The global railroad plates market is experiencing steady growth, driven by increasing investments in rail infrastructure and the expansion of freight and passenger rail networks. According to a report by Mordor Intelligence, the railroad track materials market is projected to grow at a CAGR of over 4.5% from 2023 to 2028, with demand particularly strong in North America, Europe, and Asia-Pacific regions. This growth is fueled by government initiatives to modernize aging rail infrastructure and enhance transportation efficiency. As a critical component in track stability and load distribution, railroad plates—also known as base plates or tie plates—are witnessing heightened demand from both public and private rail operators. In this competitive landscape, a select group of manufacturers have emerged as leaders, combining advanced metallurgical processes, large-scale production capabilities, and global supply chains to meet rigorous industry standards. Based on market presence, production volume, and innovation, here are the top 9 railroad plates manufacturers shaping the future of rail infrastructure.

Top 9 Railroad Plates Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Omega Industries, Inc.

Domain Est. 2000

Website: omega-industries.com

Key Highlights: Crossing End Deflector Plates · Turnout Plates · Railroad Bridge Components · Curve Blocks · Miscellaneous · Steel Fabrication · Dredging · News ……

#2 OTM (Other Track Material)

Domain Est. 2011

Website: narailproducts.com

Key Highlights: North American Rail Products has an impressive selection of track tools and other track materials: Pandrol tie plates, splice bars, rail tie plates, turnout ……

#3 Where to Buy Railroad Tie Plates

Domain Est. 2016

Website: railroadfastenings.com

Key Highlights: As a professional manufacturer of railroad fasteners, AGICO supplies high quality railroad tie plates with all kinds of dimensions. Orders welcome!…

#4 Railway Baseplates (Rail Cast Tie Plates)

Domain Est. 2021

Website: at-railfasteners.com

Key Highlights: Railway Baseplates, Cast Tie Plates offered by China manufacturer Anyang Railway Equipment. Buy railroad castings directly with low price and high quality….

#5 Koppers Railroad Products

Domain Est. 1995

Website: koppers.com

Key Highlights: We produce top-quality, customizable track components and rail joints in multiple sizes, including bolted insulated, bonded, and standard joints and gage plates ……

#6 New Rail and Accessories

Domain Est. 1996

Website: lbfoster.com

Key Highlights: Foster offers a number of rail accessories: Joint Bars. Rail Joints. Angle Bars. Compromise Joints. Tie Plates. Track Spikes….

#7 Plates

Domain Est. 1996

Website: akrailroad.com

Key Highlights: Tie plates are available in single, double shoulder, and pandrol designs. A&K maintains a vast inventory of new and quality relay tie plates….

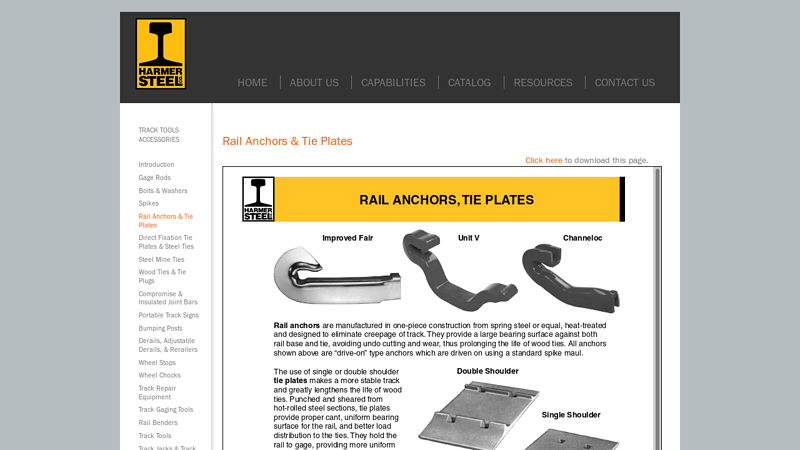

#8 Rail Anchors & Tie Plates

Domain Est. 1998

Website: harmersteel.com

Key Highlights: Rail Anchors & Tie Plates, Direct Fixation Tie Plates & Steel Ties, Steel Mine Ties, Wood Ties & Tie Plugs, Compromise & Insulated Joint Bars….

#9 All Types Sole Plate In Railway Available

Domain Est. 2020

Website: railroadrails.com

Key Highlights: Buy railway base plate of standard design or customized design. Single shoulder tie plate, double shoulder tie plate, hook twin tie plate, etc. Free quotes!…

Expert Sourcing Insights for Railroad Plates

H2: 2026 Market Trends for Railroad Plates

The global market for railroad plates—critical components in rail infrastructure including fishplates (joint bars), base plates, tie plates, and switch components—is poised for notable evolution by 2026. Driven by infrastructure modernization, sustainability mandates, and technological innovation, the sector is expected to experience steady growth and transformation. Below are the key trends shaping the railroad plates market in 2026:

1. Increased Investment in Rail Infrastructure

Governments worldwide are prioritizing rail as a sustainable mode of transport, fueling infrastructure expansions and upgrades. In North America, the U.S. Infrastructure Investment and Jobs Act continues to drive funding for rail safety and capacity improvements. Similarly, the EU’s Green Deal and Asia-Pacific’s high-speed rail initiatives (notably in India and Southeast Asia) are accelerating demand for high-quality railroad plates. This sustained public and private investment is projected to boost the global railroad plates market at a CAGR of ~3.5% through 2026.

2. Shift Toward High-Performance and Lightweight Materials

By 2026, manufacturers are increasingly adopting advanced steel alloys and composite materials to enhance durability and reduce weight. High-strength low-alloy (HSLA) steels and wear-resistant grades are becoming standard to extend plate lifespan under heavy loads and extreme conditions. Additionally, research into hybrid materials (e.g., steel-polymer composites) aims to reduce noise, vibration, and maintenance costs—particularly in urban transit systems.

3. Emphasis on Sustainability and Circular Economy

Environmental regulations are pushing rail operators and suppliers toward greener solutions. Recycled steel usage in plate manufacturing is expected to rise, supported by stricter emissions standards and ESG (Environmental, Social, Governance) reporting requirements. By 2026, leading producers are anticipated to offer certified low-carbon railroad plates, leveraging electric arc furnace (EAF) steelmaking and renewable energy in production.

4. Digitalization and Smart Monitoring Integration

The integration of IoT-enabled sensors and predictive maintenance systems is transforming rail infrastructure management. Smart plates embedded with strain gauges or RFID tags allow real-time monitoring of stress, wear, and alignment. This trend supports proactive maintenance, reduces downtime, and enhances safety—making smart railroad plates a growing niche, especially in high-density and high-speed networks.

5. Regional Market Diversification

While North America and Europe remain key markets due to aging infrastructure renewal, the fastest growth is expected in the Asia-Pacific and Middle East regions. India’s ambitious rail modernization program, China’s continued rail expansion, and Saudi Arabia’s Vision 2030 projects are driving demand for standardized, high-quality plates. Local manufacturing is also rising, reducing import dependence and shortening supply chains.

6. Supply Chain Resilience and Localization

Post-pandemic disruptions and geopolitical tensions have prompted rail operators to prioritize supply chain security. By 2026, there is a noticeable trend toward nearshoring and regional sourcing of railroad plates. This includes strategic partnerships between rail authorities and domestic steel producers to ensure consistent quality and delivery timelines.

Conclusion

By 2026, the railroad plates market will be defined by innovation, sustainability, and regional growth. As rail transport plays a central role in global decarbonization and mobility strategies, demand for durable, intelligent, and eco-friendly plates will continue to rise. Manufacturers who invest in advanced materials, digital integration, and localized production will be best positioned to capture emerging opportunities in this evolving landscape.

Common Pitfalls Sourcing Railroad Plates (Quality, IP)

Sourcing railroad plates—especially recycled or surplus ones used in construction, landscaping, or industrial applications—can present significant challenges related to material quality and intellectual property (IP) concerns. Being aware of these pitfalls helps mitigate risks.

Poor Material Quality and Condition

One of the most frequent issues when sourcing railroad plates is inconsistent or substandard quality. Plates may appear structurally sound but harbor hidden defects.

- Corrosion and Wear: Many railroad plates have spent decades in service under harsh conditions. Surface rust may be manageable, but pitting, deep corrosion, or cracking can compromise structural integrity, especially if the plates are intended for load-bearing applications.

- Inconsistent Dimensions and Thickness: Due to wear or non-standard manufacturing practices (especially with older rails), plates may vary significantly in thickness and dimensions, making them unsuitable for precision applications.

- Residual Contaminants: Plates may be coated with coal tar, creosote, or other preservatives that pose environmental or health hazards. Failure to identify and remediate these can lead to regulatory issues or unsafe installations.

Lack of Certification and Traceability

Railroad plates often enter the surplus market without proper documentation.

- No Mill Test Reports (MTRs): Without MTRs or material certifications, it’s difficult to verify steel grade, chemical composition, or mechanical properties. This lack of traceability increases liability, particularly in engineered structures.

- Unknown Service History: Plates may have been used on heavily trafficked mainlines or in corrosive environments (e.g., coastal or chemical transport routes), which can accelerate material fatigue or degradation.

Intellectual Property and Brand Infringement

Railroad plates sometimes retain identifying marks such as logos, railroad names, or proprietary rail profiles, raising IP concerns.

- Trademarked Logos and Railroad Names: Reusing plates with visible railroad emblems (e.g., Union Pacific, BNSF) without permission may infringe on trademarks. Even if the steel is recycled, commercial use of branded materials can lead to cease-and-desist letters or legal action.

- Proprietary Rail Profiles: Some rail designs are protected under industrial design patents or trade secrets. Reproducing or commercially exploiting plates based on such designs—especially if reverse-engineered—can trigger IP disputes.

- Misrepresentation Risk: Selling or using recycled plates as “authentic vintage railroad steel” when they are counterfeit or misrepresented can lead to consumer protection violations and reputational damage.

Inadequate Supplier Vetting

Working with unreliable suppliers amplifies the above risks.

- Unqualified Resellers: Some suppliers act as middlemen without metallurgical expertise, providing no quality assurance or due diligence on origin and legality.

- Failure to Comply with Regulations: Reputable suppliers should adhere to environmental, safety, and recycling regulations (e.g., EPA guidelines for treated wood or contaminated metals). Non-compliant sourcing can expose buyers to fines or project delays.

Conclusion

To avoid these pitfalls, buyers should require documentation, inspect materials in person when possible, consult legal counsel regarding IP use, and source from reputable, transparent suppliers. Due diligence ensures both the structural reliability and legal safety of railroad plate applications.

Logistics & Compliance Guide for Railroad Plates

Railroad plates, also known as rail anchors or base plates, are critical components in railway track construction and maintenance. Proper logistics and compliance ensure the safety, durability, and regulatory adherence of rail infrastructure projects. This guide outlines key considerations for handling, transporting, storing, and complying with regulations related to railroad plates.

Procurement and Specifications

Ensure all railroad plates are procured according to industry standards such as those set by the American Railway Engineering and Maintenance-of-Way Association (AREMA), American Society for Testing and Materials (ASTM), or relevant regional standards (e.g., EN standards in Europe). Key specifications include:

- Material composition (typically forged or cast steel)

- Dimensions and weight tolerances

- Surface finish and coating requirements (e.g., galvanization for corrosion resistance)

- Load-bearing capacity and design compatibility with rail profiles (e.g., 115 RE, 136 RE)

Procurement contracts should include certification of compliance with applicable standards and traceability documentation.

Packaging and Handling

Railroad plates must be packaged to prevent damage during transit and handling:

- Bundle plates securely using steel strapping or wooden crates to prevent shifting

- Use protective padding between layers to avoid surface abrasion

- Label each package with part number, quantity, heat number (if applicable), and handling instructions

- Use forklifts or cranes with appropriate lifting fixtures; avoid dragging or dropping

Ensure workers are trained in safe material handling practices to reduce injury risk and product damage.

Transportation Requirements

Transport logistics must account for the weight and volume of railroad plates:

- Use flatbed trucks or railcars designed for heavy cargo

- Secure loads with chains, binders, or tension straps to prevent movement

- Comply with Department of Transportation (DOT) or relevant regional regulations for weight distribution, load overhang, and vehicle markings

- For international shipments, adhere to International Maritime Organization (IMO) standards and customs documentation requirements

Coordinate delivery schedules with track maintenance windows or construction timelines to avoid storage delays.

Storage Guidelines

Proper storage preserves the integrity of railroad plates before installation:

- Store in a dry, well-ventilated area to prevent rust and corrosion

- Elevate bundles off the ground using wooden pallets or racks

- Protect galvanized or coated plates from moisture and chemical exposure

- Organize inventory by type and specification for easy retrieval

- Implement a first-in, first-out (FIFO) system to minimize long-term storage

Regularly inspect stored plates for damage or deterioration.

Regulatory Compliance

Adherence to regulatory standards is mandatory for safety and legal operation:

- Verify compliance with Federal Railroad Administration (FRA) regulations in the U.S., or equivalent bodies such as Transport Canada or the European Union Agency for Railways (ERA)

- Maintain documentation including Material Test Reports (MTRs), Certificates of Conformance (CoC), and quality inspection records

- Follow Occupational Safety and Health Administration (OSHA) guidelines for workplace safety during handling and installation

- Comply with environmental regulations for coating materials (e.g., VOC emissions, hazardous waste disposal)

Conduct periodic audits to ensure ongoing compliance across the supply chain.

Installation and Quality Assurance

Only trained personnel should install railroad plates using approved methods:

- Follow AREMA or manufacturer-recommended installation procedures

- Torque fasteners to specified levels using calibrated tools

- Inspect installed plates for proper alignment, contact, and anchoring

- Document installation with photos and inspection checklists

Report and investigate any non-conformances immediately.

Recordkeeping and Traceability

Maintain comprehensive records throughout the lifecycle:

- Track batch numbers, delivery dates, and storage conditions

- Record installation locations and dates for future maintenance

- Archive compliance documents for a minimum of 10 years (or as required by jurisdiction)

Digital inventory management systems can enhance traceability and reporting efficiency.

By following this logistics and compliance guide, rail operators and contractors can ensure railroad plates are handled safely, meet regulatory standards, and contribute to the long-term reliability of rail infrastructure.

Conclusion for Sourcing Railroad Plates

In conclusion, sourcing railroad plates requires a strategic approach that balances cost, quality, regulatory compliance, and supply chain reliability. Given the critical role these components play in ensuring the safety, durability, and performance of rail infrastructure, it is essential to partner with reputable suppliers who adhere to industry standards such as AREMA, ASTM, or AAR specifications. A thorough evaluation of material composition, manufacturing processes, and logistical capabilities will help ensure the longevity and integrity of the rail system.

Additionally, considering factors such as lead times, scalability, and sustainability can enhance long-term project efficiency and support environmental and operational goals. Whether sourcing domestically or internationally, conducting due diligence on suppliers—including audits and performance history—minimizes risks and supports reliable procurement.

Ultimately, effective sourcing of railroad plates is not just about acquiring materials, but about building strategic partnerships that contribute to the safety, resilience, and efficiency of rail transportation networks.