The global rail track systems market is experiencing steady growth, driven by increasing investments in railway infrastructure, urbanization, and the expansion of metro and high-speed rail networks. According to Mordor Intelligence, the rail track systems market was valued at approximately USD 38.5 billion in 2023 and is projected to grow at a CAGR of over 4.2% from 2024 to 2029. This expansion is further supported by rising demand for energy-efficient and sustainable transportation alternatives, particularly across Asia-Pacific and Europe. With countries like India, China, and Germany accelerating rail modernization and electrification programs, the demand for high-quality rail sections—critical components for track durability and safety—has surged. As a result, leading manufacturers are scaling production, investing in advanced rail profiles, and leveraging automation to meet evolving industry standards. The following list highlights the top 8 rail section manufacturers shaping the future of rail infrastructure worldwide.

Top 8 Rail Section Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Rail Products

Domain Est. 1999

Website: lpg.steeldynamics.com

Key Highlights: The only North American long rail manufacturer offering hot rolled finished rails in lengths up to 320′, Steel Dynamics is qualified to supply rail to all ……

#2 Central Rail Supply

Domain Est. 2002

Website: centralrailsupply.com

Key Highlights: At Central Rail Supply, we specialize in providing top-quality crane rail systems and industrial rail products to meet the most demanding operational needs….

#3 TX Rail Products Inc. Rail and Rail Products

Domain Est. 2005

Website: txholdings.com

Key Highlights: TX Rail Products Inc., is in the business of supplying, distributing and selling rail material to our domestic coal mining industry, short line railroads, and ……

#4 ArcelorMittal

Domain Est. 2006

Website: rails.arcelormittal.com

Key Highlights: As a leading rail producer, we offer a wide portfolio of solutions for railways, subways, tramways, light-rail tracks, crossings, crane rails and rail ……

#5 Rail

Domain Est. 2008

Website: evrazna.com

Key Highlights: ENA Pueblo is the largest producer of premium and standard rail in North America, capable of rolling all AREMA sections, and offering industry-leading head- ……

#6

Domain Est. 2011 | Founded: 2010

Website: narailproducts.com

Key Highlights: Established in 2010, North American Rail Products (NARP) sells rail material. New, relayed or reconditioned, we can supply everything from the ballast up….

#7 Rail Products & Solutions

Domain Est. 1996

Website: lbfoster.com

Key Highlights: As experienced trackwork specialists, we design and manufacture custom railroad switches, frogs, and special trackwork components, whilst our complete range of ……

#8 Rail Production

Domain Est. 1997

Website: voestalpine.com

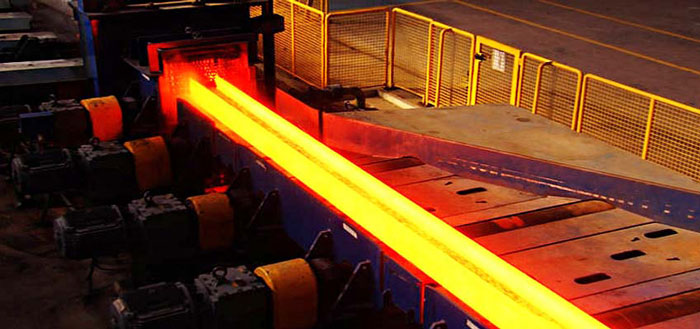

Key Highlights: We manufacture weld-free rails up to 120 meters and in more than 120 different rail profiles, which are also available in many premium and super-premium heat- ……

Expert Sourcing Insights for Rail Section

H2: 2026 Market Trends for the Rail Section

The rail sector is poised for significant transformation by 2026, driven by technological innovation, sustainability imperatives, and increasing demand for efficient mass transportation. As governments and private stakeholders prioritize infrastructure modernization and decarbonization, the rail industry is expected to witness robust growth and structural shifts. Below is an analysis of key market trends shaping the rail section in 2026:

-

Expansion of High-Speed and Urban Rail Networks

Major investments in high-speed rail (HSR) and urban transit systems are accelerating globally, particularly in Asia-Pacific, Europe, and select regions in North America and the Middle East. Countries like China, India, Japan, France, and Saudi Arabia are expanding rail networks to reduce congestion and support economic development. By 2026, HSR corridors are expected to connect more regional hubs, improving intercity mobility and reducing dependency on air travel for medium-distance routes. -

Sustainability and Electrification Drive

With global net-zero targets taking center stage, rail operators are transitioning to fully electrified systems and exploring alternative fuels such as hydrogen and battery-powered trains. Europe leads in rail electrification, while North America and parts of Asia are investing in green corridors. The shift supports compliance with environmental regulations and appeals to environmentally conscious passengers and freight clients. -

Digitalization and Smart Rail Technologies

The adoption of digital technologies—including AI-driven predictive maintenance, real-time monitoring, digital twins, and automated train operations (ATO)—is enhancing operational efficiency and safety. By 2026, smart signaling systems like the European Rail Traffic Management System (ERTMS) and Positive Train Control (PTC) in the U.S. will be more widely implemented, reducing delays and increasing network capacity. -

Growth in Rail Freight and Intermodal Logistics

As supply chains seek sustainable and cost-effective solutions, rail freight is regaining prominence. The integration of rail with port and trucking networks (intermodal transport) is improving logistics efficiency. In North America and Europe, government incentives and congestion pricing are encouraging shippers to shift from road to rail for long-haul freight, boosting demand for modernized freight rolling stock and infrastructure. -

Increased Public-Private Partnerships (PPPs) and Infrastructure Funding

Governments are increasingly relying on PPPs to fund large-scale rail projects due to budget constraints. In 2026, this trend will continue, with private investment playing a crucial role in developing high-speed lines, metro systems, and maintenance facilities. Stimulus packages and green infrastructure funds—such as the EU’s Green Deal and the U.S. Infrastructure Investment and Jobs Act—will remain key enablers. -

Focus on Passenger Experience and On-Demand Services

Rail operators are enhancing customer experience through improved connectivity, mobile ticketing, personalized services, and seamless multimodal integration. On-demand and flexible rail services, particularly in suburban and rural areas, are being piloted to increase ridership and optimize resource use. -

Supply Chain Resilience and Localization

Geopolitical tensions and past disruptions have prompted rail manufacturers to localize supply chains and diversify sourcing. By 2026, there will be a stronger emphasis on regional production of rail components—especially in North America and Europe—to mitigate risks and reduce lead times. -

Workforce Transformation and Skills Development

As automation and digital systems advance, the rail sector faces a growing skills gap. Companies and governments are investing in workforce retraining programs focused on digital technologies, cybersecurity, and green operations to prepare for future operational demands.

Conclusion:

By 2026, the rail section will be characterized by greater efficiency, sustainability, and connectivity. Technological innovation, environmental goals, and urbanization will remain primary growth drivers. Stakeholders who embrace digital transformation, invest in resilient infrastructure, and prioritize passenger and freight needs will be best positioned to capitalize on emerging opportunities in the evolving rail landscape.

Common Pitfalls When Sourcing Rail Sections (Quality, IP)

Sourcing rail sections for infrastructure or rolling stock projects involves critical considerations around quality assurance and intellectual property (IP) rights. Overlooking these aspects can lead to project delays, safety risks, legal disputes, and reputational damage. Below are common pitfalls to avoid:

1. Inadequate Quality Assurance and Certification

One of the most frequent issues when sourcing rail sections is accepting materials without proper quality verification. Rail sections must meet stringent international standards (e.g., EN 13674, AREMA, or JIS E 1101) depending on the region and application. Pitfalls include:

- Lack of third-party inspection: Relying solely on supplier declarations without independent testing.

- Inconsistent mechanical properties: Rail steel must have specific tensile strength, hardness, and fatigue resistance; substandard alloys can lead to premature wear or failure.

- Poor welding compatibility: Non-compliant rail sections may not weld properly, compromising track integrity.

Always require mill test certificates (MTCs), chemical composition reports, and mechanical test results before acceptance.

2. Failure to Verify Material Traceability

Traceability ensures that each rail section can be tracked from raw material to delivery. Without it:

- Defects cannot be easily isolated or recalled.

- Compliance with safety regulations becomes difficult to prove.

- Audits and certifications may fail.

Ensure suppliers provide heat numbers and full material traceability documentation.

3. Ignoring Intellectual Property (IP) Rights

Rail section designs—especially for high-speed or specialized applications—may be protected by patents, copyrights, or technical know-how. Common IP-related risks include:

- Using patented profiles without licensing: Some rail profiles (e.g., grooved rails for trams) are proprietary. Unauthorized production or sourcing infringes IP rights.

- Reverse engineering without due diligence: Copying rail geometry or heat treatment processes may violate patents or trade secrets.

- Supplier misrepresentation: Some vendors claim to supply “original design” rails but deliver counterfeit or unlicensed versions.

Conduct IP due diligence and request legal assurances (e.g., IP indemnity clauses) in contracts.

4. Selecting Suppliers Without Rail-Specific Experience

General steel suppliers may lack the expertise to produce or source rail sections that meet dynamic load, wear, and safety requirements. Red flags include:

- Limited experience with rail-specific standards.

- Inadequate production facilities (e.g., lack of controlled rolling or heat treatment).

- Poor quality control systems (e.g., no ISO/TS 22163 certification).

Prefer suppliers with proven rail industry credentials and certifications.

5. Overlooking Logistics and Handling Requirements

Rail sections are long, heavy, and sensitive to bending or surface damage. Poor handling can compromise structural integrity and lead to rejection on-site. Pitfalls include:

- Inadequate packaging or support during transport.

- Exposure to moisture leading to corrosion.

- Damage during unloading due to improper equipment.

Specify handling, storage, and transport conditions in procurement agreements.

6. Cost-Driven Decisions Without Lifecycle Analysis

Choosing the cheapest option often leads to higher lifecycle costs due to:

- Increased maintenance.

- Shorter service life.

- Higher risk of derailments or failures.

Evaluate total cost of ownership, including durability, maintenance needs, and safety performance.

By addressing these quality and IP-related pitfalls early, organizations can ensure reliable, compliant, and legally sound sourcing of rail sections for safe and sustainable rail infrastructure.

Logistics & Compliance Guide for Rail Section

This guide outlines key logistics processes and compliance requirements specific to rail operations, ensuring safe, efficient, and legally compliant transportation activities.

Operational Logistics

Scheduling and Dispatch

Maintain accurate train schedules in coordination with network operators. Ensure dispatchers verify crew availability, rolling stock readiness, and track conditions before authorizing departures. Real-time communication systems must be operational for dynamic adjustments.

Rolling Stock Management

Track locomotive and freight/passenger car availability, maintenance status, and service history. Implement preventive maintenance programs per manufacturer and regulatory standards to minimize downtime and ensure operational safety.

Yard Operations

Standardize yard procedures for car sorting, marshalling, and inspection. Use yard management systems to optimize space utilization and reduce turnaround times. Enforce safety protocols, including proper shunting practices and secure coupling.

Intermodal Coordination

Synchronize rail movements with truck, port, and warehouse operations. Use shared tracking platforms to facilitate seamless cargo transfers and provide end-to-end visibility to stakeholders.

Regulatory Compliance

Safety Regulations

Adhere to national and international rail safety standards (e.g., FRA in the U.S., ERA in Europe). Conduct regular safety audits, maintain Positive Train Control (PTC) systems where required, and enforce strict adherence to signal systems and speed limits.

Crew Certification and Training

Ensure all operating personnel (engineers, conductors, dispatchers) hold valid certifications. Provide ongoing training in safety protocols, emergency response, and regulatory updates. Maintain training records for audit purposes.

Hazardous Materials Handling

For rail transport of dangerous goods, comply with ADR/RID (Europe), 49 CFR (U.S.), or equivalent regional regulations. Use approved containers, proper placarding, and documentation. Conduct route risk assessments and coordinate with emergency response agencies.

Environmental Compliance

Monitor and report emissions, noise levels, and fuel usage as required. Implement spill prevention and response plans. Comply with regulations on waste disposal from maintenance facilities and locomotive depots.

Documentation and Recordkeeping

Maintain accurate logs of train movements, equipment inspections, crew hours, and incident reports. Retain records for the legally mandated duration (typically 1–7 years, depending on jurisdiction and document type).

Incident Response and Reporting

Emergency Protocols

Establish clear procedures for derailments, collisions, hazardous material releases, and medical emergencies. Ensure all personnel are trained in emergency communication, evacuation, and first response.

Mandatory Reporting

Report incidents to relevant authorities (e.g., FRA, RAIB, TSB) within stipulated timeframes. Submit detailed investigation reports and corrective action plans to prevent recurrence.

Post-Incident Review

Conduct internal reviews to identify root causes and update operational procedures. Share lessons learned across teams to strengthen system-wide safety culture.

Technology and Data Compliance

System Security

Protect rail control systems (e.g., ETCS, CTC) from cyber threats. Apply cybersecurity frameworks (e.g., NIST, ISO/IEC 27001) and conduct regular vulnerability assessments.

Data Privacy

Ensure compliance with data protection laws (e.g., GDPR, CCPA) when handling employee, customer, or operational data. Implement access controls and encryption for sensitive information.

Audit and Continuous Improvement

Internal Audits

Perform routine audits of logistics workflows and compliance adherence. Address findings promptly and document corrective actions.

Regulatory Updates

Monitor changes in rail legislation and industry standards. Update policies, training materials, and operational procedures accordingly.

Performance Metrics

Track KPIs such as on-time performance, incident rates, equipment uptime, and compliance violations. Use data analytics to drive efficiency and safety improvements.

By following this guide, rail operations can achieve reliable logistics performance while maintaining full compliance with legal and safety requirements.

Conclusion for Sourcing Rail Sections

In conclusion, the sourcing of rail sections is a critical component in ensuring the safety, durability, and performance of railway infrastructure. A successful procurement process requires a comprehensive evaluation of material quality, supplier reliability, compliance with industry standards (such as AREMA, UIC, or EN), and total cost of ownership—including logistics, lead times, and lifecycle maintenance.

Prioritizing high-quality steel with appropriate wear resistance, fatigue strength, and dimensional accuracy helps minimize track degradation and reduces long-term maintenance costs. Additionally, engaging with reputable suppliers who demonstrate technical expertise, consistent manufacturing standards, and a proven track record enhances project reliability and timeliness.

Sustainable and strategic sourcing—supported by market analysis, supplier audits, and risk assessment—ensures that rail sections meet both immediate project needs and long-term operational demands. Ultimately, a well-structured sourcing strategy contributes to the overall efficiency, safety, and economic viability of railway development and expansion initiatives.