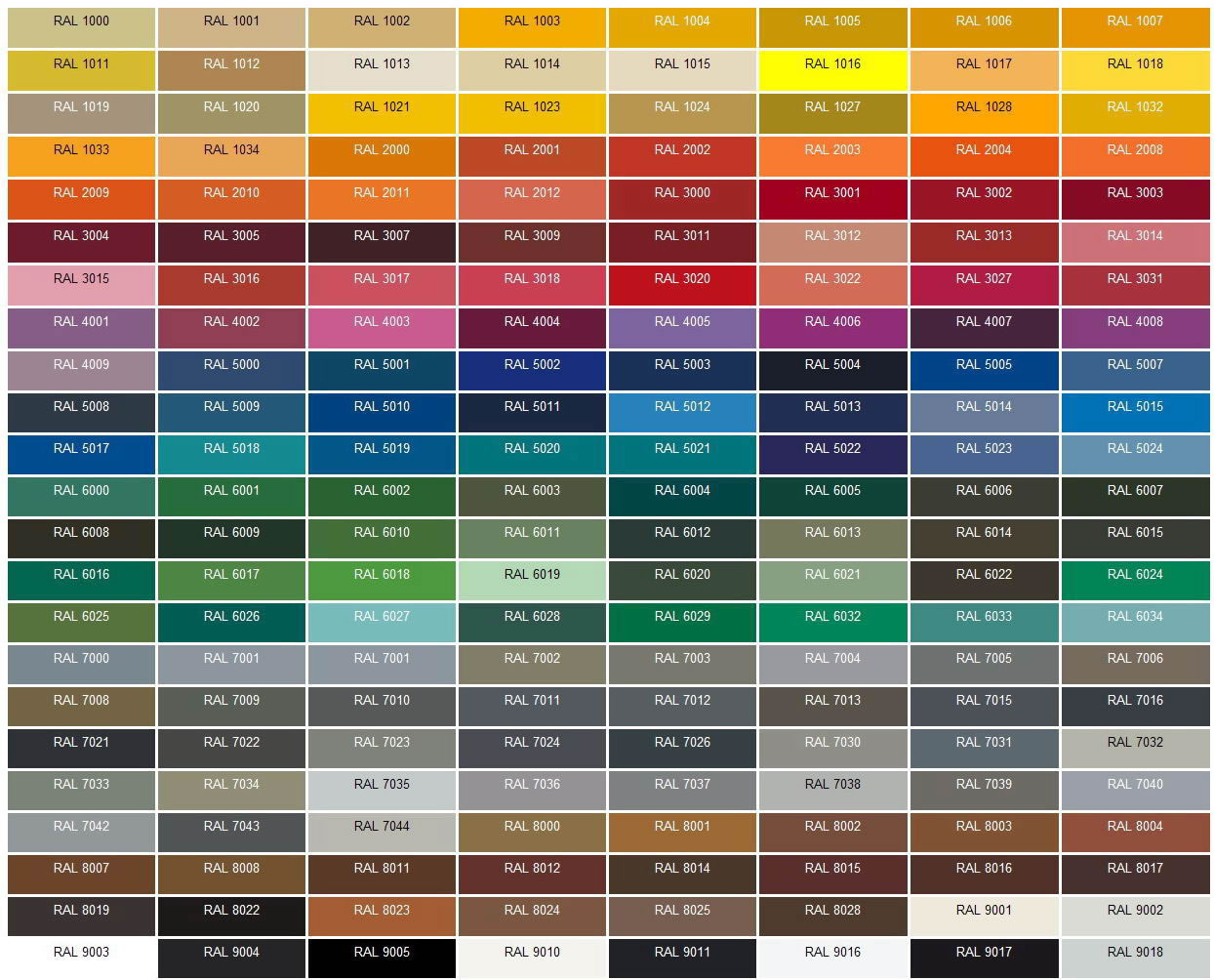

The global powder coating market is experiencing robust growth, driven by increasing demand for durable, eco-friendly, and cost-effective surface finishing solutions across industries such as automotive, construction, and appliances. According to a report by Mordor Intelligence, the powder coatings market was valued at USD 13.43 billion in 2023 and is projected to reach USD 19.67 billion by 2029, growing at a CAGR of approximately 6.5% during the forecast period. This expansion is fueled by regulatory support for low-VOC (volatile organic compound) coatings and the superior performance attributes of powder coatings over traditional liquid paints. As one of the most popular pigment systems in the segment, RAL-standard powder coatings ensure color consistency and global compatibility, making them a preferred choice for industrial applications. Amid this growth, a select group of manufacturers have emerged as leaders in delivering high-quality RAL powder coat colors, combining technical innovation, color precision, and sustainability to meet evolving market demands.

Top 6 Ral Powder Coat Colors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 RAL Powder Colors

Domain Est. 1998

Website: industrial.sherwin-williams.com

Key Highlights: Our Powdura® RAL Series offers superior weatherability and TGIC-Free polyester powder coatings across a broad range of 188 colors, available in full gloss and ……

#2 RAL Color System Powder Collection

Domain Est. 1990

#3 RAL Colors for Commercial Garage Doors

Domain Est. 1996

Website: cornelliron.com

Key Highlights: Custom Powder Coat Colors for Commercial Garage Doors. Find the perfect hue for your project with our RAL colors for power-coated doors at Cornell….

#4 RAL Color Chart Custom Powder Coating

Domain Est. 1998

Website: wrightcoating.com

Key Highlights: We are able to apply powder coatings in a wide selection of custom and RAL colors including black, blue, yellow, red, silver, orange, white, and more!…

#5 RALcolorchart.com

Domain Est. 2015

Website: ralcolorchart.com

Key Highlights: RAL is a color matching system that defines colors for paints, coatings and plastics. On this website you find all RAL colors (2,831). RAL Classic is the most ……

#6 RAL Matched Powder Coated Color Plate Samples

Domain Est. 2019

Website: crosslinkpaints.com

Key Highlights: In stock $15 deliveryRAL Matched Color Chip Samples made from aluminium and powder coated to the RAL specification required. Perfect for displays, examples, color comparison, etc….

Expert Sourcing Insights for Ral Powder Coat Colors

H2: 2026 Market Trends for RAL Powder Coat Colors

As we approach 2026, the global demand for RAL powder coat colors is undergoing a transformative shift, driven by sustainability mandates, technological advancements, and evolving consumer preferences across key industries such as architecture, automotive, and industrial manufacturing. The RAL color system—renowned for its precision and standardization—continues to play a pivotal role in meeting these demands, with several notable trends shaping the market landscape.

1. Surge in Sustainable and Eco-Friendly Coatings

Environmental regulations such as REACH, RoHS, and the EU Green Deal are accelerating the adoption of low-VOC, recyclable, and bio-based powder coatings. By 2026, manufacturers are increasingly aligning RAL color offerings with eco-certifications, introducing formulations that reduce carbon footprints without compromising on color accuracy or durability. Matte and textured finishes in earth-toned RAL shades—such as RAL 7040 (Window Grey), RAL 7024 (Graphite Grey), and RAL 6005 (Moss Green)—are gaining traction in green building projects and sustainable urban infrastructure.

2. Dominance of Neutral and Monochromatic Palettes

Urbanization and minimalist design aesthetics are fueling demand for neutral RAL colors. Shades like RAL 9006 (White Aluminium), RAL 7016 (Anthracite Grey), and RAL 9005 (Jet Black) remain dominant in architectural facades, window frames, and street furniture. Monochromatic schemes using subtle tonal variations within the RAL Classic system are being favored for their timeless appeal and adaptability to smart city designs.

3. Growth in Customization and Digital Color Matching

Advancements in digital color management tools are enabling precise RAL color replication and customization. By 2026, AI-driven software integrated with spectrophotometers allows manufacturers to match or modify RAL shades with greater speed and accuracy. This trend supports niche markets, such as heritage restoration projects requiring exact RAL historical color matches (e.g., RAL 840-HR for retro designs).

4. Expansion of RAL Effect and Metallic Finishes

Demand for premium aesthetics is driving growth in RAL Effect powders, including metallic, pearlescent, and textured finishes. Colors like RAL 9006 with metallic effect or RAL 842-M (a brushed aluminum tone) are increasingly used in high-end appliances, transportation, and luxury architectural elements. The RAL Design System, with its expanded 1,825 colors and enhanced finish options, is becoming more integrated into B2B procurement platforms.

5. Regional Market Diversification

While Europe remains the core market for RAL standards, Asia-Pacific—particularly China and India—is witnessing rapid adoption due to urban development and industrial modernization. Local manufacturers are licensing RAL color standards to ensure international compliance, especially in export-oriented sectors like automotive and construction. North America is also seeing increased use of RAL specifications in commercial and government infrastructure projects.

6. Integration with Smart Manufacturing and Industry 4.0

Powder coating processes are becoming more automated, with RAL color data integrated into digital production systems. By 2026, smart factories use IoT-enabled mixing systems that automatically calibrate pigments to achieve precise RAL tones, reducing waste and enhancing efficiency.

Conclusion

The 2026 RAL powder coat color market is defined by innovation, sustainability, and digital integration. As industries prioritize both aesthetic consistency and environmental responsibility, RAL’s role as a global color authority is being reinforced through adaptive product development and technological synergy. Companies that leverage the full spectrum of RAL’s standardized yet customizable offerings—spanning Classic, Design, and Effect systems—are best positioned to lead in this dynamic market.

Common Pitfalls When Sourcing RAL Powder Coat Colors (Quality & IP)

Sourcing RAL powder coat colors seems straightforward, but several critical pitfalls related to quality and intellectual property (IP) can lead to project delays, cost overruns, and legal issues. Being aware of these challenges is essential for ensuring a successful supply chain.

Inconsistent Color Matching and Quality Control

One of the most frequent issues is receiving powder that does not accurately match the specified RAL color. While RAL provides standard color definitions, not all powder manufacturers adhere strictly to these tolerances. Poor quality control can result in batch-to-batch variations, leading to visible inconsistencies in finished products—especially when parts are coated at different times or by different suppliers. Buyers may assume “RAL 9005” means a uniform black, but differences in pigment concentration, resin base, and curing processes can produce noticeable hue or sheen differences.

Use of Non-Standard or “RAL-Style” Color Names

Many suppliers offer colors labeled as “RAL 7016” or similar, but these may not be officially licensed or certified. Some manufacturers produce “RAL-style” or “RAL equivalent” powders without proper authorization, potentially infringing on RAL’s intellectual property. These products may drift in color accuracy or lack the durability specifications of genuine RAL-compliant coatings, risking non-compliance in architectural or industrial specifications.

Lack of RAL Certification and Licensing

RAL color standards are protected intellectual property. Legitimate use of RAL color names and codes requires adherence to RAL’s licensing framework. Unauthorized use—such as labeling a product with a RAL number without certification—can lead to legal consequences. Buyers must verify whether the powder supplier is an authorized RAL licensee. Choosing uncertified suppliers may save short-term costs but exposes the buyer to IP infringement risks and potential rejection of finished goods in regulated industries.

Poor Documentation and Traceability

High-quality sourcing requires full traceability, including batch numbers, test reports, and certification documents. Many suppliers fail to provide proper documentation, making it difficult to verify compliance with RAL standards or to troubleshoot quality issues. Without material safety data sheets (MSDS), color tolerances (ΔE values), and durability test results (e.g., QUV, salt spray), buyers cannot ensure long-term performance or regulatory compliance.

Substandard Raw Materials Affecting Performance

Even if the color matches, the functional performance of the coating depends on the quality of resins, pigments, and additives. Some low-cost suppliers cut corners by using inferior raw materials, resulting in poor weather resistance, reduced gloss retention, or inadequate adhesion. This compromises not only aesthetics but also the protective function of the coating, leading to premature failure in demanding environments.

Inadequate Testing and Validation

Assuming that a supplier’s claim of “RAL-compliant” is sufficient is a mistake. Buyers should conduct independent testing—such as spectrophotometric color measurement and performance testing under real-world conditions—before committing to large orders. Skipping validation can result in costly rework or warranty claims down the line.

Conclusion

To avoid these pitfalls, buyers should only source RAL powder coatings from certified, reputable suppliers with transparent quality control processes and proper licensing. Always request documentation, verify compliance, and validate both color accuracy and performance characteristics before full-scale production.

Logistics & Compliance Guide for RAL Powder Coat Colors

This guide outlines the essential logistics and compliance considerations when sourcing, handling, and applying RAL powder coat colors to ensure consistency, regulatory adherence, and efficient operations.

Order Fulfillment & Lead Times

- RAL powder coatings are typically available from global manufacturers and distributors, but custom or less common shades may require longer lead times.

- Confirm standard lead times with your supplier—typically 2–6 weeks, depending on location and stock levels.

- For large or time-sensitive orders, provide advance notice and consider maintaining safety stock of frequently used RAL colors.

- Specify exact RAL code (e.g., RAL 9003 Signal White) and include any suffixes (e.g., -M for metallic) to avoid formulation errors.

Packaging & Handling

- RAL powders are supplied in sealed, moisture-resistant containers (e.g., 5 kg, 10 kg, or 25 kg bags or drums).

- Store in a cool, dry environment (ideally 15–25°C; 40–60% relative humidity) away from direct sunlight and contamination.

- Avoid temperature fluctuations to prevent clumping or degradation.

- Label containers clearly with RAL number, batch number, and expiration date.

- Follow first-in, first-out (FIFO) inventory practices.

Transportation Requirements

- Use enclosed, climate-controlled vehicles where possible, especially in extreme weather conditions.

- Protect packaging from physical damage, moisture, and contamination during transit.

- Provide documentation (packing slip, safety data sheet) with each shipment.

- Comply with local and international transport regulations for non-hazardous industrial powders (typically UN 3077, Class 9, if classified).

Regulatory Compliance

- RAL powder coatings must comply with regional environmental and safety regulations:

- REACH (EU): Ensure substances in the formulation are registered and SVHC (Substances of Very High Concern) are declared.

- RoHS (EU/UK): Confirm absence of restricted heavy metals (e.g., lead, cadmium).

- TSCA (USA): Verify compliance with U.S. Toxic Substances Control Act.

- Proposition 65 (California): Check for chemicals requiring consumer warnings.

- Suppliers should provide up-to-date Safety Data Sheets (SDS) in the local language.

Environmental & Safety Standards

- Use appropriate personal protective equipment (PPE) during handling: respirator, gloves, and protective clothing.

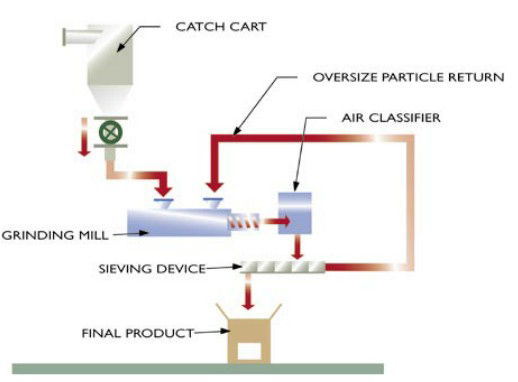

- Ensure powder coating systems are equipped with proper ventilation and filtration (e.g., cartridge collectors) to minimize airborne particulates.

- Follow local waste disposal regulations for overspray and expired powder—some formulations may be recyclable.

- Avoid open flames and static discharge; powders may be combustible in dust form.

Quality Assurance & Color Consistency

- Request color certification or batch-specific test reports from the supplier to confirm conformance to RAL standards.

- Conduct incoming quality checks using a spectrophotometer to verify color match against RAL reference standards.

- Maintain traceability by logging batch numbers and usage per project or job.

- Store unused powder in original packaging until ready for use to preserve integrity.

Documentation & Traceability

- Keep records of:

- Supplier certifications (ISO 9001, ISO 14001)

- SDS and technical data sheets (TDS)

- Batch numbers and expiry dates

- Color verification reports

- Required for audits, customer compliance requests, and product traceability.

International Considerations

- When shipping across borders, ensure all import/export documentation is complete.

- Verify customs classification (HS Code) for powder coatings—typically under 3907 or 3808.

- Account for potential tariffs, duties, or labeling requirements in the destination country.

Adhering to this guide ensures reliable supply, legal compliance, and consistent quality when using RAL powder coat colors in industrial and commercial applications.

Conclusion for Sourcing RAL Powder Coat Colors:

Sourcing RAL powder coat colors offers a reliable and standardized solution for achieving consistent, high-quality finishes across various industries. The RAL Classic color system, in particular, provides a comprehensive and internationally recognized palette that ensures color accuracy and uniformity, which is essential for architectural, industrial, and manufacturing applications. When sourcing RAL powder coatings, it is critical to partner with reputable suppliers who offer genuine, certified products that adhere to RAL standards. Additionally, considerations such as substrate type, environmental exposure, and application method should inform the selection of the appropriate powder formulation (e.g., polyester, epoxy, or hybrid) to ensure durability and performance. By leveraging the precision and consistency of RAL colors and maintaining strong supplier relationships, businesses can enhance product aesthetics, meet client specifications, and uphold quality benchmarks across projects. Ultimately, effective sourcing of RAL powder coat colors supports both functional longevity and visual integrity in finished products.